Method and device for strengthening oil-water separation and coupled desalting functions in cold low pressure separator

A cold and low-pressure separator, oil-water separation technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of increasing downstream load, ineffective removal, poor liquid-gas separation effect, etc., to improve coalescence. Performance, not easy to break and emulsification, to achieve the effect of deep desalination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

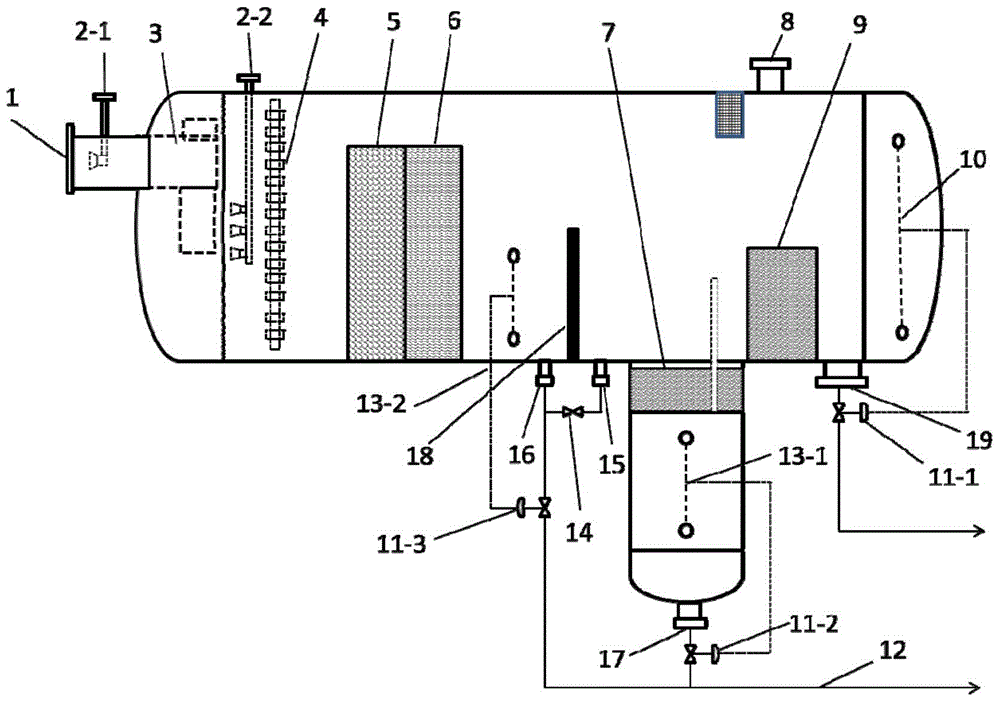

[0036] Such as figure 1 As shown, the oil-water separation and coupling desalination functional device in the enhanced cold and low-pressure separator includes a shell, an oil-water-gas inlet 1 arranged on the shell, a water injection port 2-1 connected to the oil-water-gas inlet 1 and a T-shaped liquid Gas separator 3 (or cyclone degasser), secondary water injector (including water injection port 2-2), rectifier distributor 4, oil-water coarse-graining module 5, CPI quick separation module 6 arranged in sequence inside the shell , (oil-water) interface controller 13-1, 13-2, partition 18, liquid level controller 10 and oil phase outlet 19 at the tail of the housing; the depth degreasing module 7 placed at the bottom of the housing, the The top has a gas phase outlet 8; the bottom of the shell is also provided with a water phase outlet 17. The oil phase outlet 10, the water phase outlet 17, and the water phase outlet 16 are respectively provided with regulating valves 11-1, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com