Method for adjusting calcination temperature of rutile type titanium dioxide and automatic control method thereof

A technology of rutile titanium dioxide and calcination temperature, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of not strictly controlling the calcination temperature, adjusting the reaction time lag, and high production cost, so as to reduce the manual workload, The effect of reducing work difficulty and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

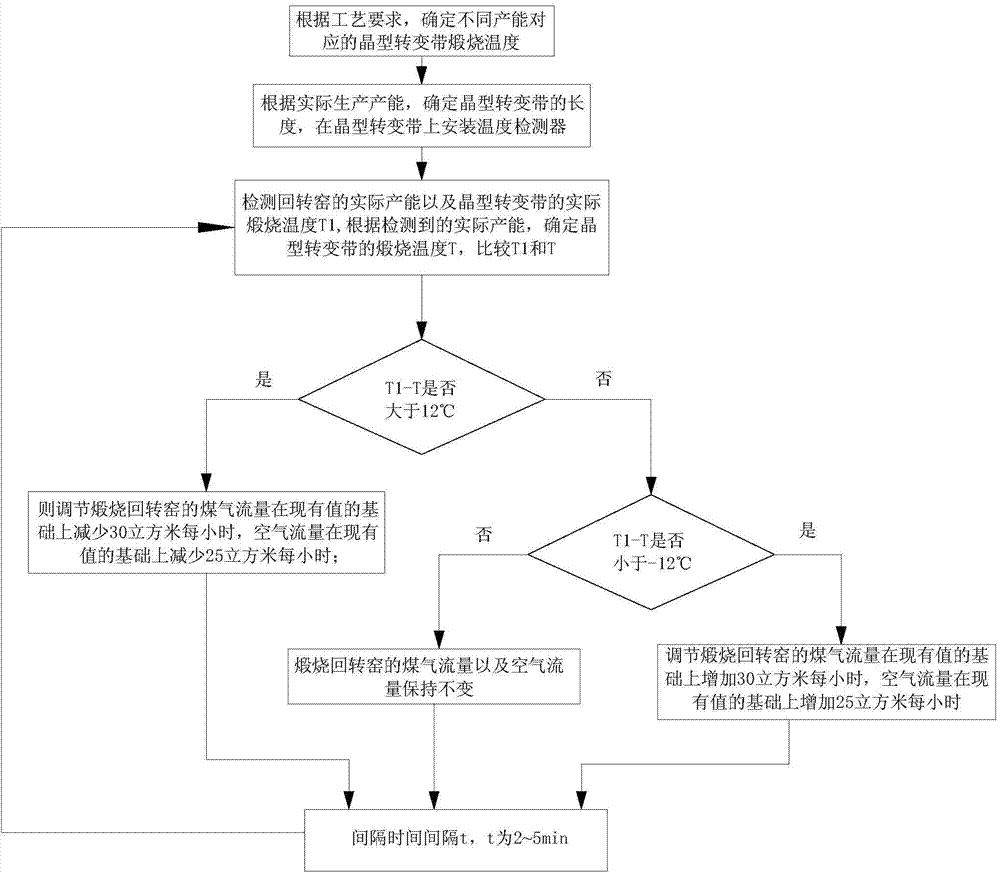

Method used

Image

Examples

Embodiment

[0060] An enterprise produces a kind of rutile titanium dioxide with a designed production capacity of 40,000 tons, a rotary kiln with a diameter of 3.6m and a length of 58m. The original process is as follows:

[0061] The implementation process is as follows:

[0062] (1) Through the adjustment of production capacity, gas flow, air flow, kiln speed, etc., it is determined that the length of the crystal transformation zone of the rotary kiln is 6.5m.

[0063] (2) Determine the relationship between production capacity and calcination temperature through industrial tests of different production capacities, and establish process control table 1, which shows the calcination temperature corresponding to part of production capacity.

[0064] Table 1 Production capacity and its corresponding calcination temperature

[0065] serial number

production capacity

temperature °C

1

60% design capacity

825

2

80% design capacity

845

3

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com