Micro-bubble axial flow and swirl double-field three-stage tube type T-type degassing device

A degassing device and micro-bubble technology, applied in the general layout of liquid degassing, liquid degassing, and production of fluids, etc., can solve problems such as deterioration of separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

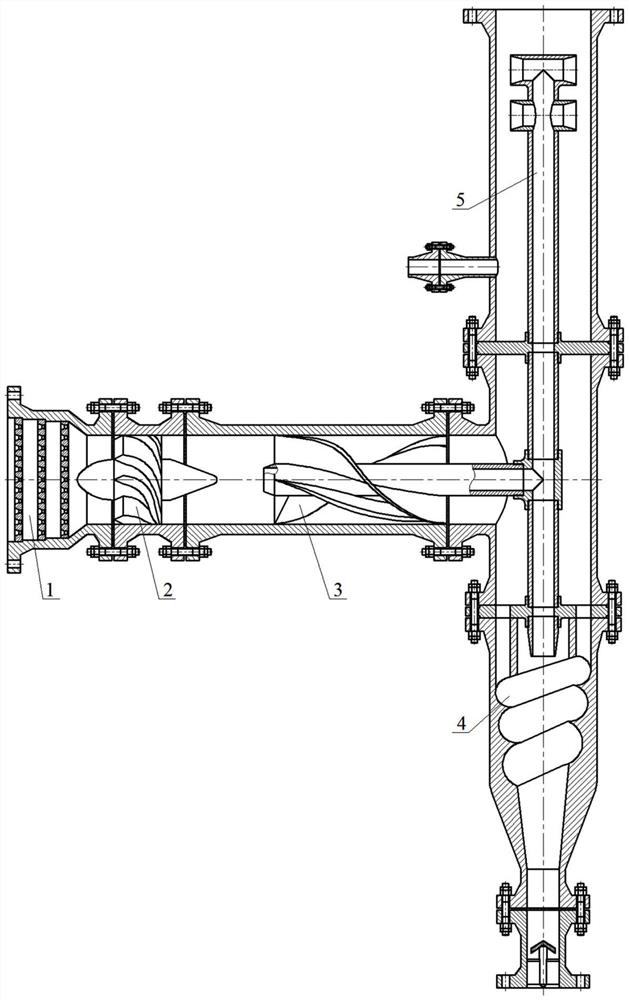

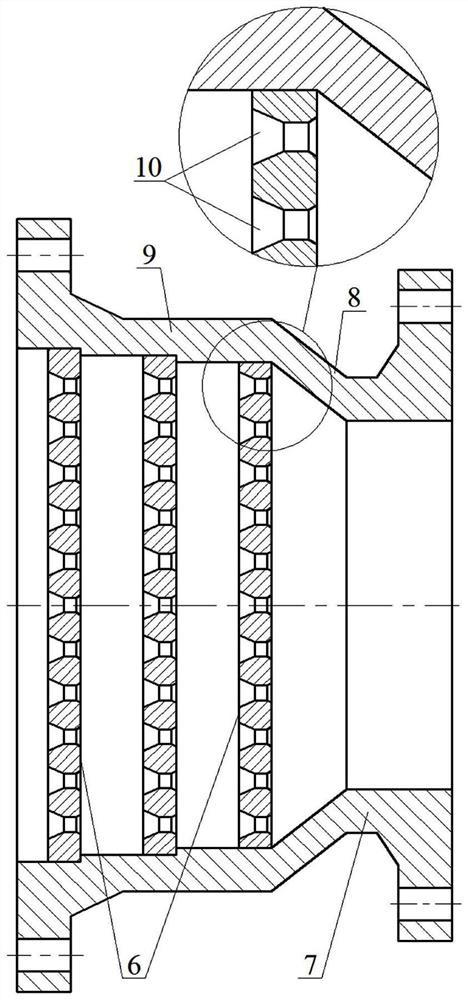

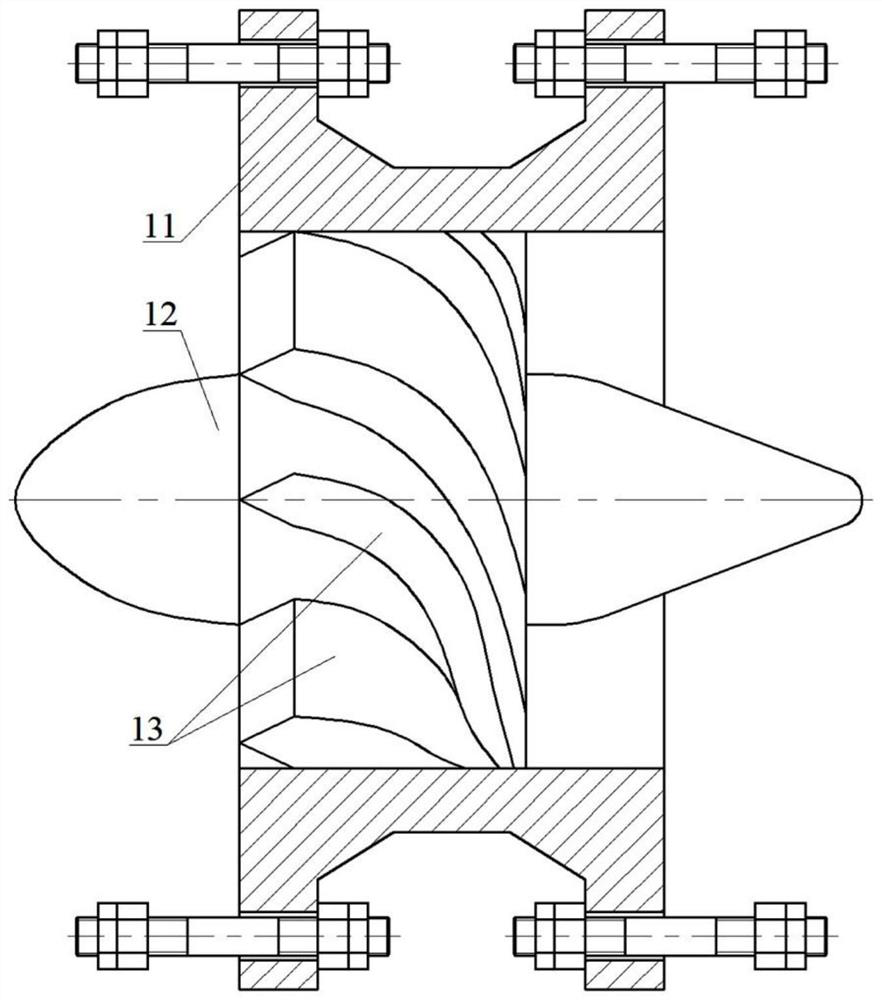

[0046] exist figure 1Among them, the micro-bubble axial flow and swirl double-field three-stage T-type degasser consists of a micro-bubble homomixer 1, a micro-bubble cyclone generator 2, a rotating axial flow degasser 3, and a conical cyclone degasser 4 and jet flow reversing degasser 5, which adopts the rapid degassing technology combining the micro-bubble homogeneous rotating axial flow field and the conical swirling flow field of the spiral channel with the stratified jet collision and reversing degassing. Micro-bubble homogeneous mixing and splitting rotating axial flow degassing operation, vertical spiral channel single-strand conical swirling degassing operation and vertical layered jet collision reversing degassing operation, reversing of jet reversing degasser 5 The buffer column tube body is connected to the gas delivery pipe sink through a flange, and the degassed reversing gas is pressurized and then exported. The reversing liquid discharge pipe is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com