Electric pum

A technology of electric pumps and pump chambers, which is applied in the direction of pumps, pump devices, pump components, etc., and can solve the problem of difficult fluids being sucked into the pump chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

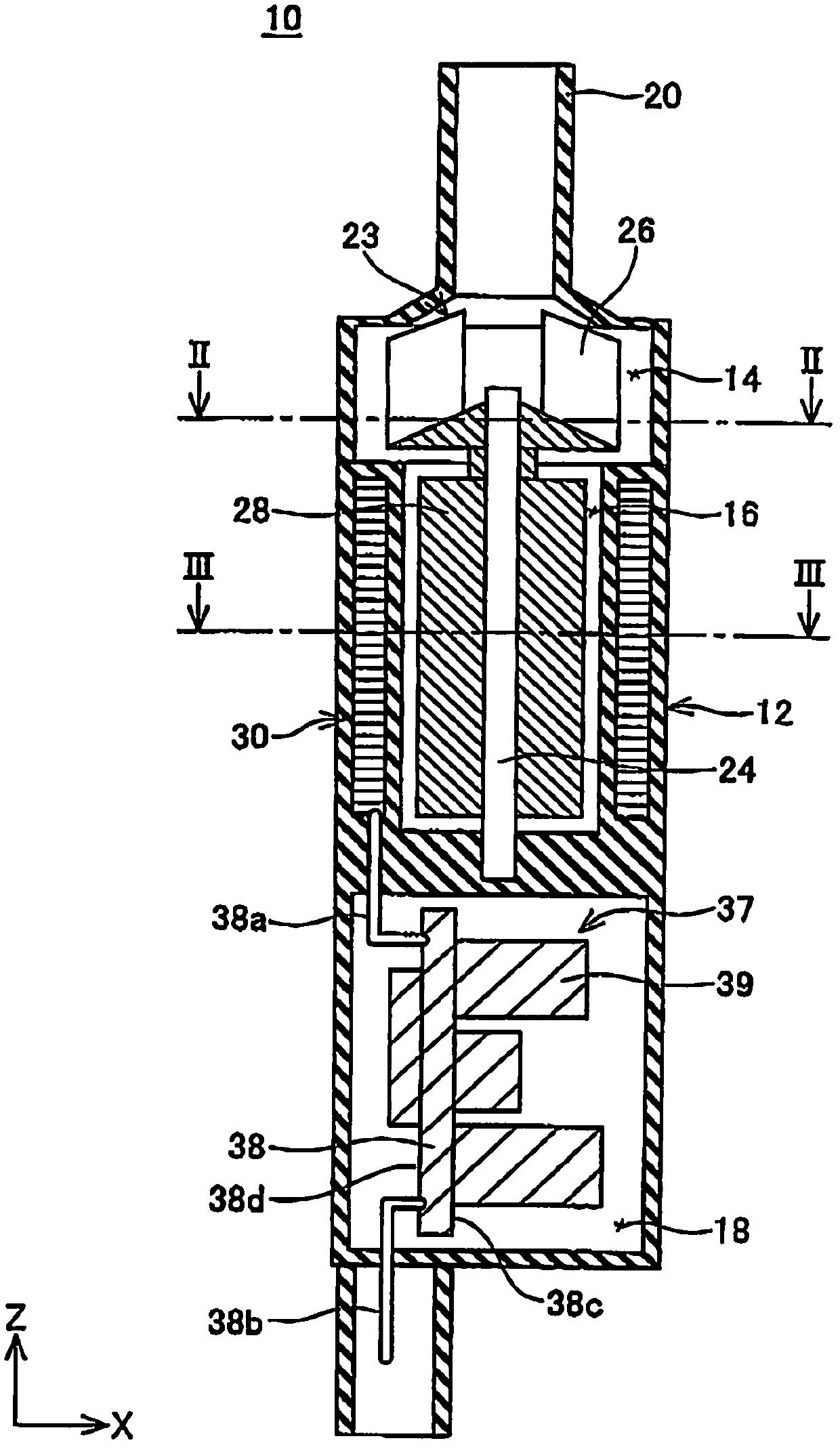

[0047] The electric pump 10 of Embodiment 1 is provided in an engine room of an automobile, and is used for circulating cooling water for cooling an engine, an inverter, and the like. Such as figure 1 As shown, the electric pump 10 includes a casing 12 , a fixed shaft 24 , a rotating body 23 and a stator 30 .

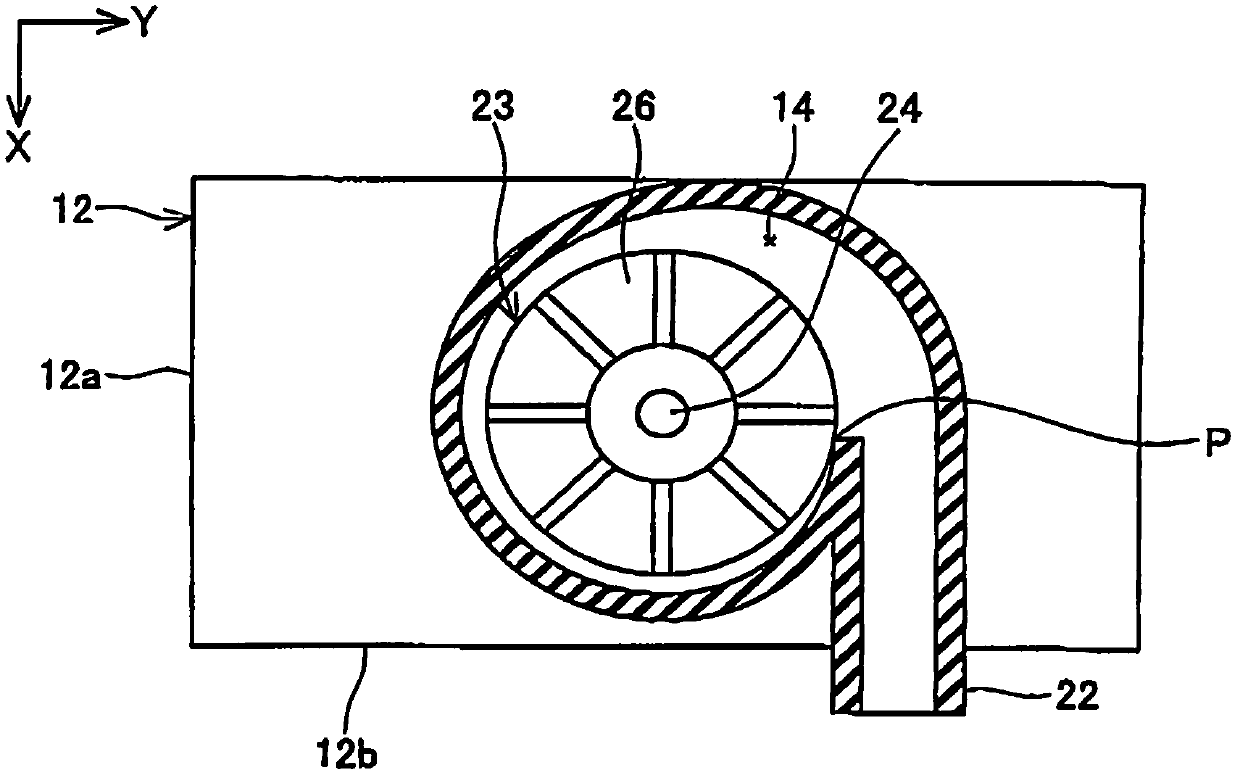

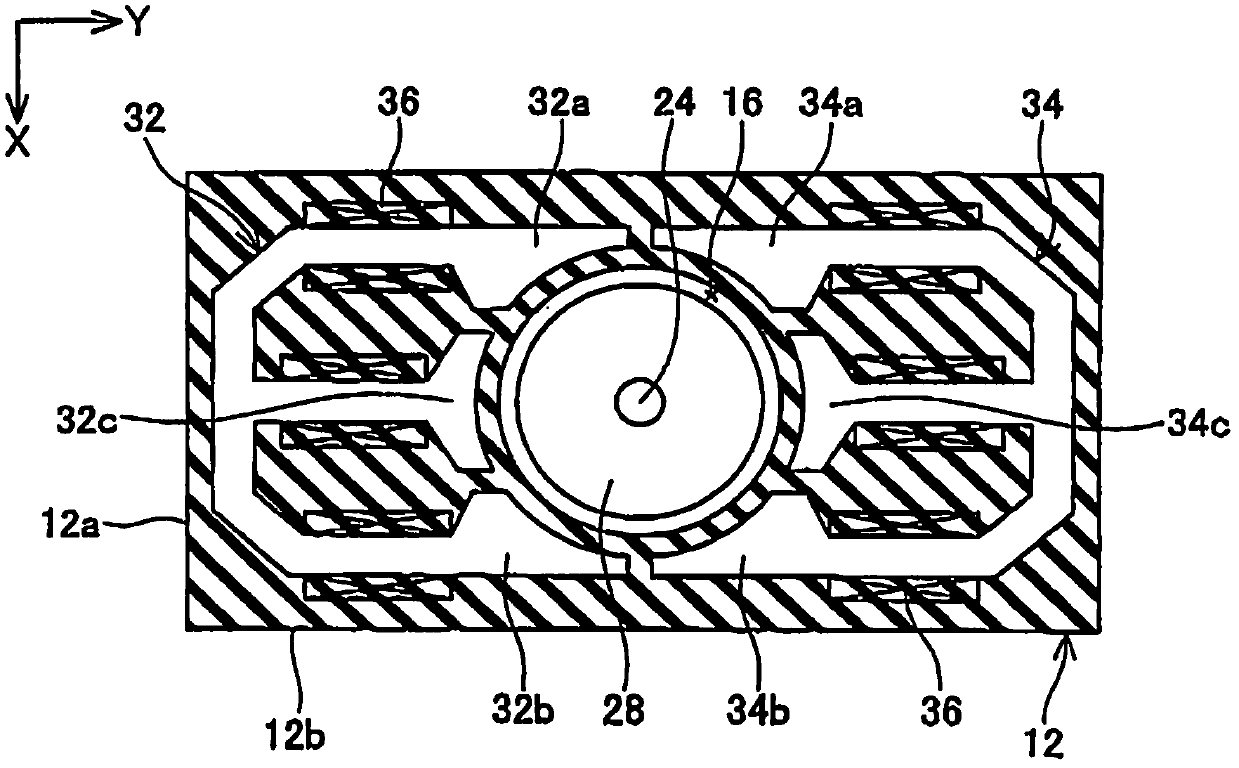

[0048] Three spaces of a pump chamber 14 , a motor chamber 16 , and a circuit chamber 18 are formed in the housing 12 . The pump chamber 14 is formed in the upper portion of the housing 12 . A suction port 20 and a discharge port 22 formed on the housing 12 (in figure 2 Indicated) is connected to the pump chamber 14. The suction port 20 is connected to the upper end of the pump chamber 14 . The suction port 20 extends in the direction in which the rotation axis of the rotating body 23 extends (ie, the z direction). Such as figure 2 As shown, the discharge port 22 is connected to the outer periphery of the pump chamber 14 . The discharge port 22 extends in a ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com