Ultrasonic thawing device and method and application in ice breaking and defrosting

An ultrasonic and equipment technology, applied in the field of thawing, can solve the problems of shortening thawing time, reducing food quality, waste of water resources, etc., and achieves the effect of improving thawing efficiency and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

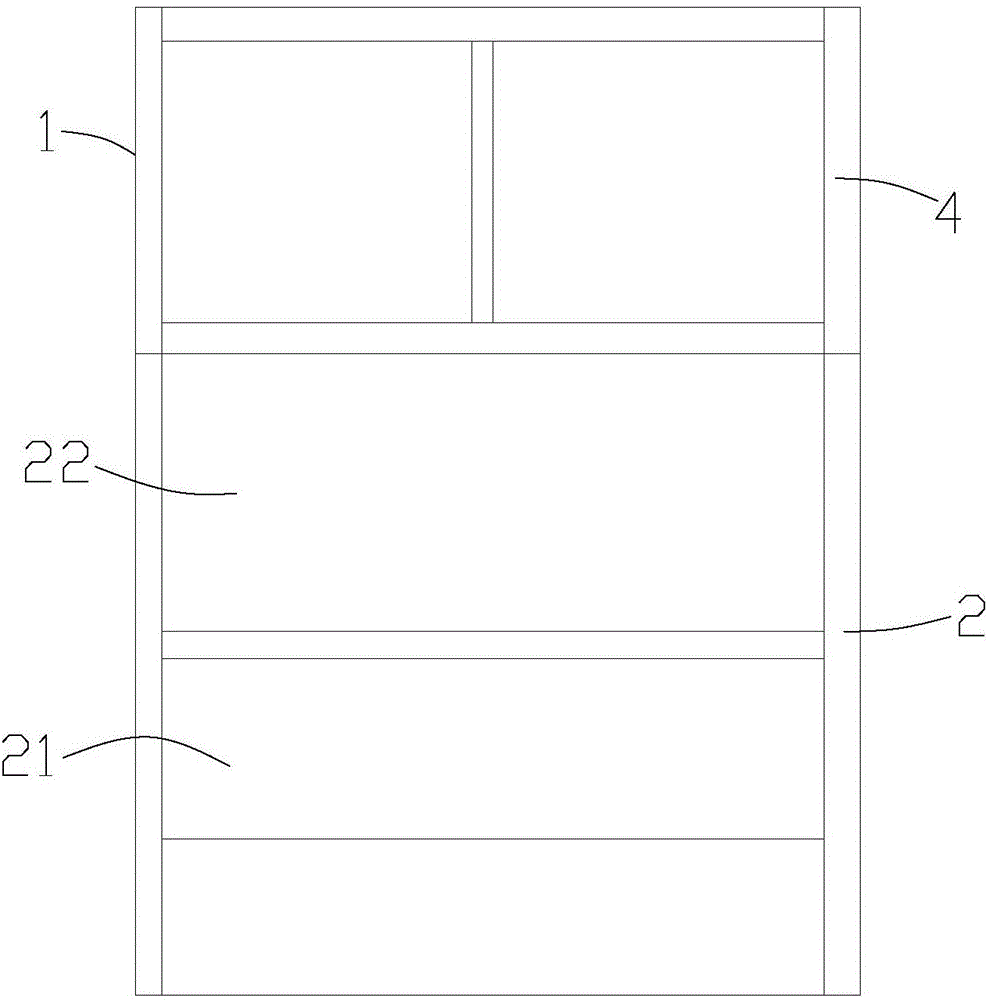

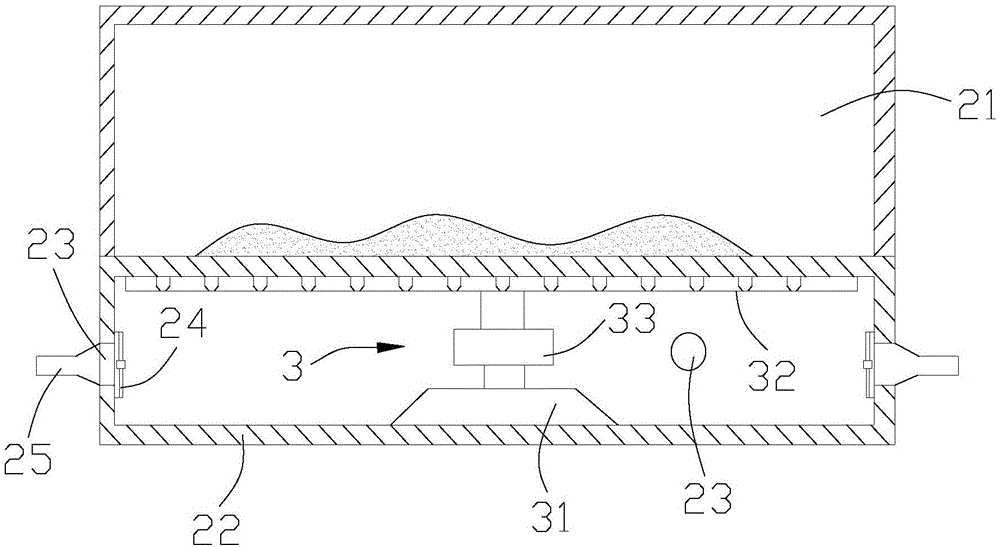

[0017] Combine below figure 1 and figure 2 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0018] An ultrasonic thawing device, comprising a body 1 and a freezing zone 2 arranged on the body. The temperature of the freezing zone is lower than 0°C. An ozone generator can be installed in the freezing zone to sterilize the food inside to ensure that the food does not deteriorate; Zone 2 includes a thawing cabinet 21 and a refrigerating cabinet 22 that can freeze food. The refrigerating cabinet can quickly freeze the food in the refrigerating cabinet. An ultrasonic thawing device 3 is arranged on the thawing cabinet. The frozen ice on the frozen food is quickly shattered, so as to achieve the purpose of rapid thawing.

[0019] During implementation, at least one outer side of the cabinet body of the thawing cabinet 21 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com