Online degassing method and device for pipeline fluid

A degassing device and fluid technology, used in liquid degassing, separation methods, chemical instruments and methods, etc., can solve the problems of rapid online degassing of pipeline fluids, large equipment volume and complex structure, etc. Small size, fast degassing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

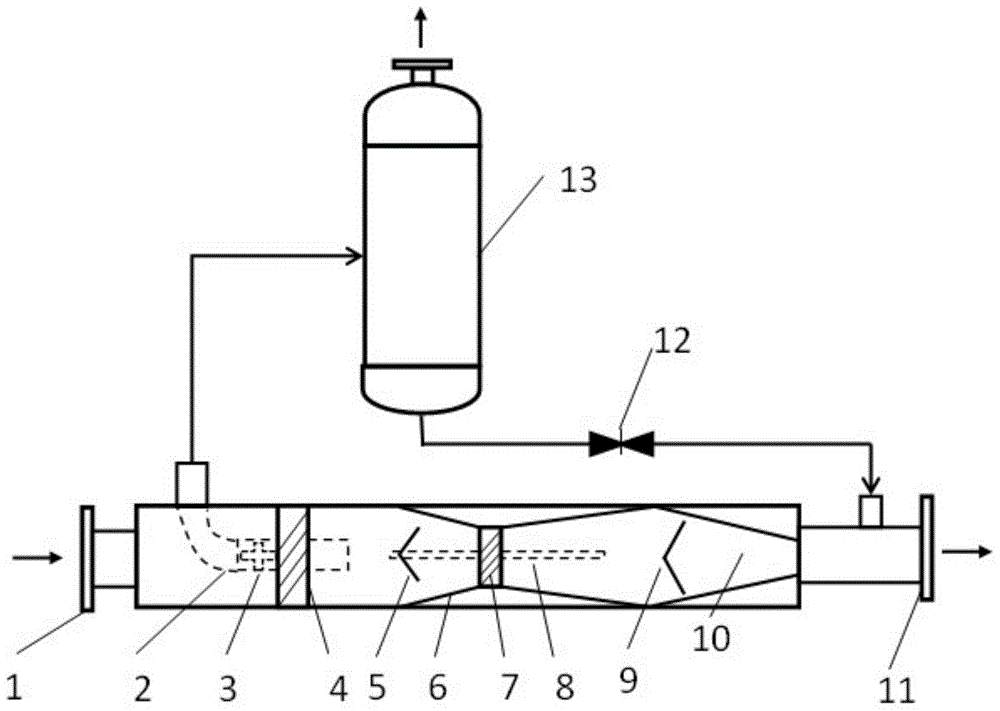

[0041] Such as figure 1 As shown, the online degassing device of this embodiment includes an inlet connection flange 1, a primary air guide pipe 2, a vortex breaker 3, a primary spiral deflector 4, a primary umbrella-shaped top hat 5, and a Venturi injector 6 , Secondary spiral deflector 7, secondary air guide pipe 8, secondary umbrella-shaped top cap 9, shell 10, outlet connecting flange 11, one-way diversion valve 12, liquid separator 13.

[0042] Wherein, the inlet flange 1 is arranged at one end of the outer shell 10, and the outlet flange 11 is arranged at the other outer end of the outer shell 10;

[0043]The primary spiral deflector 4, the primary air guide pipe 2, the primary umbrella-shaped top cap 5, the Venturi injector 6, the upper separation chamber (between the primary spiral deflector 4 and the secondary spiral deflector 7 Cavity), the secondary air duct 8, and the secondary umbrella-shaped top cap 9 are placed inside the shell 10;

[0044] The primary air gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com