Hood-shaped circulation vacuum degassing device and method of use thereof

A vacuum degassing device and vacuum degassing technology are applied in the field of vacuum treatment of molten ferrous alloys, which can solve the problems of the vacuum degassing device affecting the vacuum degree, restricting the RH vacuum degassing device, and the large circulating air volume of the dip tube, etc. Good metallurgical effect, lengthening the argon rising path, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

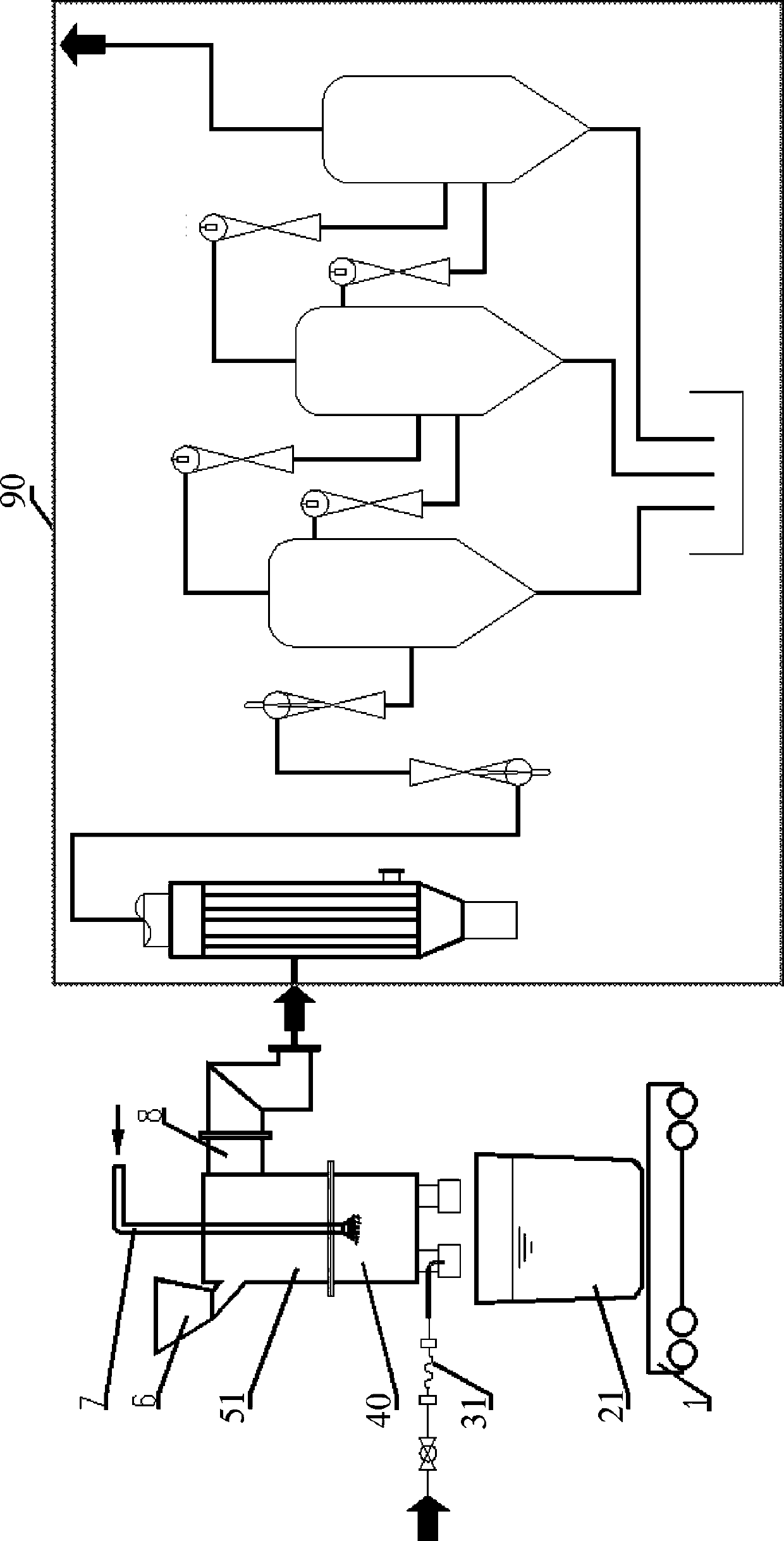

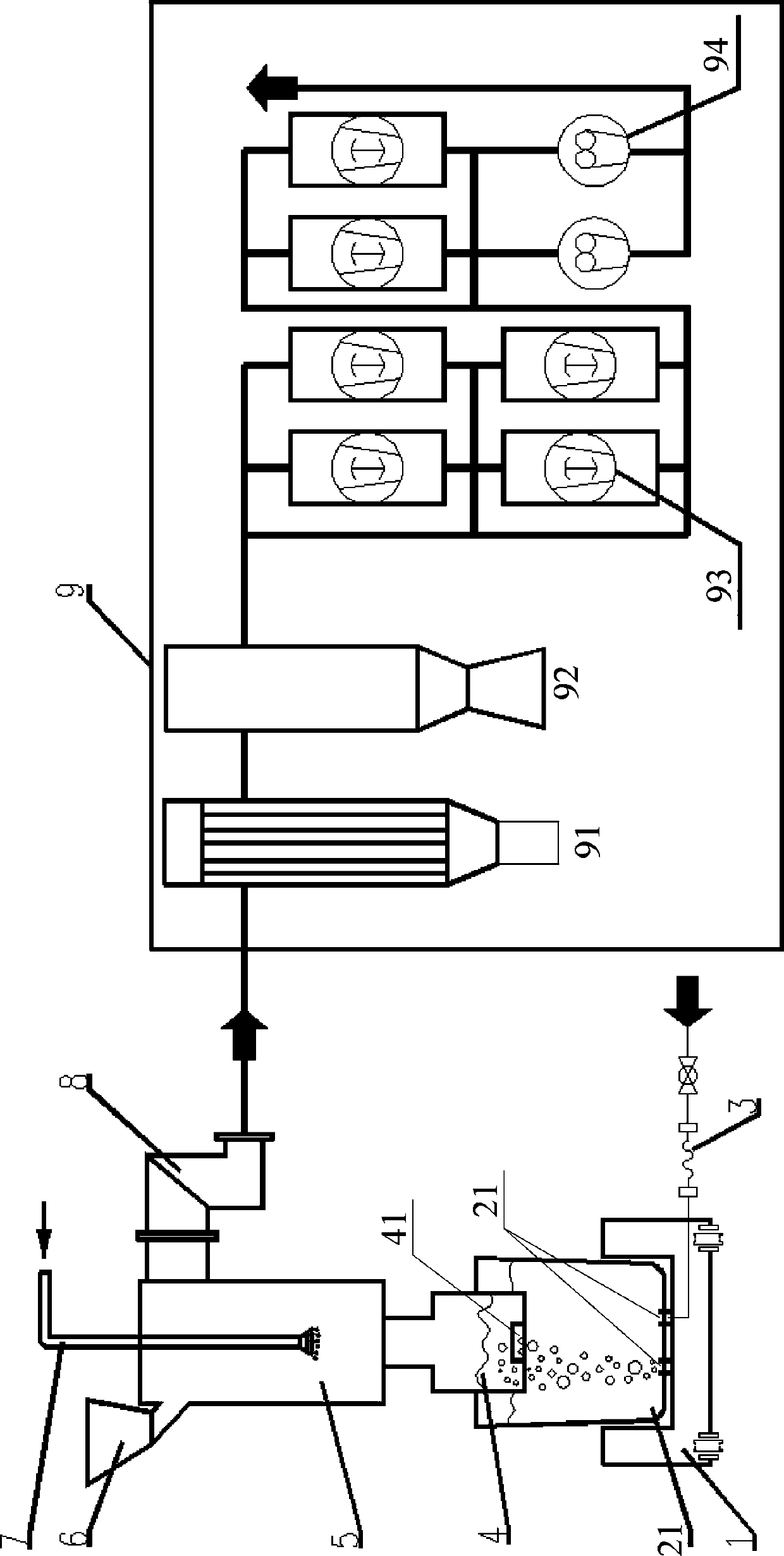

[0023] A cover-shaped circulating vacuum degassing device, comprising a ladle trolley 1, a ladle 2, a bottom blowing argon gas valve station 3, an insertion cover 4, a vacuum degassing tank 5, an alloy material feeding device 6, a top blowing oxygen lance 7, a heating Elbow 8 and dry mechanical vacuum pump exhaust 9, such as figure 2 As shown, the specific structure is:

[0024] The ladle 2 is set on the ladle trolley 1, and the molten steel is contained in the ladle 2;

[0025] Bottom-blowing argon valve station 3 is connected to vent hole 21 at the bottom of ladle 2 through a gas delivery pipe; vacuum degassing tank 5 is set directly above the opening of ladle 2, and the bottom of vacuum degassing tank 5 is welded and inserted into the top of cover 4 , the bottom of the insertion cover 4 is submerged below the molten steel level of the ladle 2; the two sides of the top of the vacuum degassing tank 5 are respectively connected to the discharge port of the alloy feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com