Patents

Literature

65results about How to "Avoid manual collection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Video fault feedback method, client and server

InactiveCN105978703AAvoid manual collectionImprove service qualityData switching networksQuality of serviceClient-side

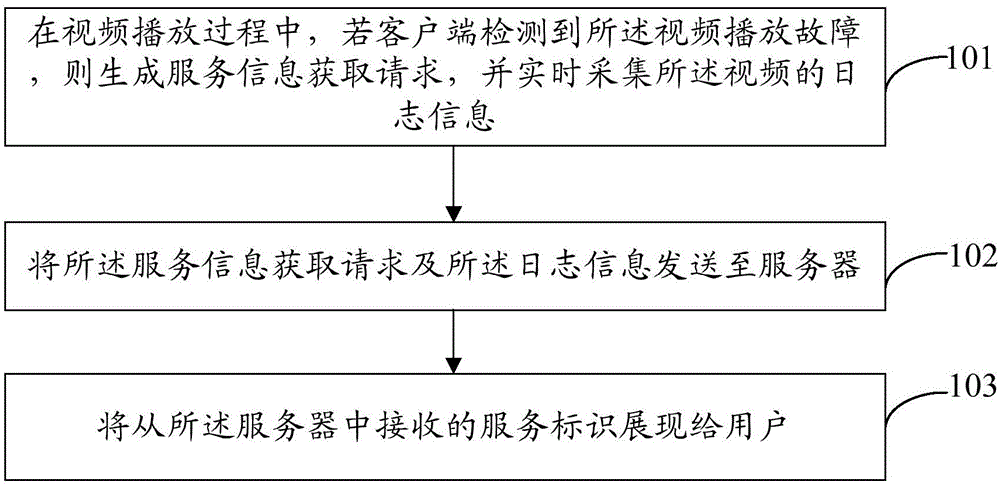

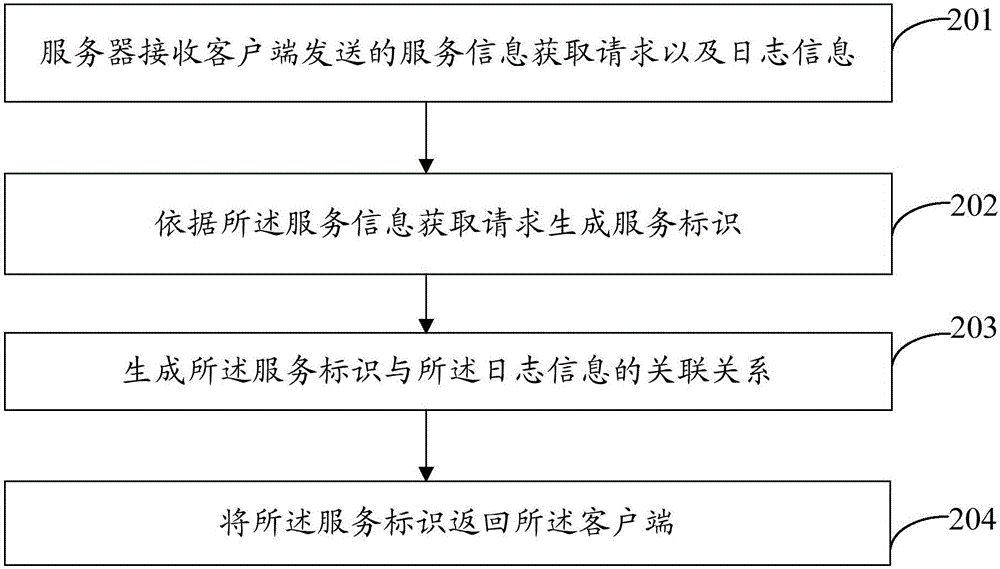

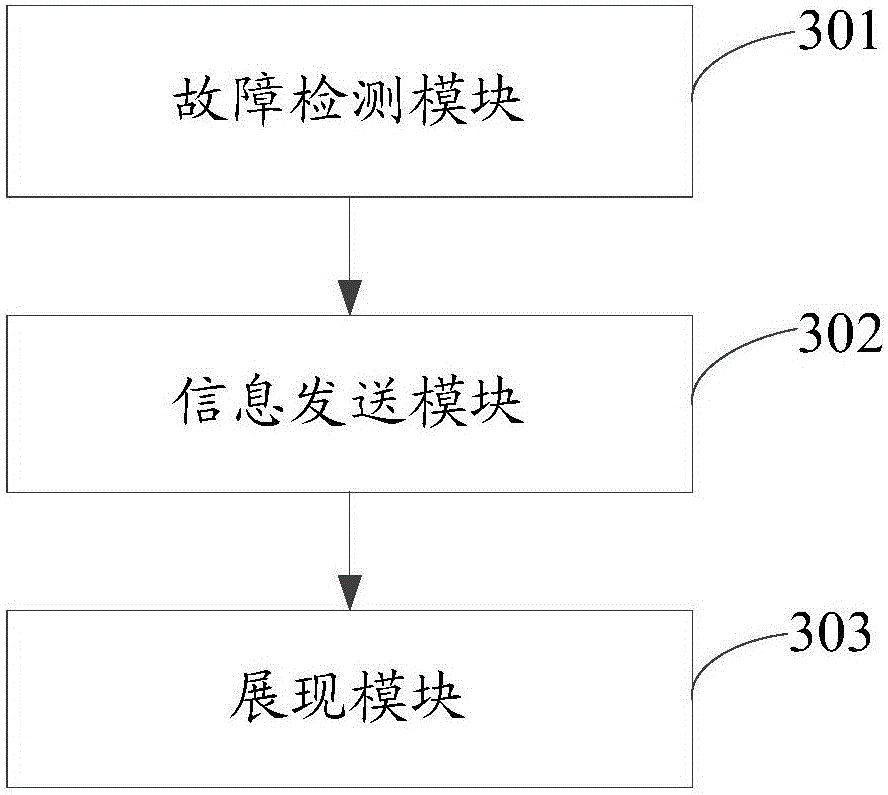

The embodiment of the invention provides a video fault feedback method, client and server. The method comprises: in the process of video play, if a client detects video play faults, a service information obtaining request is generated, and the video log information is collected in real time; the service information obtaining request and the log information are sent to a server to urge the server to generate service identification and generate the correlation of the service identification and the log information, and the service identification is returned back to the client; and the service identification received from the server is displayed to users, and the service identification is configured to indicate the server to obtain corresponding fault information when users perform fault feedback. According to the embodiment of the invention, the timeliness of log report is improved, the fault processing efficiency and accuracy are enhanced, and the service quality of a video service provider is improved.

Owner:LETV CLOUD COMPUTING CO LTD

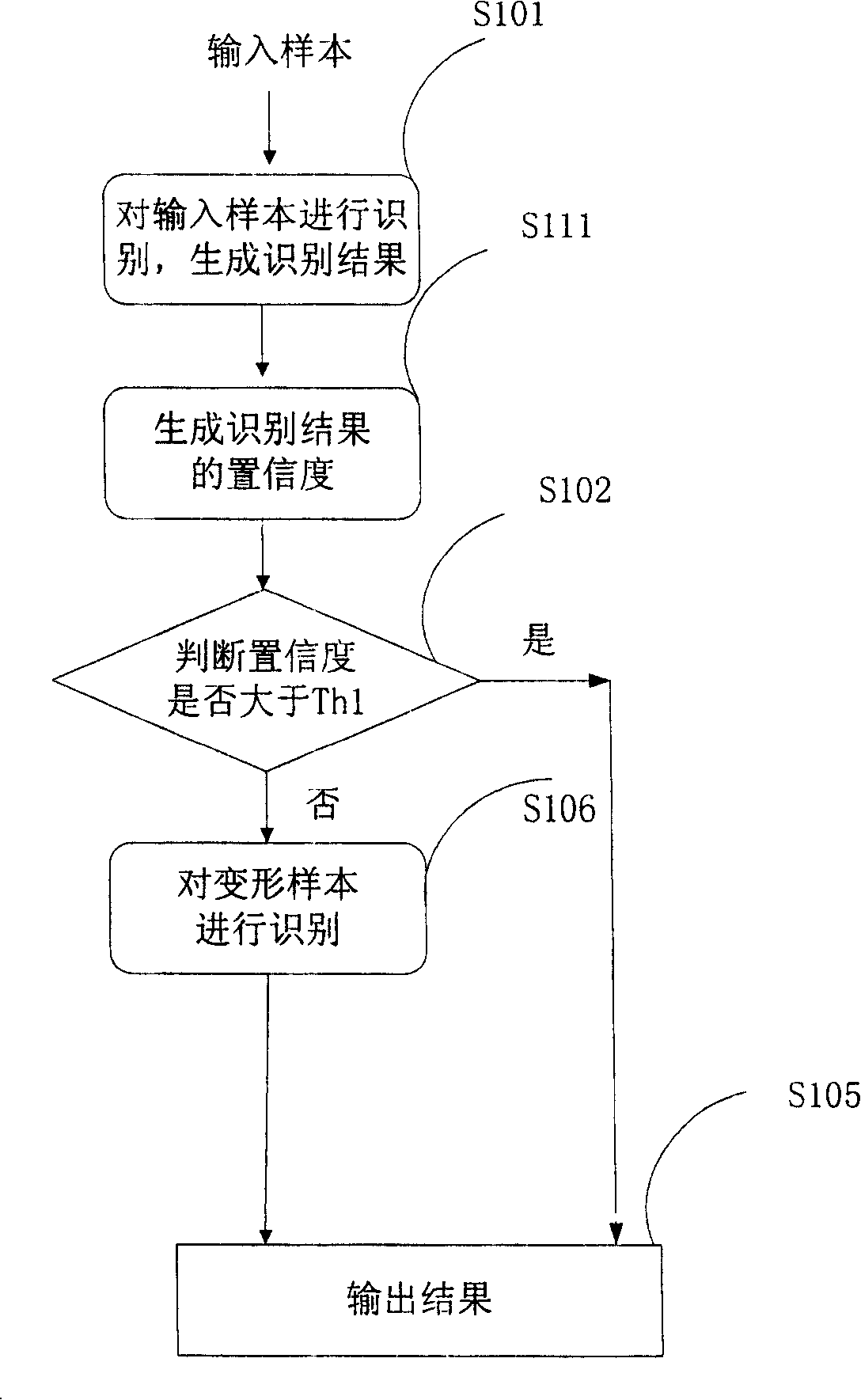

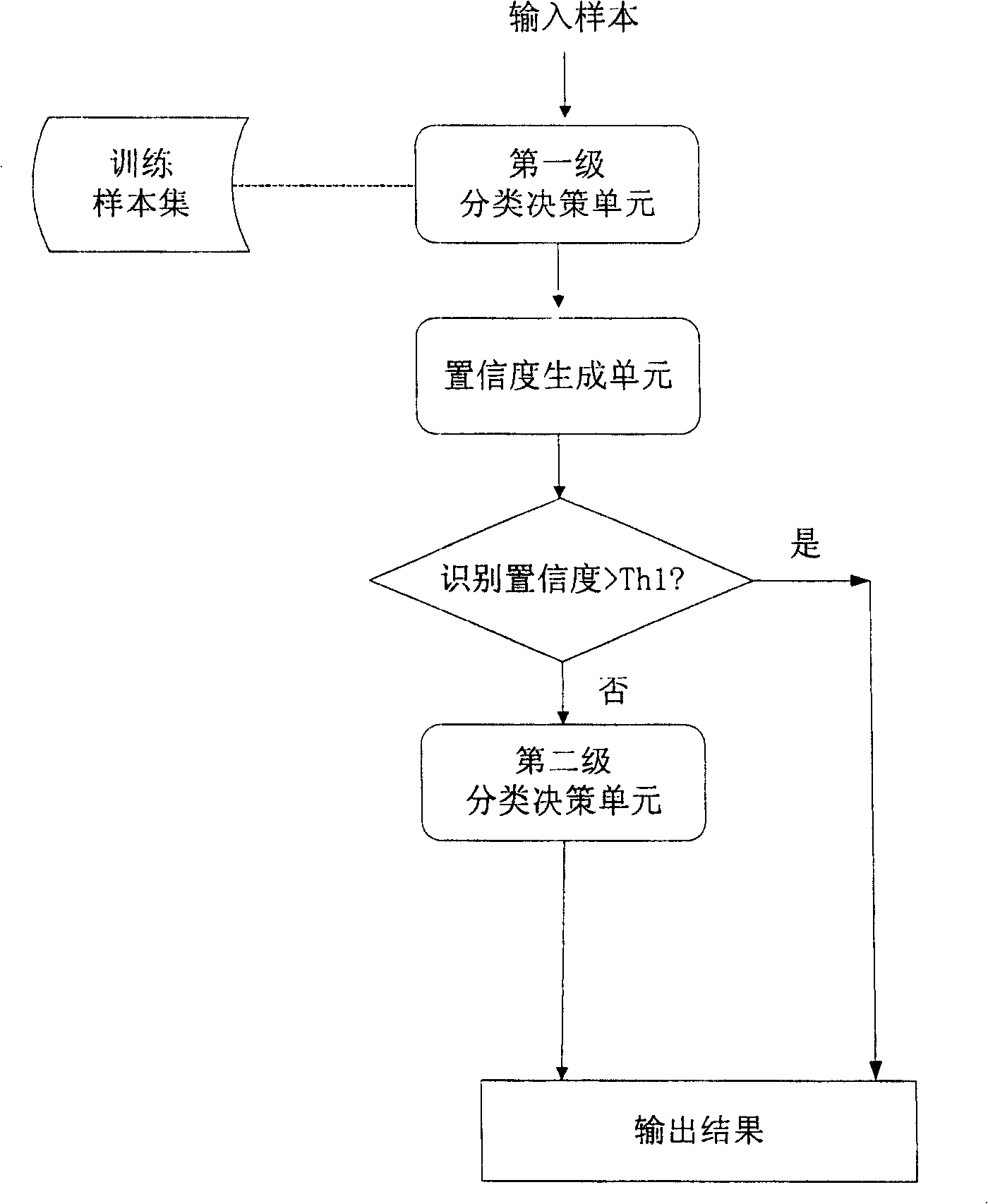

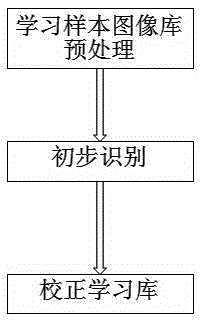

Method, apparatus, program and readable storage medium for character recognition

InactiveCN101256631AEasy to handleAvoid manual collectionCharacter and pattern recognitionSoftware engineeringIdentification error

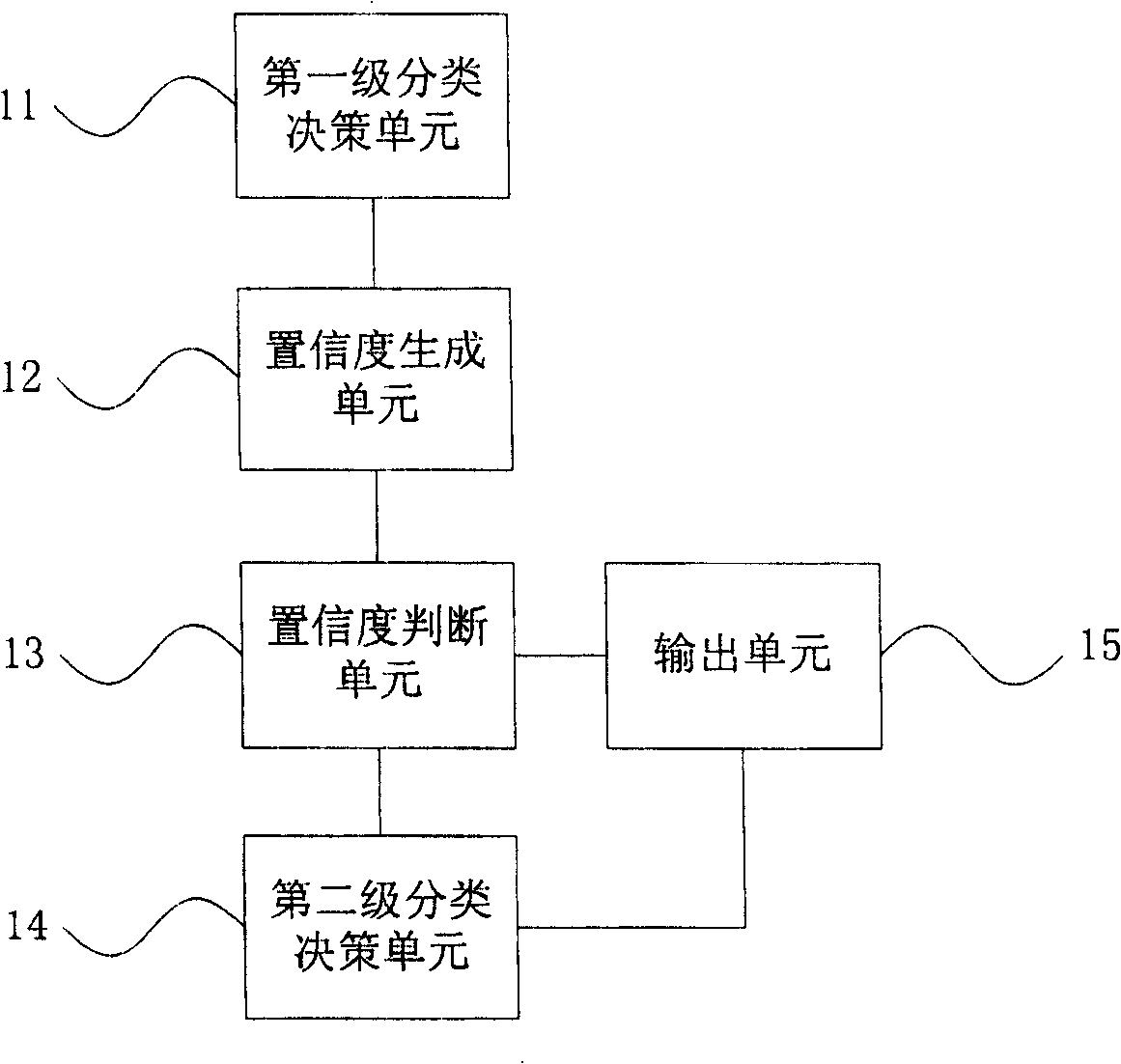

The invention provides a method, a device, a program and a readable storage medium for identifying characters. The method comprises the steps of: identifying the input character samples to generate the identification result; generating degree of confidence of the identification result; in accordance with the degree of confidence, judging whether the input character samples belong to deformed samples, if not, regarding the identification result as the final identification result; if so, identifying the deformed samples and generate the final identification result. The technical proposal of the invention can effectively process the deformed samples by directly regarding the samples which are incorrectly identified at the first level as the basic training samples at the second level, thus improving the identification accuracy of the system.

Owner:FUJITSU LTD

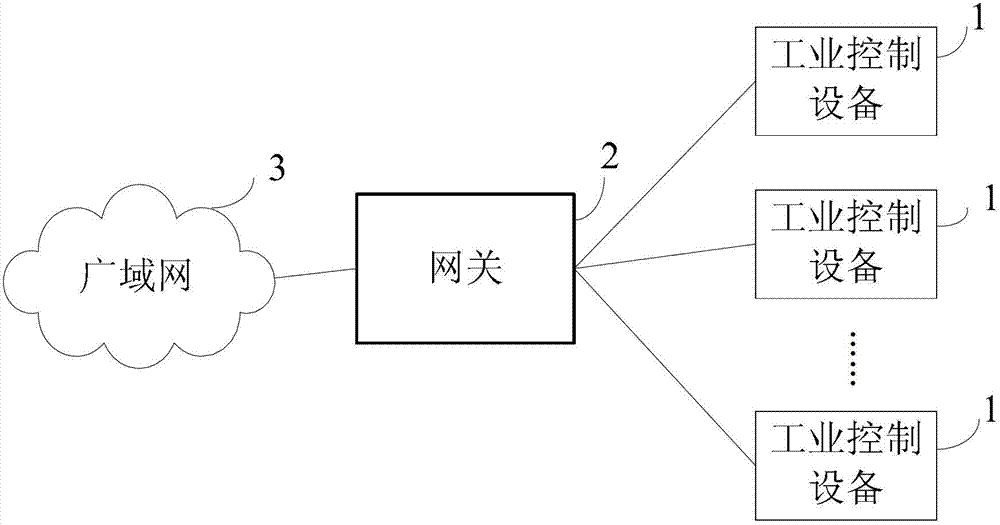

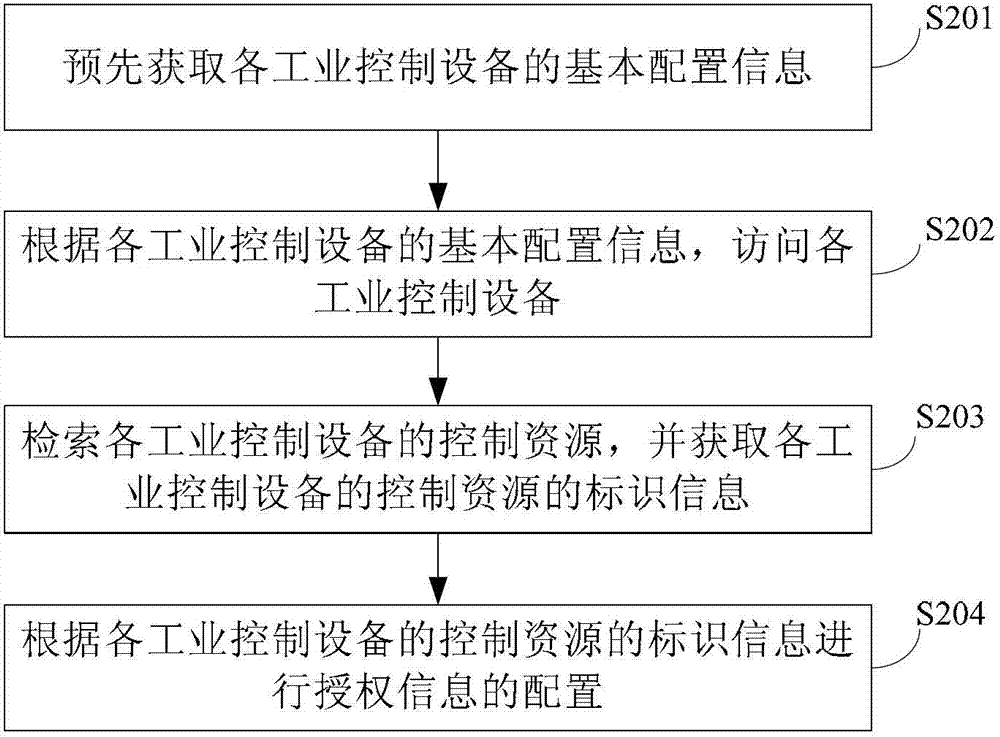

Method and apparatus for automatically acquiring and configuring authorization information

The invention discloses a method and apparatus for automatically acquiring and configuring authorization information, which can avoid and control hand-operated collection of information for authorization by engineers and enables an ICS can automatically acquire, configure and expanse the authorization information. The method comprises the following steps: according to the basic configuration information of each industrial control device, accessing each industrial control device; according to a communication protocol and an access mode of control resources, employed by each industrial control device, retrieving the control resources of each industrial control device, and obtaining the identification information of the control resources of each industrial control device; and according to the identification information of the control resources of each industrial control device, carrying out configuration of the authorization information.

Owner:SIEMENS AG

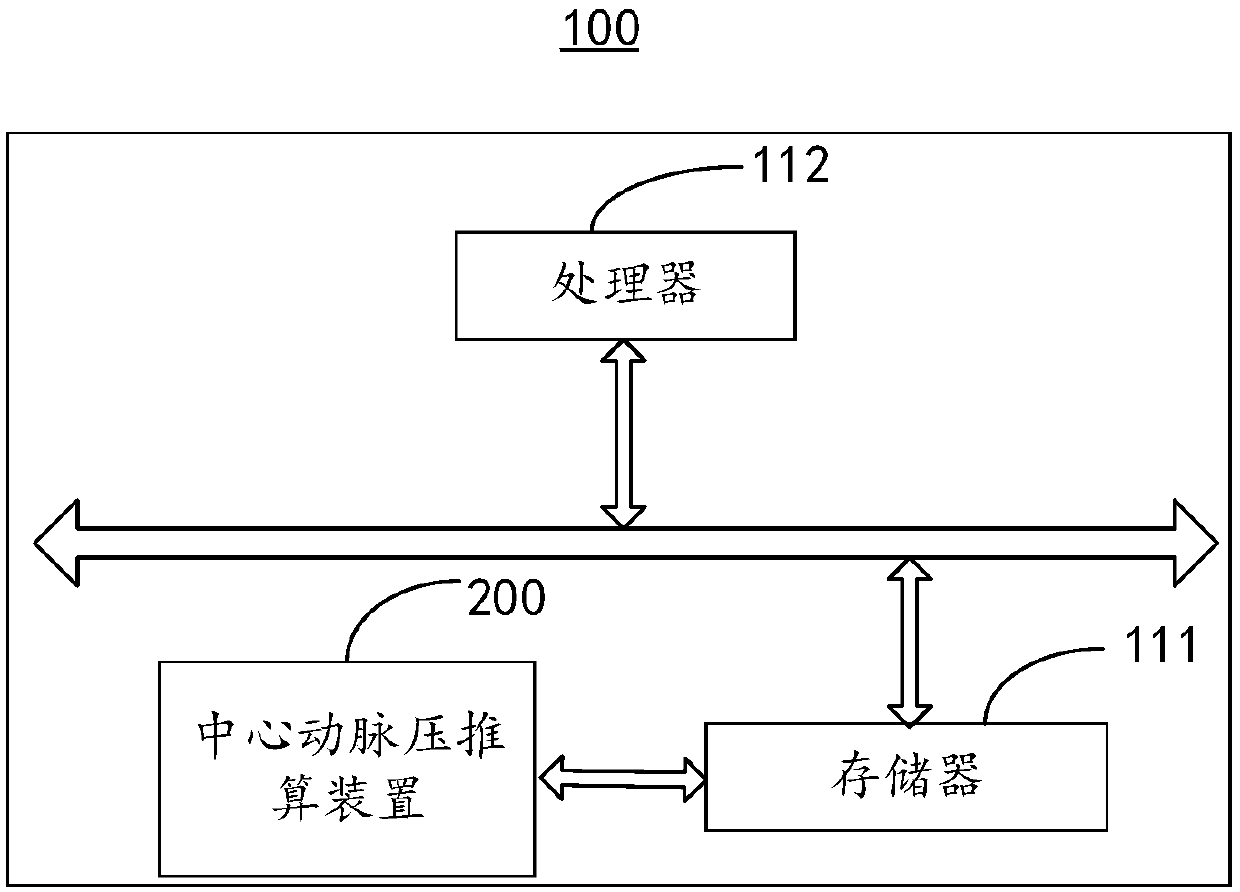

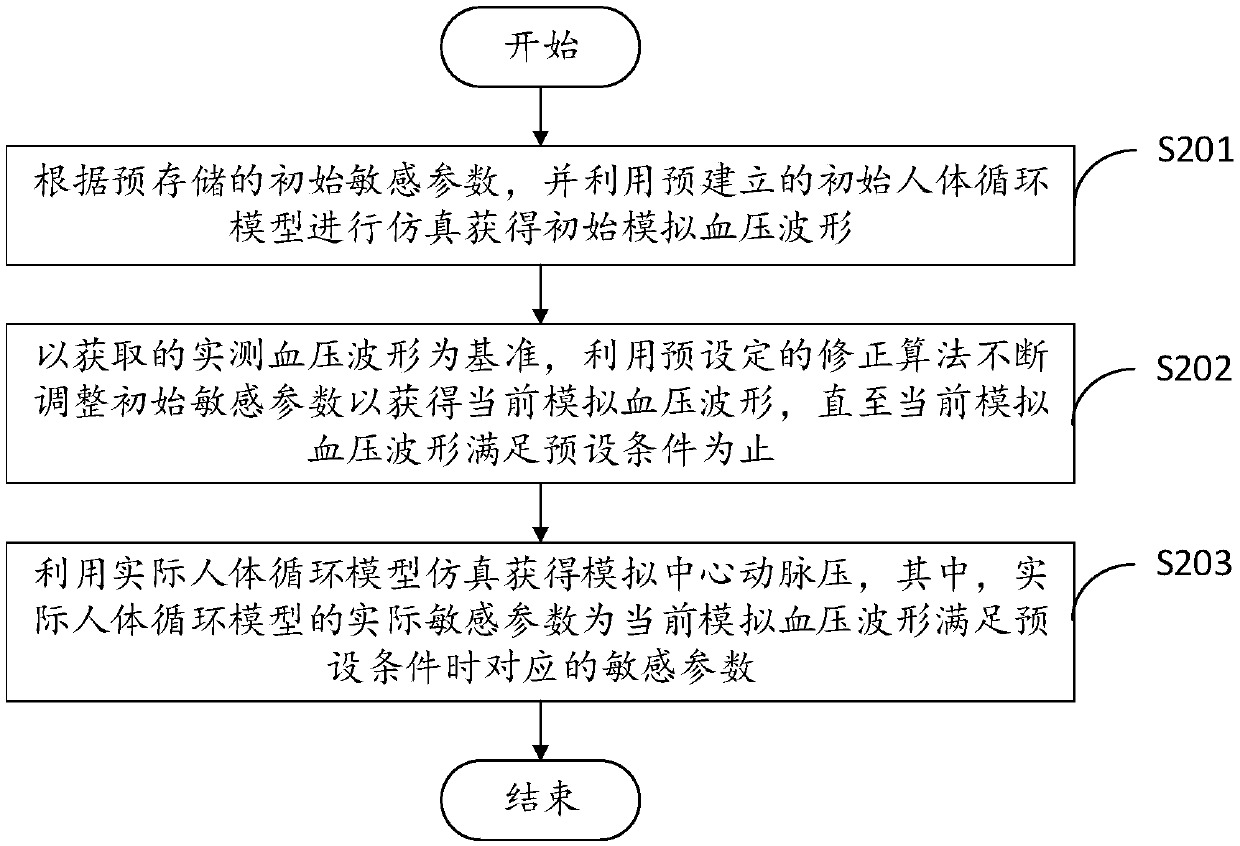

Central arterial pressure calculating method and device

ActiveCN109620187ASimulation is accurateIndividual adaptabilityEvaluation of blood vesselsSensorsCorrection algorithmDecreased mean arterial pressure

The embodiment of the invention provides a central arterial pressure calculating method and device and a method and device for establishing a central arterial pressure calculating model, and relates to the technical field of medical instruments. According to the method and device, according to pre-stored initial sensitivity parameters, by means of a pre-established initial human body circulation model, simulation is conducted, and an initial simulated blood pressure waveform is obtained, then the obtained measured blood pressure waveform serves as a benchmark, and by means of a preset correction algorithm, initial sensitive parameters are adjusted continuously so as to obtain a current simulated blood pressure waveform until the current simulated blood pressure waveform meets the preset condition, and finally simulated central arterial pressure is obtained by means of actual human body circulation model simulation; due to the fact that the initial human boy circulation model simulatesan arterial network through a one-dimensional arterial network model with the physical meaning, real continuous blood pressure waveforms of different individuals can be accurately simulated, and thenafter the real continuous blood pressure waveformsare simulated successfully, and simulation is conducted directly to obtain the simulated central arterial pressure with individual adaptability.

Owner:SHENZHEN INST OF ADVANCED TECH

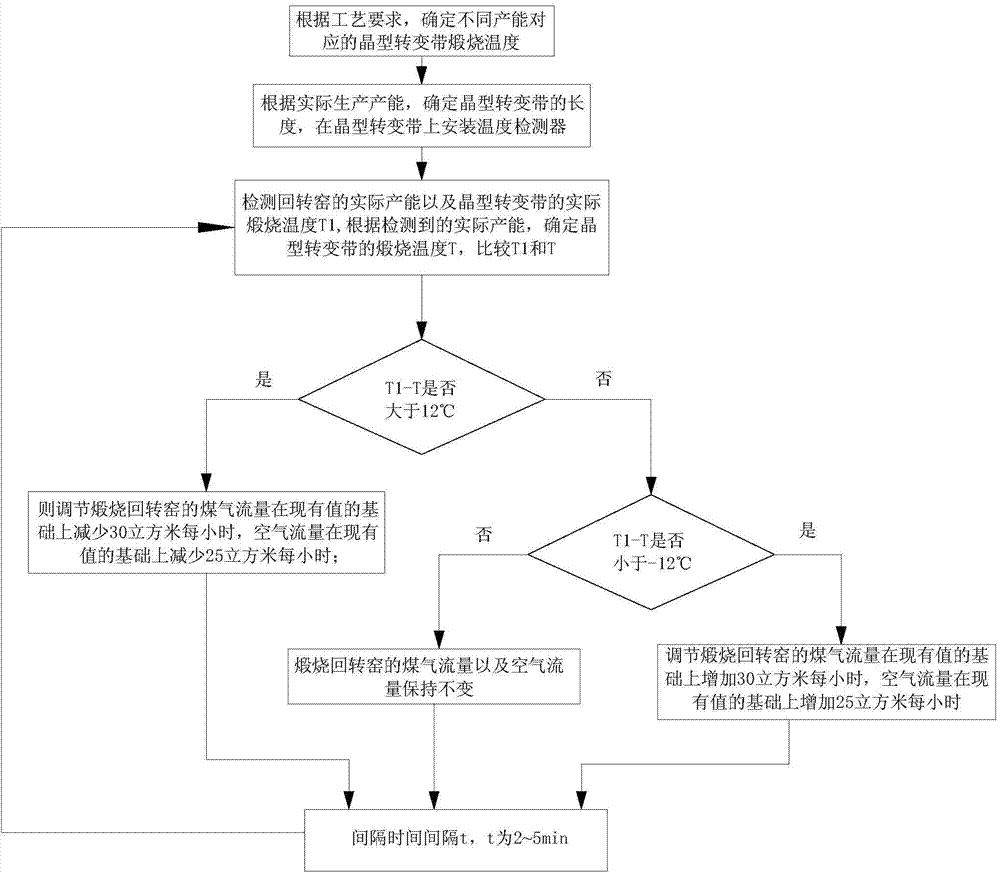

Method for adjusting calcination temperature of rutile type titanium dioxide and automatic control method thereof

ActiveCN104495919AEase of workAvoid manual collectionTitanium dioxideAutomatic controlProgrammable logic controller

The invention discloses a method for adjusting calcination temperature of rutile type titanium dioxide, which can be used for adjusting the calcination temperature of the rutile type titanium dioxide in real time according to specific productivity of a rotary kiln. The method comprises the following steps: determining the corresponding calcination temperature when the rotary kiln is used for performing production according to different productivities; selecting the calcination temperature of a corresponding crystal form transformed band; and performing real-time detection on the calcination temperature of the rotary kiln in the production process, and then adjusting the calcination temperature of the rotary kiln. The invention also discloses an automatic control method for the method for adjusting the calcination temperature of rutile type titanium dioxide. By adopting the automatic control method, a detection device is used for transmitting productivity conditions of the rotary kiln to a PLC (programmable logic controller), and then the PLC controls the corresponding temperature adjusting equipment to adjust the calcination temperature of the crystal form transformed band, so that automatic control is realized. By virtue of the calcination temperature adjusting method, the production energy consumption can be reduced, and the finished product quality of titanium dioxide can be ensured; and meanwhile, by virtue of the automatic control method, automatic control can be realized, the working efficiency can be improved, and the production cost can be reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

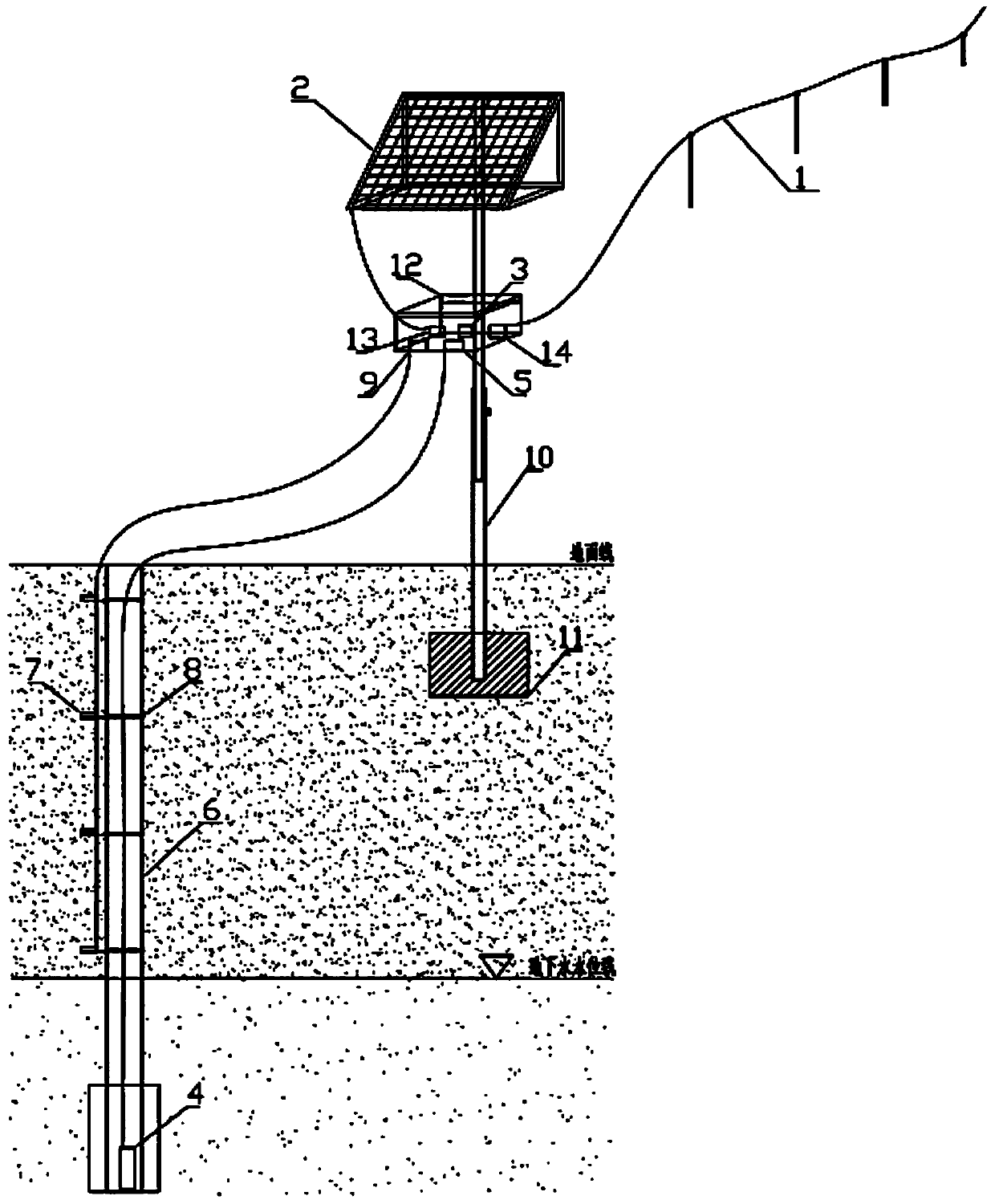

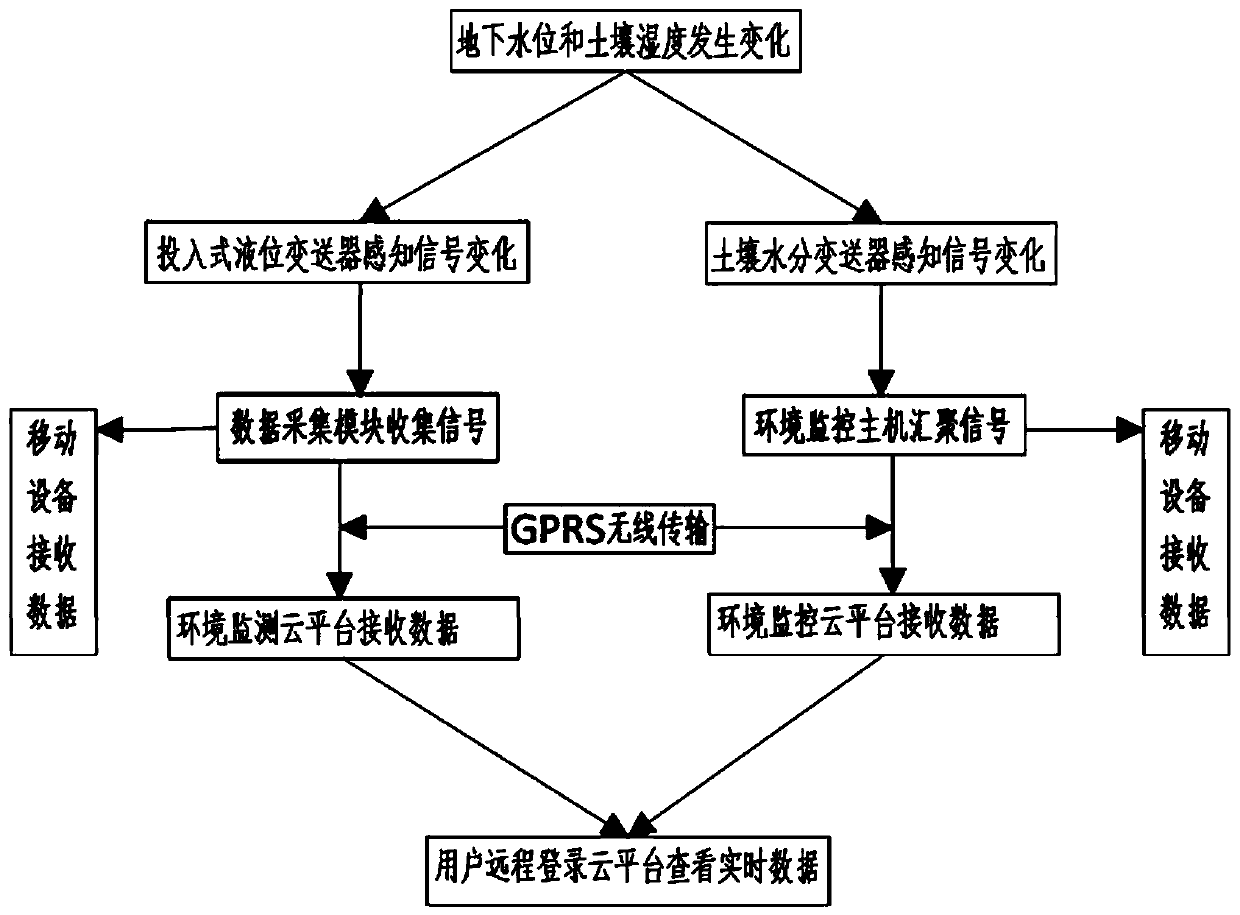

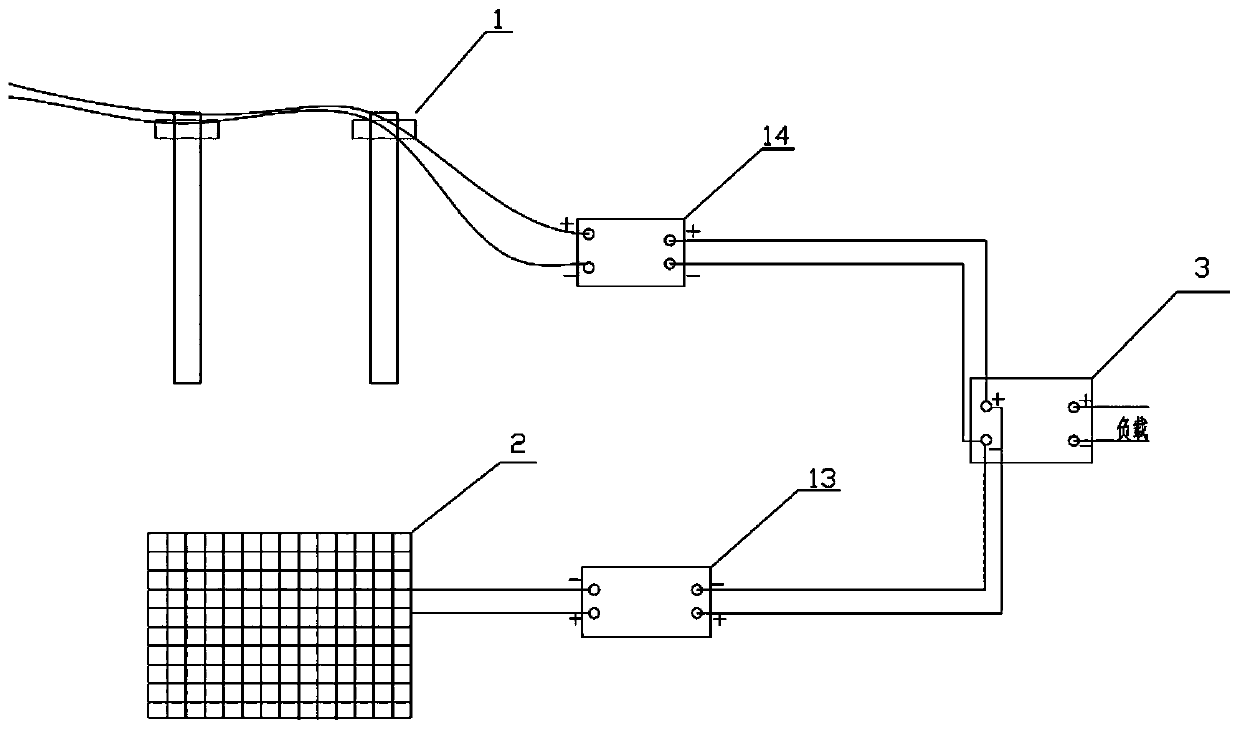

Real-time monitoring device and method for groundwater level and soil moisture in gully head landfill area

PendingCN110207758AGuaranteed uptimeImprove reliabilityPhotovoltaic supportsBatteries circuit arrangementsData acquisitionEngineering

The invention discloses a real-time monitoring device and a real-time monitoring method for groundwater level and soil moisture in a gully head landfill area. The monitoring device comprises a groundwater observation well arranged in a region to be monitored, wherein a throw-in type liquid level transmitter is placed in the groundwater observation well, and the throw-in type liquid level transmitter senses water level variation of groundwater and transmits data to an environment monitoring cloud platform by means of a data acquisition module; a plurality of soil moisture transmitters are arranged on the well wall of the groundwater observation well layer by layer, each soil moisture transmitter transmits acquired signals to a signal bus, the signal bus is connected to an environment monitoring host, the environment monitoring host is in wireless connection with the environment monitoring cloud platform, and a user can view real-time data through logging in the environment monitoring cloud platform and the environment monitoring cloud platform remotely; and the data acquisition module and the environment monitoring host are connected with a power supply module, and the power supplymodule comprises a storage battery and two power supply branch circuits. The monitoring method of the invention can be used for simultaneously monitoring real-time data of the groundwater level and soil moisture, reduces the workload and improves the data precision.

Owner:CHANGAN UNIV

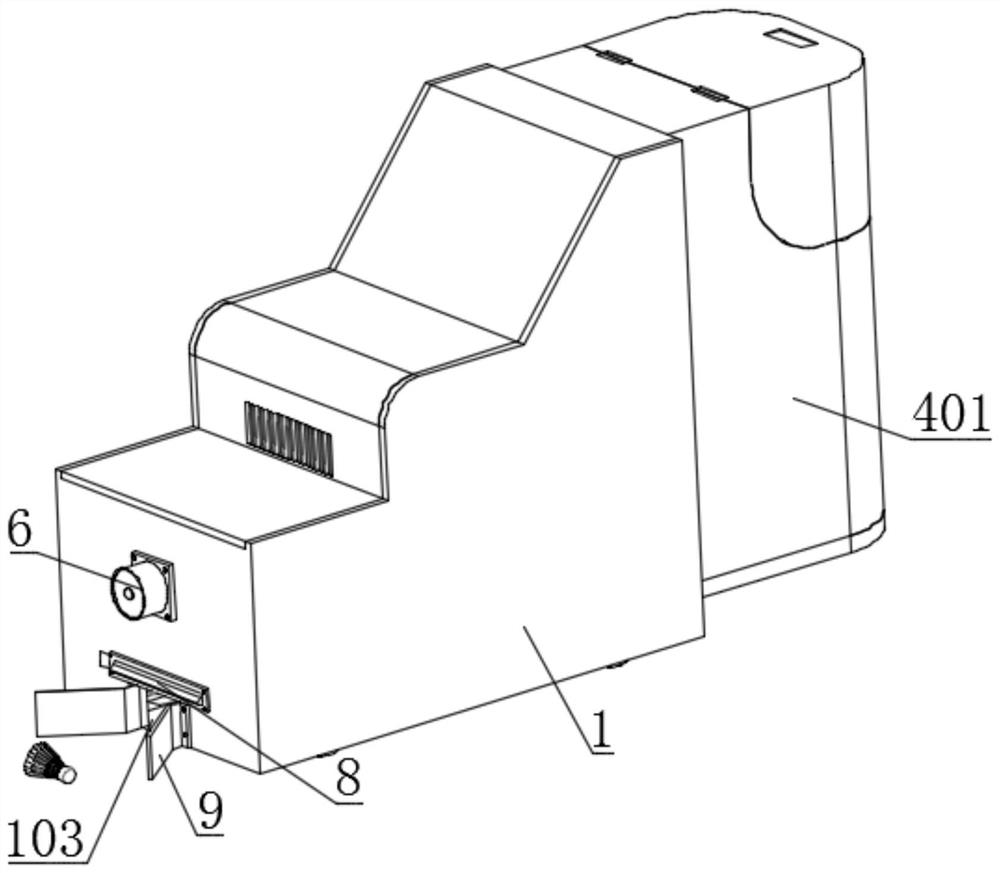

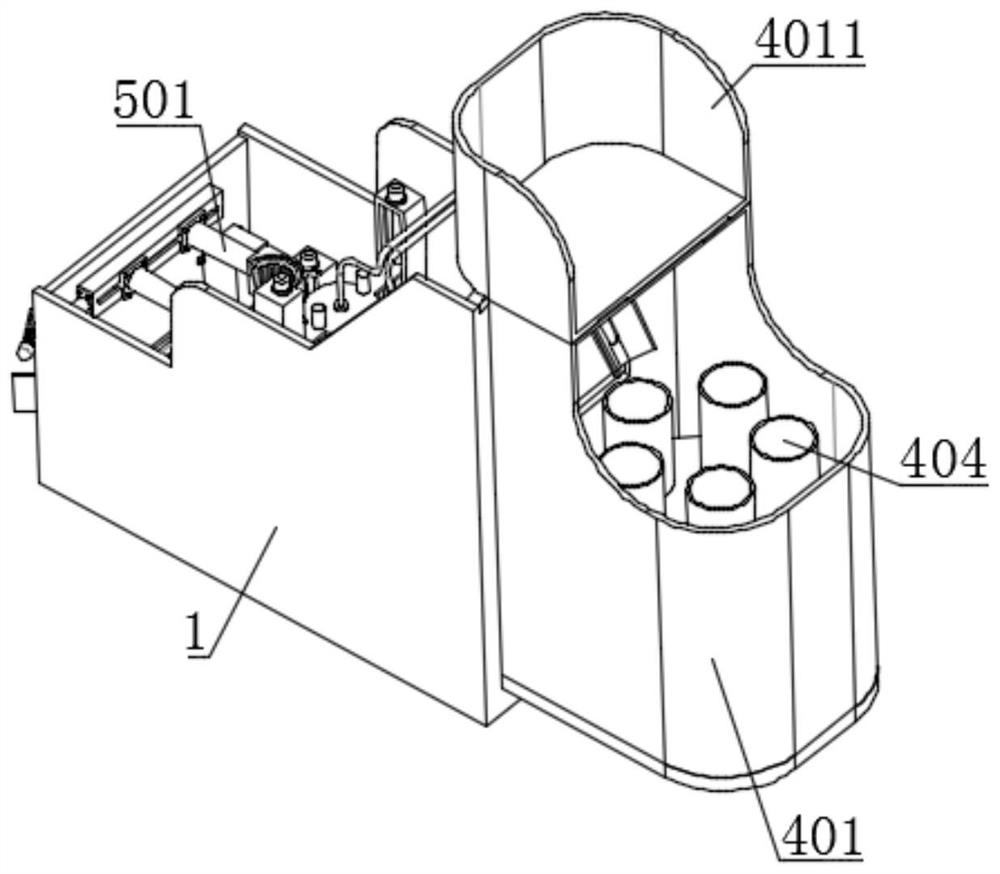

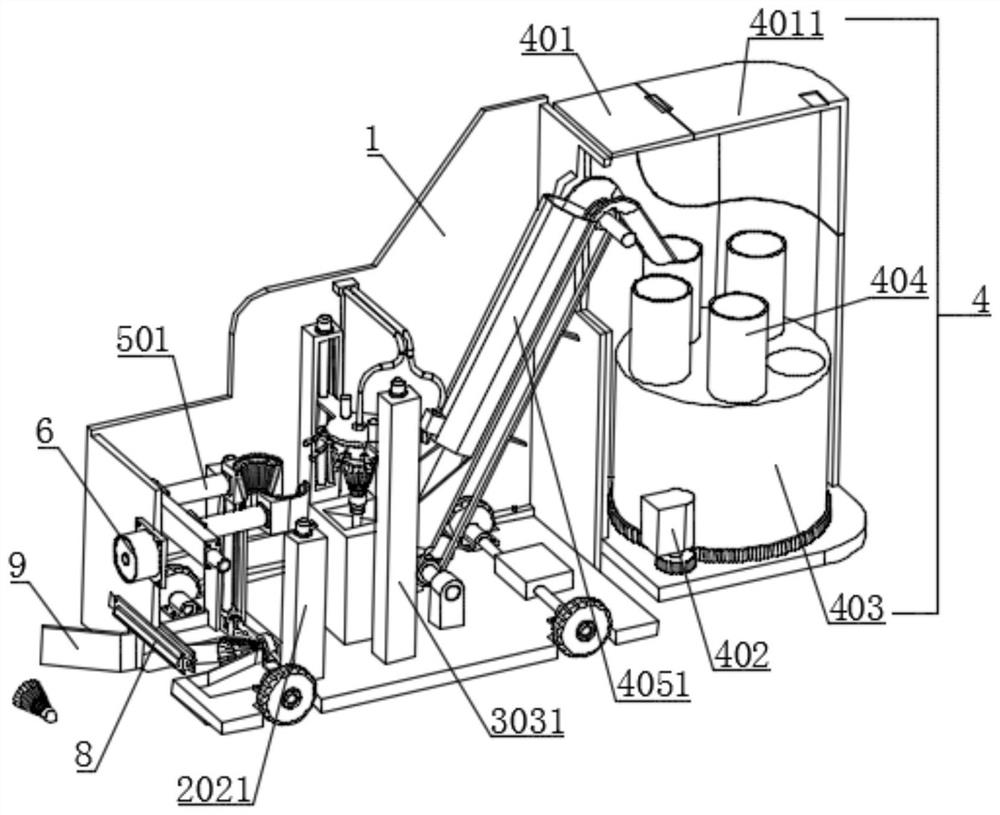

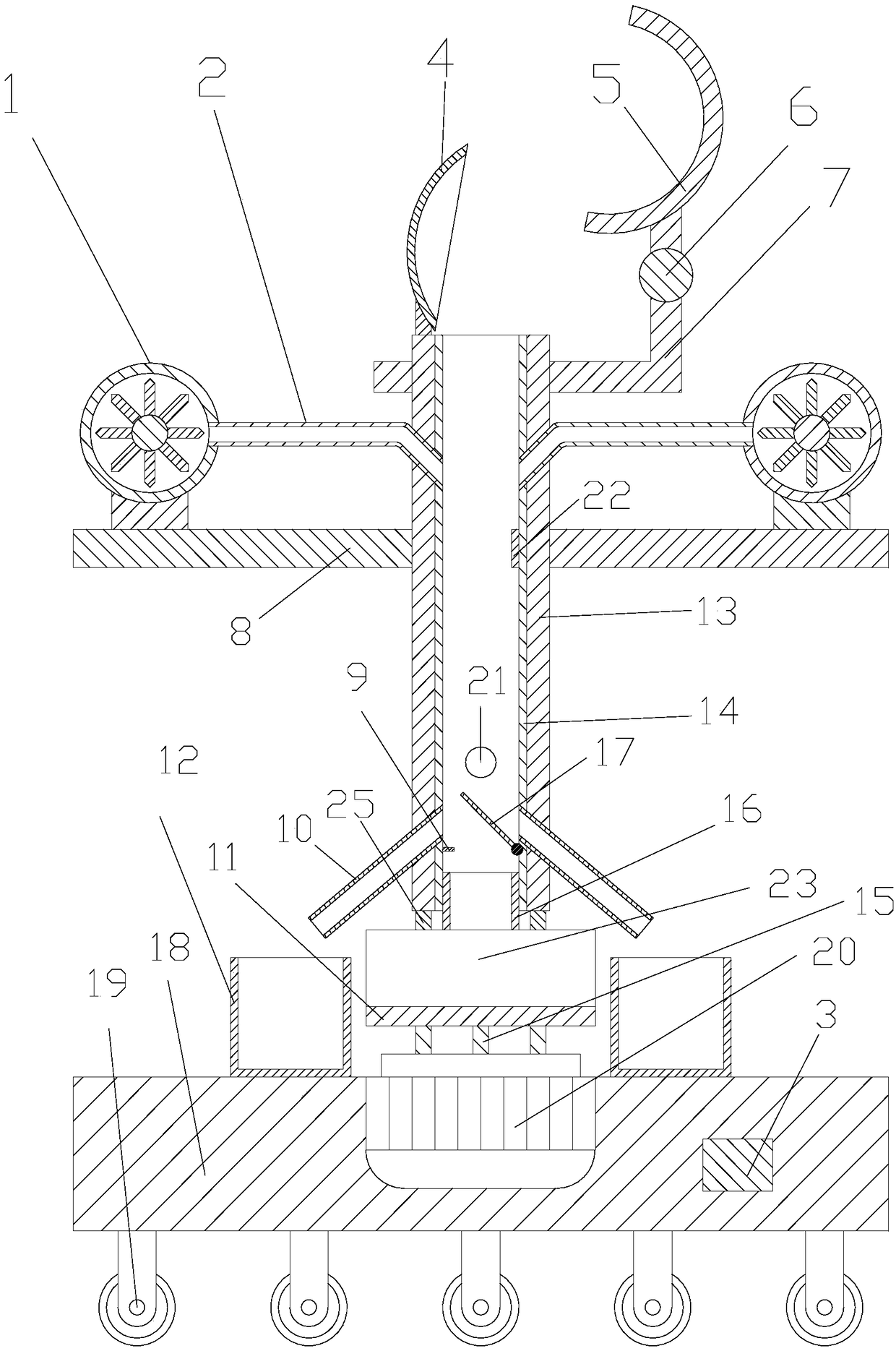

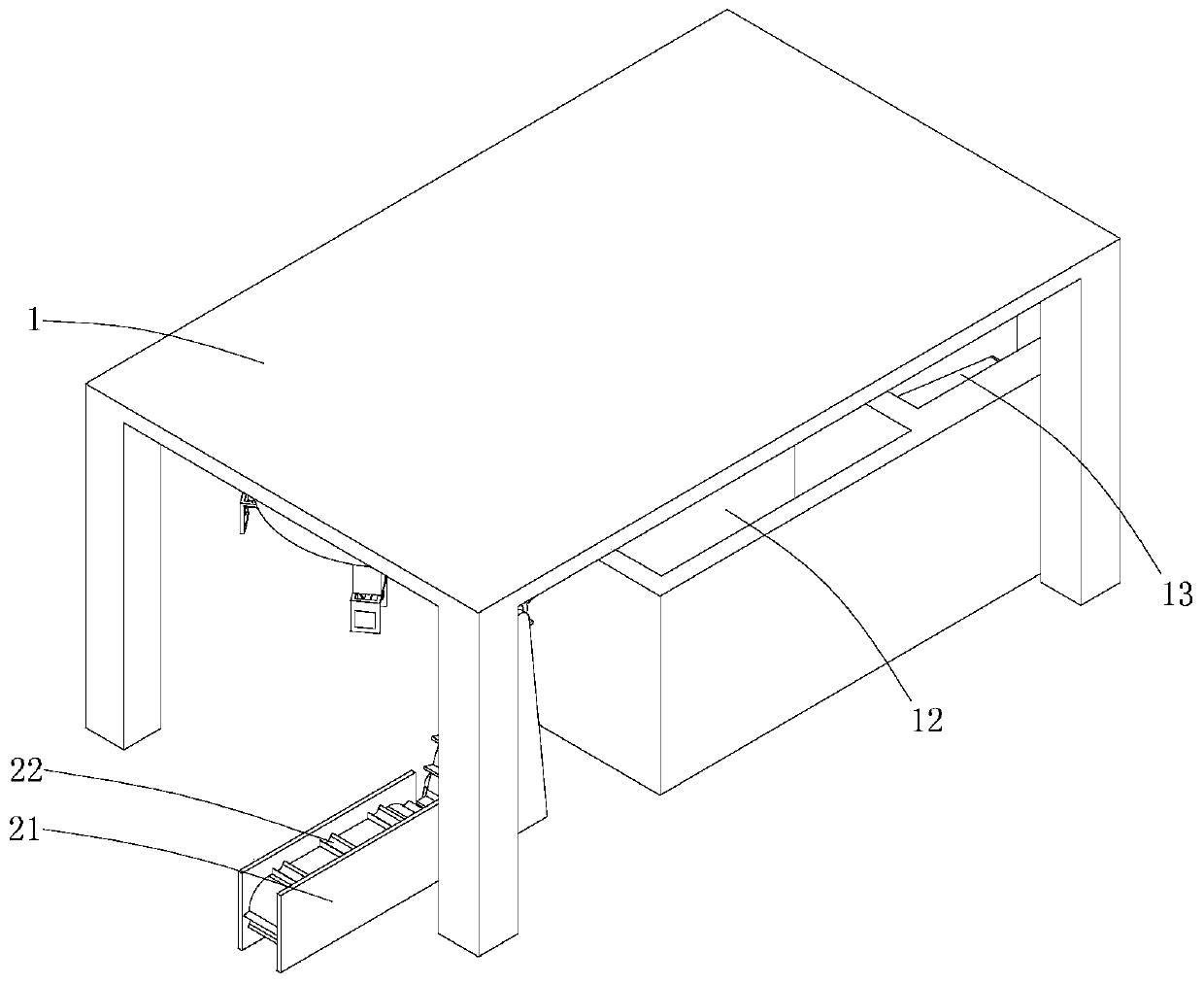

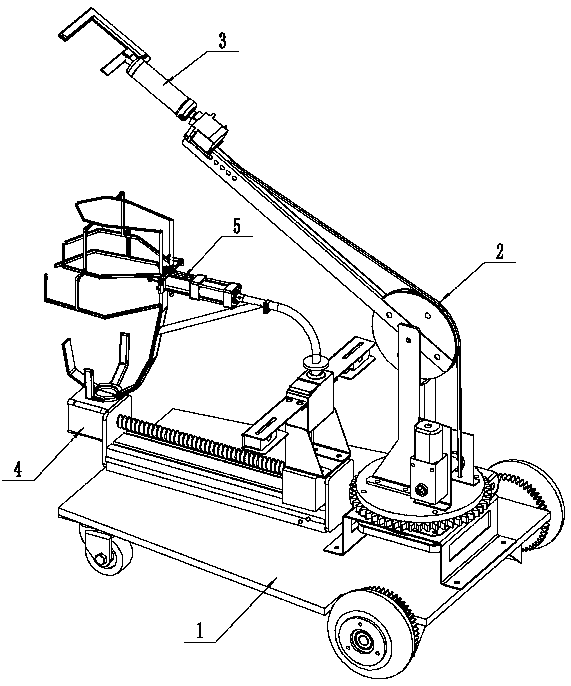

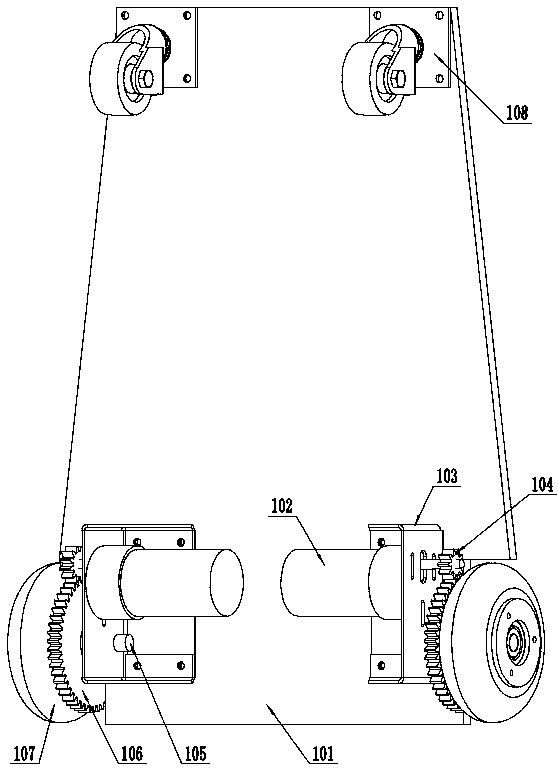

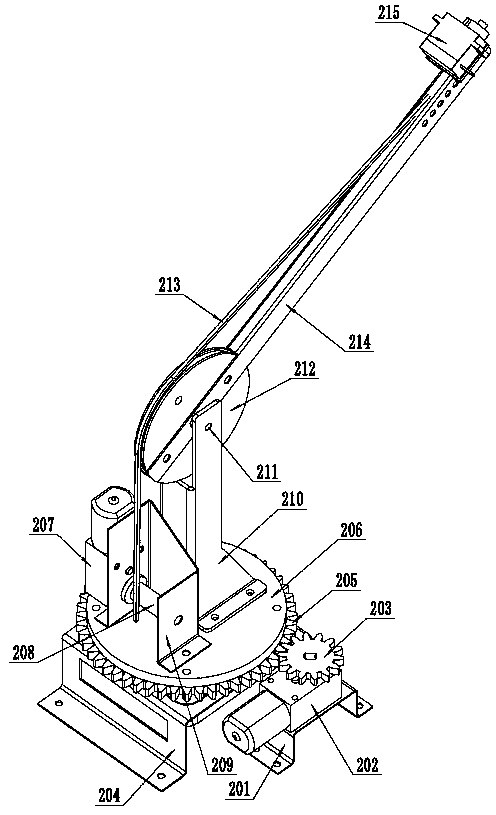

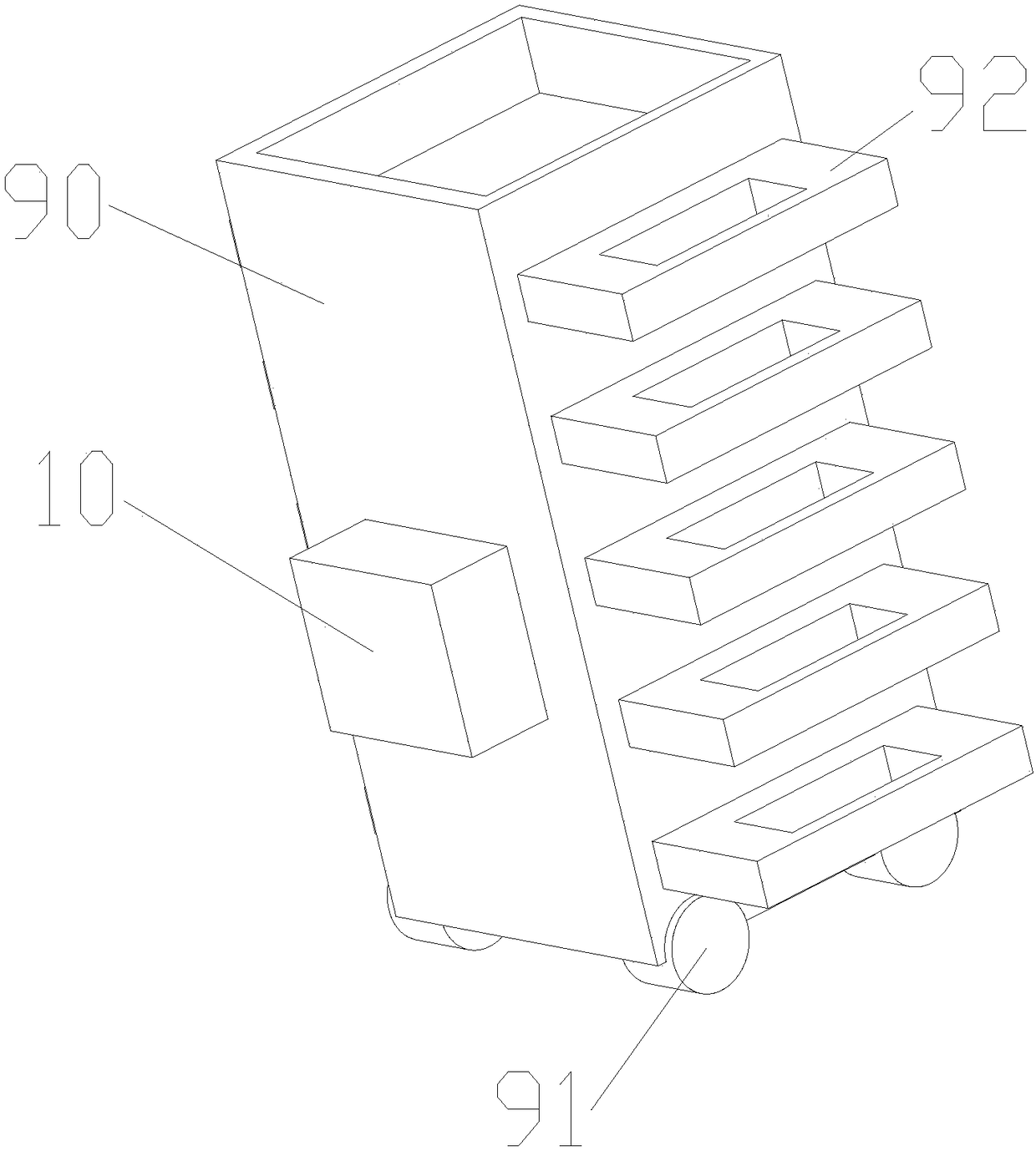

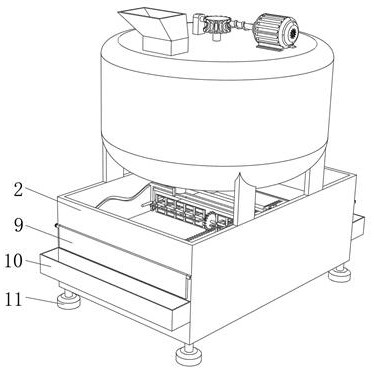

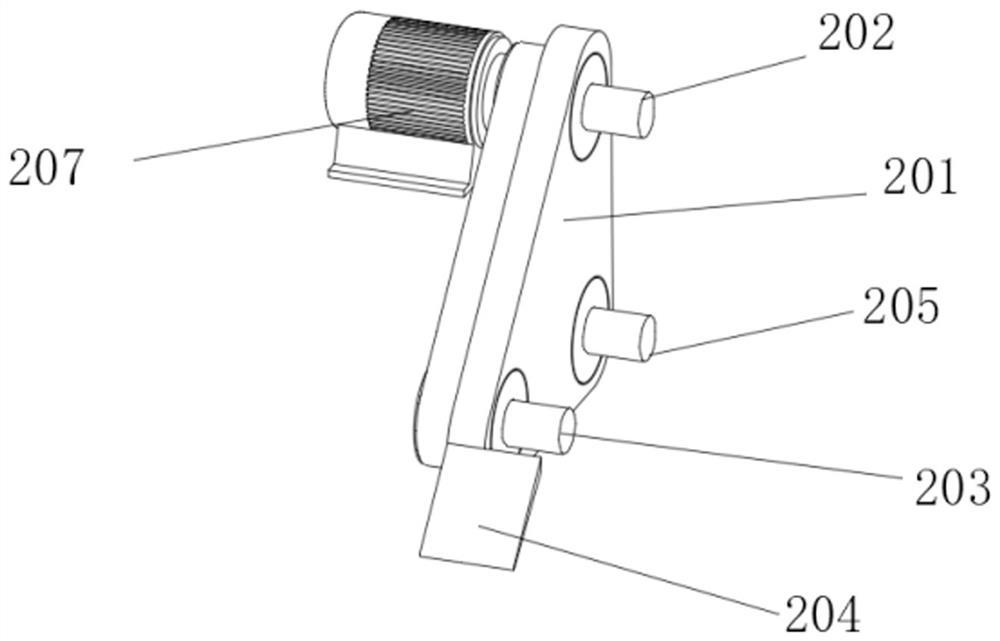

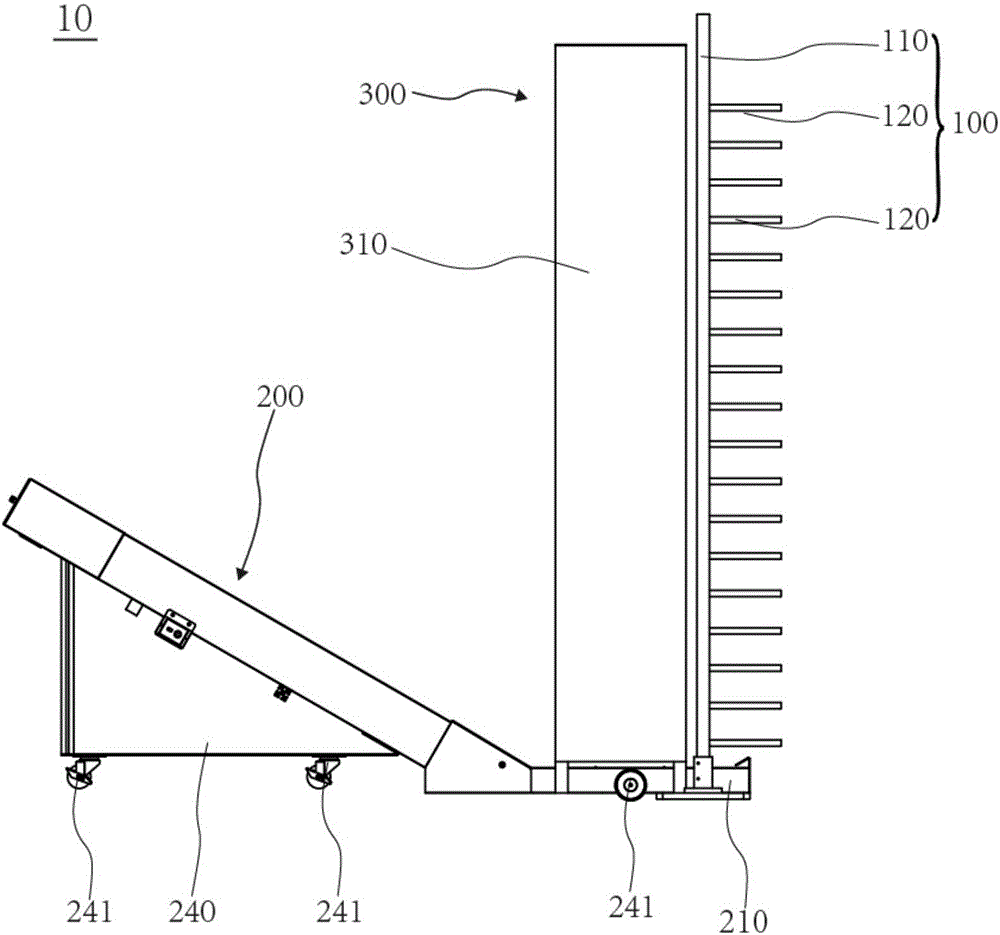

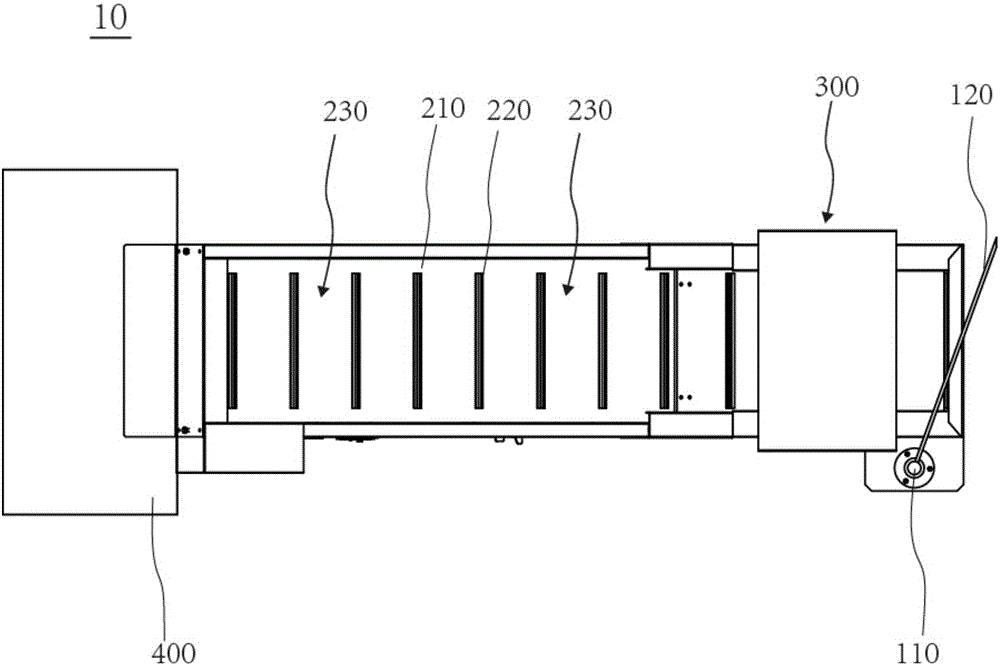

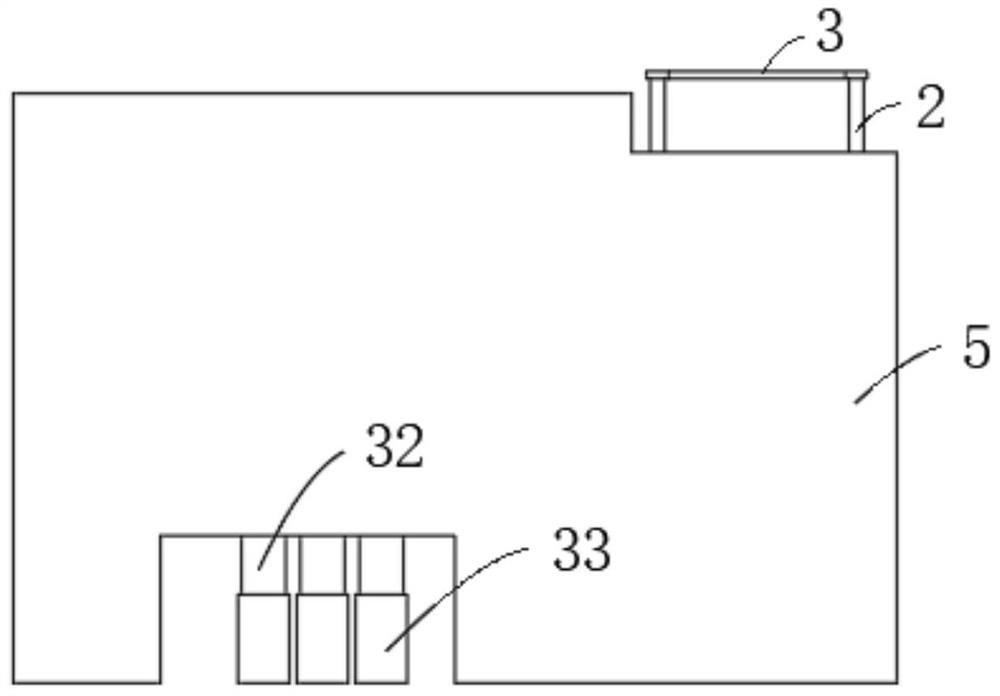

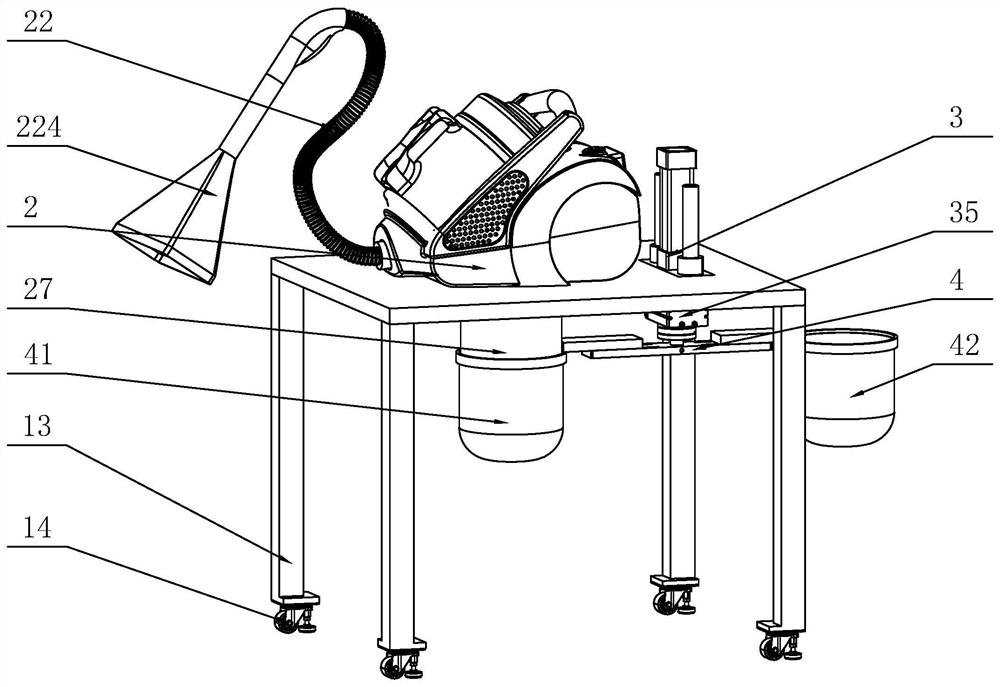

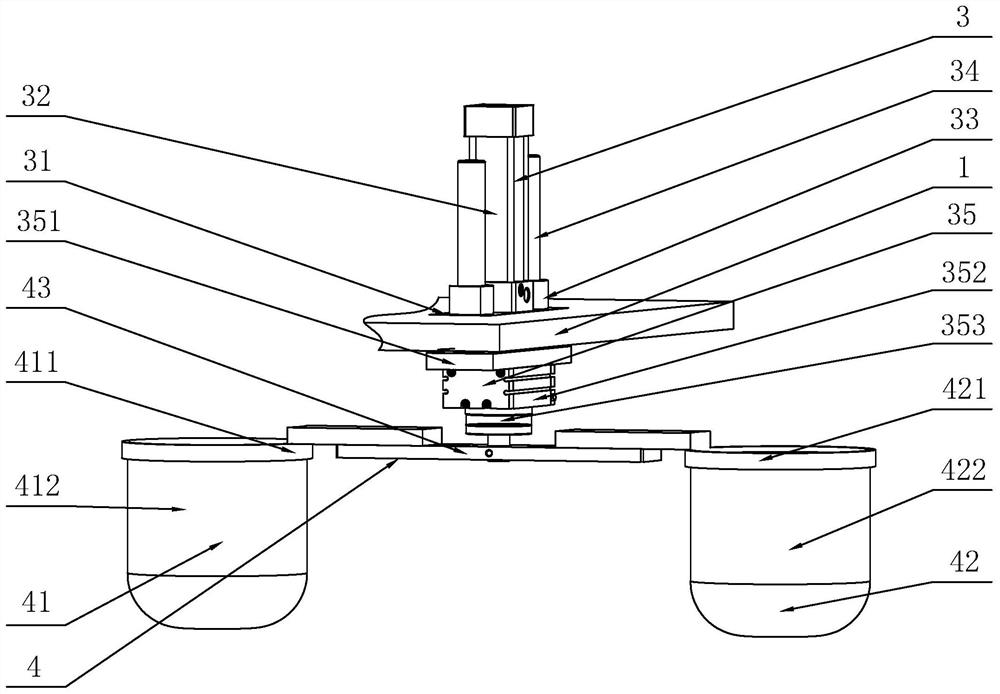

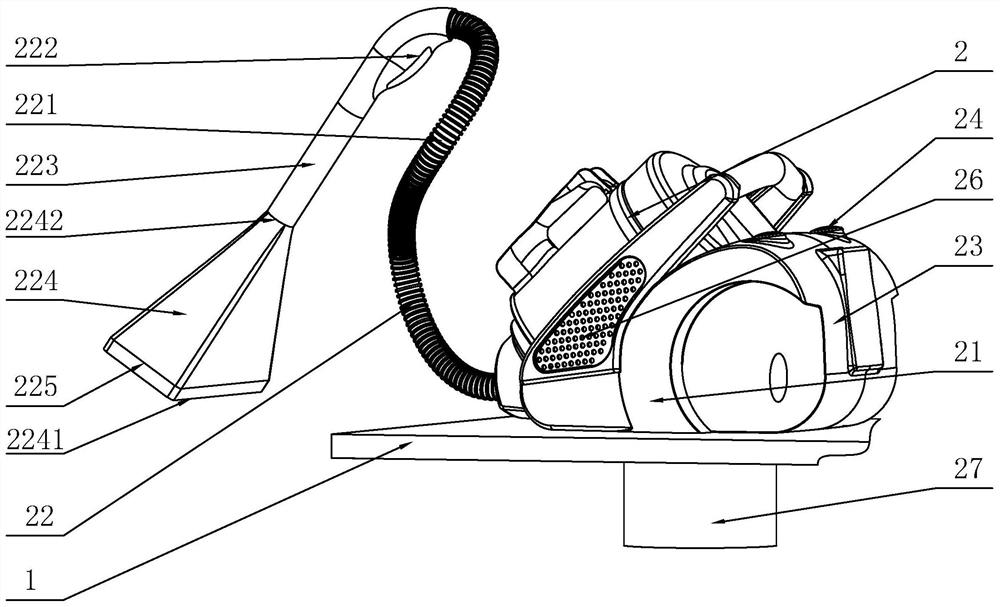

Automatic shuttlecock picking robot based on computer vision judgment

ActiveCN113069740ARealize automatic ball picking operationAvoid manual collectionBall sportsSortingComputer visionObstacle avoidance

The invention discloses an automatic shuttlecock picking robot based on computer vision judgment. The robot comprises a moving trolley, a shuttlecock picking device, a correcting device and a collecting device; a camera for collecting position information of shuttlecocks is fixedly connected to the front side of a trolley body; and a controller and an intelligent obstacle avoidance system are further mounted on the trolley body. According to the automatic shuttlecock picking robot based on computer vision judgment of the invention, after the camera is used for collecting data, a ball type condition on the ground can be identified;and after a shuttlecock is identified, the moving trolley moves towards the identified shuttlecock; and the skirt of the shuttlecock is blown by a blowpipe, so that the head of the shuttlecock enters an opening firstly, and the head of the shuttlecock can be clamped by a clamping piece, and the shuttlecock is lifted into the trolley body through a lifting piece, and therefore, automatic shuttlecock picking operation is achieved, manual collection is avoided, and time and labor are saved.

Owner:HUNAN POLYTECHNIC OF ENVIRONMENT & BIOLOGY

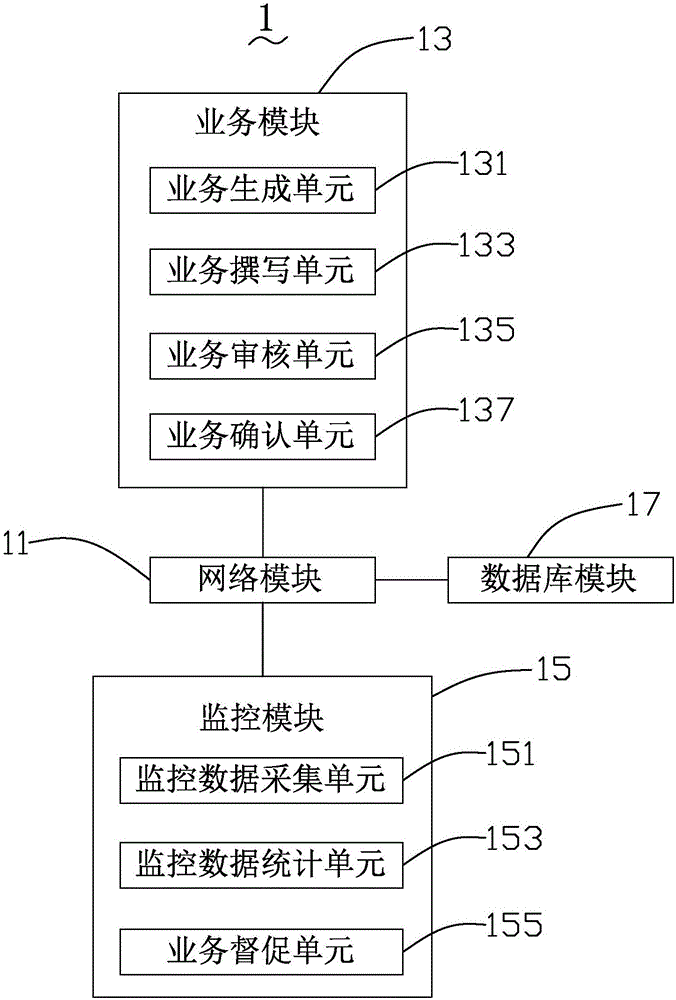

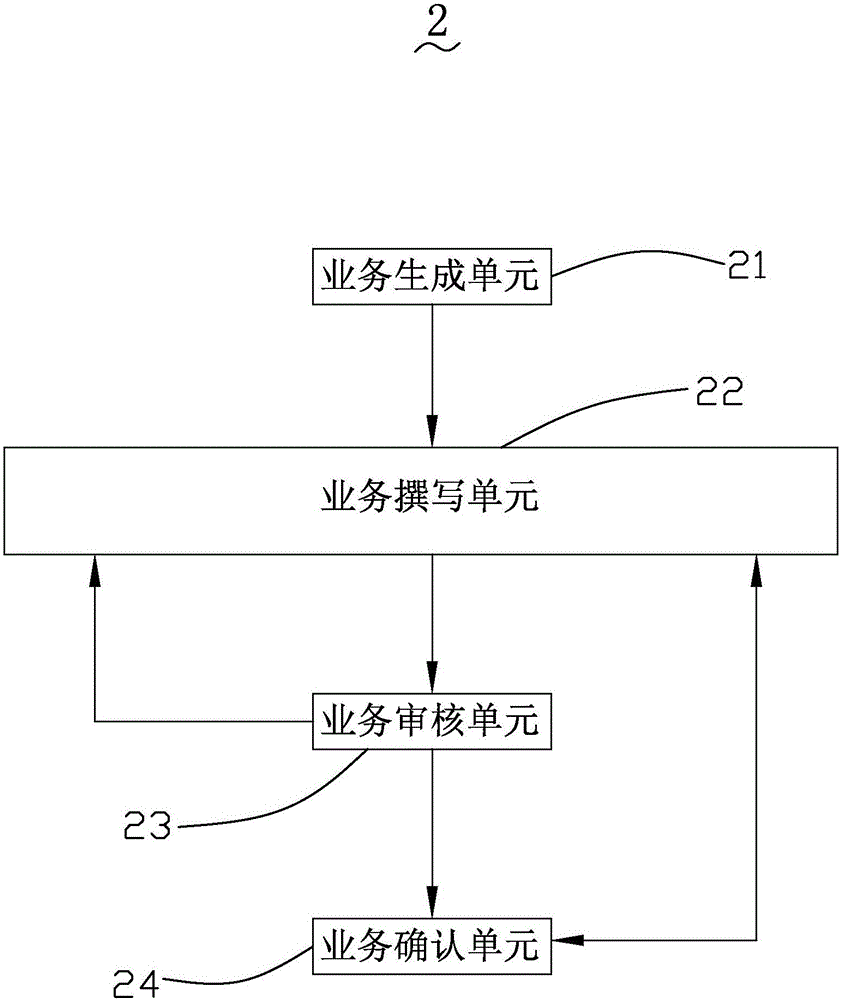

On-line patent writing business monitoring system

InactiveCN105069511ASave statistics timeStatistics shortcutData processing applicationsMonitoring systemComputer module

The present invention provides an on-line patent writing business monitoring system, comprising a network module, a business module, a monitoring module and a database module. The monitoring module includes a data acquisition unit, a monitoring data statistics unit and a business supervision unit. The monitoring data statistics unit is configured to acquire business information of the business module through the network module and to send the business information of the business module to the monitoring data statistics unit for data statistics; and the business supervision unit is configured to determine whether the network module sends a business supervision instruction to the business module or not according to the statistical results of the business information. According to the present invention, the on-line patent writing business monitoring system is configured to perform the statistics of business information and the transmission of business supervision instructions through the monitoring module so that comprehensive, accurate and timely statistics may be provided and business process may be supervised in time, therefore the work efficiency is effectively improved.

Owner:CHANGSHA LUZHI INFORMATION TECH

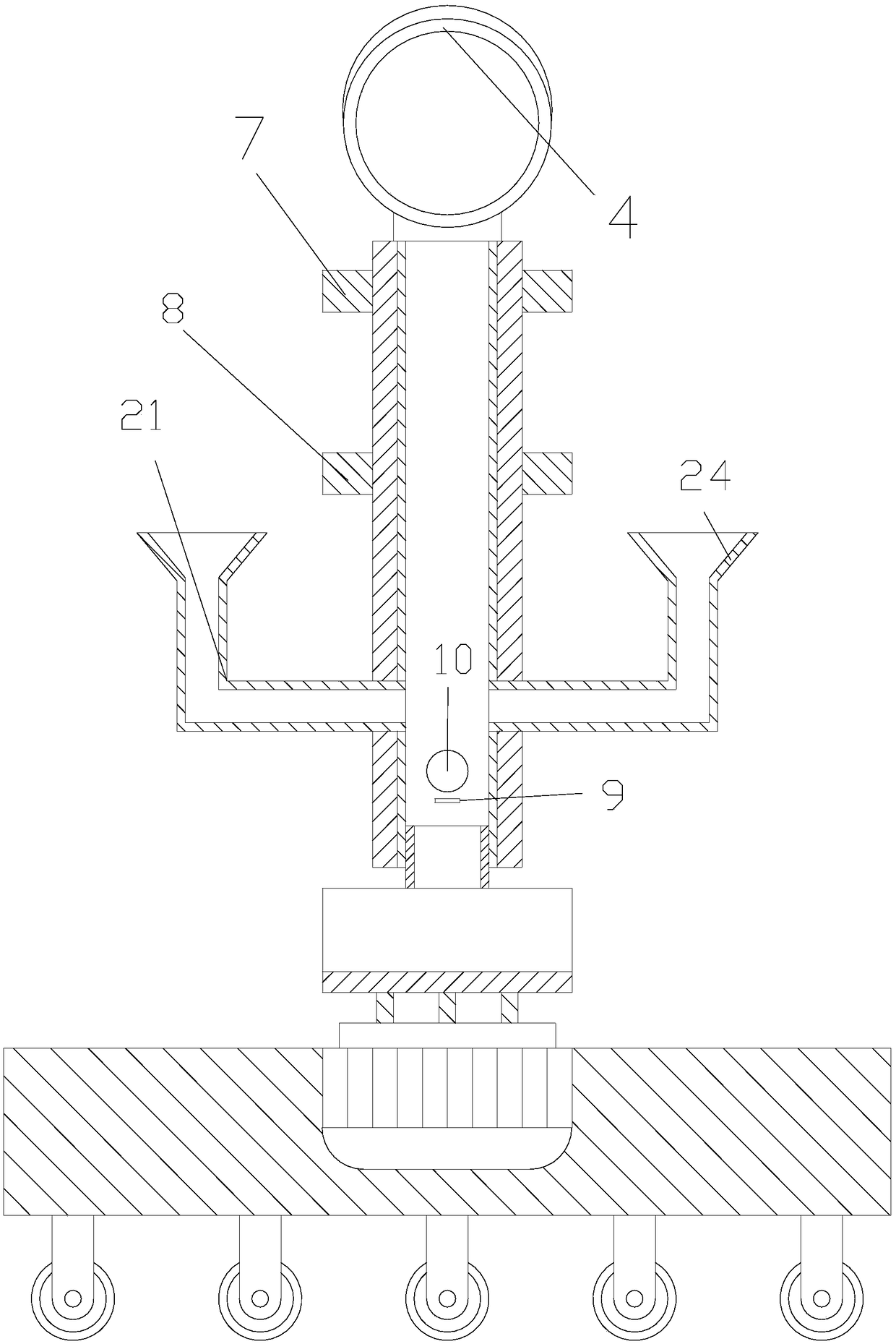

Reflection automatic tea sunning device and application method

InactiveCN109489398AAvoid manual collectionSimple structurePre-extraction tea treatmentDrying solid materials with heatEngineeringSunset

The invention discloses a reflection automatic tea sunning device. The device comprises a barrel. A reflection lens is fixedly mounted on the inner wall of the barrel. An electronic hygrothermograph is fixedly mounted on the inner wall of the right side of the reflection lens. An L-shaped support is fixedly mounted at the right end of the barrel. A cardan joint is fixedly mounted at the top of theL-shaped support. A solar cooker is arranged above the cardan joint and fixedly connected with the cardan joint. The reflection automatic tea sunning device has the beneficial effects that the deviceis simple in structure and easy and convenient to operate, sunning is performed in a solar cooker reflection mode, the area of land can be greatly saved, more tea leaves can be sunned on the same area of land, in addition, reflection of the solar cooker can change as the solar altitude changes, sunning can be performed from the sunrise to the sunset, then a control chip can automatically judge whether tea sunning is completed or not, furthermore, automatic collection can be performed through gravity after sunning is completed, and the full process is operated automatically.

Owner:陈惠英

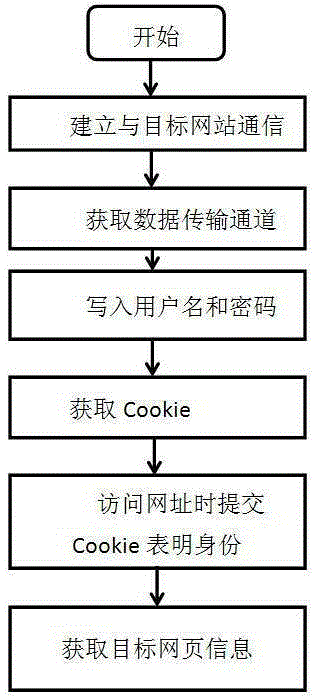

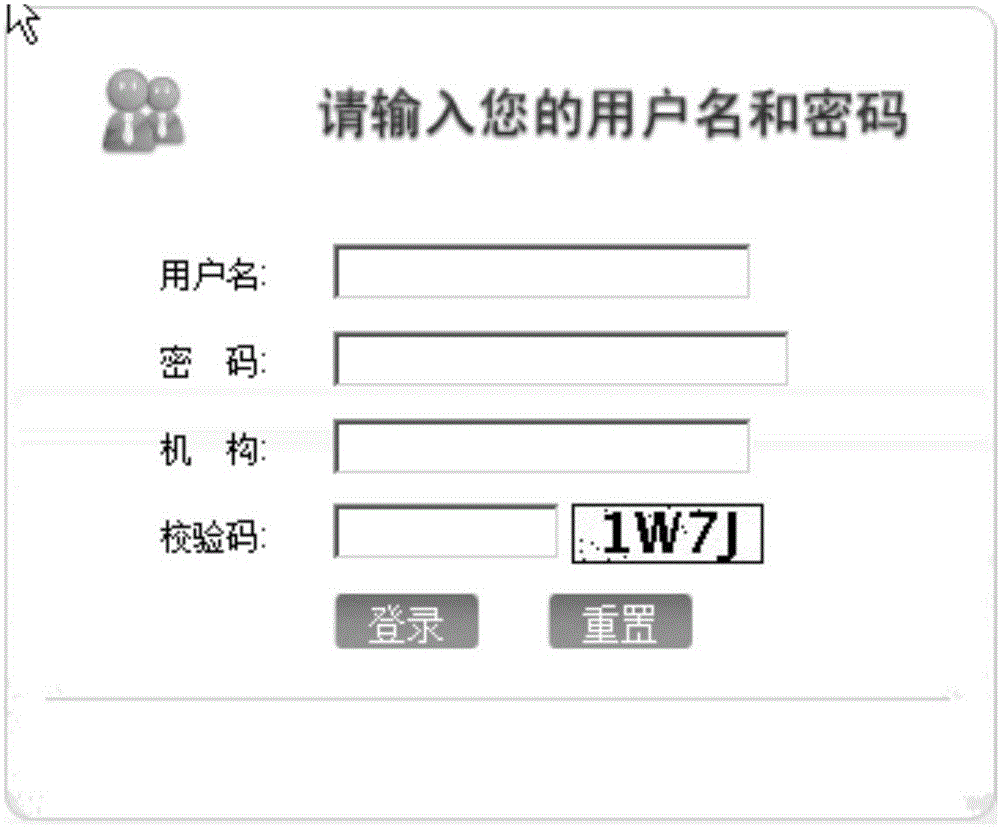

Data collection method based on virtual login

InactiveCN105306293AAvoid Manual CollectionImprove collection efficiencyDigital data authenticationData switching networksInternet privacyData acquisition

The invention provides a data collection method based on virtual login, and relates to the technical field of data collection. The data collection method provided by the invention comprises the following steps: 1) HttpClient virtual login; and 2) identification and submission of a verification code. User information is stored by Cookie to achieve analog website login to obtain contents which can be only accessed by registered users, and thus webpage contents are collected without registration.

Owner:INSPUR QILU SOFTWARE IND

Roller flaw detection process for steel structure production

ActiveCN110376277AShorten the timeImprove flaw detection efficiencyMaterial magnetic variablesEngineeringImpurity

The invention discloses a roller flaw detection process for steel structure production. The roller flaw detection process is characterized by comprising the steps of: a, precleaning, which is implemented by removing grease and other impurities possibly affecting normal distribution of magnetic powder and affecting density, characteristics and clarity of magnetic powder deposits on surfaces of allmaterials and test piece; b, flaw detection of defects, which is implemented by performing flaw detection of defects on a roller by means of magnetic powder flaw detection equipment; c, demagnetization, which is implemented by demagnetizing magnetic powder directly by means of the magnetic powder flaw detection equipment; d, post-cleaning, which is implemented by cleaning all magnetic powder on the test pieces after inspection and demagnetization, and thoroughly removing all blockages in holes and cavities.

Owner:浙江阳力钢结构股份有限公司

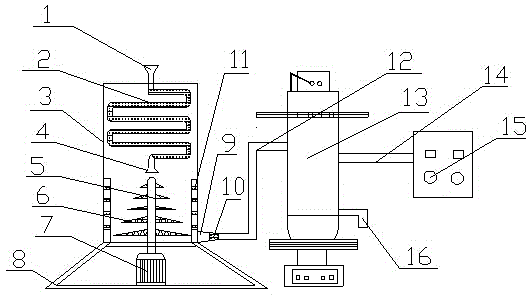

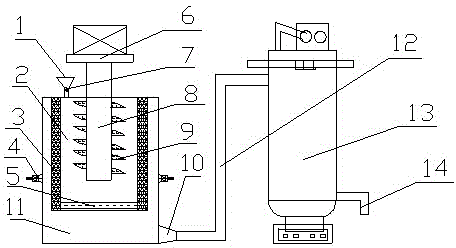

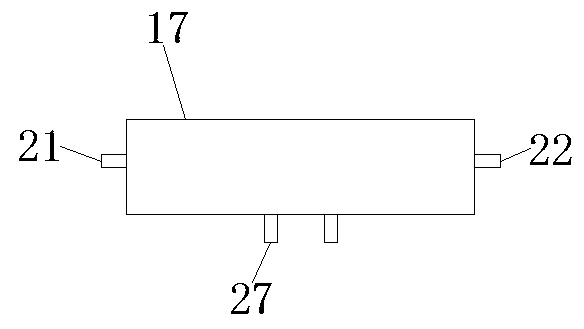

Pymetrozine powder drying machine

InactiveCN105318699AReduce lossHigh purityDrying gas arrangementsDrying solid materialsImpellerPulp and paper industry

The invention discloses a pymetrozine powder drying machine which comprises a drying machine body, a feeding hopper, a discharging port and a motor. The drying machine body is supported on a base, stirring vane wheels are arranged on a stirring shaft arranged on the motor, airflow holes are formed in the two ends of the drying machine body, the feeding hopper is arranged at the top end of the drying machine body, one end of the feeding hopper is connected to an electric heater, a spray head is arranged at the tail end of the electric heater, a connector is arranged at the lower end of the drying machine body, the other end of the connector is connected to a vacuum feeding machine through a conveying pipe, the discharging port is formed in the bottom end of the vacuum feeding machine, and the vacuum feeding machine is connected to an electric control device through a power line. The pymetrozine powder drying machine is sufficient and uniform in drying, short in time and high in efficiency, purity of products is ensured, meanwhile, materials are automatically collected, and hand labor is reduced.

Owner:ANHUI YANGZI CHEM

Banana picking vehicle

Owner:罗晓辉

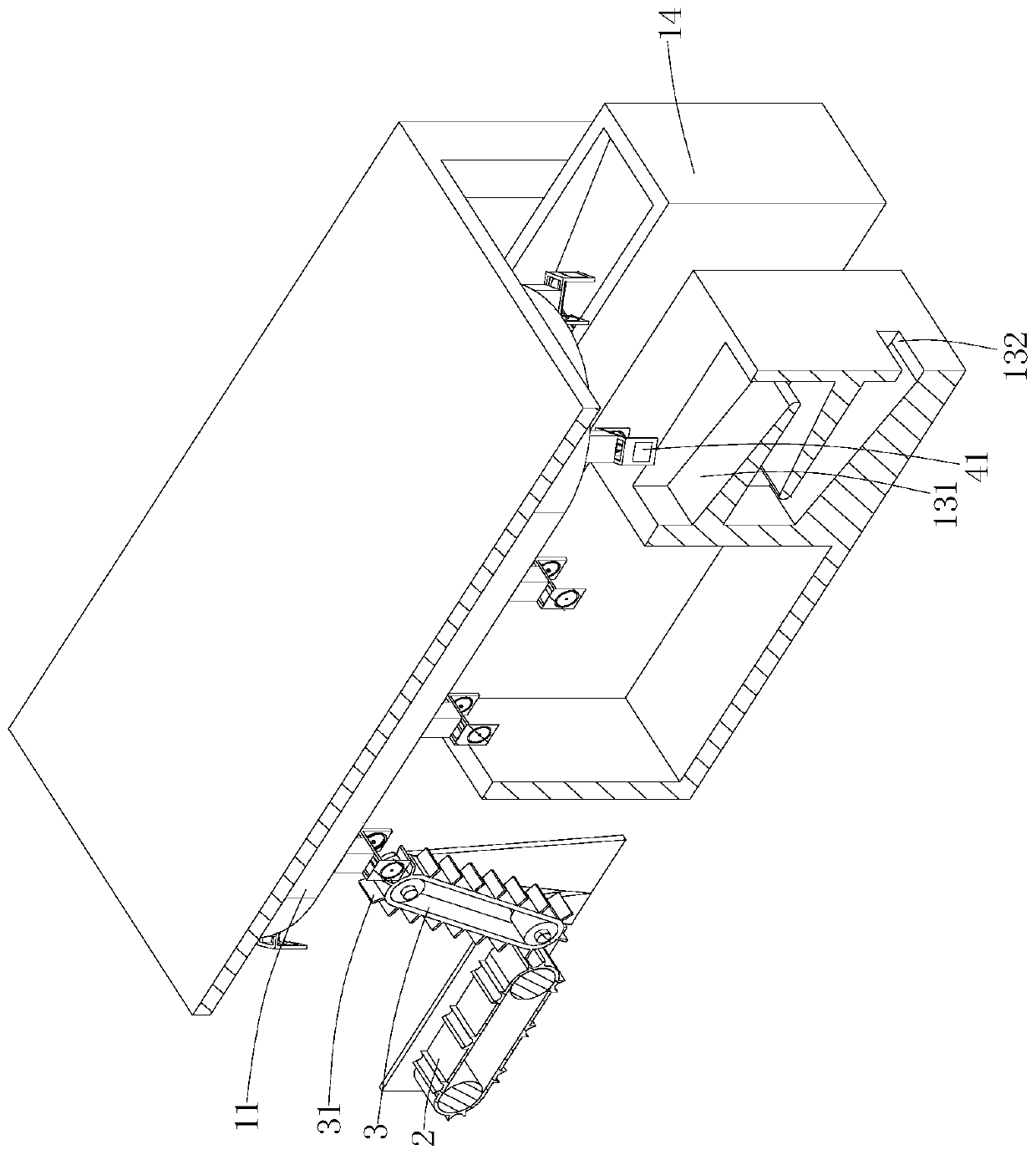

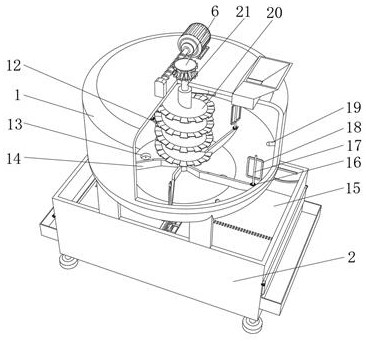

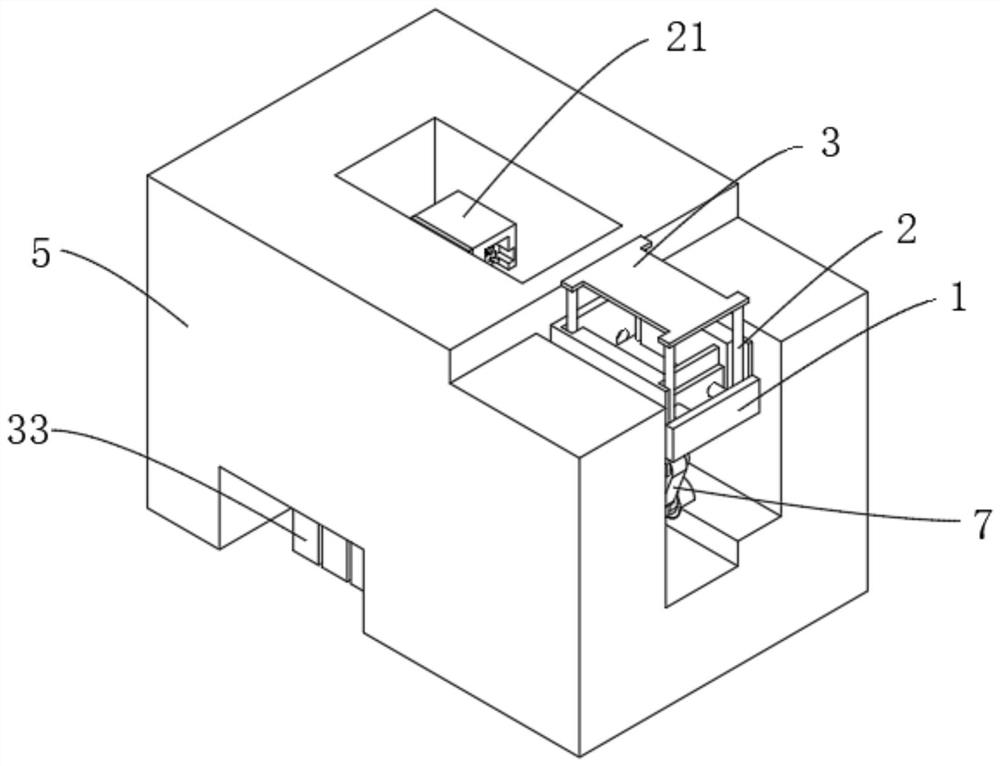

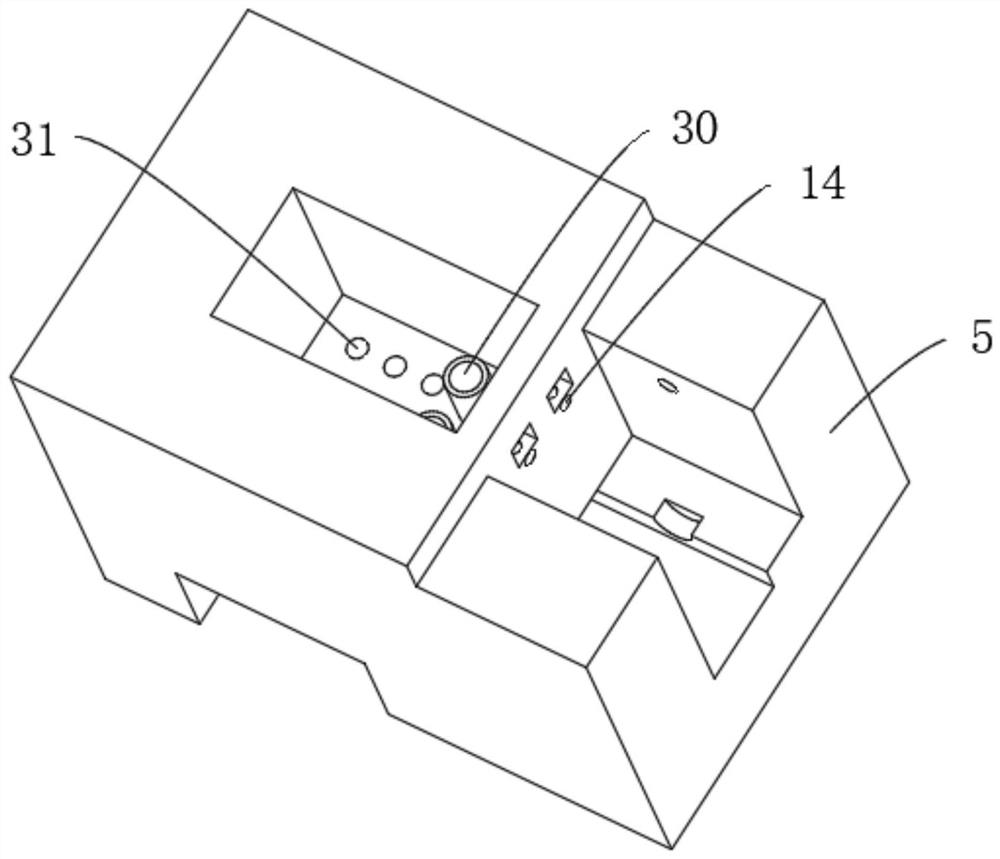

Lower mould base mechanism capable of automatically collecting materials

InactiveCN108326180AMeet processing needsAvoid manual collectionShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention relates to a lower mould base mechanism capable of automatically collecting materials. A through hole which communicates with an accommodating cavity of a base is formed in the upper endof the base; a lower mould base capable of moving up and down through a drive mechanism is arranged in the through hole; the drive mechanism is arranged in the base; a concave mould is arranged at the upper end of the lower mould base; a rotary motor positioned in the base is arranged at one side of the drive mechanism; the upper end of the rotary motor is connected with a rotatable rotary framethrough a rotary shaft; the rotary frame is positioned at one side away from the drive mechanism; a telescopic pole is arranged at the lower end of the rotary frame; a sucking disc is arranged at thelower end of the telescopic pole; a storage mechanism is arranged below the sucking disc; one end of the storage mechanism is connected with an iron plate through an electromagnet; and the iron plateis positioned between the rotary motor and the electromagnet. According to the lower mould base mechanism disclosed by the invention, the mechanism capable of automatically collecting materials is additionally arranged on the lower mould base for automatically collecting stamped parts, so that manual collecting is avoided, time and labor power are saved, efficiency of the whole production processis improved, and processing needs of enterprises are met.

Owner:SUZHOU RIPU MOLD CO LTD

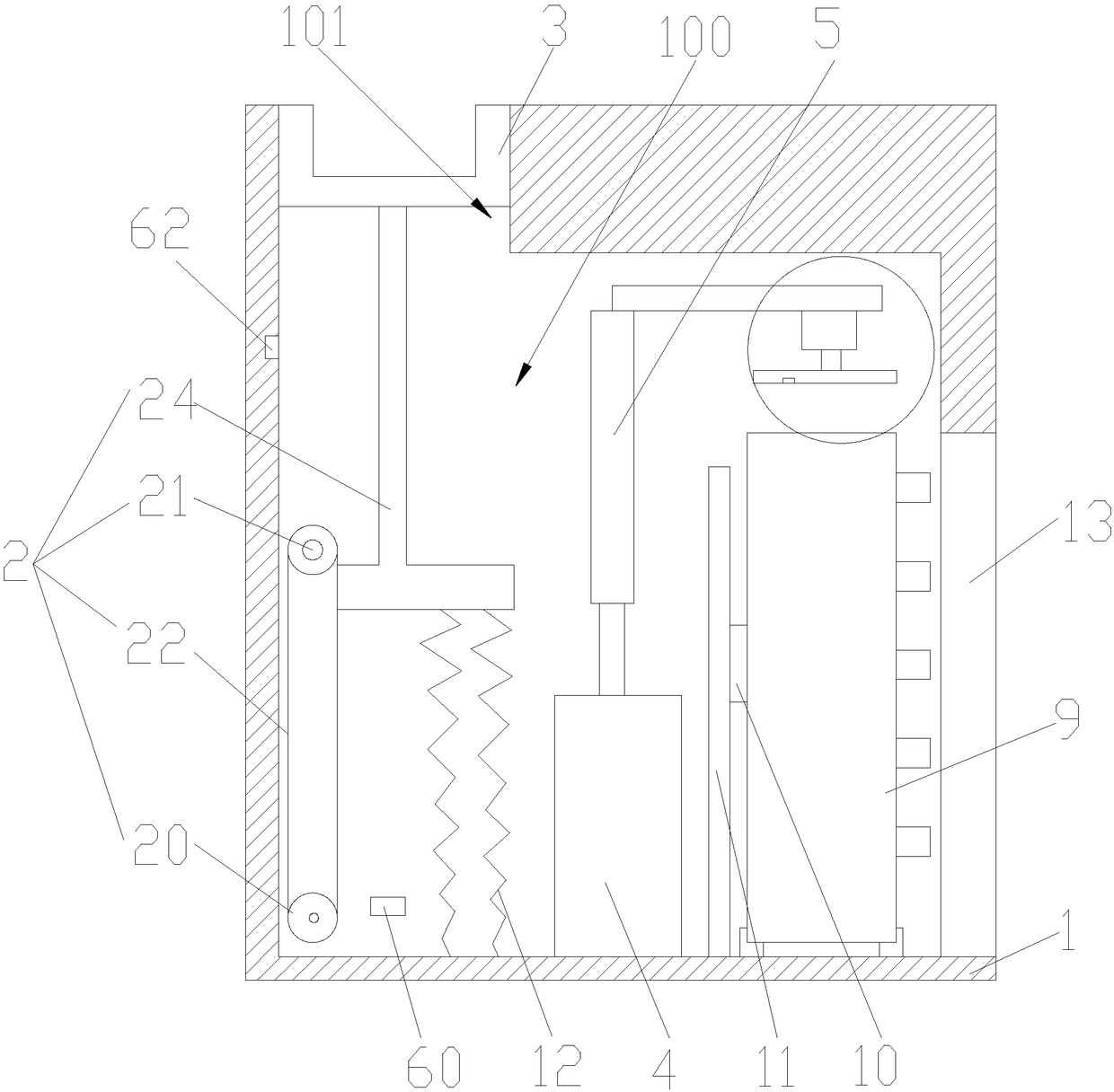

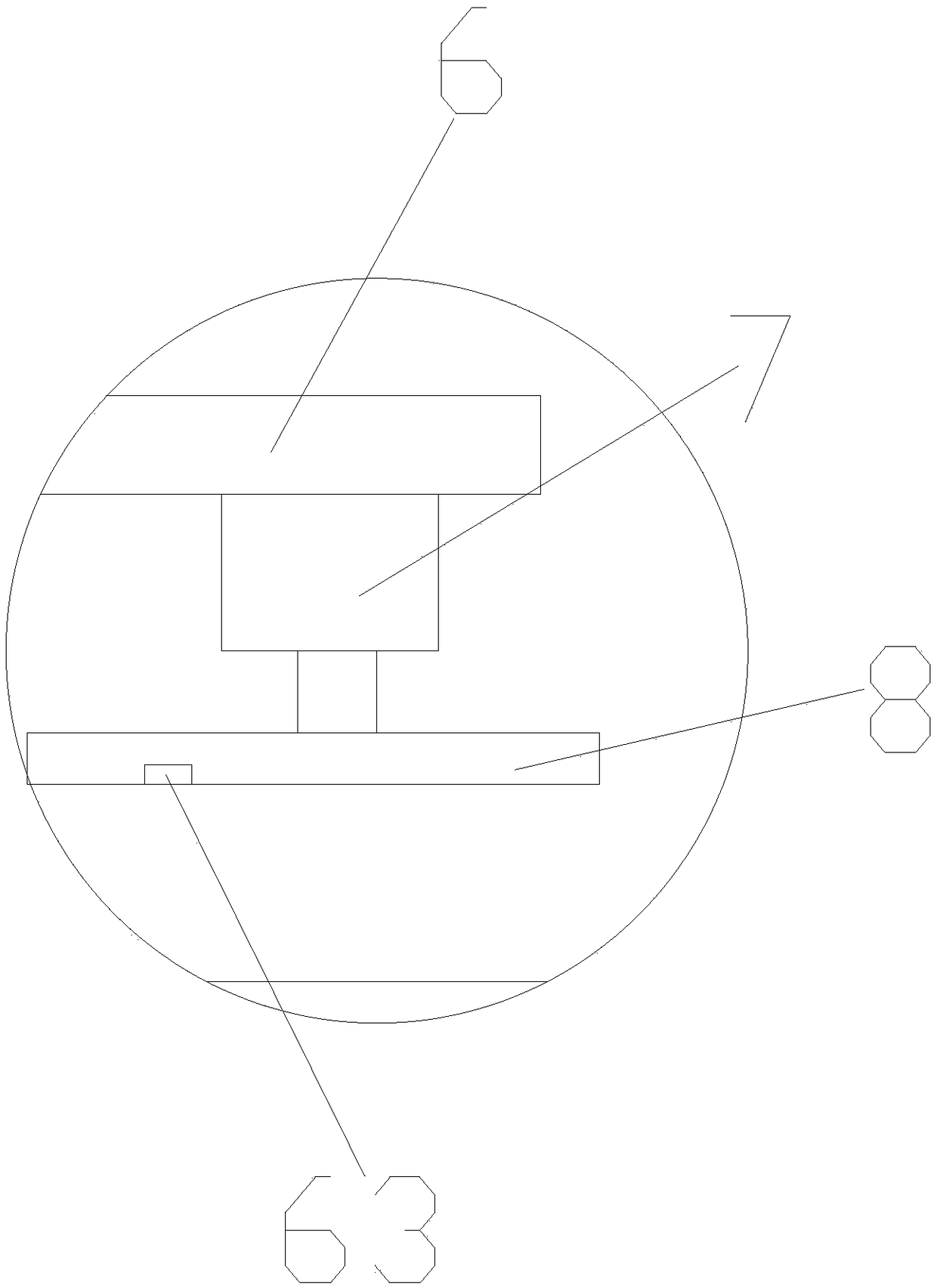

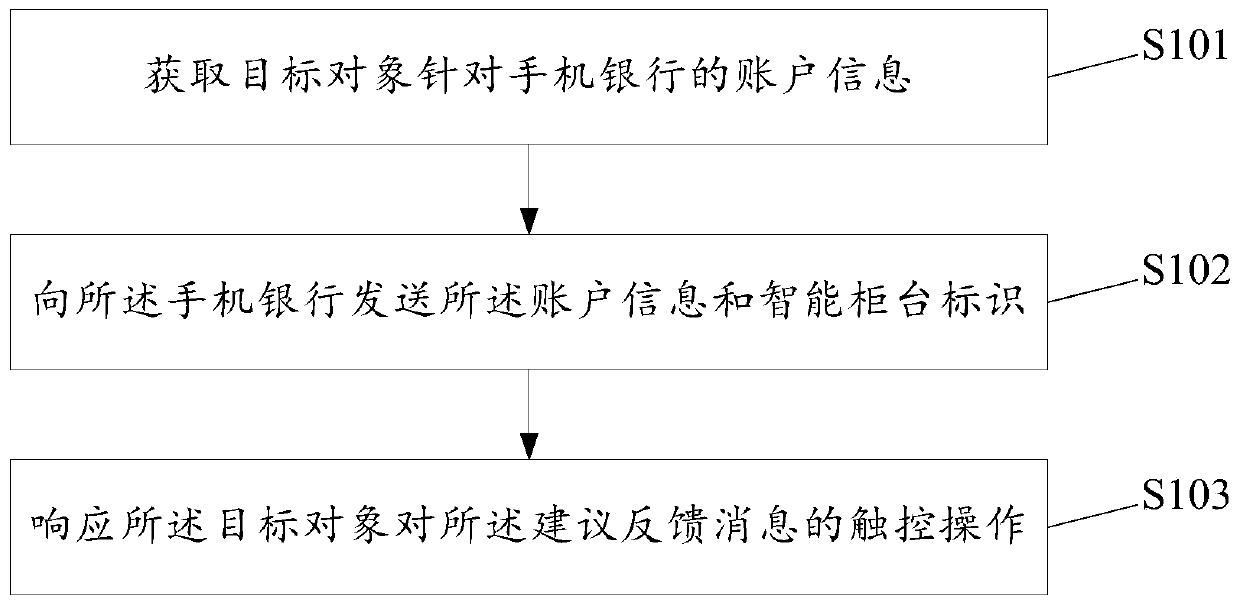

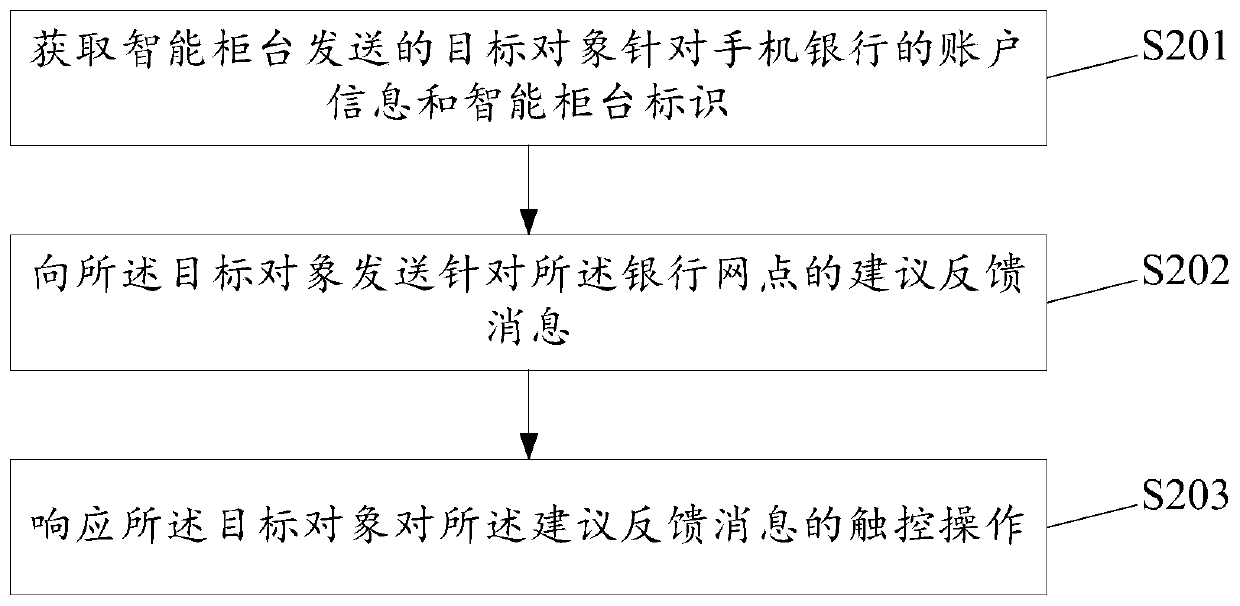

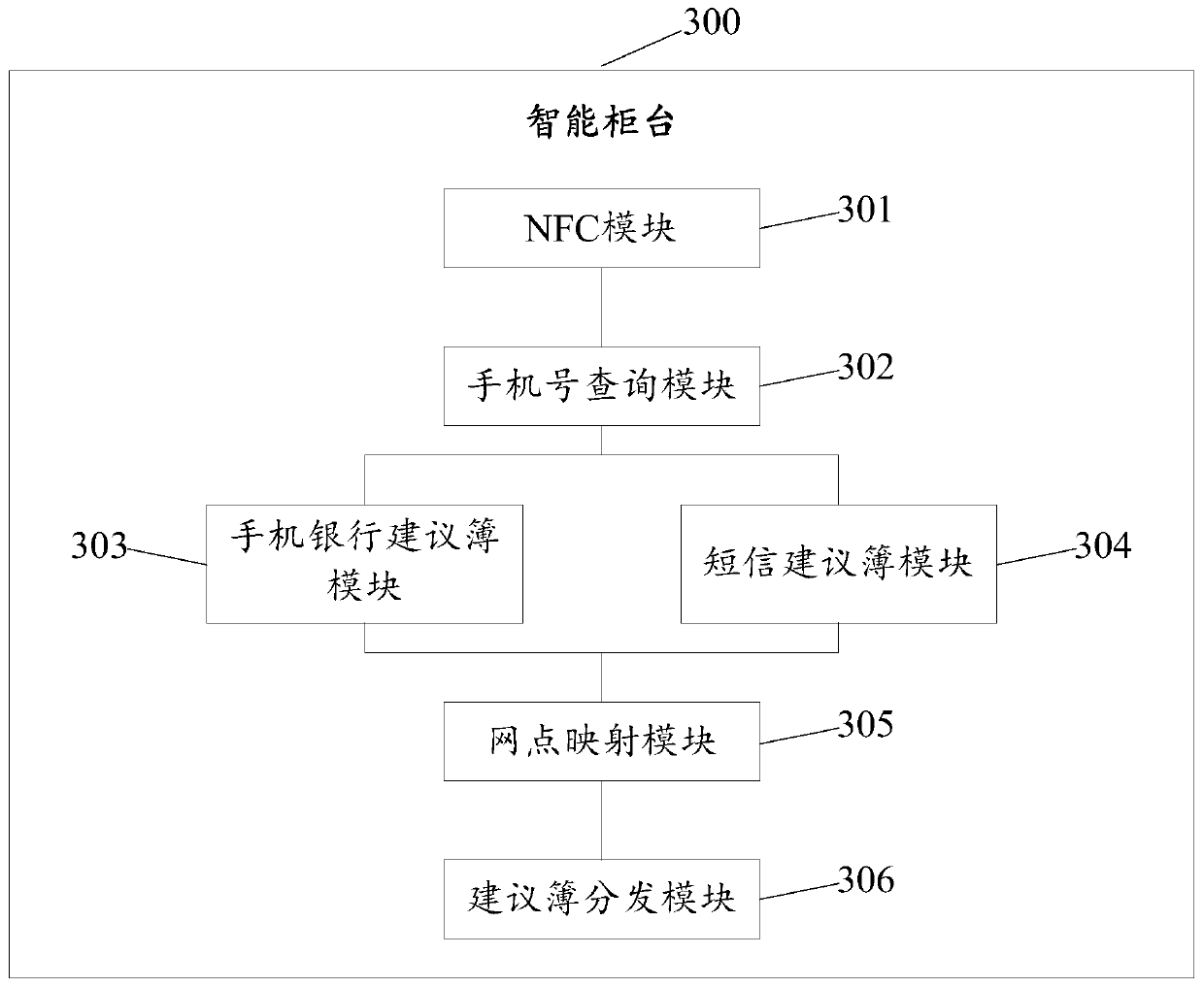

Bank outlet suggestion feedback method and related equipment

PendingCN111524003AImprove feedback efficiencyRealize automatic collectionCustomer relationshipFinanceHuman–computer interactionReal-time computing

The invention provides a bank outlet suggestion feedback method and related equipment, and the method comprises the steps that an intelligent counter obtains account information for a cellphone bank,and transmits the account information and an intelligent counter identification to the cellphone bank, so as to enable the cellphone bank to transmit a suggestion feedback message to the cellphone bank of a target object. And the intelligent counter responds to the touch operation of the target object on the suggestion feedback message to obtain the suggestion of the target object on the bank outlet where the intelligent counter is located. Due to the fact that the account information of the target object is associated with the mobile banks, the intelligent counter performs information interaction with the mobile banks of the target object, suggestions of customers for bank outlets are automatically collected, the process of manually collecting and sorting customer suggestions is avoided,and the efficiency of suggestion feedback for the bank outlets is improved.

Owner:BANK OF CHINA

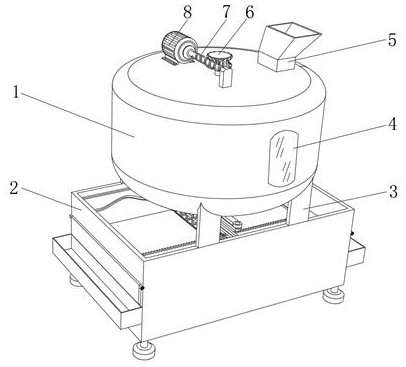

Self-collecting device for industrial solid powder

The invention discloses a self-collecting device for industrial solid powder. The self-collecting device comprises a separation cabin, a feeding hopper and a discharging opening. The separation cabin is of a cylindrical and vertical structure and provided with a motor, the output end of the motor is connected with a rotating shaft, the rotating shaft extends into the separation cabin, the rotating shaft is provided with impellers, and the feeding holler is arranged on one side of the motor and internally provided with a sealing curtain. The two sides of the separation cabin are provided with filter mesh layers, a discharging cabin is arranged outside the filter mesh layers, a material blocking plate is arranged between the separation cabin and the discharging cabin, the right side of the discharging cabin is provided with a connector, the connector connects the discharging cabin and a vacuum feeding machine by means of a material conveying pipe, and the right side of the vacuum feeding machine is provided with the discharging opening. By means of the self-collecting device, separated materials and material slag can be separated and collected automatically, energy is saved, the environment is protected, meanwhile detaching is convenient to conduct, maintenance time is short, and the cost is low.

Owner:ANHUI YANGZI CHEM

Biological product sterilization device

ActiveCN113663587AImprove the bactericidal effectAvoid manual collectionShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringMechanical engineering

The invention relates to the technical field of biological product processing, in particular to a biological product sterilization device which comprises a power mechanism and a shell, the top of the shell is fixedly connected with a plurality of fixing plates, the top ends of the fixing plates are fixedly connected with a tank body, and the bottom of the tank body is movably connected with a second connecting shaft; the bottom end of the second connecting shaft is fixedly connected with a first connecting plate, one end of the first connecting plate is movably connected with a second connecting plate, and a sliding groove is formed in the inner wall of one side of the shell. According to the device, the rotating frame and the moving frame are matched for use, so that biological products are stirred and turned over, the sterilization effect of the device is improved, a spiral piece and a turbulent flow frame are matched for use, so that the biological products are fully stirred and mixed, the mixing effect of the device is improved, and a stress plate and a blocking column are matched for use, the biological products are intermittently discharged, and the discharging effect of the device is improved.

Owner:南通广恒生物科技有限公司

Automatic labeling machine with double-sided labeling function

InactiveCN112193560AHigh strengthImprove stabilityLabelling flat rigid surfacesLabelling machinesStructural engineeringMechanical engineering

The invention discloses an automatic labeling machine with a double-sided labeling function. The machine comprises a bottom plate, a labeling assembly, a turning assembly and a transferring assembly,wherein a mounting frame is arranged at the bottom of the labeling assembly, the labeling assembly is located above the front side of the bottom plate, a main conveying belt is mounted on the right side of the upper surface of the bottom plate, an auxiliary conveying belt is arranged on the left side of the main conveying belt, a steering table is arranged at the bottom of the turning assembly, the turning assembly is located on the rear side of the main conveying belt, a pneumatic chuck is arranged on the front side of the upper portion of a steering table, a toothed column is connected to the rear side of the pneumatic chuck, meshing strips are arranged below the two ends of the toothed column, hydraulic rods are connected to the rear sides of the meshing strips, a frame is arranged above the transferring assembly, and the transferring assembly is located above the rear side of the bottom plate. According to the automatic labeling machine with the double-sided labeling function, double-sided labeling on products can be completed through the turning assembly and the transferring assembly, the labor cost is reduced, and the production efficiency is improved.

Owner:昆山英合达精密机械有限公司

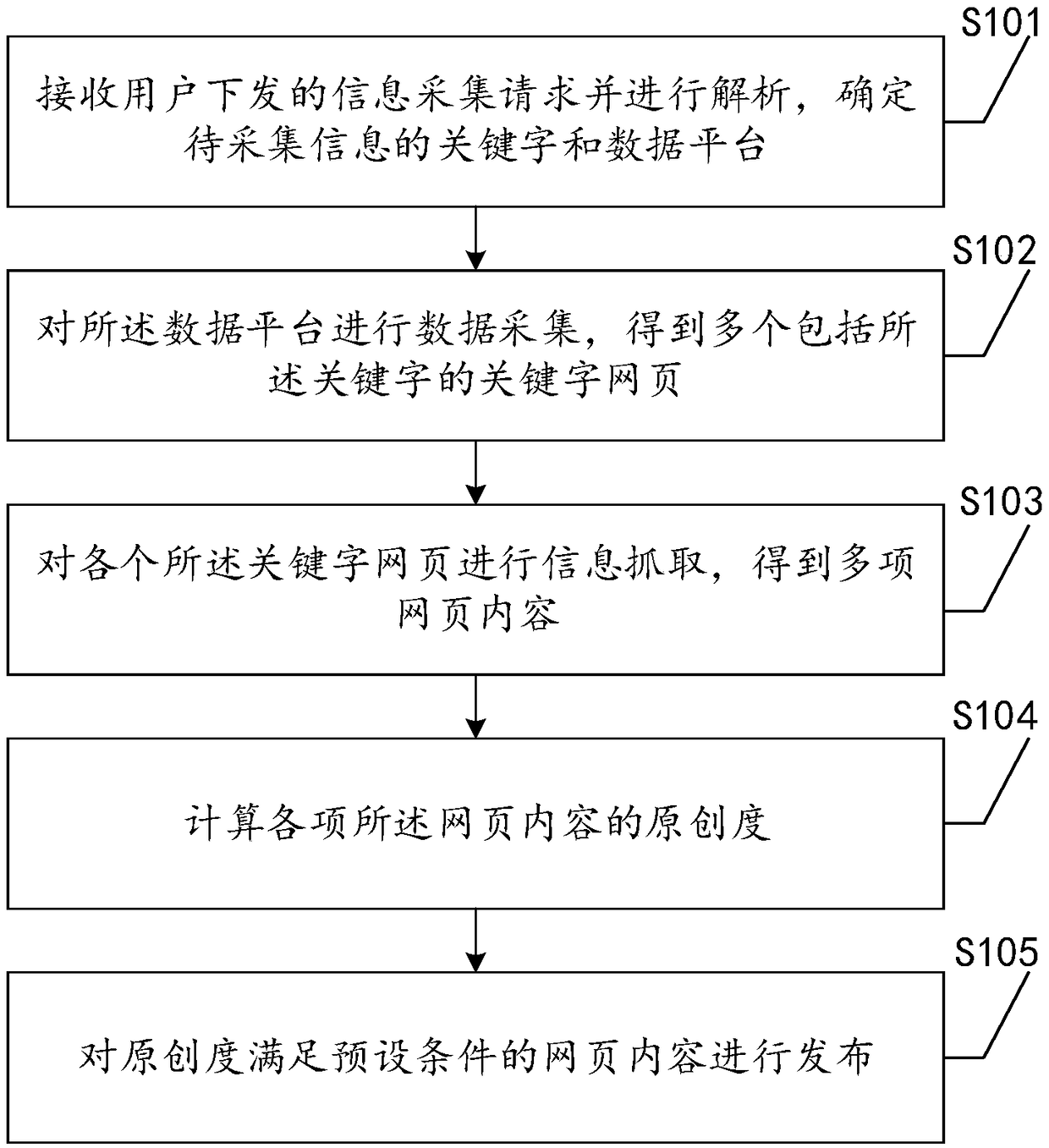

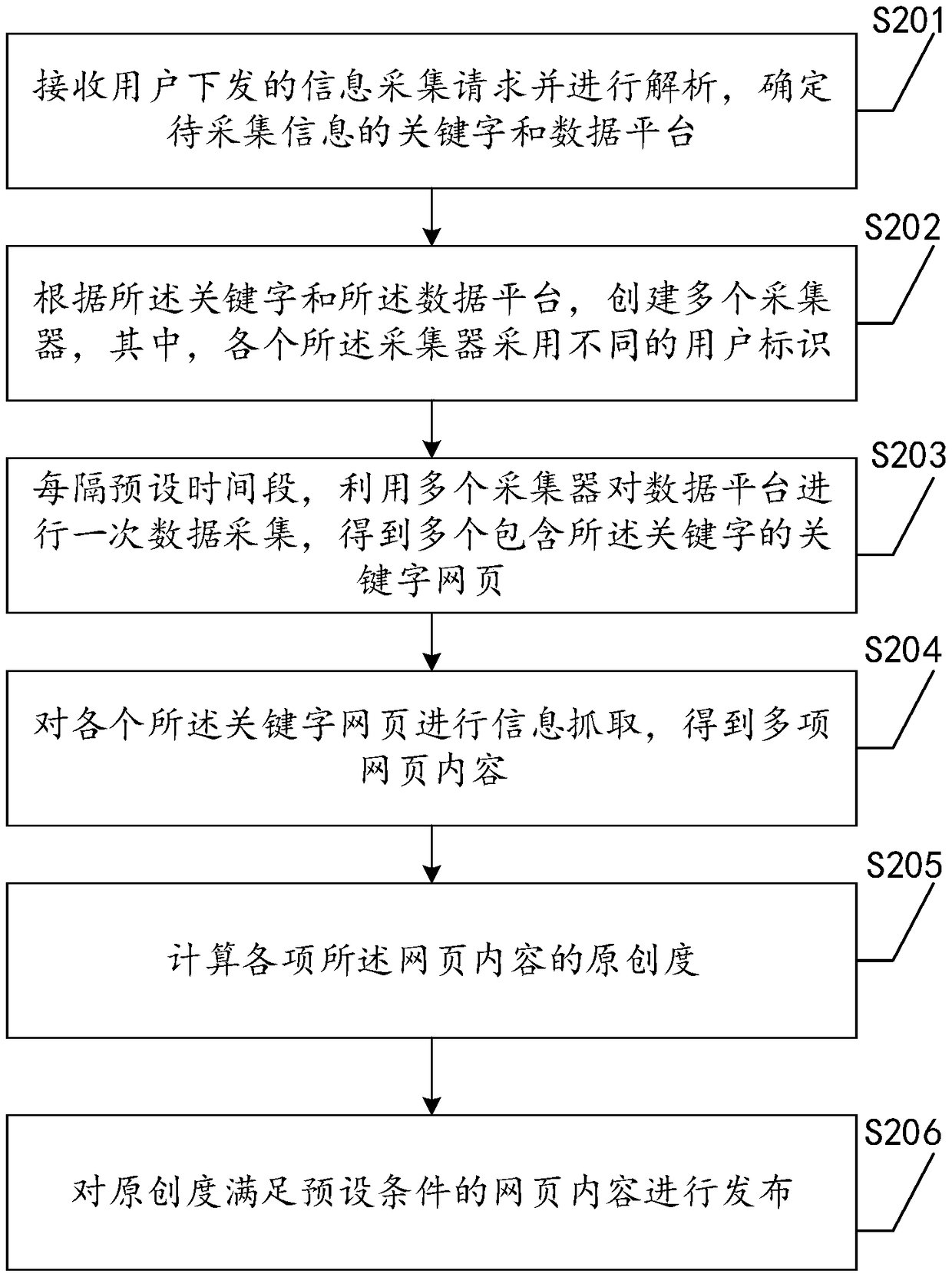

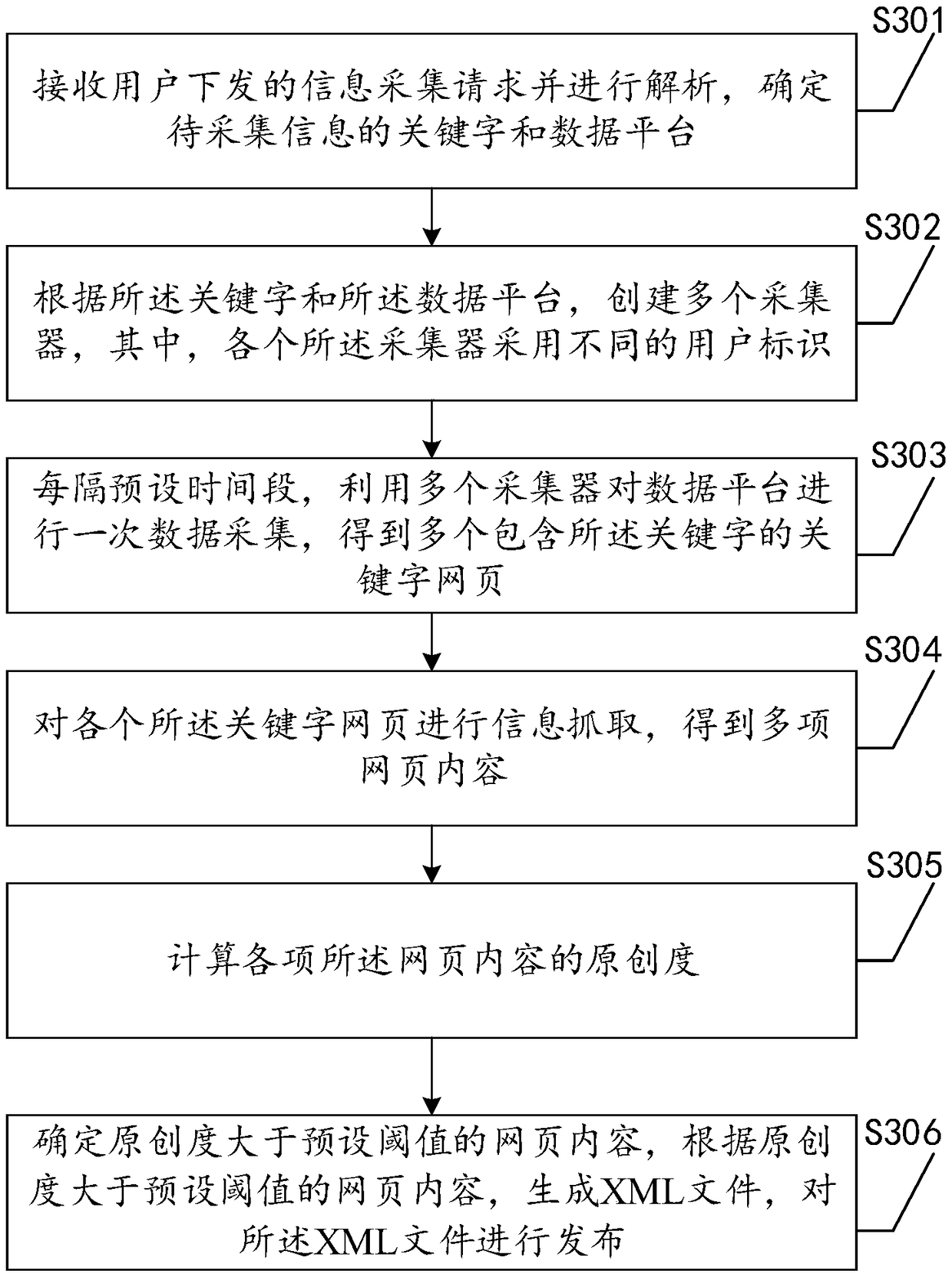

A method and system for collecting and publishing network information

InactiveCN109446425AImprove collection and release efficiencyRealize automatic collectionDigital data information retrievalSpecial data processing applicationsData platformData acquisition

The present invention discloses a method for collecting and publishing network information, comprising receiving the information collection request sent by the user and analyzing the information, determining the keywords and data platform of the information to be collected, and then collecting data from the data platform to obtain a plurality of keyword webpages including keywords, and then grasping the webpage content of the keyword webpage, finally calculating the originality of each webpage content, and publishing the webpage content whose originality meets the preset conditions, so that bythis method, users only need to set keywords and data platforms and send out information collection requests, subsequently, the information including the keyword on the data platform can be automatically collected, and the information whose originality satisfies the preset conditions can be screened out for publication, thus avoiding the process of manual collection, screening and publication, saving the consumption of manpower and time, and greatly improving the efficiency of information collection and publication. In addition, the invention also provides a system for collecting and publishing the network information, the function of which corresponds to the function of the method.

Owner:郑州市景安网络科技股份有限公司

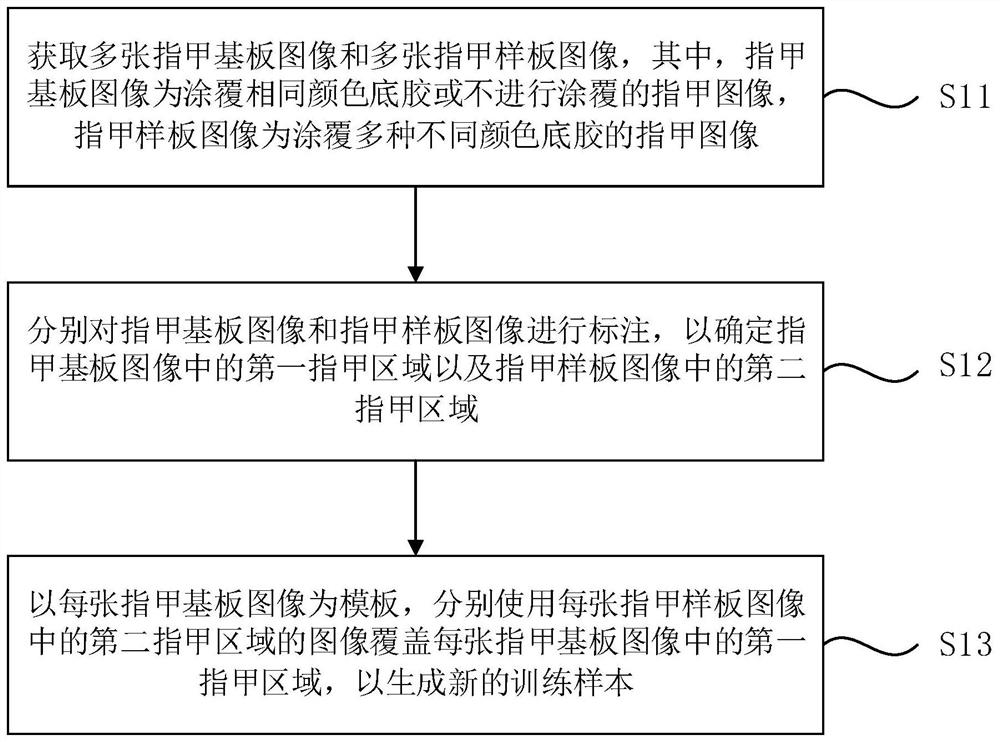

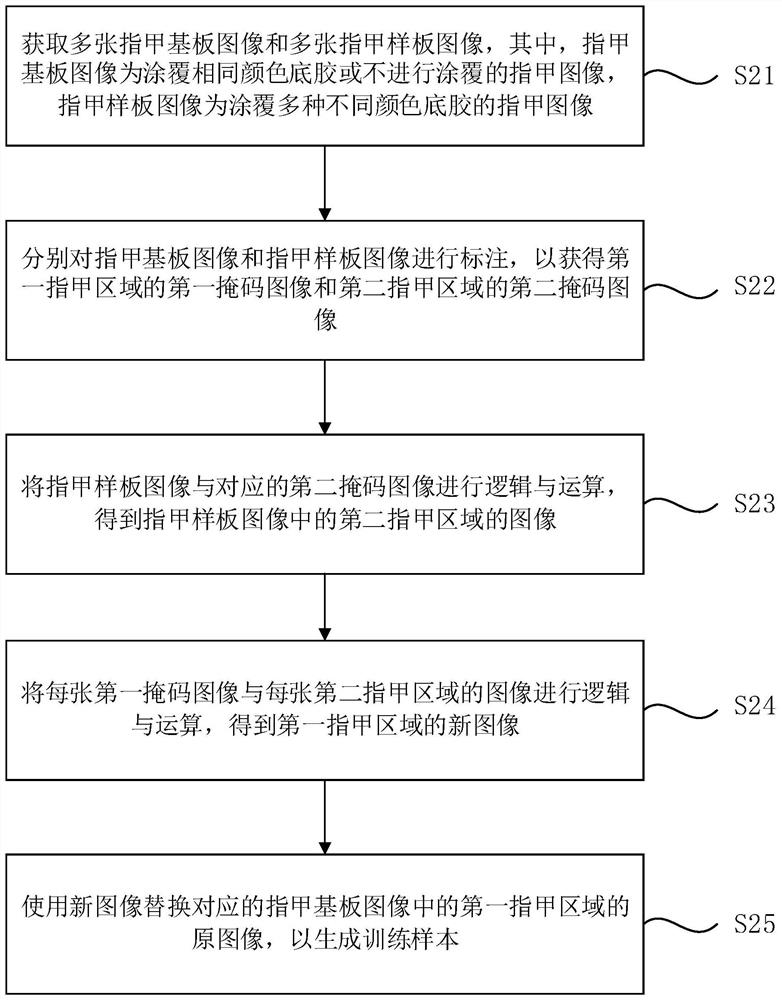

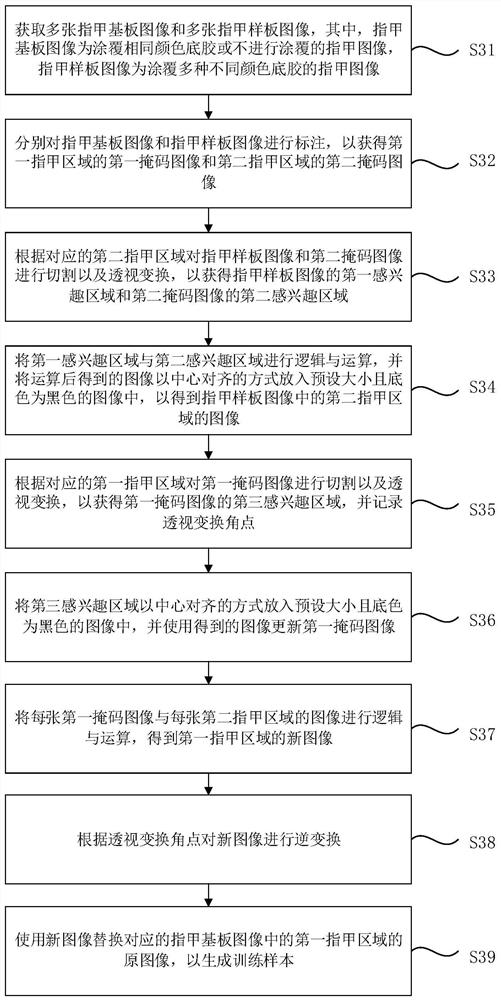

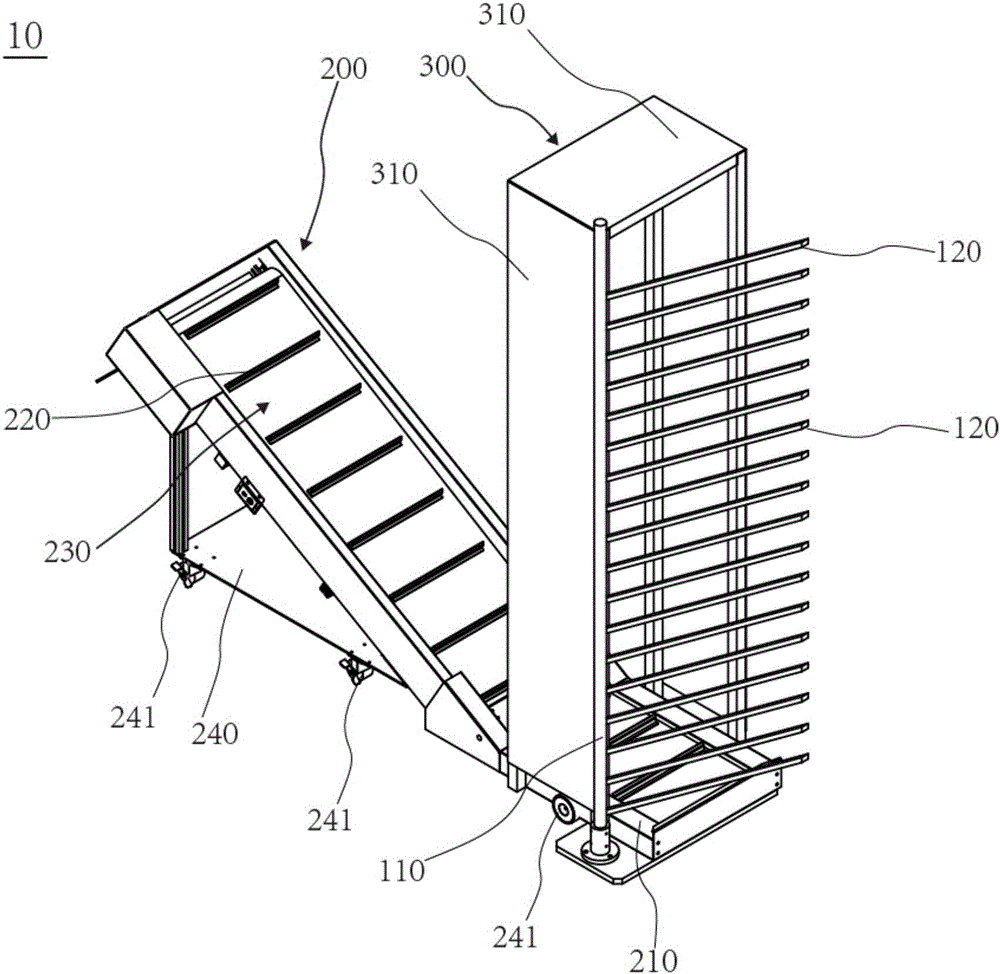

Method and device for generating training samples in nail semantic segmentation, equipment and medium

InactiveCN112861854AGet quicklyMake it easier to getCharacter and pattern recognitionComputer visionEngineering

Owner:SHENZHEN DANYA TECH CO LTD

Preparation process of diamond grinding wheel

InactiveCN107457720AImprove bindingGuaranteed immersionAbrasion apparatusGrinding devicesMixed materialsThermal treatment

The invention relates to a preparation process of a diamond grinding wheel. The preparation process comprises the following steps: preparing titanium dioxide gel, and cleaning diamond granules; putting cleaned diamond granules on a screen net inside a device chamber; pumping the titanium dioxide gel into the device chamber, sucking out the titanium dioxide gel inside the device chamber, collecting diamond granules through the screen net, drying, cooling, performing thermal treatment so as to obtain a diamond grinding material, conveying the diamond grinding material to a ball mill through a rotating shaft, performing mixing ball milling with nickel-chromium alloy powder, silicon carbide powder and sodium bicarbonate powder, screening so as to obtain a mixed material, further performing mold pressing molding on the mixed material in a mold, and sintering, thereby obtaining the diamond grinding wheel. According to the preparation process, the diamond granules are placed on the screen net, then the titanium dioxide gel can be pumped into the device chamber, the screen net is submerged by the gel, the diamond granules are soaked in the gel, the gel inside the device chamber is pumped out, diamond granules with the gel can be conveniently collected through the screen net, and then the production efficiency is improved.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

Automatic doffing system

The invention discloses an automatic doffing system which comprises a doffing device and a creel, wherein the doffing device is provided with a doffing rod and a doffing stop lever; one end of the doffing stop lever is connected with the doffing rod; the doffing device is placed on the edge of the creel; the doffing stop lever is parallel to a yarn insertion rod on a yarn fixing rod on the creel; and the end part of the doffing stop lever faces the creel. When the yarn fixing rod rotates to the doffing stop lever, the doffing stop lever and the yarn insertion rod are in staggered intersection; and the space between the doffing stop lever and the yarn insertion rod is less than the maximum outer diameter of an upper bobbin of the yarn insertion rod. Through the automatic doffing system, the labor intensity of workers is reduced, the labor force is saved, and the doffing efficiency is greatly improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

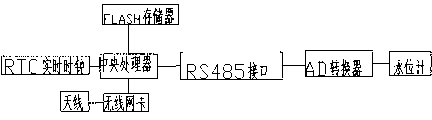

Terminal for water level detecting

InactiveCN103344303AFree from pollutionDoes not damage the structureMachines/enginesLevel indicatorsReal-time clockRemote control

The invention discloses a terminal for water level detecting. The terminal comprises a central processor, an RS485 interface, an AD converter, an ultrasonic water level gauge, a FLASH storage and an RCT real-time clock. The RS485 interface, the FLASH storage and the RCT real-time clock are all connected with the central processor. The AD converter is connected with the RS485 interface. The ultrasonic water level gauge is connected with the AD converter. According to the principle, the terminal cannot be polluted by a water body, detecting results are accurate, and remote control can be achieved.

Owner:CHENGDU HANKANG INFORMATION IND

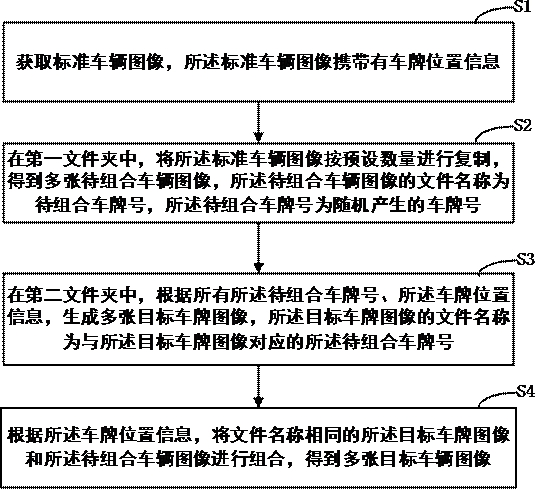

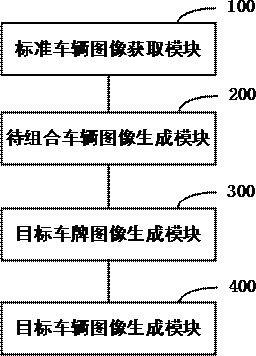

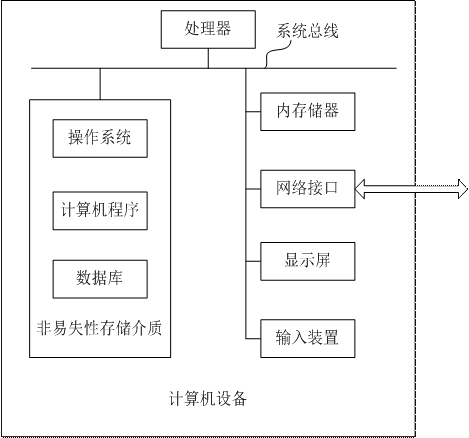

Paired license plate image and vehicle image generation method and device, medium and equipment

ActiveCN111784569AQuick buildAvoid manual collectionImage enhancementImage analysisPattern recognitionEngineering

The application relates to the technical field of artificial intelligence, and discloses a paired license plate image and vehicle image generation method and device, a medium and equipment. The methodcomprises the steps: obtaining a standard vehicle image which carries license plate position information; in a first folder, copying the standard vehicle image according to a preset number to obtaina plurality of to-be-combined vehicle images, the file names of the to-be-combined vehicle images being to-be-combined license plate numbers, and the to-be-combined license plate numbers being randomly generated license plate numbers; in a second folder, generating multiple target license plate images according to the to-be-combined license plate numbers and the license plate position information,the file name of each target license plate image being the to-be-combined license plate number corresponding to the target license plate image; and according to the license plate position information, combining the target license plate image and the to-be-combined vehicle images with the same file name to obtain a target vehicle image. Therefore, a large number of paired license plate images andvehicle images can be quickly generated, manual image collection is avoided, and the workload is reduced.

Owner:PINGAN INT SMART CITY TECH CO LTD

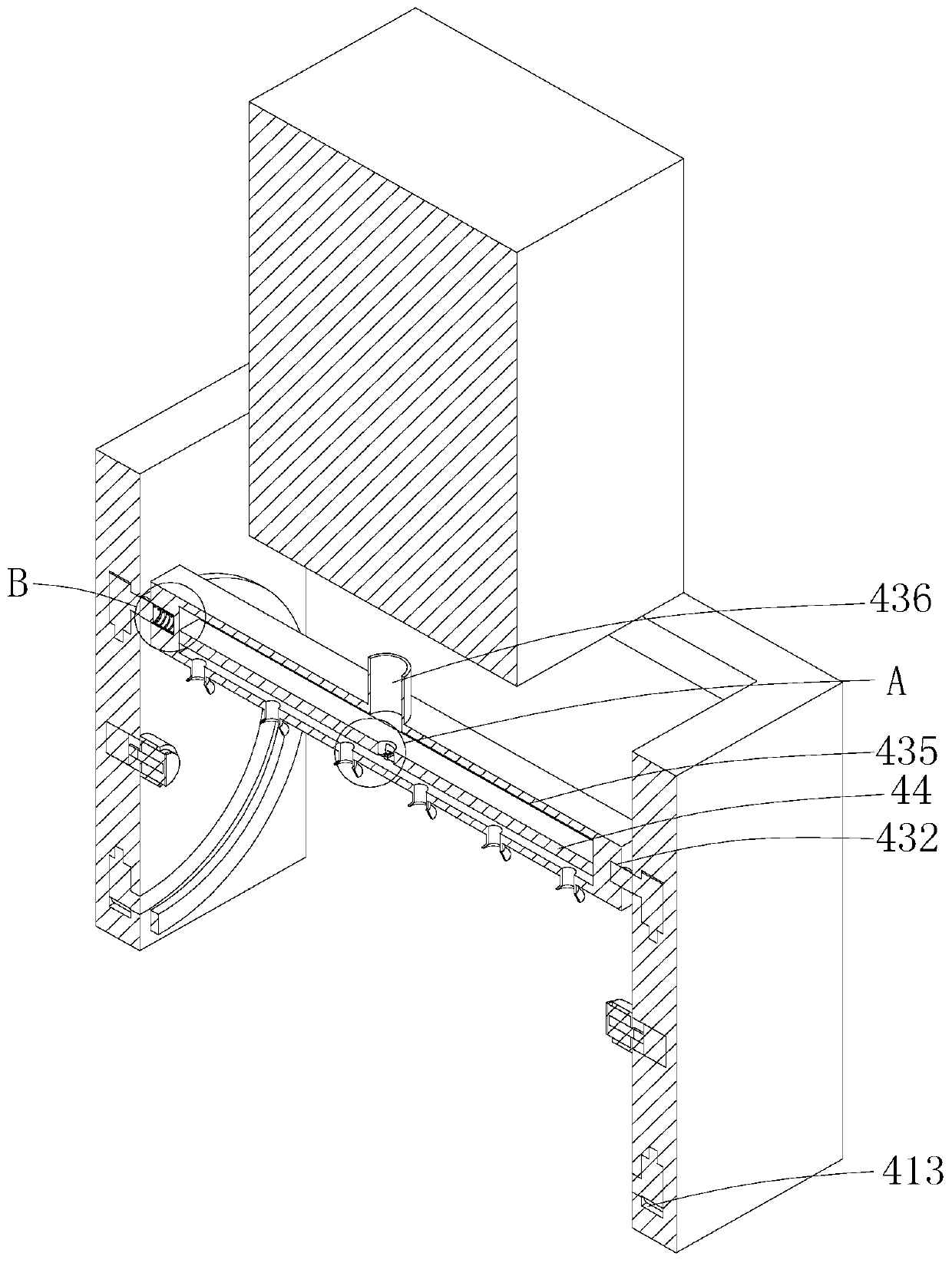

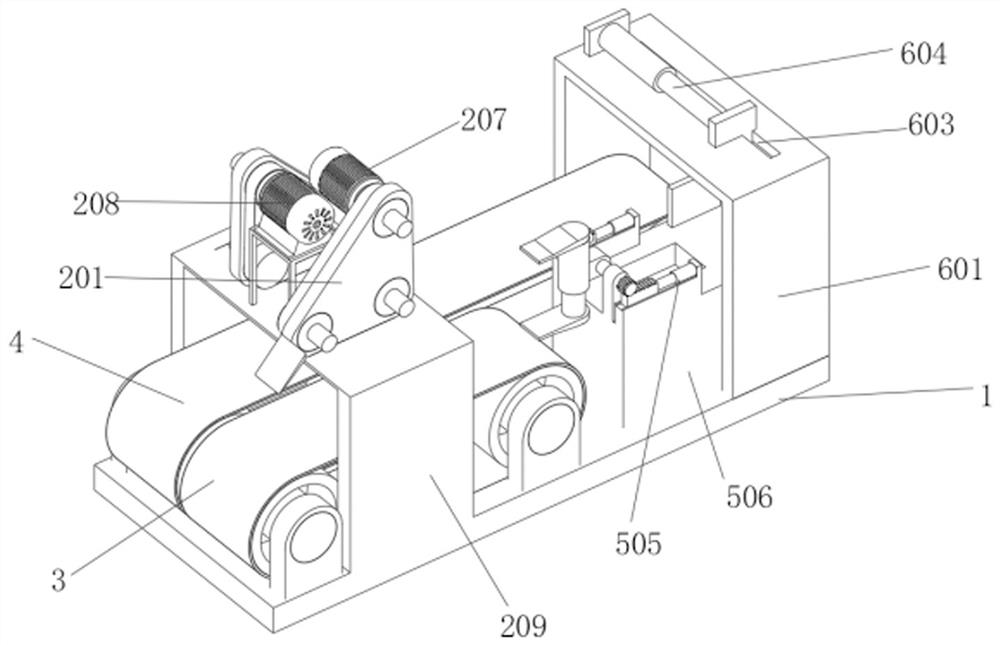

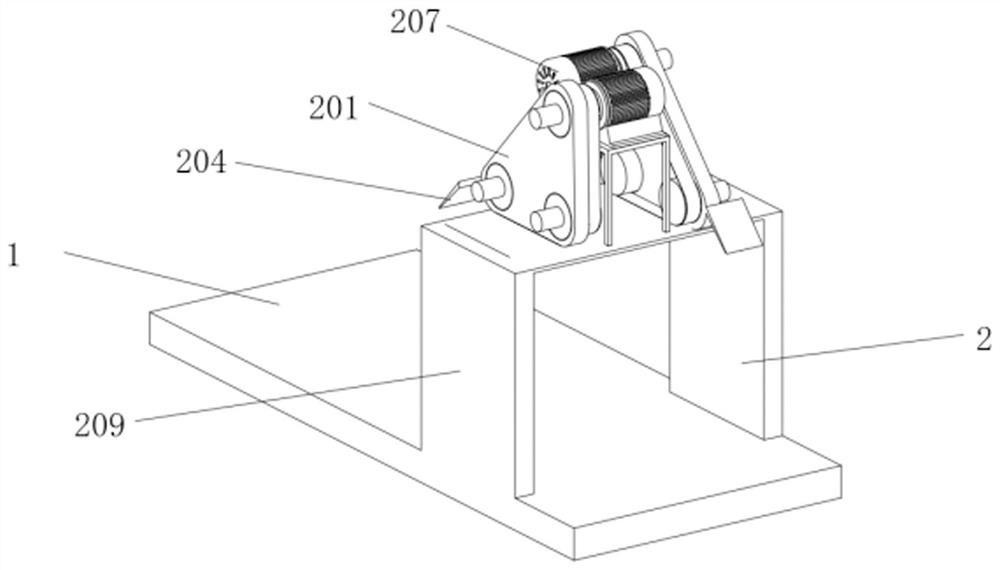

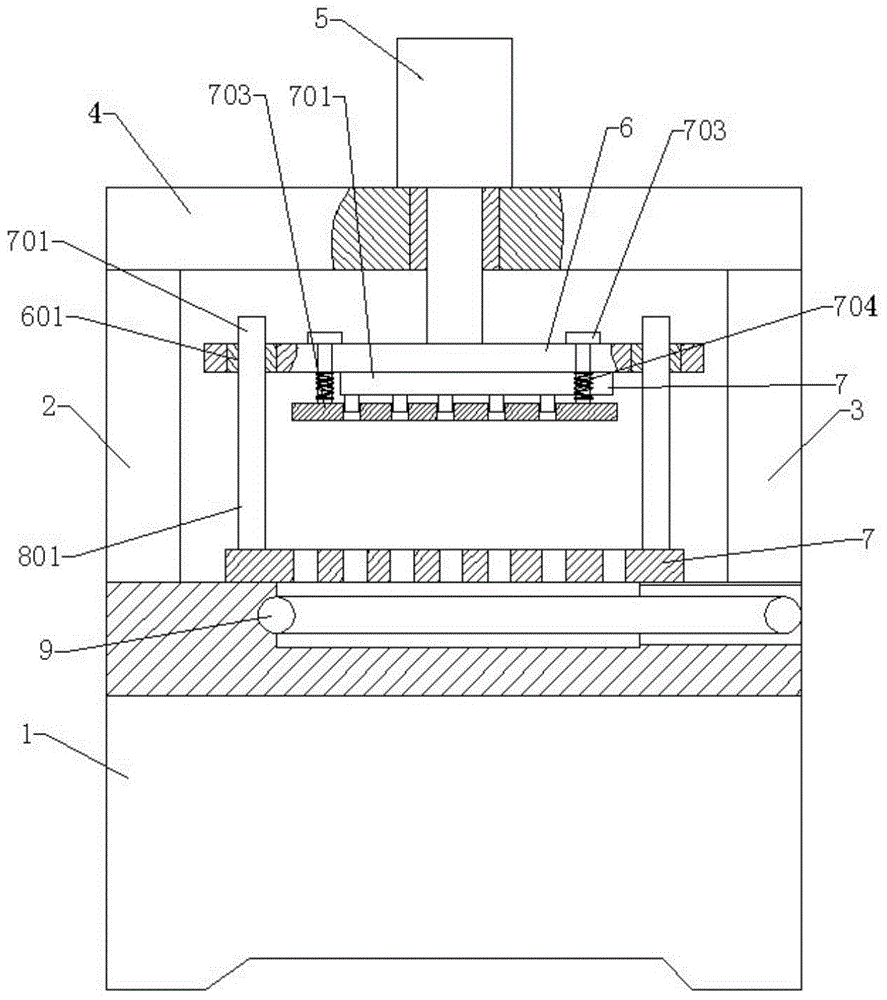

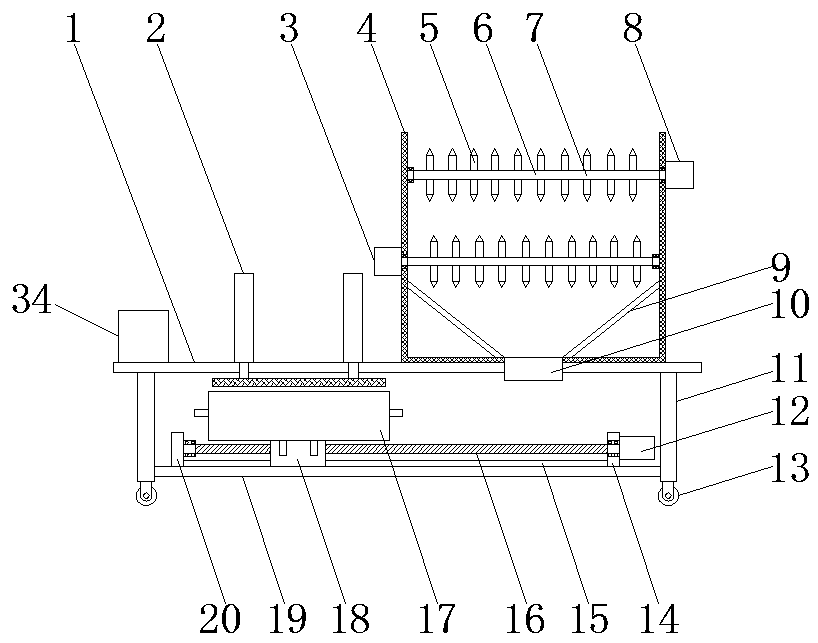

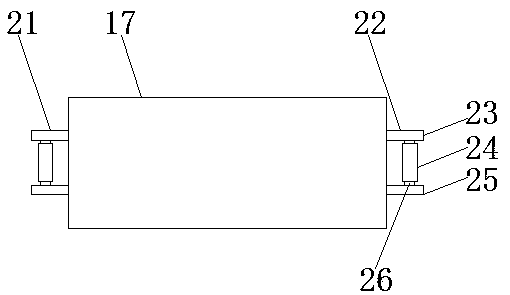

IC chip shearing equipment with floating device

InactiveCN104608193AIncrease productivityAvoid manual collectionMetal working apparatusHydraulic cylinderEmbedded system

The invention discloses IC chip shearing equipment with a floating device. The IC chip shearing equipment with the floating device comprises an engine base which comprises a left supporting seat, a right supporting seat, a roof, a hydraulic cylinder, an upper die plate, an upper floating shearing die, a lower shearing die and a conveyor; compared with the prior art, resin which contains the IC chip is put in the lower shearing die, the upper floating shearing die which is pushed to go down through hydraulic pressure and the lower shearing die together shear the resin which contains the IC chip into a single piece, the single piece falls on the top of the conveyor, and the single piece of the IC chip is conveyed out of the equipment through the conveyor to conduct tidying up and packaging manually. Therefore, the production efficiency is improved, the manual collection is avoided, and the occurrence of accidental casualty is prevented.

Owner:CHIZHOU RICHSEMI ELECTRONICS

Inner sleeve cleaning device for disinfection supply room

InactiveCN113770129AEasy to cleanReduce distanceHollow article cleaningSortingMedical equipmentReciprocating motion

The invention discloses an inner sleeve cleaning device for a disinfection supply room, and relates to the technical field of medical equipment. The inner sleeve cleaning device for the disinfection supply room comprises a containing box, one end of the containing box is fixedly connected with a second electric telescopic rod, and one end of the second electric telescopic rod is fixedly connected with a push plate; a supporting spring is fixedly connected to the interior of the push plate, an adjusting plate is fixedly connected to the top end of the supporting spring, a pressure sensor is fixedly connected to one end of the push plate, and a contact plate is fixedly connected to one end of the pressure sensor. According to the inner sleeve cleaning device for the disinfection supply room, the distance between the push plate and the inner sleeve is continuously reduced along with continuous reciprocating motion of the inner sleeve, and when the pressure change detected by a pressure sensor located in a groove in the push plate is reduced to be below the rated value, a second electric telescopic rod stops moving; and the push plate and the placement box are tightly attached to the two ends of the inner sleeve correspondingly, and then the inner sleeve can be automatically arranged.

Owner:商希芹

Crushing device for recycling farmland straw

The invention discloses a crushing device for recycling farmland straw. The device comprises an anti-skid sleeve, a first motor, a second motor, a first crushing device, a receiving tank, a bottom plate and a crushing box. The friction force between the hands of a user and the outer side of a handle is increased by arranging the anti-skid sleeve, so that the situation that the handle slides when the handle is held by the user is avoided. The first motor is used for rotating to drive a crushing blade on a crushing rotary shaft to rotate so as to crush the straw. The first crushing device is arranged, so that the aim of further crushing the straw is achieved, and the straw crushing effect is improved. The second motor rotates to drive a screw rod to rotate, so that a sliding block moves towards a first limiting plate on the screw rod, the receiving tank is further driven to move to the portion under a discharging pipe, the crushed straw falls into the receiving tank after passing throughthe discharging pipe, the crushed straw is collected, manual collection is not needed, and a large amount of manpower is saved.

Owner:荆门市手拉手农机股份有限公司

Wood chip bagging equipment for furniture factory

InactiveCN113353351AAvoid manual collectionImprove work efficiencyPackaging by pressurising/gasifyingSolid materialAgricultural engineeringMechanical engineering

The invention discloses wood chip bagging equipment for a furniture factory. According to the technical scheme, the wood chip bagging equipment for a furniture factory is characterized in that the wood chip bagging equipment comprises a bagging device used for wood chip bagging. The bagging device comprises a first bagging station and a second bagging station, and a first driving device drives the bagging device to rotate, so that the first bagging station or the second bagging station is connected with a wood chip collecting device. The wood chip bagging equipment has the following beneficial effects that the first bagging station on the bagging device is connected with the wood chip collecting device in a clamped mode through the first driving device, wood chips are collected through the wood chip collecting device, and after the first bagging station is filled with the wood chips, the first driving device drives the bagging device to rotate; and the second bagging station and the wood chip collecting device are connected in a clamped mode, the first bagging station and the second bagging station alternately work, continuous collection is achieved, the working efficiency is improved, manual wood chip collection is avoided, and the labor intensity is reduced.

Owner:WENZHOU POLYTECHNIC

System and method for carrying out high-availability exercise on network devices

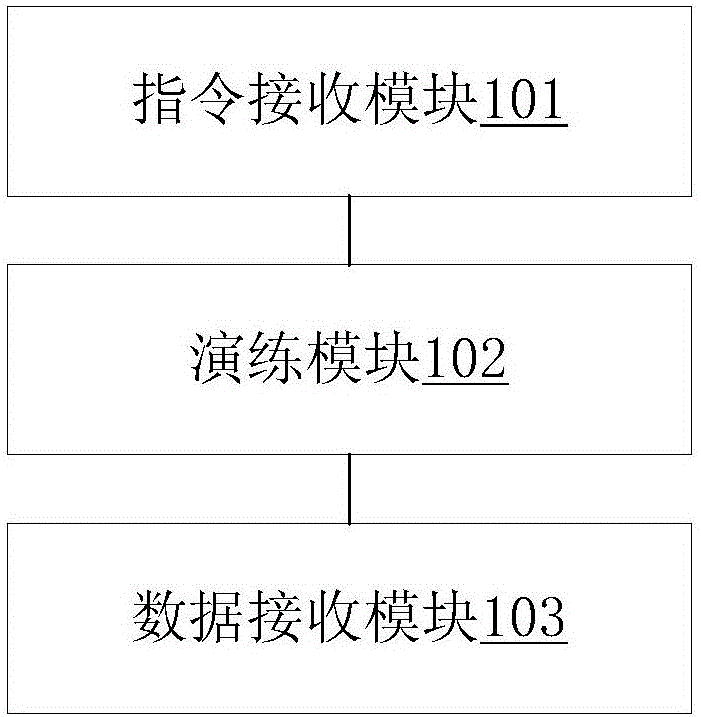

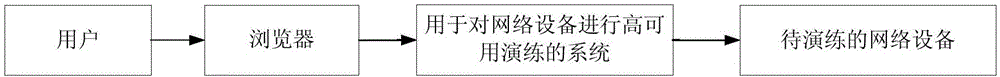

ActiveCN106789260AEfficiency of High Availability ExercisesImprove the efficiency of available drillsData switching networksUser inputHigh availability

The embodiment of the invention provides a system and method for carrying out high-availability exercise on network devices. The system comprises an instruction receiving module which is used for receiving an exercise instruction input by a user, wherein the exercise instruction comprises identification information of to-be-exercised network devices and exercise actions; an exercise module which is used for calling preset degree segments to communicate with the to-be-exercised network devices according to the identification information and the exercise actions in the exercise instruction, carrying out high-availability exercise of the exercise actions on the to-be-exercised network devices, wherein degree segments for finishing different exercise actions of different networks are set in the system for carrying out high-availability exercise on the network devices; and a data receiving module which is used for receiving high-availability exercise result data obtained by carrying out the exercise actions on the to-be-exercised network devices. According to the scheme, the efficiency of carrying out high-availability exercise on the network devices is improved, the condition of influencing transactions due to detection mistakes and omissions is reduced, and hidden dangers possibly brought to operation and maintenance are reduced.

Owner:CHINA UNIONPAY

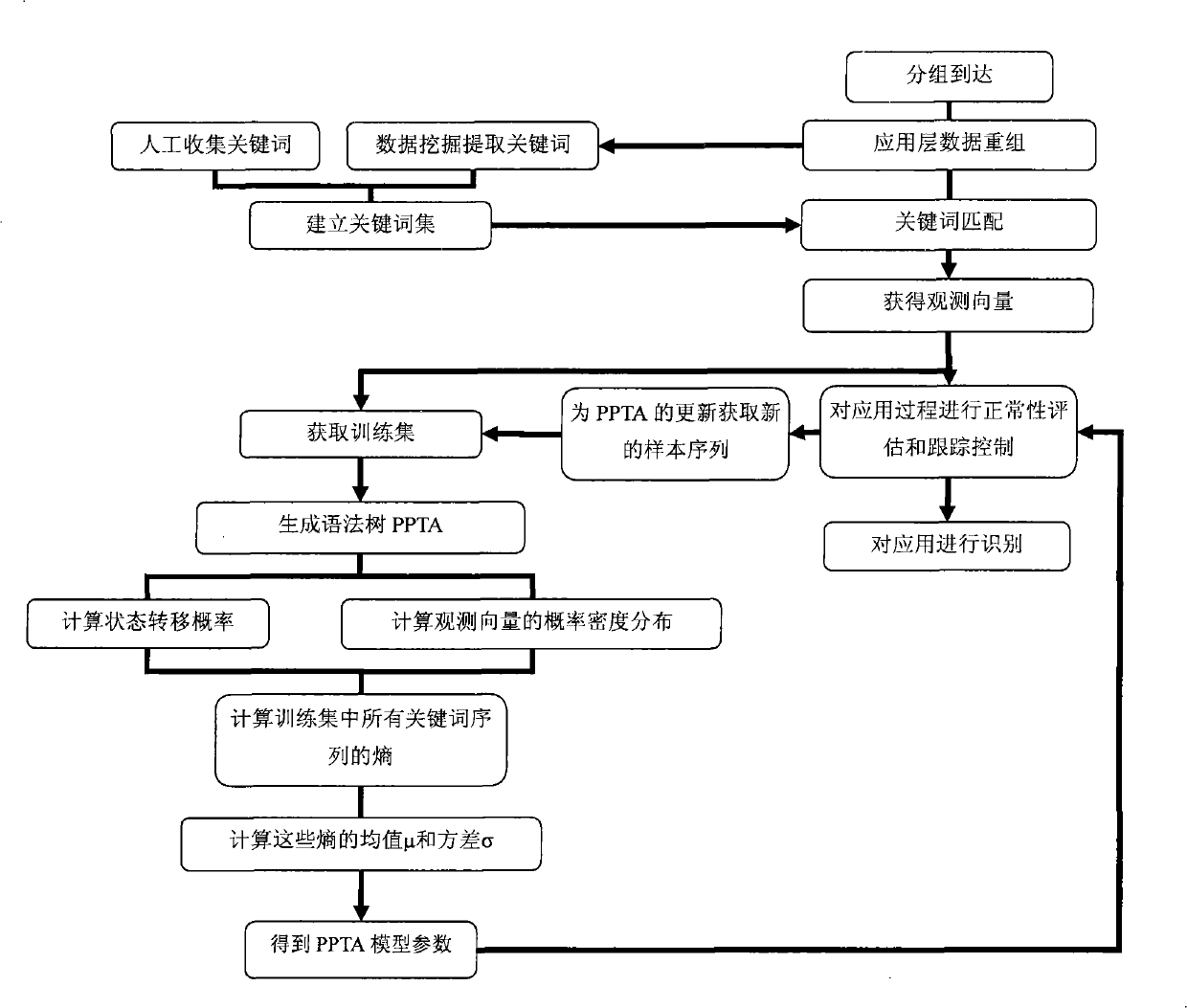

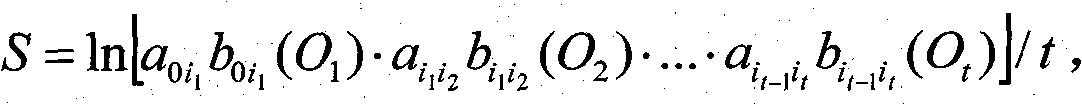

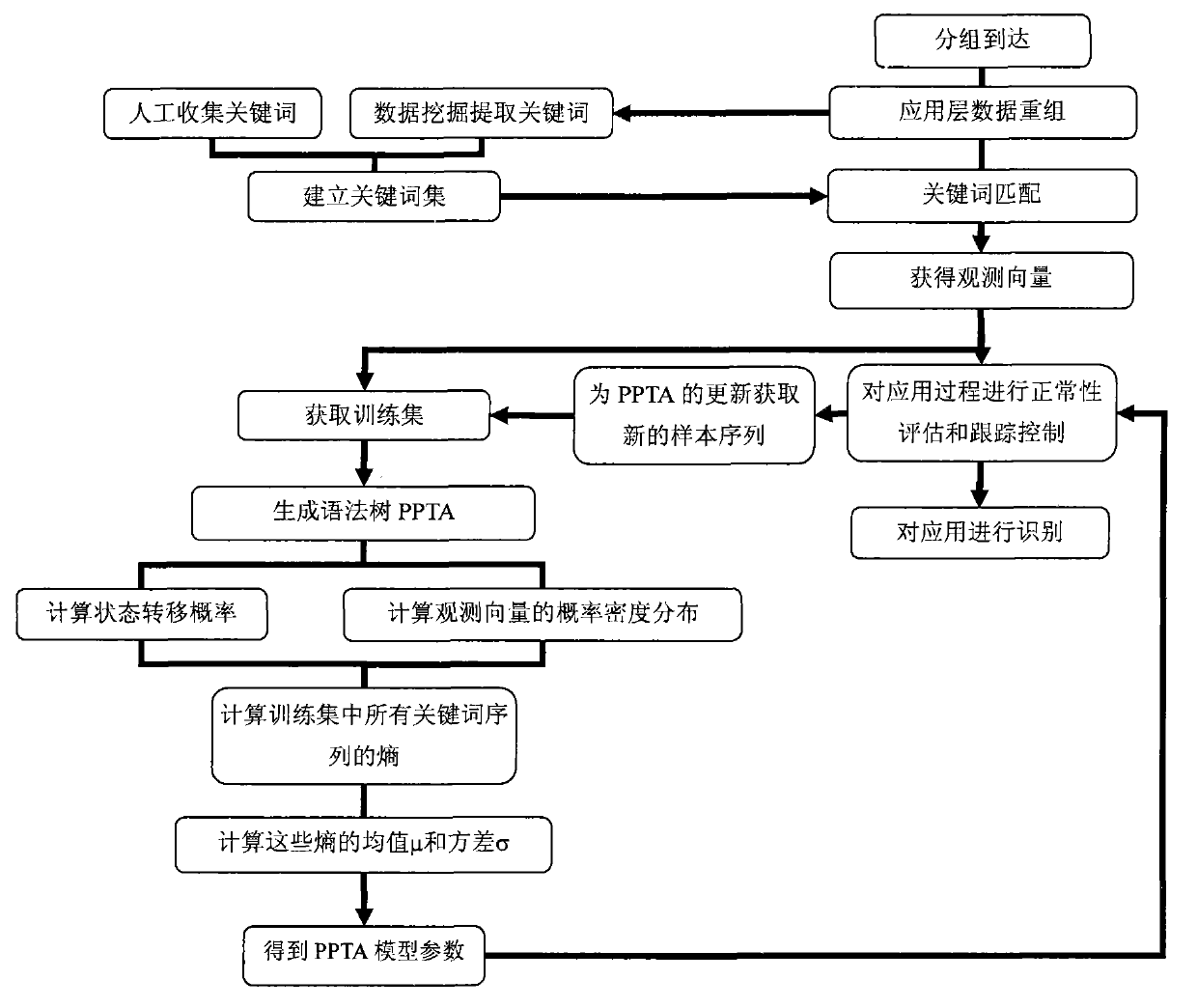

Method for recognizing and tracking application based on keyword sequence

InactiveCN101442535BAvoid manual collectionImplement trackingData switching networksSpecial data processing applicationsSyntaxProtocol Application

The invention provides an application, identification and tracking method based on a keyword sequence, which comprises: firstly, establishing a keyword set; secondly, matching keywords with data in an application layer; thirdly, performing syntax tree judgment and evaluation on a keyword sequence obtained after matching; and fourthly, tracking the keyword sequence and identifying application types. The application, identification and tracking method based on the keyword sequence does not need manually understanding and programming an application layer protocol, manually analyzing unique characteristics of application and writing out a regular expression, can realize automatic modeling, identification and tracking of known or unknown application, and further realizes flow control and security defense of fine grain of the application and the application process.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com