Substrate floating device

A technology of substrates and buffer tanks, which is applied in the directions of measuring devices, manual conveying devices, transportation and packaging, etc. It can solve problems such as increased pressure loss, complicated piping operations, and constant floating pressure of unfloatable plates, so as to prevent pressure poor effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

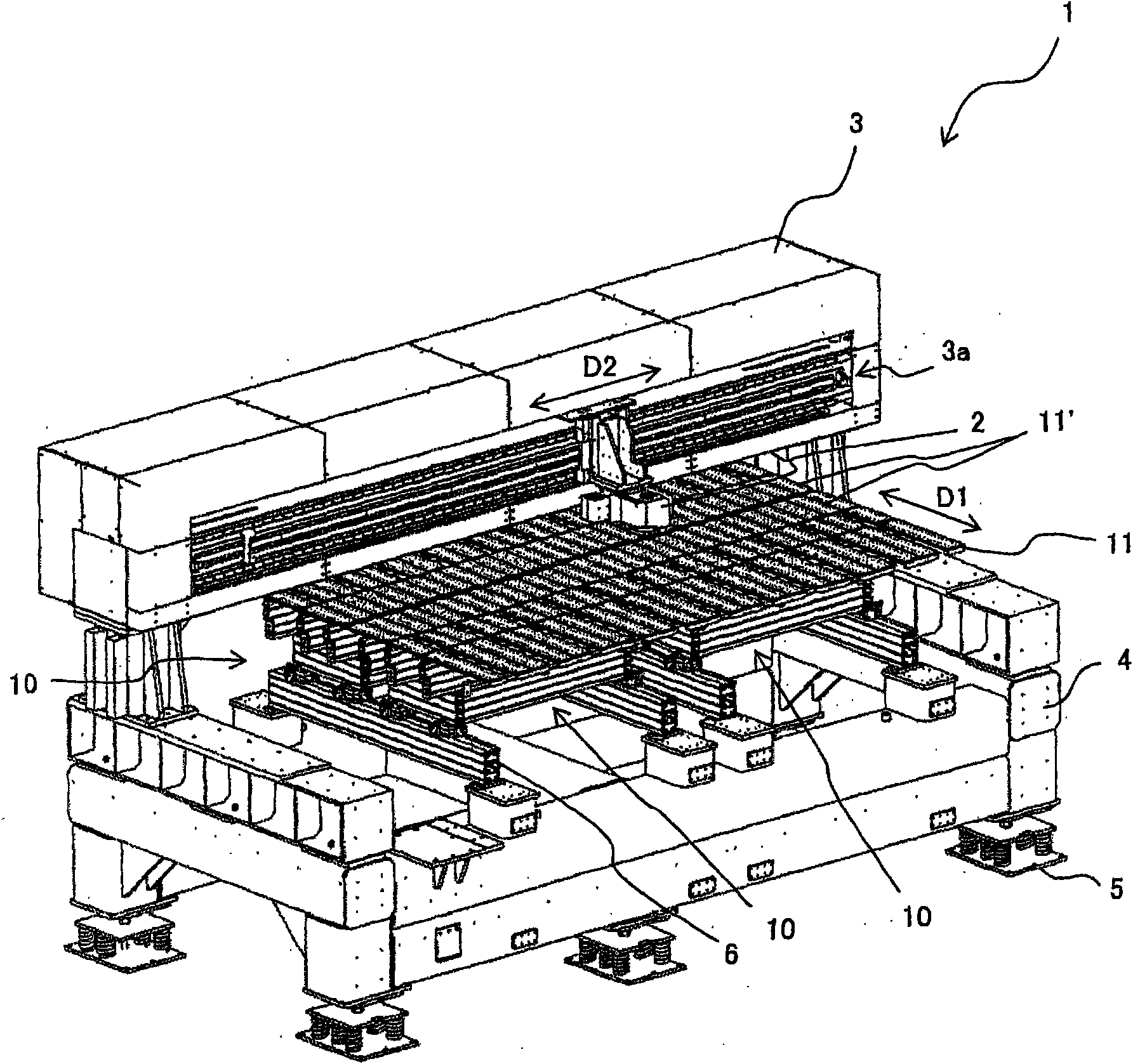

[0019] Below, while referring to the attached Figure 1 Next, a substrate floating device according to an embodiment of the present invention will be described.

[0020] figure 1 It is a perspective view showing a substrate inspection device 1 including a substrate floating device 10 according to an embodiment of the present invention. In addition, in this figure, the illustration of the substrate conveying device for carrying in and carrying out the substrate and the slider for holding and conveying one side end of the substrate floated on the floating plate 11 is omitted. The substrate floating device 10 is arranged in the inspection area of the substrate inspection device 1 , and the substrate carrying devices for carrying in and carrying out the substrate are arranged before and after the substrate carrying device 10 in the substrate carrying direction (arrow D1 ).

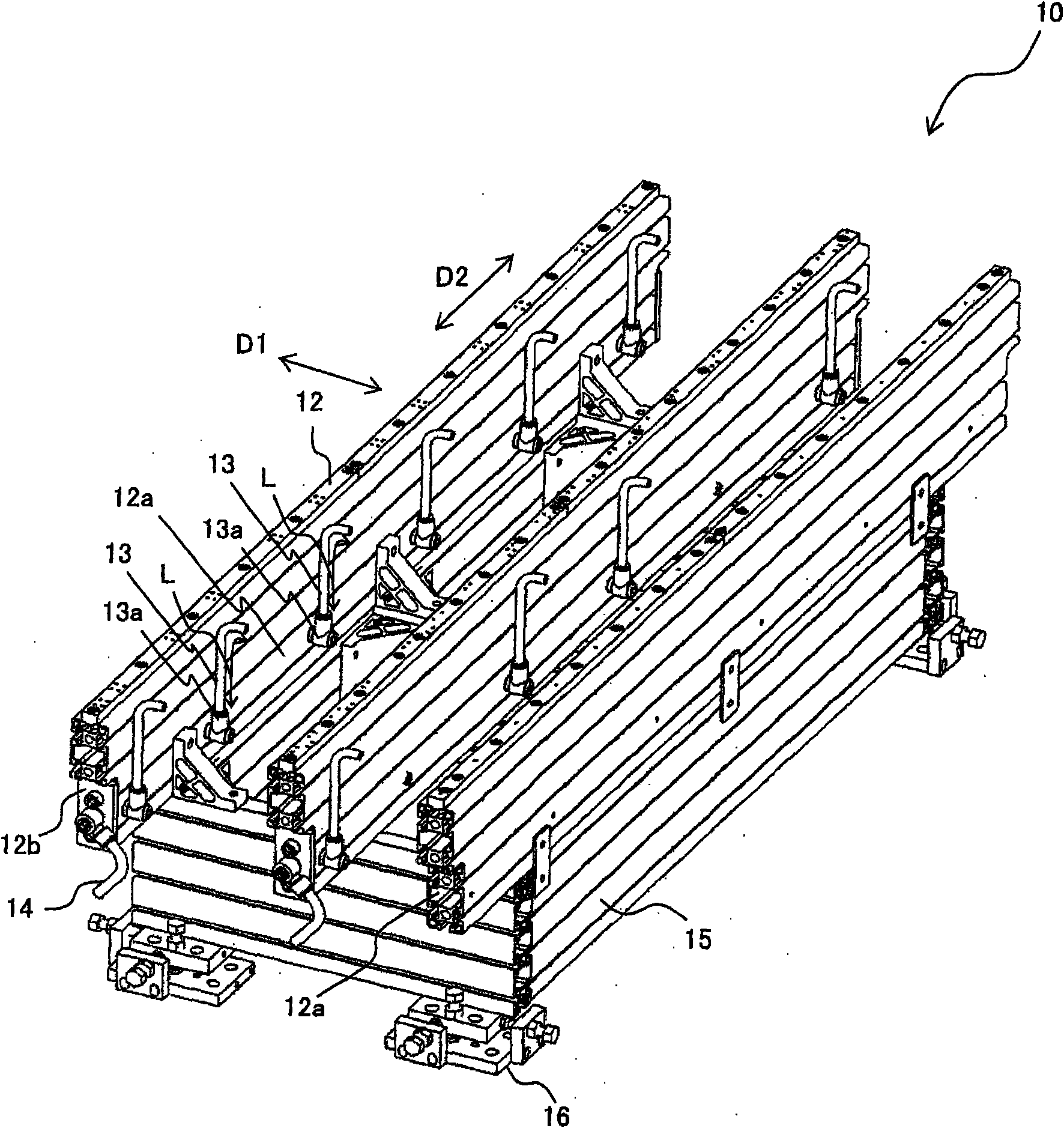

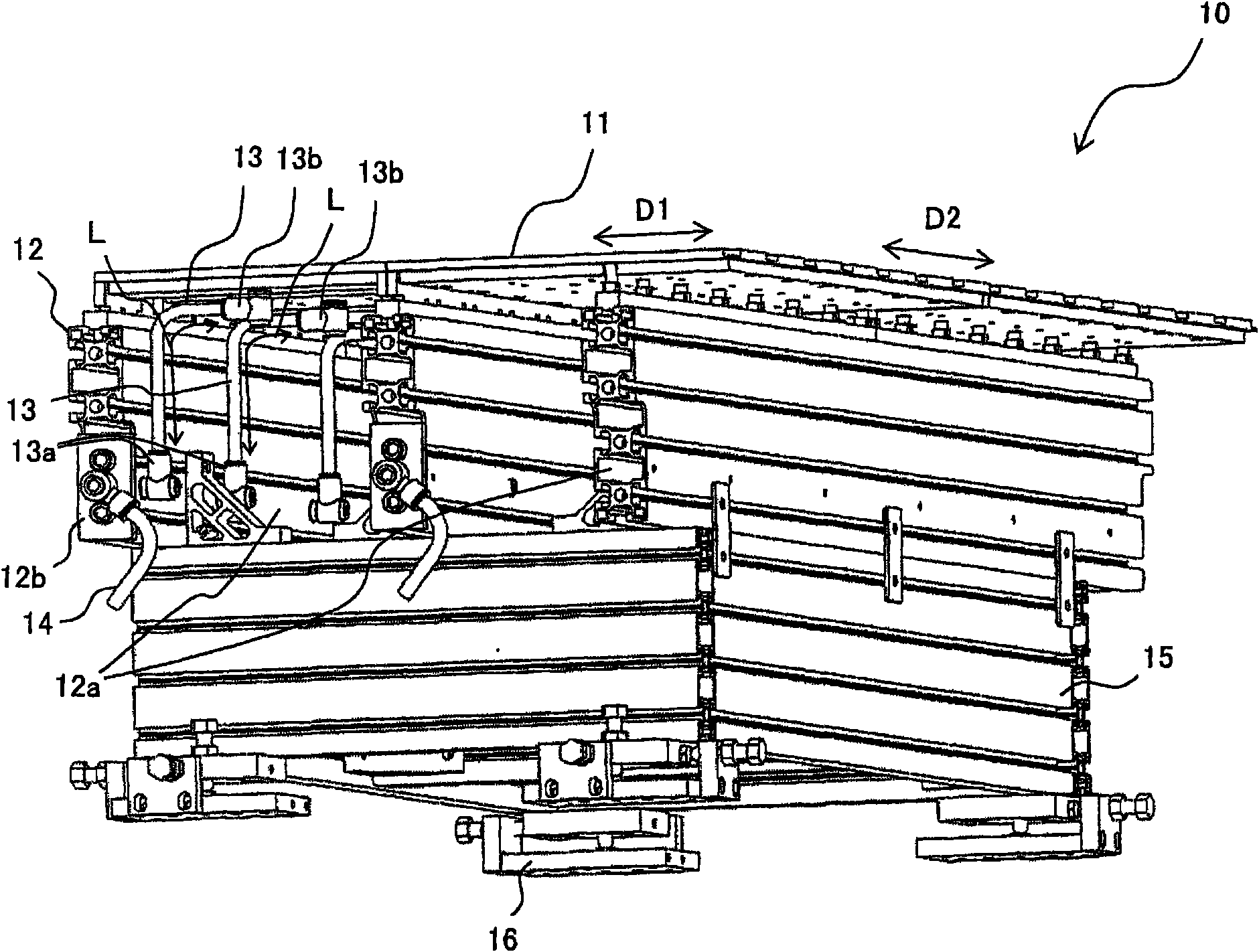

[0021] figure 2 is a perspective view of the substrate lifting device 10 viewed from above, image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com