Roller flaw detection process for steel structure production

A steel structure and roller technology, applied in the direction of material magnetic variables, can solve the problems of reducing the efficiency of roller flaw detection, and achieve the effects of avoiding collection and sorting, reducing time, and improving flaw detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

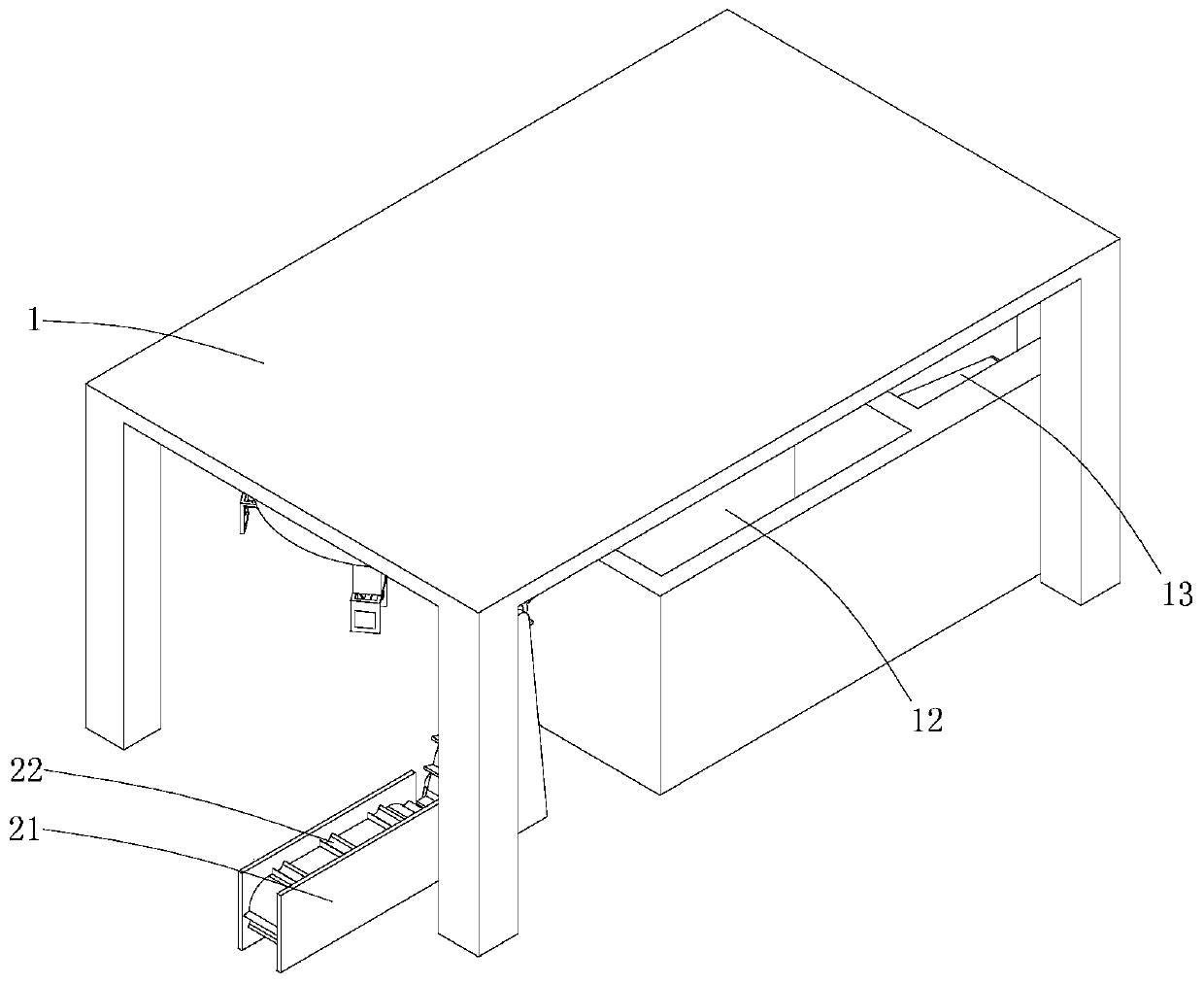

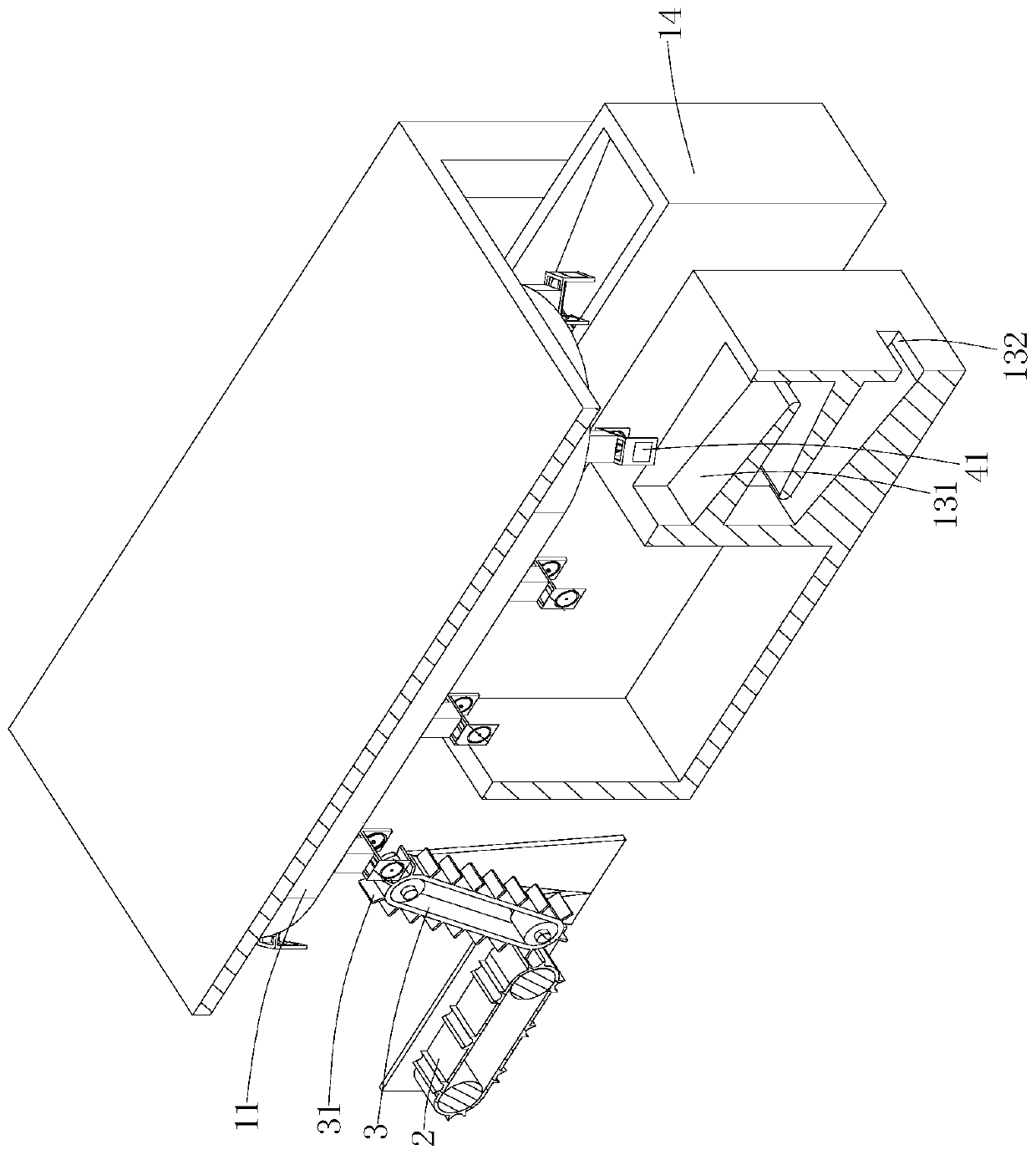

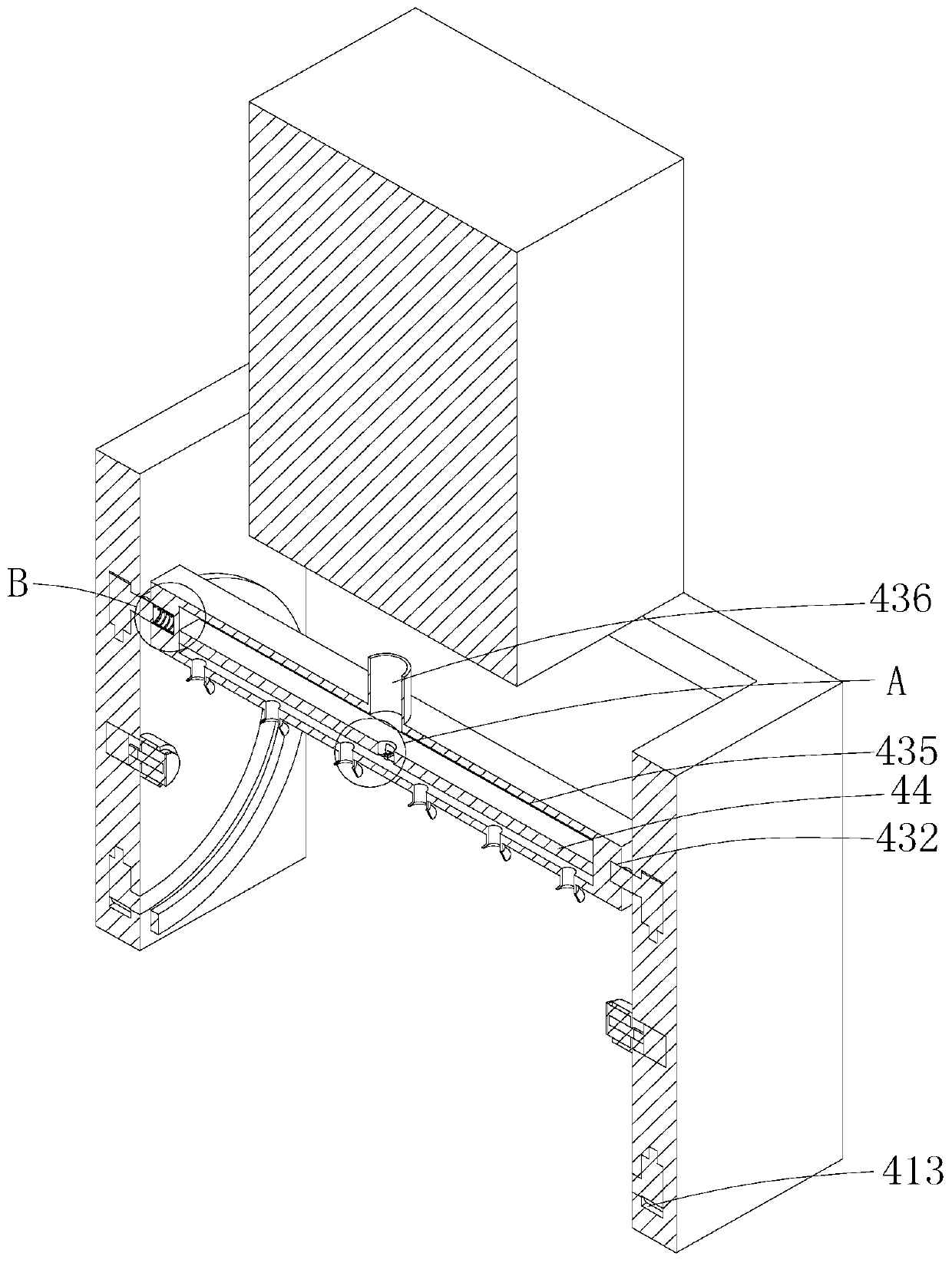

[0024] A roller flaw detection process for steel structure production, the roller flaw detection process includes: a. Pre-cleaning: remove the grease on the surface of all materials and test pieces and other things that may affect the normal distribution of magnetic particles, affect the density of magnetic powder accumulations, characteristics and clarity of impurities; b. Defect detection: use magnetic particle inspection equipment to detect defects on the roller; c. Demagnetization: use magnetic particle inspection equipment to directly demagnetize the magnetic powder; d. Post cleaning: after inspection and demagnetization, put Clean all the magnetic particles on the test piece, and thoroughly remove all blockages in the holes and cavities; the cleaning solution for cleaning the material and the test piece in the step a uses a water-based metal oil stain cleaning agent; after using the above cleaning solution, The chemical impact on the rollers can be avoided to ensure the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com