A kind of zinc alloy smelting equipment and its production process

A technology of smelting equipment and production process, which is applied in the field of zinc alloy smelting equipment and its production process, and can solve problems such as difficult addition and complex smelting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

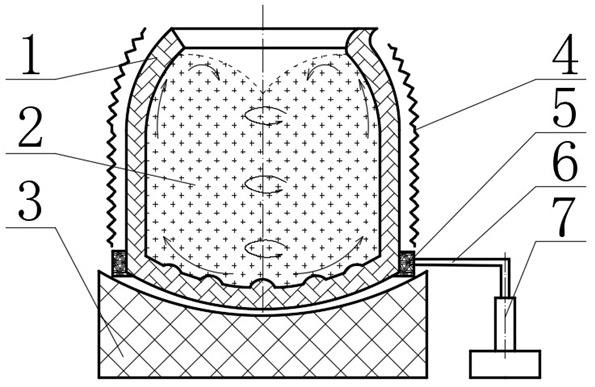

[0038] a kind of like figure 1 , figure 2 The zinc alloy smelting equipment shown is composed of three systems during use, which are heating smelting system, electromagnetic induction stirring system and hydraulic vibration system;

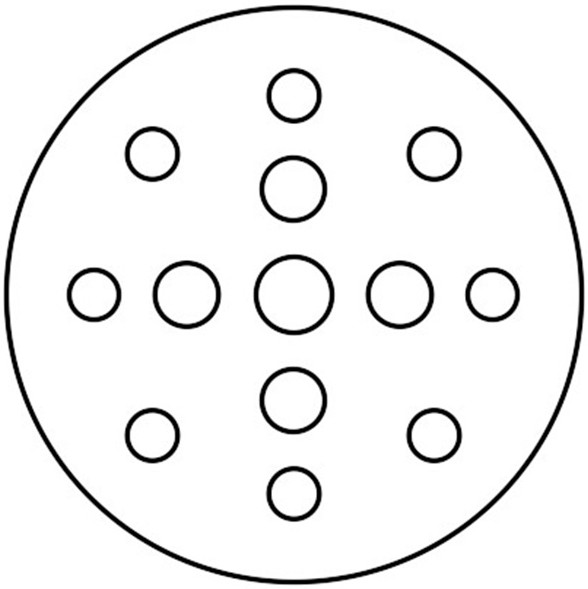

[0039] The heating and smelting system is composed of a heating device 4 and a graphite crucible 1; the graphite crucible 1 is specifically a pot-like structure sintered with crystalline natural graphite, clay and silicon carbide skeleton clinker as raw materials, specifically: the height of the bottom accounts for the total The height is 1 / 8-1 / 6, showing a concave arc-shaped bottom with a total radian of π / 12-π / 10. The concave arc-shaped bottom is based on the center of the arc-shaped bottom, and there are 1 large, 4 There are 13 medium-sized and 8 small-sized arc-shaped protrusions in total, 1 large-sized arc-shaped protrusion with a diameter of 5cm-8cm, the height of the central protrusion is 15mm-20mm, and the center of the circle is set at ...

Embodiment 2

[0044] The whole is consistent with Example 1, the difference is:

[0045] The stirring medium is 1J85C permalloy particles with a particle size of 3mm-5mm.

[0046] Compared with Example 1, it is mainly because the purchase cost of the stirring medium has increased, but the technical effects are basically the same, and the difference has no statistical significance.

Embodiment 3

[0048] The whole is consistent with Example 1, the difference is:

[0049] The hydraulic vibration system controls the graphite crucible 1 to reciprocate up and down through the locking device 5, and the height range of the reciprocating up and down is 3cm-5cm.

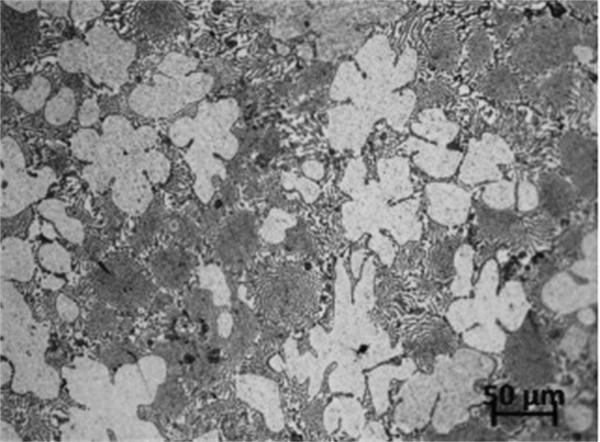

[0050] According to the ingot produced in this embodiment, its grain size is reduced by 1-2 grades compared with Example 1. Taking ZnAl4 as an example, its density drops from 6.72g / cm3-6.74g / cm3 in Example 1 to 6.68g / cm3. cm3-6.70g / cm3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com