Pull tab turnover device and pull tab feed device

A technology of turning over device and pulling tab, applied in the field of pulling tab turning device and pulling tab supply equipment, can solve the problems such as inability to realize the forward and reverse direction or front and rear direction turning of the pulling tab, poor versatility, and laborious processing and adjustment of the transfer path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

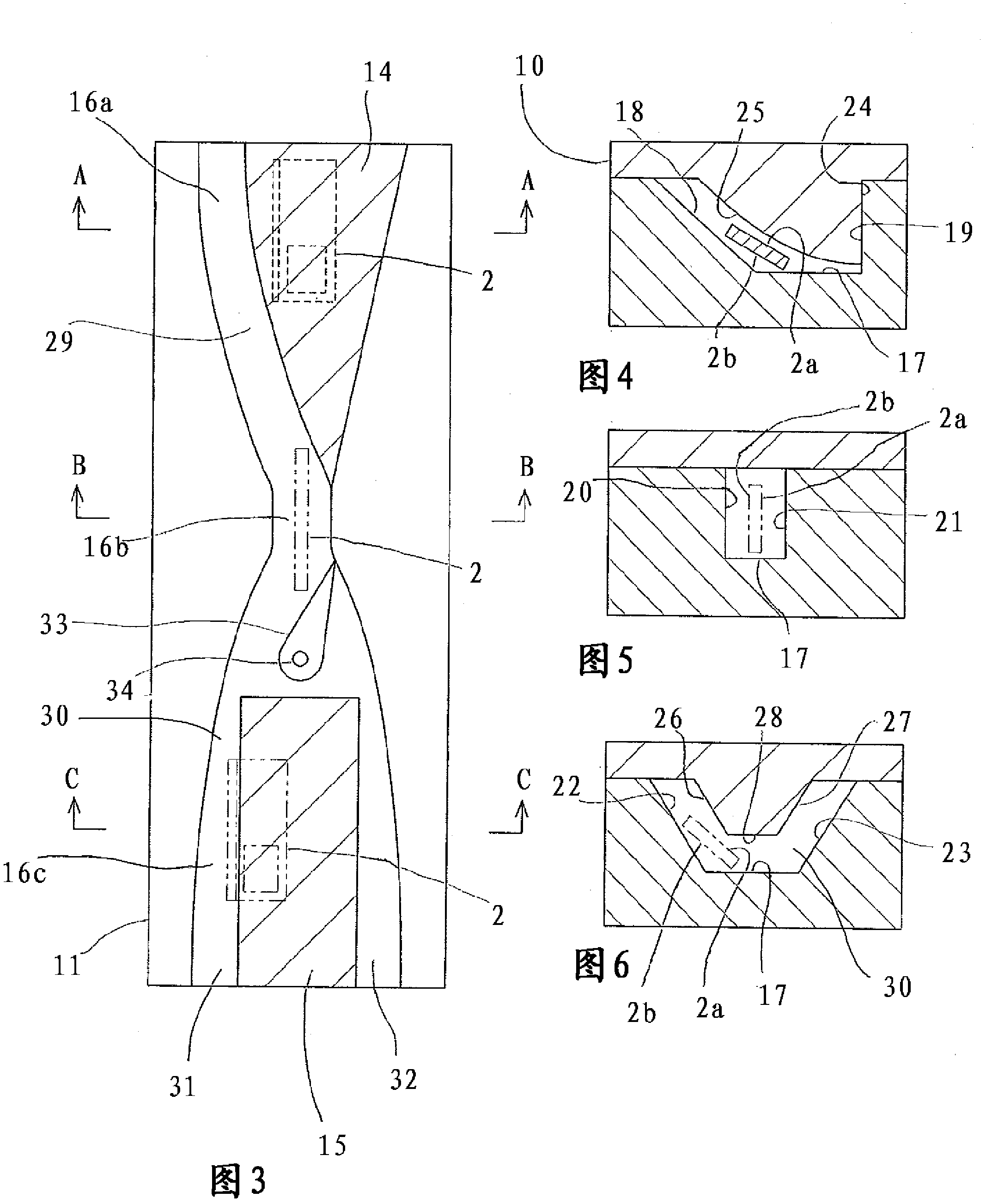

[0084] Figure 29 It is a partial enlarged view of the modification 2 of the handle supply apparatus 1. This modification 1 corresponds to the case where the front-rear inversion part 8 is not provided and only the front-rear inversion part 9 is provided. At the downstream end of the front and rear turning parts 9, the front and back turning parts 8 are not provided, but only a slideway 41 through which the pull tab 2 can directly slide down by its own gravity is provided. After the pull-tab 2 is discharged from the front and rear inverting portion 9 by gravity, it continues to be transferred downstream in the slideway 41 without reverse inverting. Of course, in this modified example, both the second component 38 and the slideway 41 can be omitted, so that the handle 2 enters the front and rear turning parts 9 directly after being discharged from the transfer path 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com