High-low hydraulic switching mechanism as well as water spraying system and method for pavement milling machine

A technology of switching mechanism and water spray system, which is applied in the directions of machines/engines, roads, roads, etc., can solve the problems of increasing the production cost of the whole machine, prolong the life of the milling cutter, improve the working environment, and reduce the layout of components and pipelines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

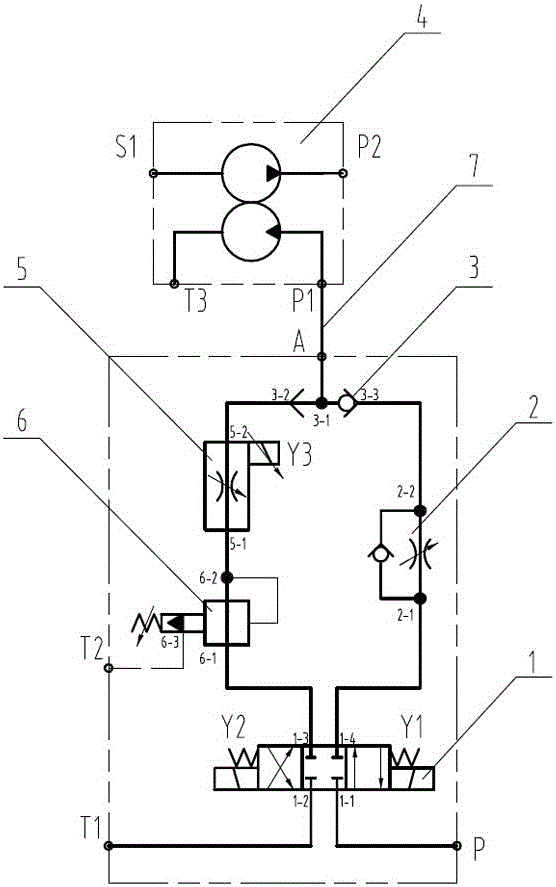

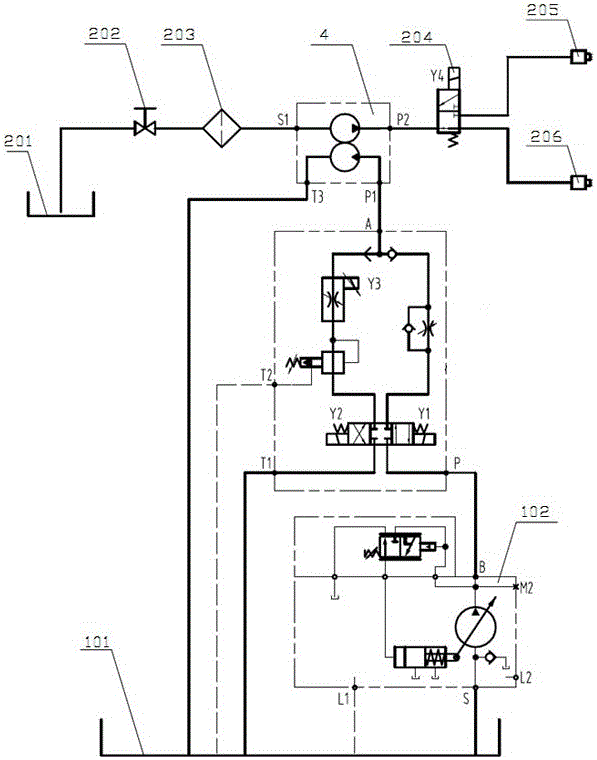

[0022] see figure 1 and figure 2 , a high-low hydraulic switching mechanism for a road milling machine related to the present invention, the mechanism includes an electromagnetic reversing valve 1, and the electromagnetic reversing valve 1 is a three-position, four-way electromagnetic reversing valve, and the electromagnetic reversing valve Oil port 1-1 of valve 1 is connected to oil inlet P, oil port 2 1-2 of electromagnetic reversing valve 1 is connected to oil return port T1, oil port 3 1-3 of electromagnetic reversing valve 1 is decompressed The valve 6 and the electric proportional speed regulating valve 5 are connected to the second oil port 3-2 of the shuttle valve 3, and the oil port 4 1-4 of the electromagnetic reversing valve 1 is connected to the first port of the shuttle valve 3 through the one-way throttle valve 2. Three oil ports 3-3, the first oil port 3-1 of the shuttle valve 3 is connected to the oil outlet A;

[0023] When electromagnetic coil 1 Y1 of elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com