Patents

Literature

62 results about "Fast Freeze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

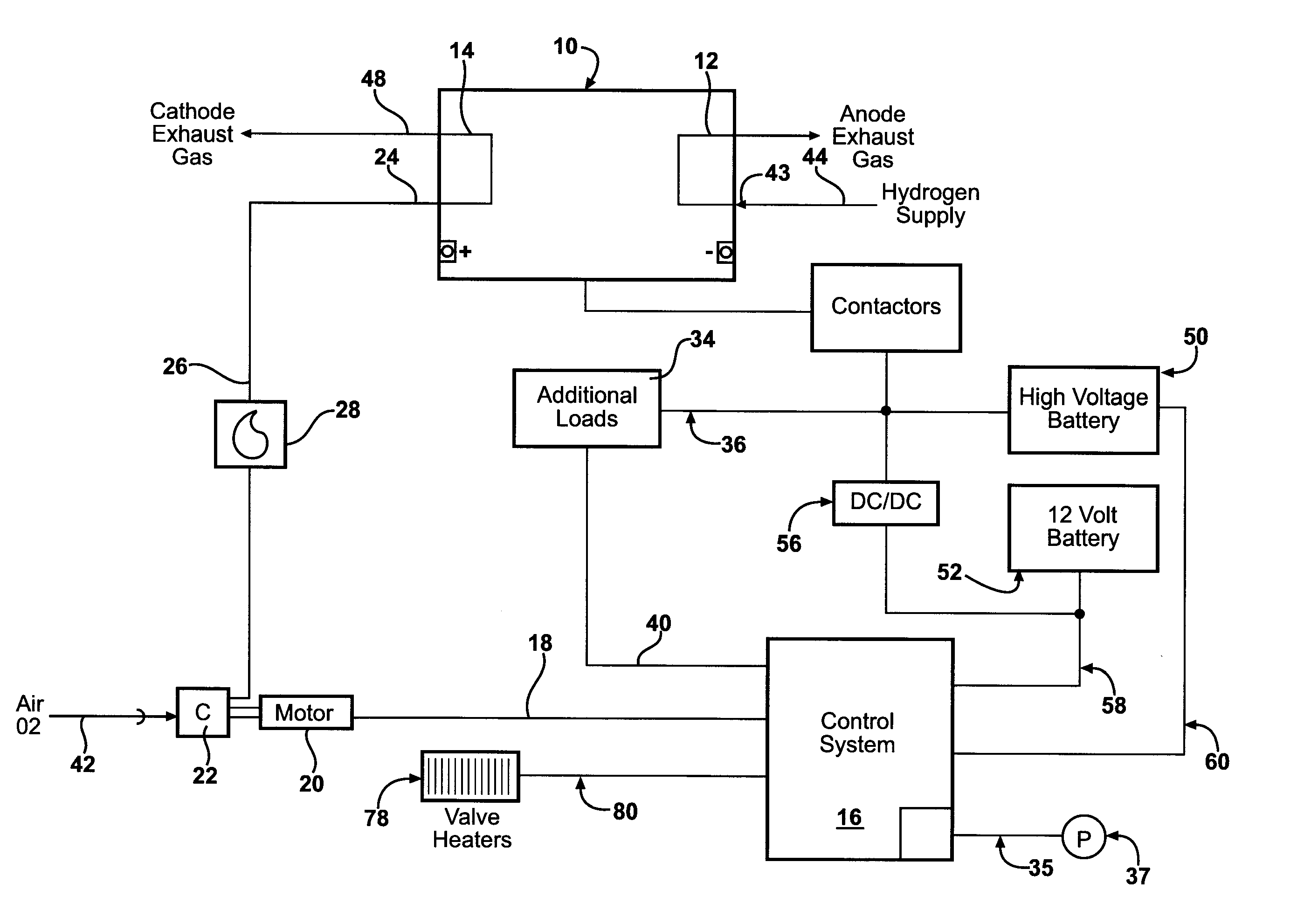

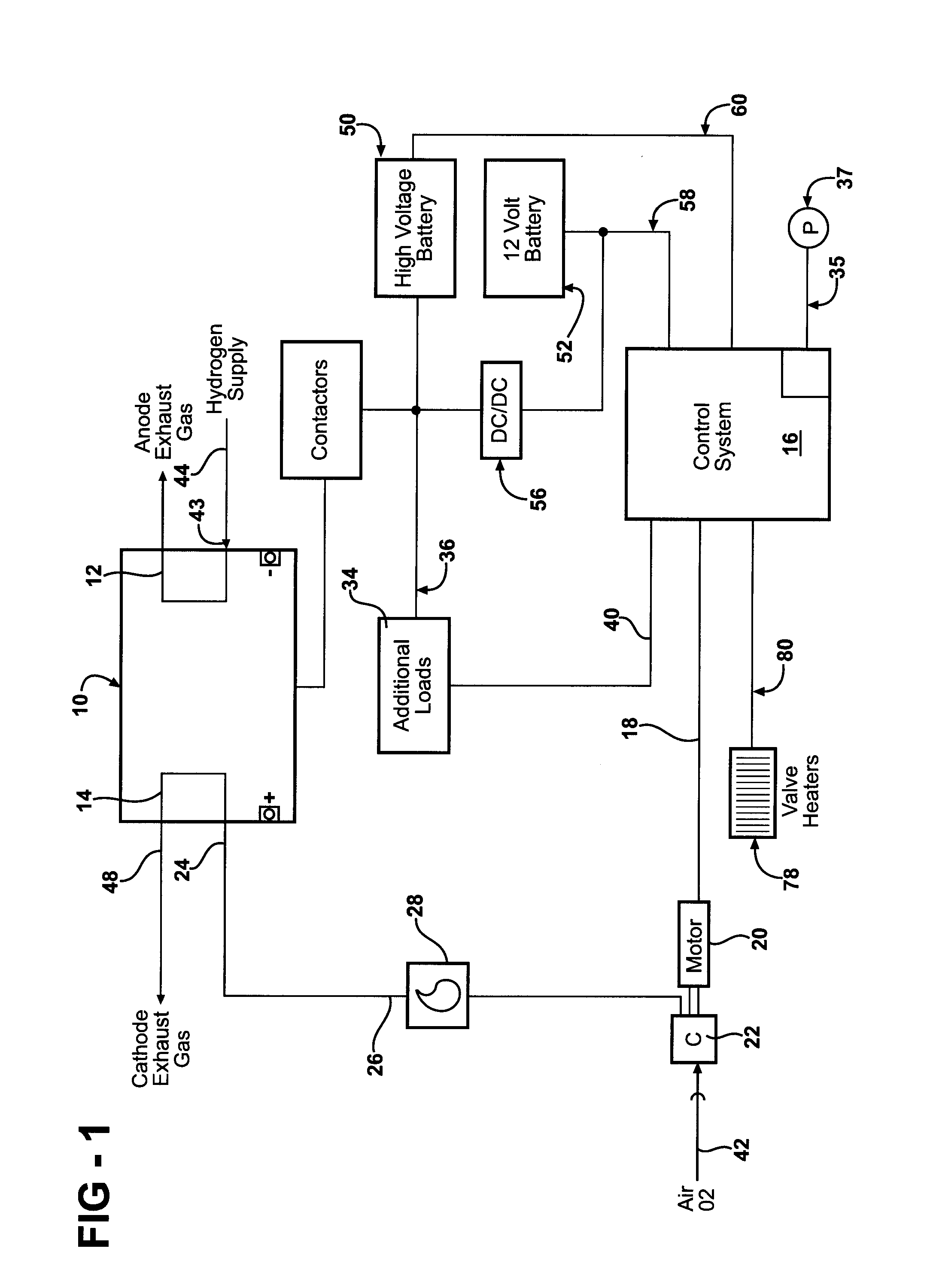

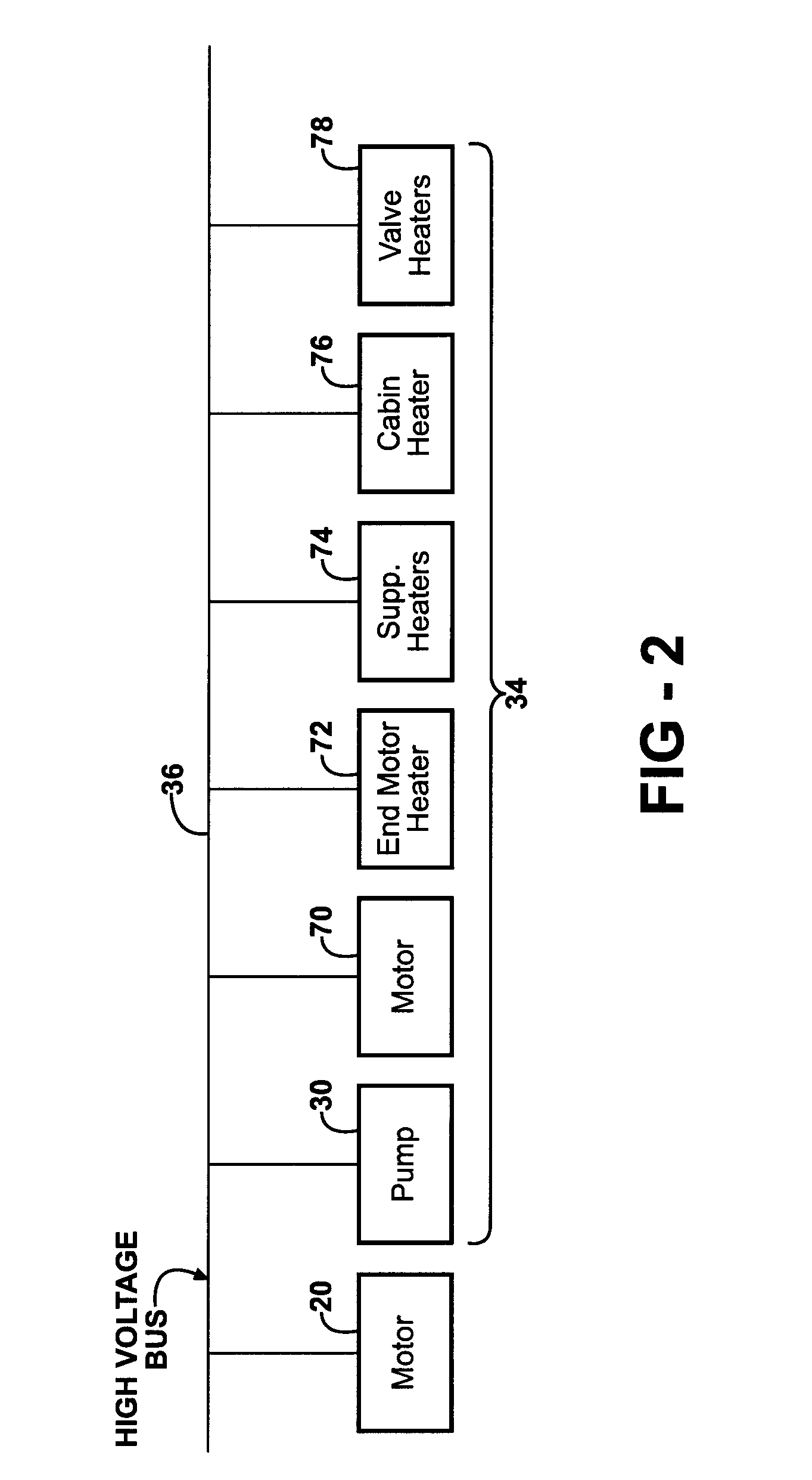

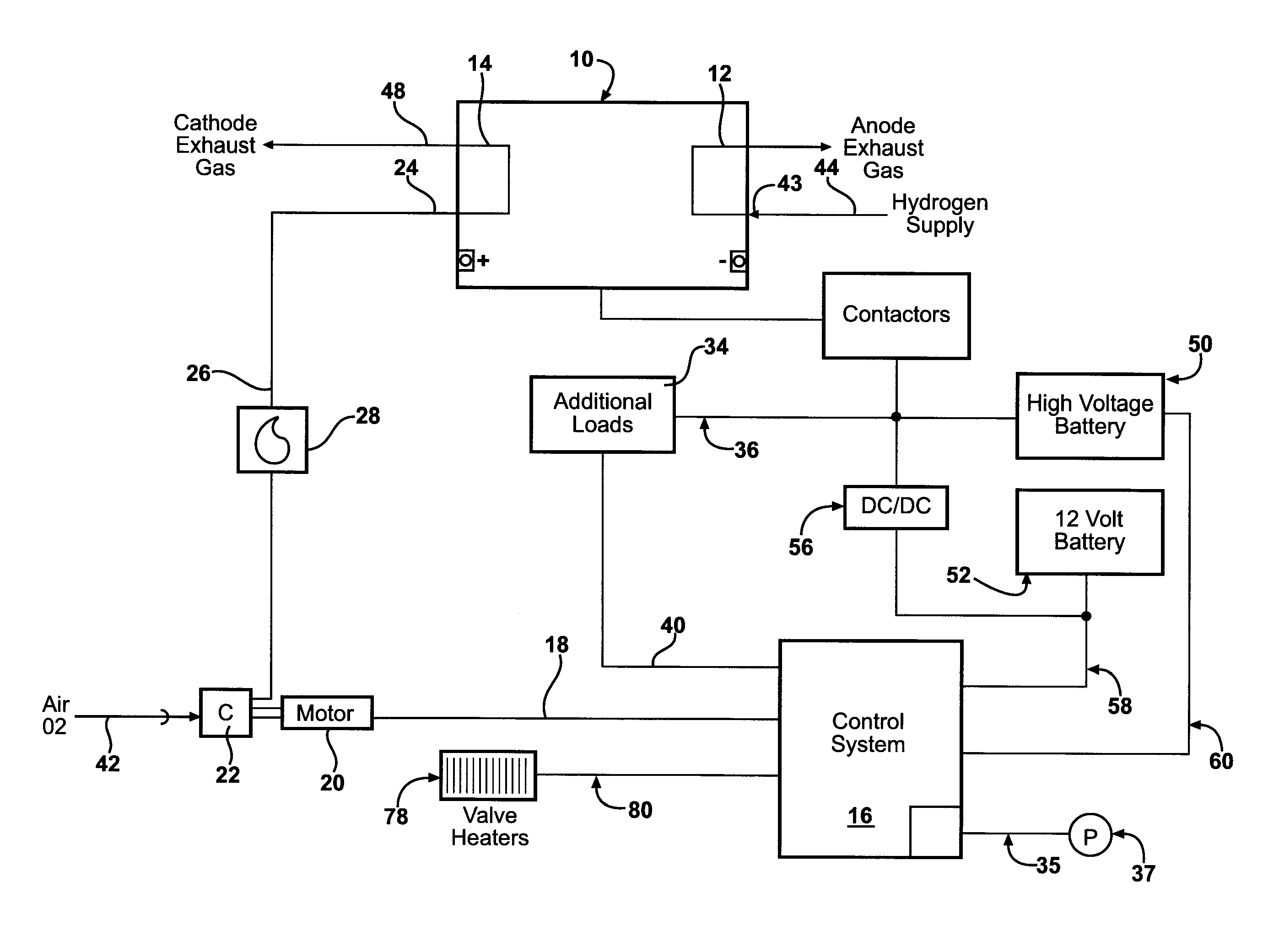

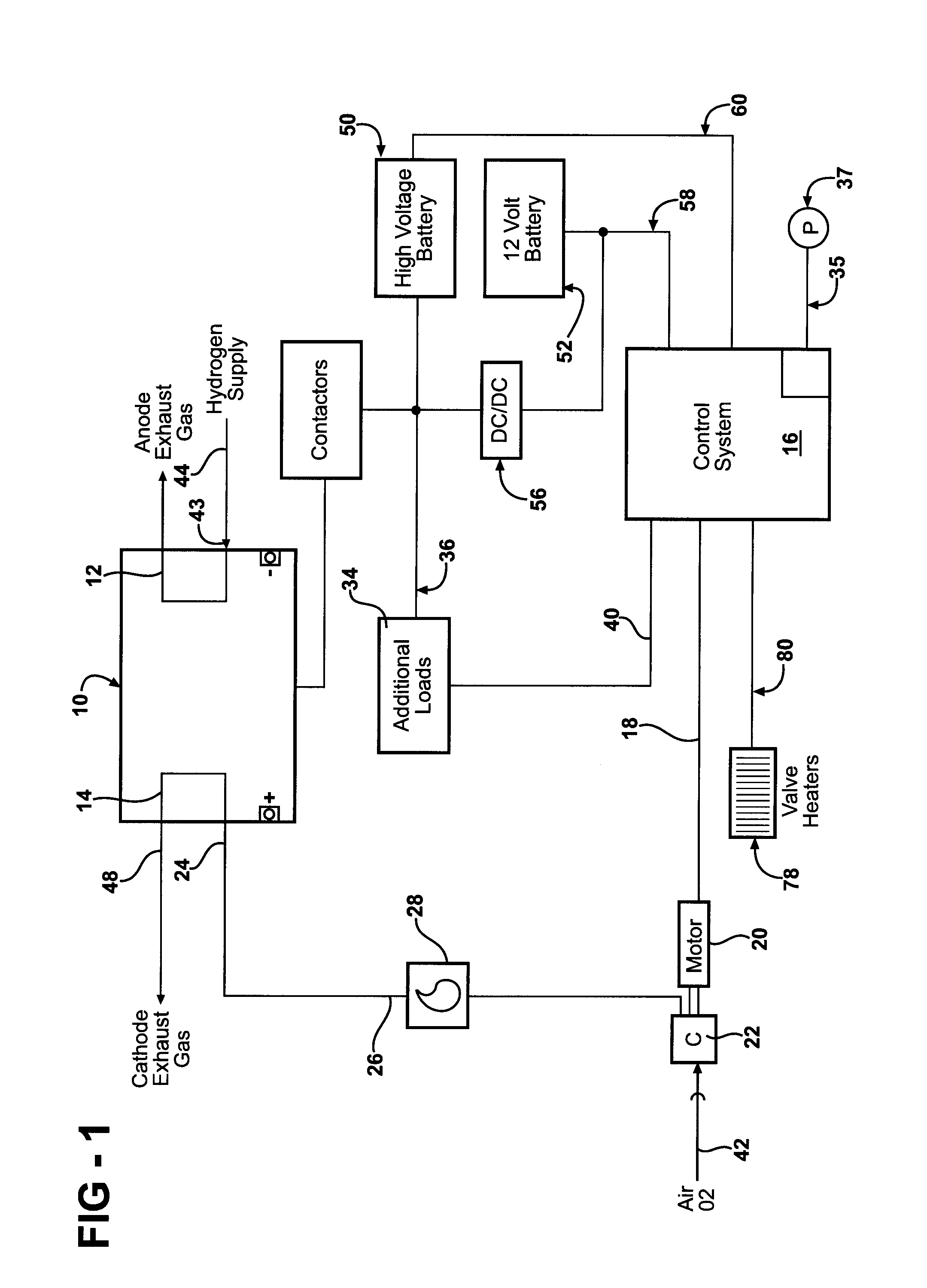

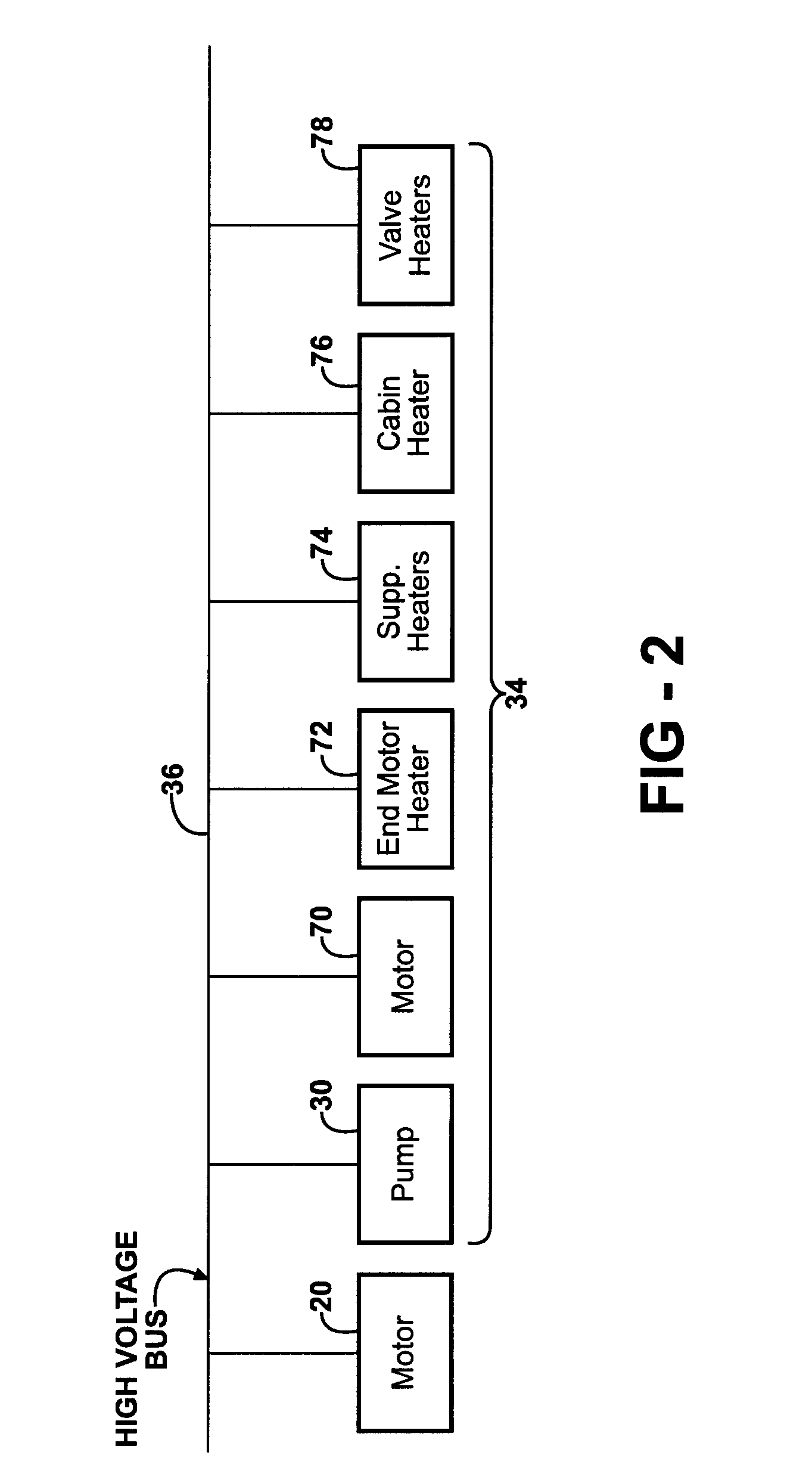

Fuel cell startup method for fast freeze startup

ActiveUS20080081224A1Increase ratingsOptimizes warm-up timeFuel cell heat exchangeConverter typesFuel cellsStart time

Owner:GM GLOBAL TECH OPERATIONS LLC

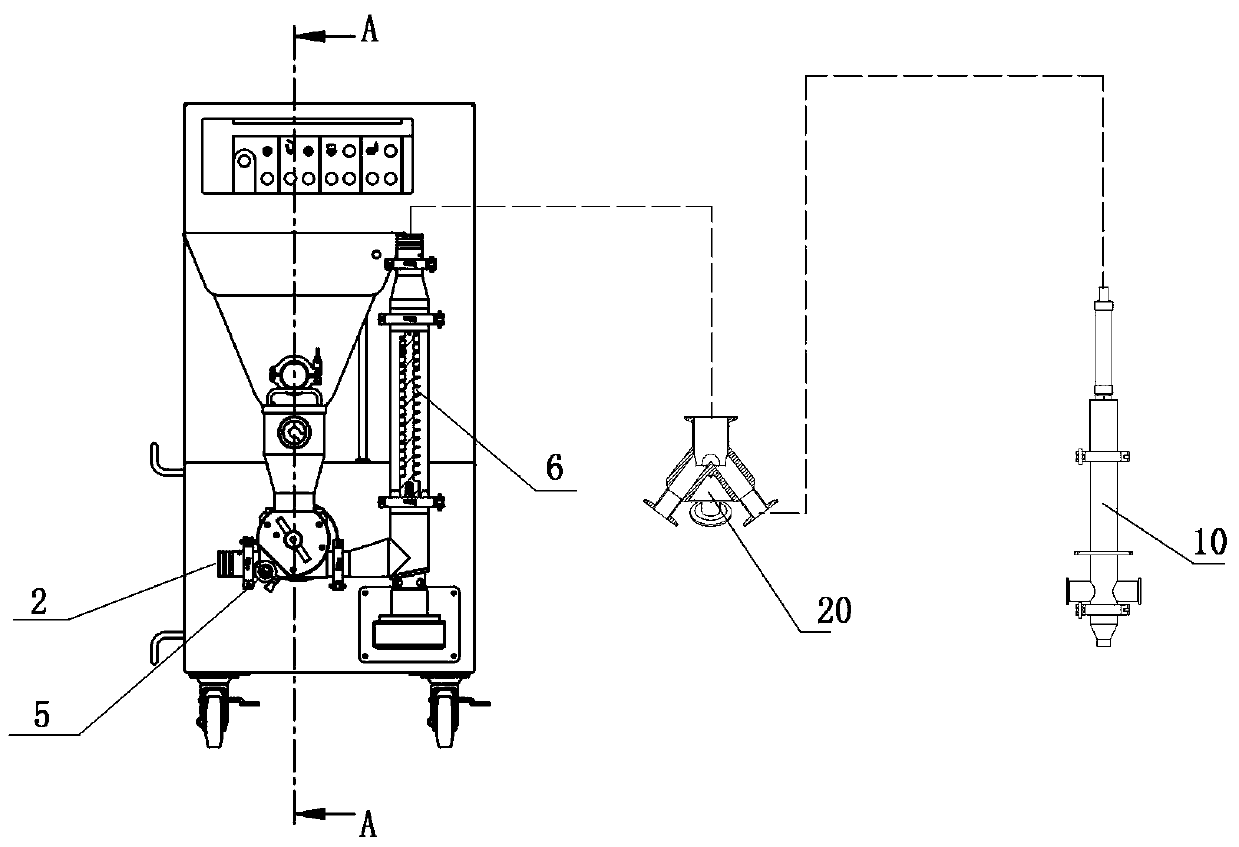

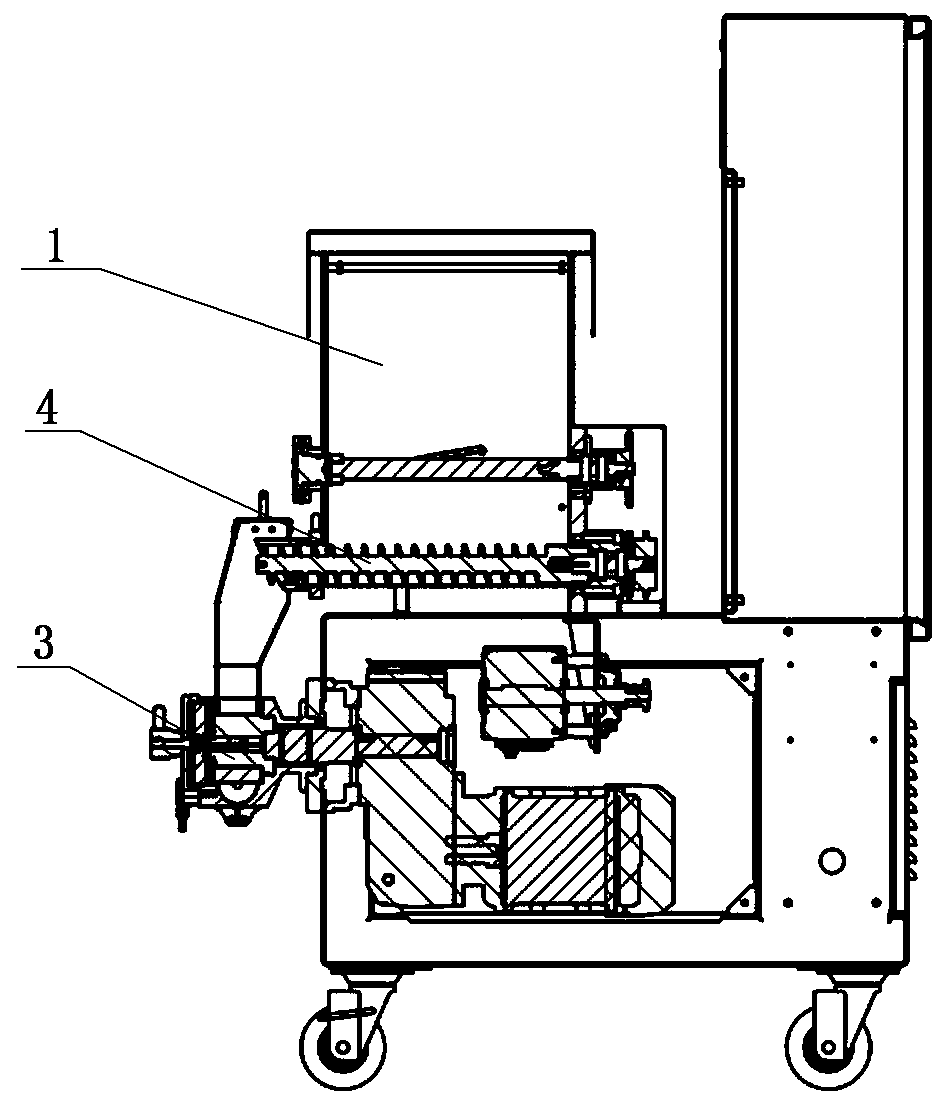

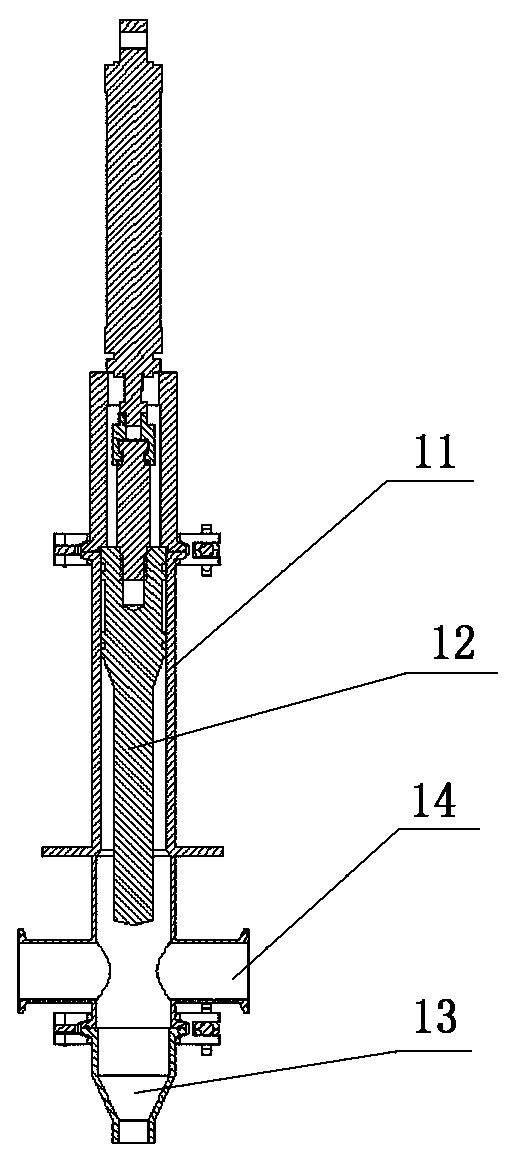

Ultrasonic thawing device and method and application in ice breaking and defrosting

PendingCN106721903AKeep it authenticEasy to break awayOverhead installationFood freezingProcess engineeringFreezing environment

The invention relates to a thawing technology, in particular to an ultrasonic thawing device and method and application in ice breaking and defrosting. The ultrasonic thawing device comprises a machine body and a freezing area arranged on the machine body, wherein the freezing area comprises a thawing cabinet and a cold storage cabinet capable of freezing food, the thawing cabinet is provided with an ultrasonic thawing apparatus, the ultrasonic thawing apparatus breaks ice on the frozen food in the thawing cabinet under the freezing environment, so that nutritional substances of the food can be prevented from being lost along with the water, the original taste of the food is ensured, the taste is good, and the thawing efficiency is improved. The ultrasonic thawing method can be used for ice breaking of ocean, rivers, roads, railways, bridges, electric power and telecommunication circuits, can also be used for defrosting of fast-freezing tunnels, subzero storages, refrigerators, and air conditioner condensers, is not only short in ice breaking time and high in efficiency, but also low in energy consumption and convenient in operation.

Owner:HUNAN JIASHENG FRESH PRESERVATION TECH

A method for preparing fermented meat cake or meat ball

InactiveCN1864549ASolve the problem of low absorption utilization rateIncrease appetiteFood scienceGlucose polymersFermentation

The present invention relates to fermented meat product, and is especially the making process of fermented meat pie or fermented meat ball. The making process includes the following steps: 1. cutting and chopping to obtain meat paste; 2. adding glucose and salt into meat paste, mixing and heating to sterilize; 3. inoculating lactic acid bacteria and saccharomycete; 4 fermenting; 5. making no-fermentation meat paste; 6. mixing the fermented meat paste and no-fermentation meat paste; and 7. adding supplementary material, forming and fast freezing to obtain fermented meat pie or fermented meat ball. The fermented meat pie and fermented meat ball have attractive fragrance, rich nutrients and unique sourish taste.

Owner:HARBIN UNIV OF COMMERCE

Preparation technology for beef balls

The invention relates to a preparation technology for beef balls, which is characterized by comprising the following steps: (1) preprocessing: selecting and cleaning fresh rump steak and fresh chicken breast, wherein the weight ratio of the fresh rump steak to the fresh chicken breast is (3:1)-(3:2); (2) curing: curing the obtained beef and chicken in an aqueous solution of prickly ash and nitrite for 1-1.5 h at 0-4 DEG C; (3) meat grinding; (4) chopping and mixing; (5) beef ball shaping: extruding meat paste manually or mechanically into beef balls with diameters of 2-2.5 cm; (6) cooking and cooling; (7) vacuum packing and then sterilizing; (8) fast freezing. The preparation technology provided by the invention can be used for producing beef balls which contain rich nutrient substances, high-quality animal protein, mineral substances, vitamins and various amino acids necessary for human bodies, and the beef balls are convenient, fast, safe and sanitary to eat and are not required to be secondarily processed.

Owner:王婵

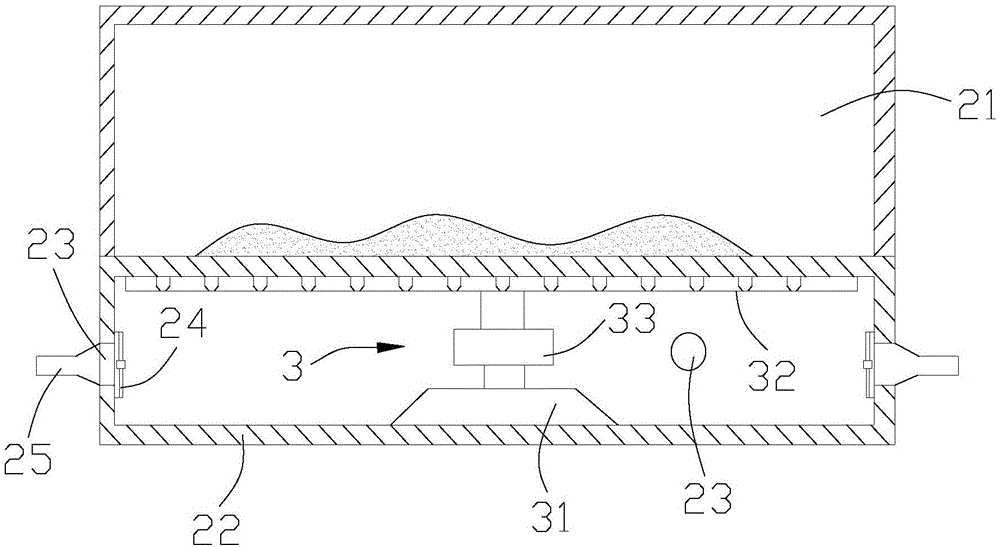

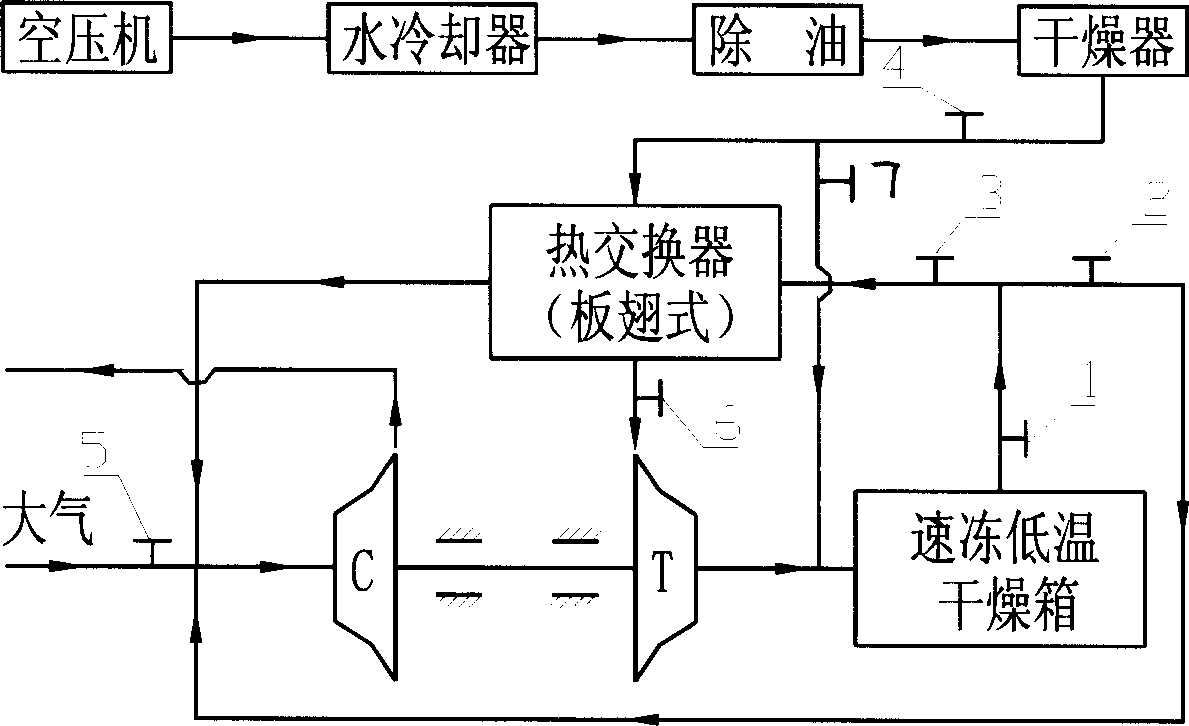

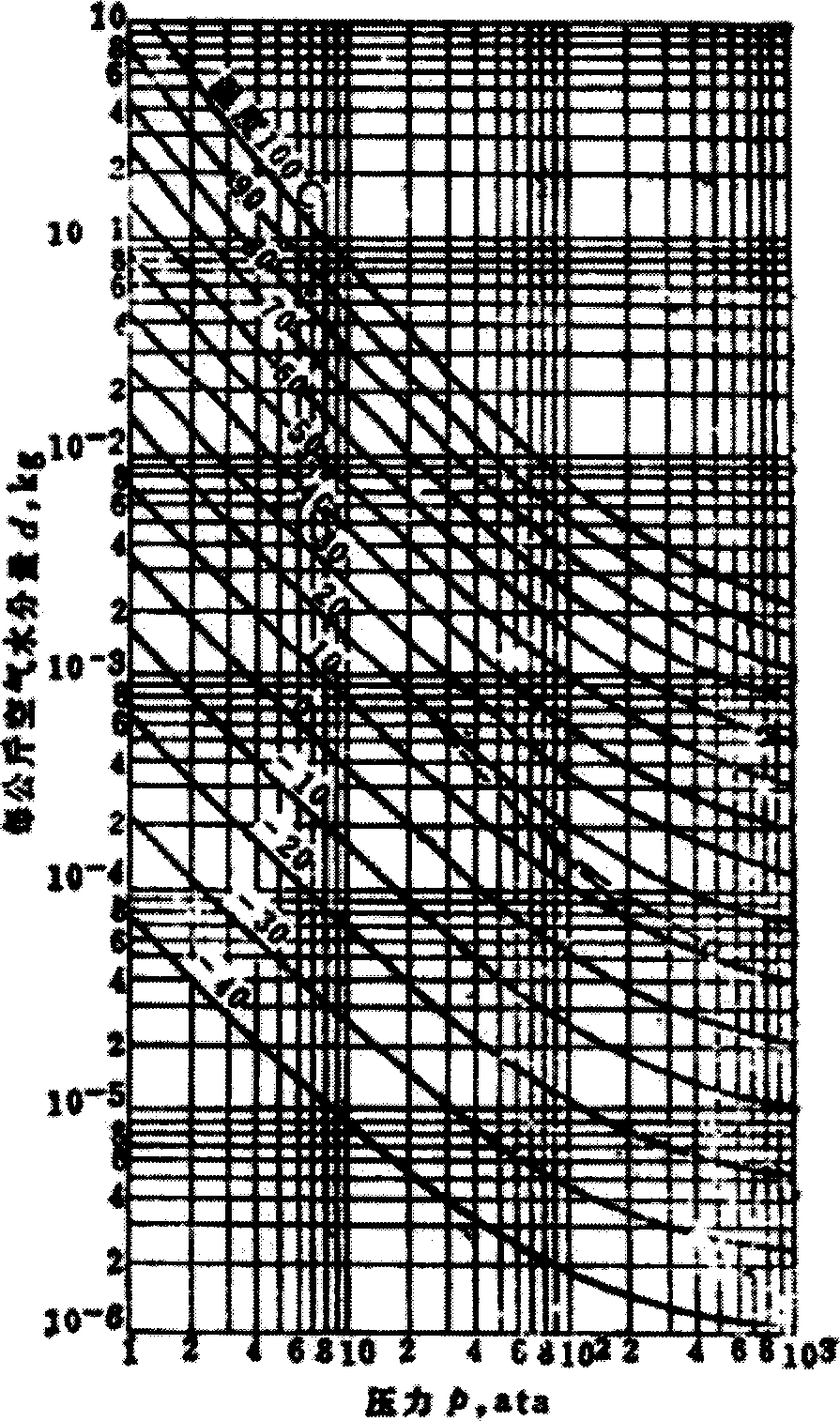

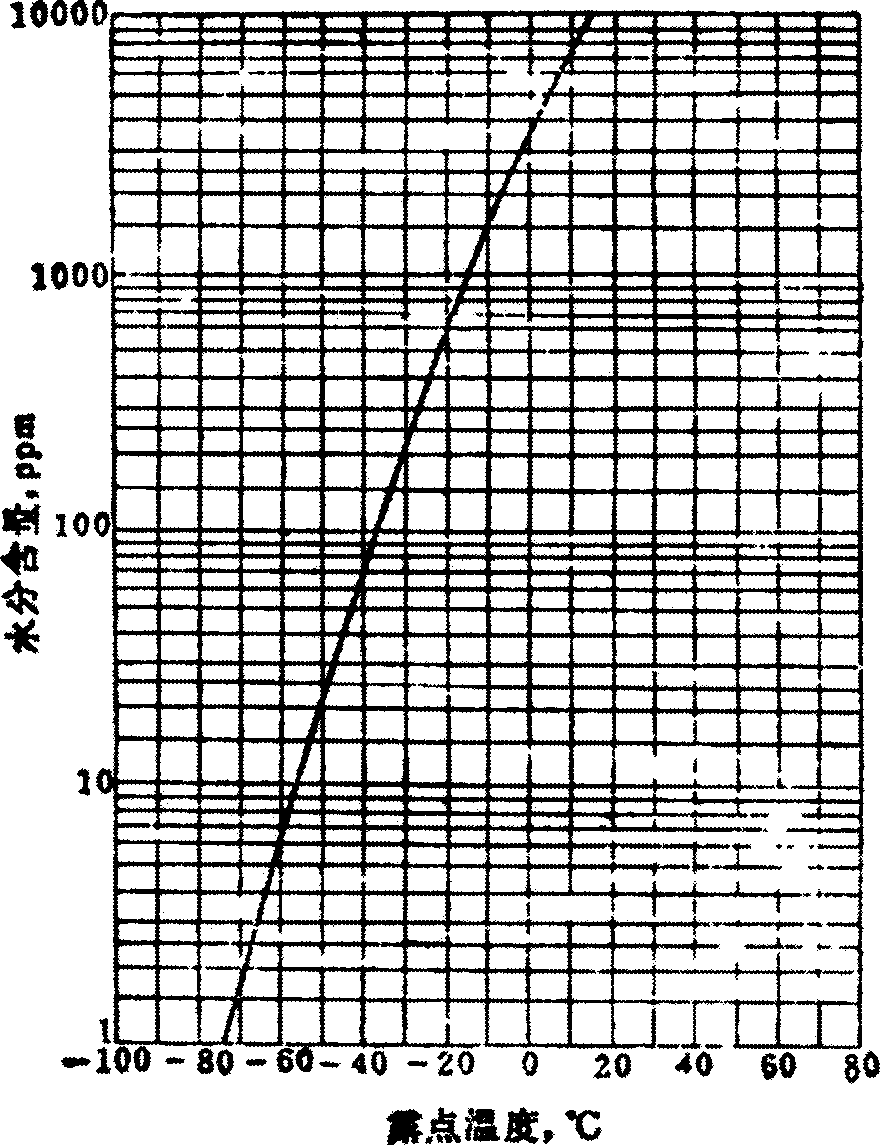

Method and apparatus for cryogenic fast freezing preservation and refrigerating dry of Chinese medicines and food

InactiveCN1439316AReduce energy consumptionLow costFruit and vegetables preservationCompression machines using turbinesFreeze-dryingCell membrane

A process for antistaling and drying the Chinese-medicinal materials or food features that an air turbine with reflux condenser is used for refrigerating, which can quickly freeze the Chinese-medicinal materials or food for antistaling them, and said drying them features the direct sublimation. Its advantages are no damage to cell membrane, very low water content, and long storage period.

Owner:BEIHANG UNIV

Instant sea cucumber with primary taste and is manufacturing method

InactiveCN1653960AMaintain molecular structureReserve statusFood preservationFood preparationFast FreezeSea cucumber

The instant sea cucumber with primary taste is made through cleaning, water boiling and fast freezing. Specifically, the making process includes eliminating internal organs of live sea cucumber and cleaning; boiling first in water at 30-40 deg.c for 5-10 min on slow fire and then at 50-60 deg.c for another 5-10 min until sea cucumber stretches to live state; fast freezing at temperature from -40 deg.c to -30 deg.c in fast freezing machine for 15-20 min; and packing. The said making process can maintain the molecular structure, nutritious components and taste of live sea cucumber radically, and the sea cucumber may be eaten in different modes after being defrozen.

Owner:许毅

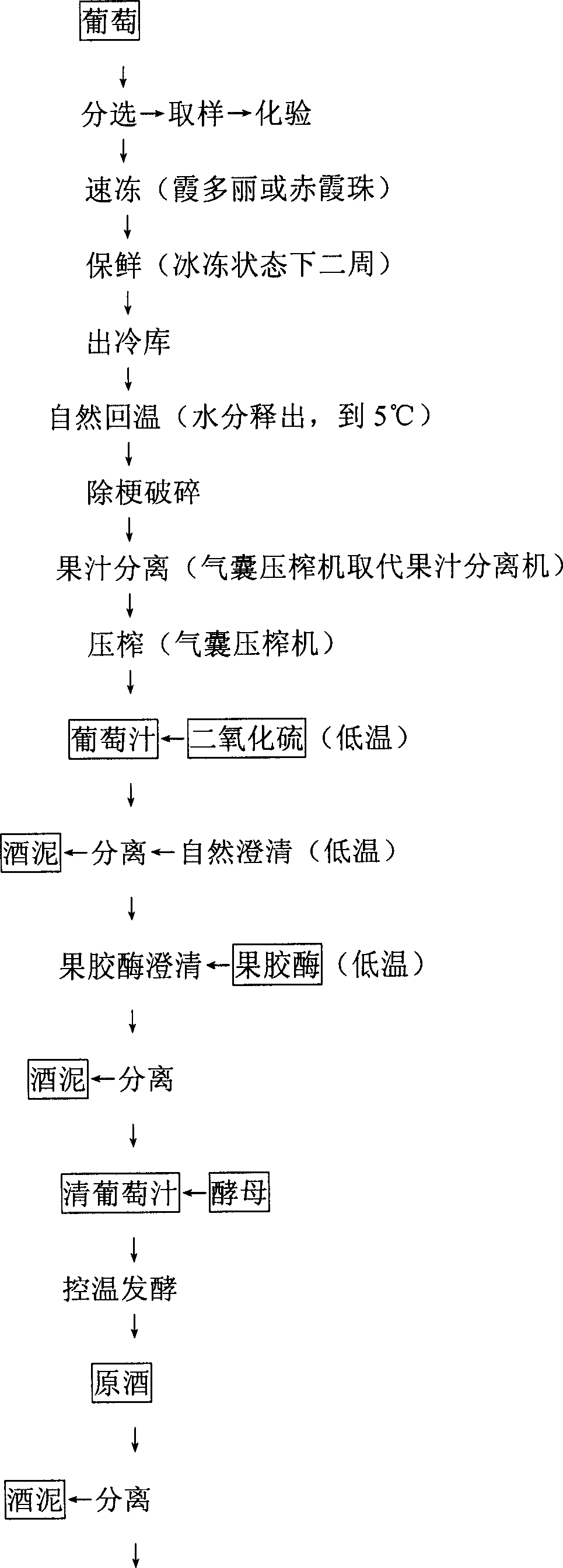

Frozen wine and its preparing method

The invention relates to a freeze grape wine and the method to manufacture that belongs to wine producing field. The process includes the following steps: selecting grape and taking fast freezing to keep fresh in low temperature, warming in natural temperature, reducing peduncle, compressing, separating the flesh and the juice, purifying, fermenting at a certain temperature, separating to kettle and storage, mixing, taking second freezing process, filtering and bottling. The invention has taken strict test from the four aspects of color aroma, taste and alimentation. And it has all the features of the existing freeze wine.

Owner:马玉祥 +1

Clean silkworm cocoon cooking method

ActiveCN106012037AGood relaxing effectQuality improvementSilk filament obtainingVacuum pressureMicrowave

The invention discloses a clean silkworm cocoon cooking method. The method comprises the following steps: putting selected silkworm cocoons in a home-made soaking agent to be soaked, then washing the silkworm cocoons with clear water and drying the silkworm cocoons by microwave and far infrared optical wave and then sending the silkworm cocoons to be directly steamed; putting the silkworm cocoons in a vacuum cocoon cooking permeator after direct steaming is completed, adding proper amount of unwinding agent, controlling the water temperature at 30-50 DEG C, carrying out vacuum permeation, and when the vacuum pressure is -0.1Mpa, taking out the silkworm cocoons to enter the next cocoon cooking procedure after continuing for 1-5 minutes, after cocoon cooking is completed, putting the obtained silkworm cocoons in a fast freezing tank at 23 DEG C to be fast frozen for seven hours, then putting the silkworm cocoons in an environment at minus 10.5 DEG C and with vacuum degree of 270pa to be sublimated for 230 minutes and sending the silkworm cocoons to a silk reeling workshop. The method has the beneficial effects that by adopting the cocoon cooking method to cook cocoons, the obtained cooked cocoons have high silk yields and good quality; the quality indicator levels of the cooked cocoons are greatly improved; the cleaning, strength and cohesion indexes are improved by more than or equal to one grade.

Owner:SHANGLIN ZHONGXING SILK

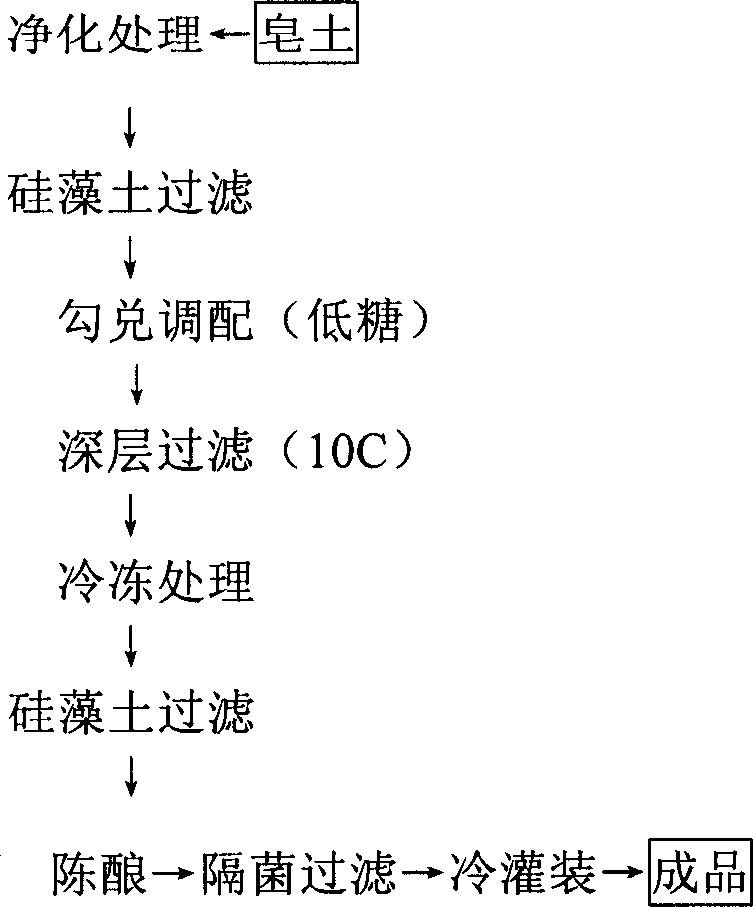

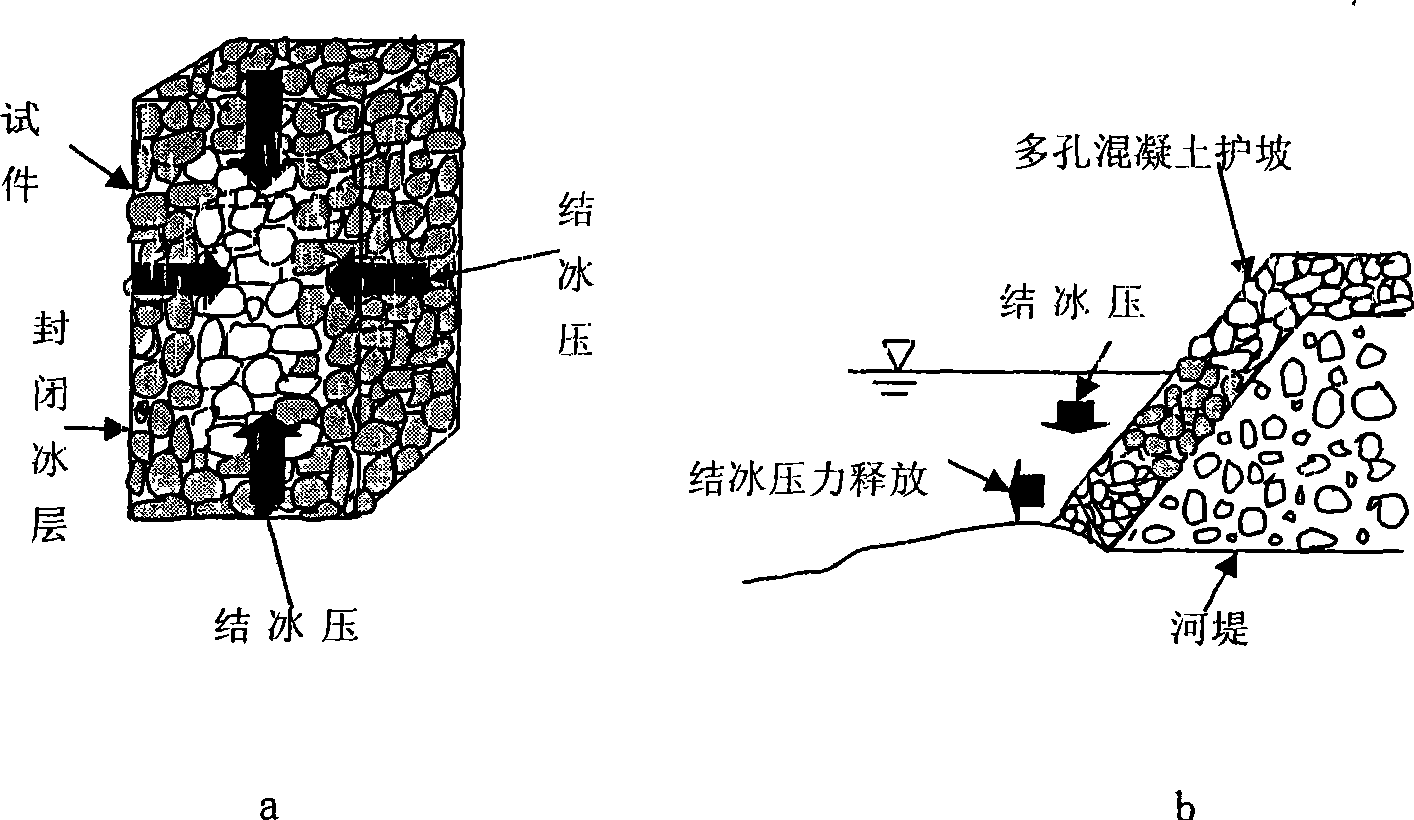

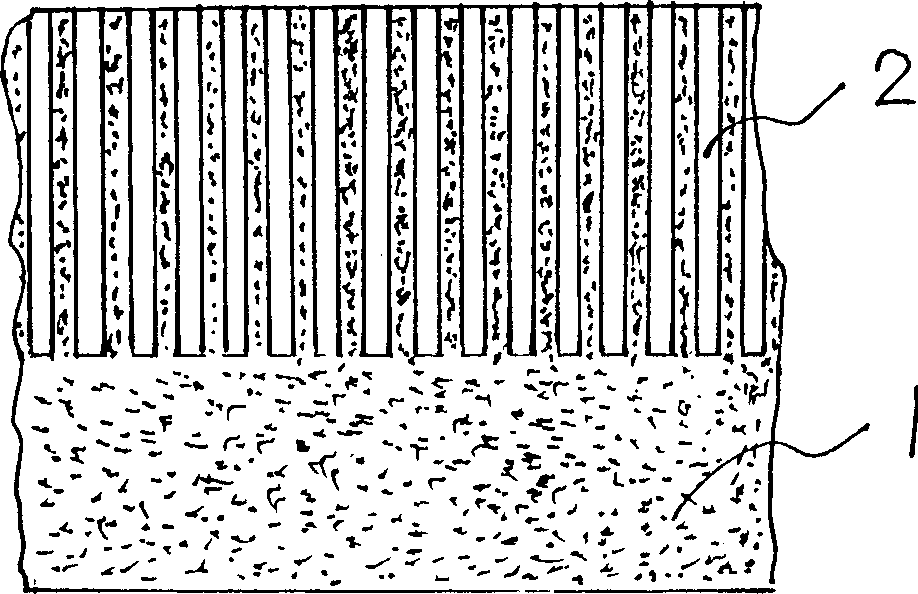

Method for testing dough recovery of ecological type porous concrete

InactiveCN101382535AFreeze Resistance EvaluationAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial testing goodsFreeze thawingExperimental methods

The invention relates to an experimental method for the frost resistance of ecotype cellular concrete, which adopts the cellular concrete fast freeze-thaw method to carry out evaluation on the frost resistance of the ecotype cellular concrete, generally, the test pieces are destroyed by above 100 times of freeze-thaw cycle, if the 'fast freeze method' is adopted, only a plurality of test pieces are destroyed, if the 'slow freeze method' is adopted, the test pieces are not destroyed by hundreds of cycle. Compared the 'fast freeze method' with and the 'slow freeze method', the cellular concrete fast freeze-thaw method can accurately and effectively evaluate the frost resistance of the cellular concrete, the cellular concrete fast freeze-thaw method experiment is characterized in that the icing pressure of the water with large volume in the voidage of the cellular concrete during the freezing process can be released to the unfreezed water, and the freeze-thaw process of the cellular concrete in natural environment is stimulated.

Owner:SOUTHEAST UNIV

Filling process for ice cream containing large-particle mixed material

The invention relates to a filling process of ice cream containing a large-particle mixed material. The filling process comprises the following steps: 1) preparing ice cream raw materials; 2) connecting the ice cream with an ice cream inlet of a particle adding machine from an outlet of a congelation machine through a pipeline, wherein the particle adding machine adopts an impeller for uniform feeding, setting the ratio of the speed of a feeding pump of the particle adding machine to the discharging speed of the congelation machine according to the mixing ratio of the material to the ice cream, and guiding the mixed material out from an outlet of a mixing cavity through spiral blades; 3) controlling the pressure of an outlet pipeline of the mixing cavity to be 0.2-0.3 Mpa, distributing materials at the tail end of the pipeline through a large-drift-diameter distributor, and outputting the materials through a filling gun rod; and (4) after the ice cream is poured, quickly freezing the ice cream, wherein the quick freezing temperature is -35 DEG C to -40 DEG C, and the freezing time is controlled to be 30-45 minutes. The process not only ensures that the texture and taste of the icecream reach the optimal state, but also can realize uniform mixing of large-particle materials and the ice cream.

Owner:杨皓翔

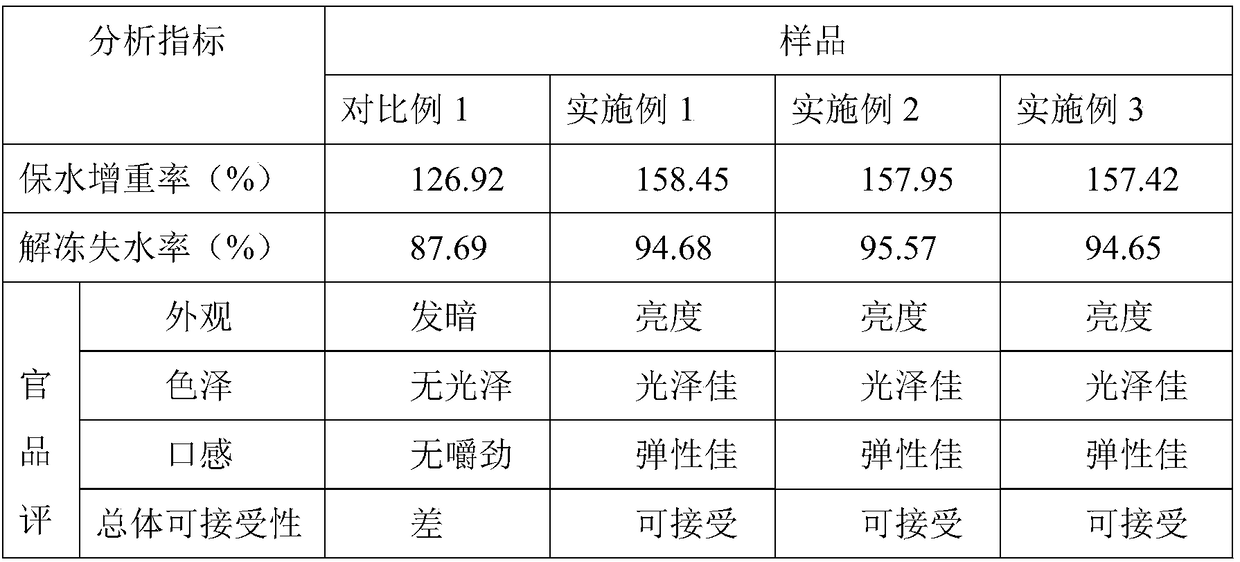

Method for improving frozen prepared fish fillets

The present invention discloses a method for improving frozen prepared fish fillets. The method comprises the following steps: step 1: selecting a fresh live fish, removing scales, head, internal organs and bones, cutting the fish into 2-3mm fillets, and conducting washing and draining; step 2, adding, in parts by mass, 1.5-2 parts of a compound fish fillet tissue improver into every 100 fish fillets, adding 1.0-1.2 parts of salt, 0.5-0.6 part of monosodium glutamate, 0.01-0.1 part of I+G, 0.08-0.15 part of white pepper powder, 3-8 parts of starch and 30-65 ice water, and conducting vacuum rolling and pickling; step 3, conducting vacuum packaging, and conducting pickling 12-16h; and step 4, fast freezing the fillets until the center temperature of the fish fillets is -18 DEG C or below, and conducting freezing storage. The method maintains the nutritional value, the flavor and the taste of the prepared fish fillets during freezing and transportation process. The fish fillets are extremely resistant to boiling, the cooked fish fillets are still fresh, the fish fillets are shrunk-proof and fuller, and the yield is increased. The fillets are slightly brittle and free from peculiar taste in mouth feel, have no loss of raw material nutrients, and are suitable for a plurality of cooking methods such as hot pot.

Owner:杭州众香科技有限公司

Copious cooling fast freezing infrared drying technology

InactiveCN109780821AImprove protectionNo pollution in the processDrying solid materials without heatLiquid waterFreeze-drying

The invention discloses a copious cooling fast freezing infrared drying technology and belongs to the technical field of chemical engineering and light industry machining. The copious cooling fast freezing infrared drying technology is characterized in that a gas turbine expanding refrigerating technology is adopted for performing copious cooling fast freezing on materials, compressed air at 0.5-0.9 Mpa is used, the initial air expanding pressure intensity ratio is 3-9, and fresh product vegetables and fruits and traditional Chinese medicinal materials except mineral drug are fast cooled to minus 20- minus 120 DEG C within 5-30 min, so that liquid water in a raw material organization structure fast solidifies, and becomes extremely micro ice crystal; and then, the materials are fed into aninfrared vacuum freezing drying bin to be heated, so that solid water in the materials sublimates into vaporous water, and the water content of the materials is lowered to 0-10%. The copious coolingfast freezing infrared drying technology has the characteristics of being high in freezing speed, low in cooling temperature, high in drying speed, uniform in material heating, uniform in material product quality and good in drying effect.

Owner:海尔生物医疗科技(成都)有限公司

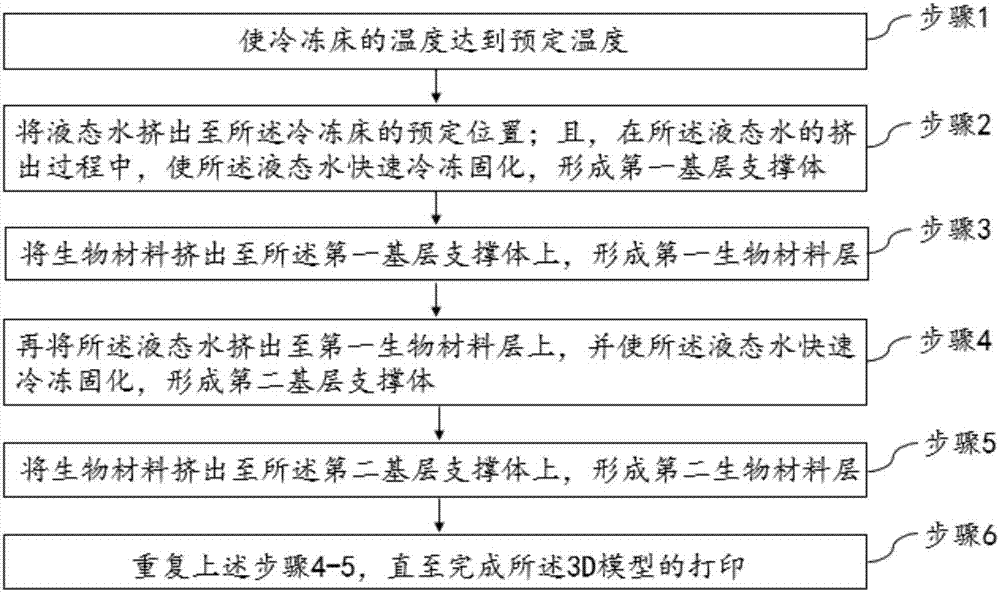

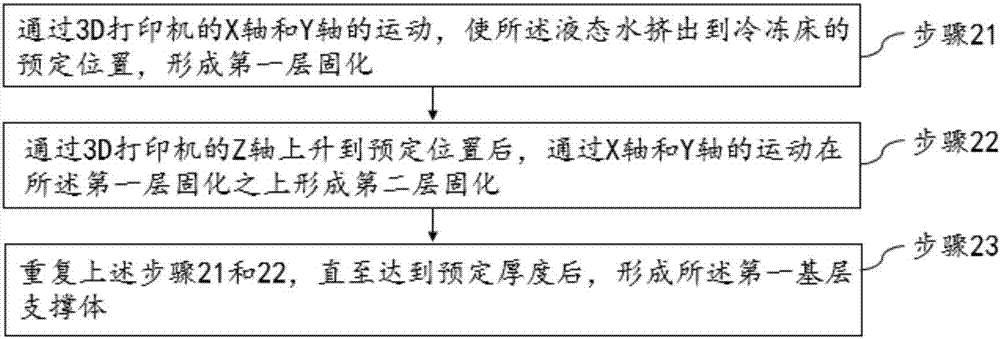

3D printing method

ActiveCN107267386AResolve cytotoxicitySolving technical problems of biorejectionAdditive manufacturing apparatusTissue/virus culture apparatusLiquid waterEngineering

The invention relates to the technical field of 3D printing, especially to a 3D printing method. The method comprises: step 1, allowing a refrigeration bed to reach a predetermined temperature; step 2, extruding liquid water to a predetermined position of the refrigeration bed, and during an extrusion process of liquid water, fast freezing the liquid water for solidification to form a first base support; step 3, extruding a biological material to the first base support to form a first biological material layer; step 4, extruding liquid water to the first biological material layer, and fast freezing the liquid water for solidification to form a second base support; step 5, extruding the biological material to the second base support to form a second biological material layer; and step 6, repeating the step 4 and 5 until printing of a 3D model is completed. According to the technical scheme, the technical problem of cytotoxicity and biological rejection due to a support material of 3D printing in the prior art is solved.

Owner:PARTICLE CLOUD BIOTECHNOLOGY (HANGZHOU) CO LTD

Refrigeration pretreatment method for shrimps

InactiveCN103431496AExtension of timeGuaranteed qualityFood preservationSaline waterPretreatment method

The invention relates to a refrigeration pretreatment method for shrimps. The method is characterized in that: the pretreatment method employs a shrimp pretreatment line for treating of the shrimps, the main steps of the method comprise a water spraying process, a water draining process, a freezing process and a vibration ice coating process; a salt brine with a concentration of 3%-4% is cooled to 0 DEG C-2 DEG C, and are uniformly sprayed over the shrimps which pass therebeneath; after water is drained, the shrimps are transported to a fast freezing apparatus with a temperature of -30 DEG C or less; and after fast frozen, the shrimps are put in a vibration ice coating apparatus of the shrimp pretreatment line, the vibration ice coating apparatus sprays potable water approximating mist or a salt brine with a concentration of 0-4% to the surface of the frozen shrimps for formation of ice coating. The whole pretreatment method helps to substantially improve the quality of the treated shrimps, and is beneficial to improvement on quality of the shrimps.

Owner:NANTONG SINROFREEZE EQUIP

Double-door refrigerator

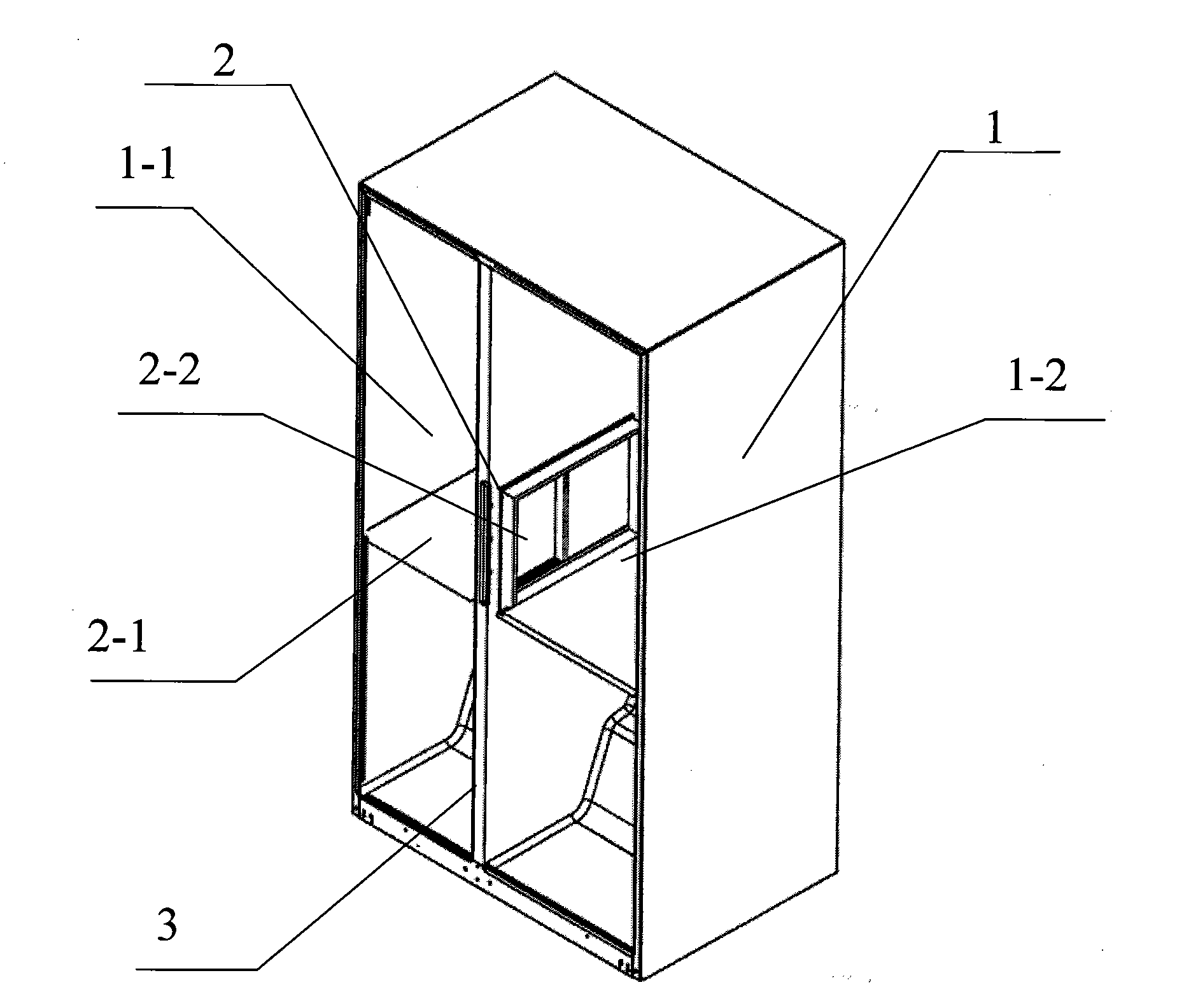

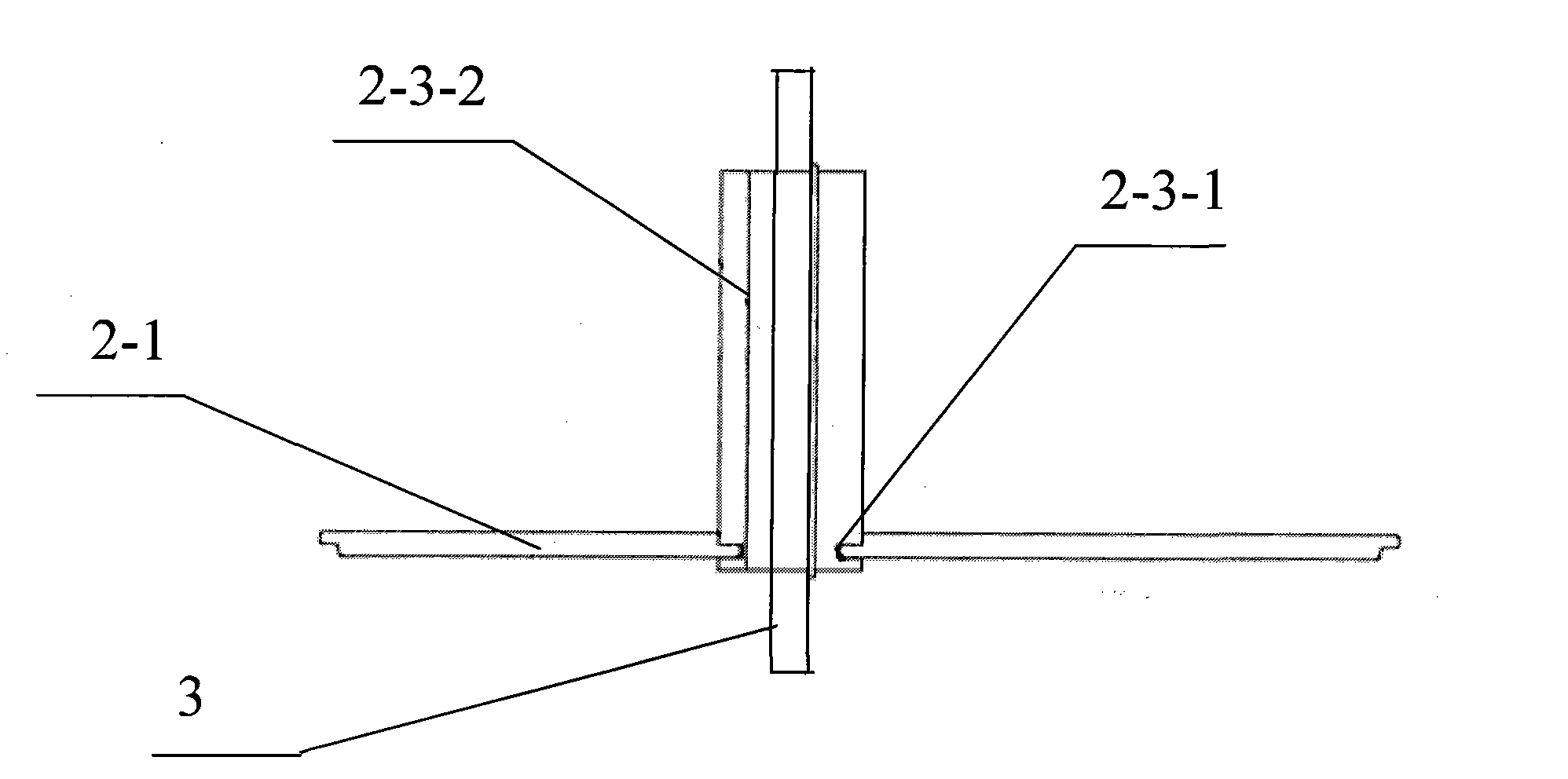

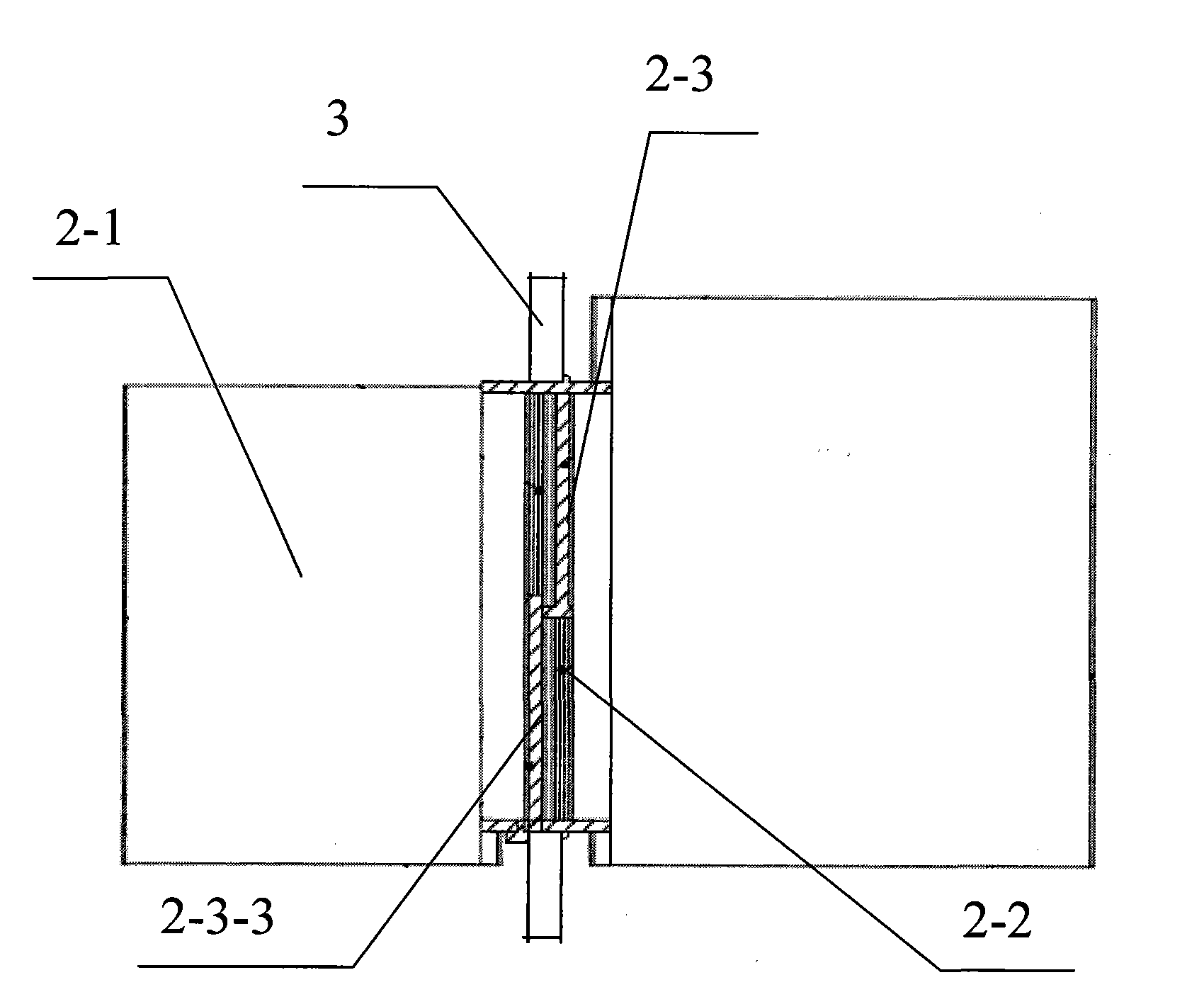

InactiveCN102080914AEasy to thawAvoid churnDomestic cooling apparatusLighting and heating apparatusCold airEngineering

The invention relates to a double-door refrigerator, comprising a refrigerating storage chamber, a refrigerating chamber and a heat insulating board and further comprising a communication device capable of communicating the refrigerating storage chamber with the refrigerating chamber, wherein the refrigerating storage chamber is isolated from the refrigerating chamber through the heat insulating board, the communication device is arranged on the heat insulating board and composed of a moving window and a guide part, the moving window is arranged on a guide rail of the guide part, shelves at left and right sides of the communication device are positioned on the same horizontal plane, one end of the shelf is installed inside a partition connecting part of the guide part while the other end of the shelf is installed on a housing of the refrigerator, the shelves are detachably connected with the communication device, and a baffle plate is arranged in front of the communication device. The double-door refrigerator can not only help users thaw and fast freeze food in the refrigerator, but also can prevent the loss of too much cold air, thereby saving energy.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Preparation method of low-agglomeration nanoscale tea powder

InactiveCN105724627ASolve powder agglomerationSolve the two major technical problems of nano-scale particlesPre-extraction tea treatmentPrillHigh energy

The invention relates to a preparation method of low-agglomeration nanoscale tea powder and belongs to the technical field of tea leaf processing.The preparation method includes: taking matcha, black tea or other tea; crushing tea leaves with a universal crusher, and crushing with a fluidized bed type airflow ultrafine grinder under a low temperature state; adding water to the ultrafine tea powder, and grinding with a high-energy nano ball mill; fast freezing the nano tea powder to below minus 25 DEG C, and continuously drying and sublimating under a vacuum state, sieving with a sieving machine, and bagging and sealing; or directly performing spraying drying on the nano tea powder to obtain the low-agglomeration nanoscale tea powder.By the preparation method, the two technological difficulties that traditional ultrafine tea powder is prone to agglomeration and cannot reach nano scale are solved.Compared with the prior art, the method has the advantages that sufficient cell wall breaking is achieved, the tea powder can reach nano scale, the absorption rate and dispersing effect of tea healthcare factors are increased at the same time, and the prepared tea powder is original in taste, capable of being dissolved and dispersed fast and widely applicable to food and beverage.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

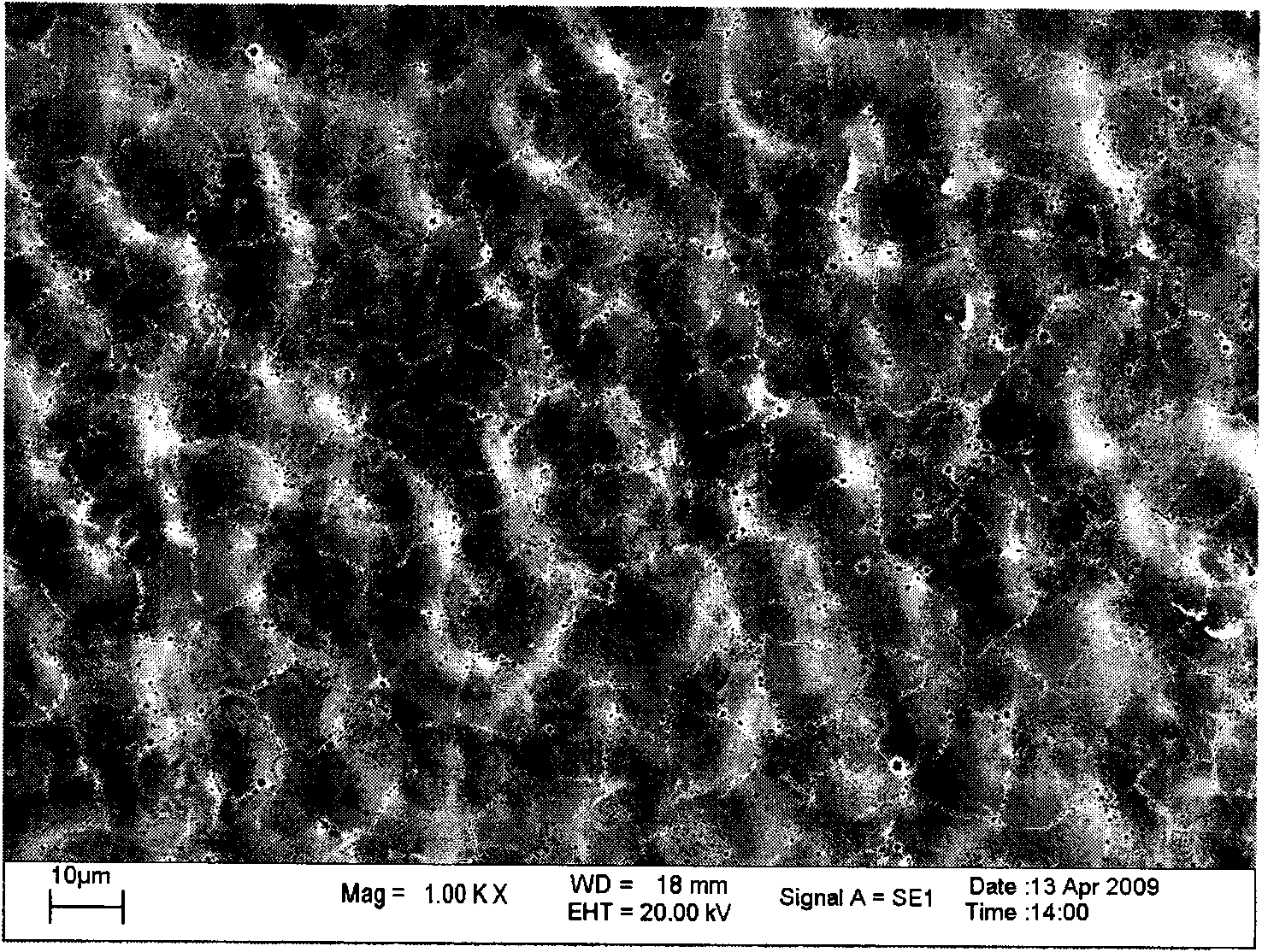

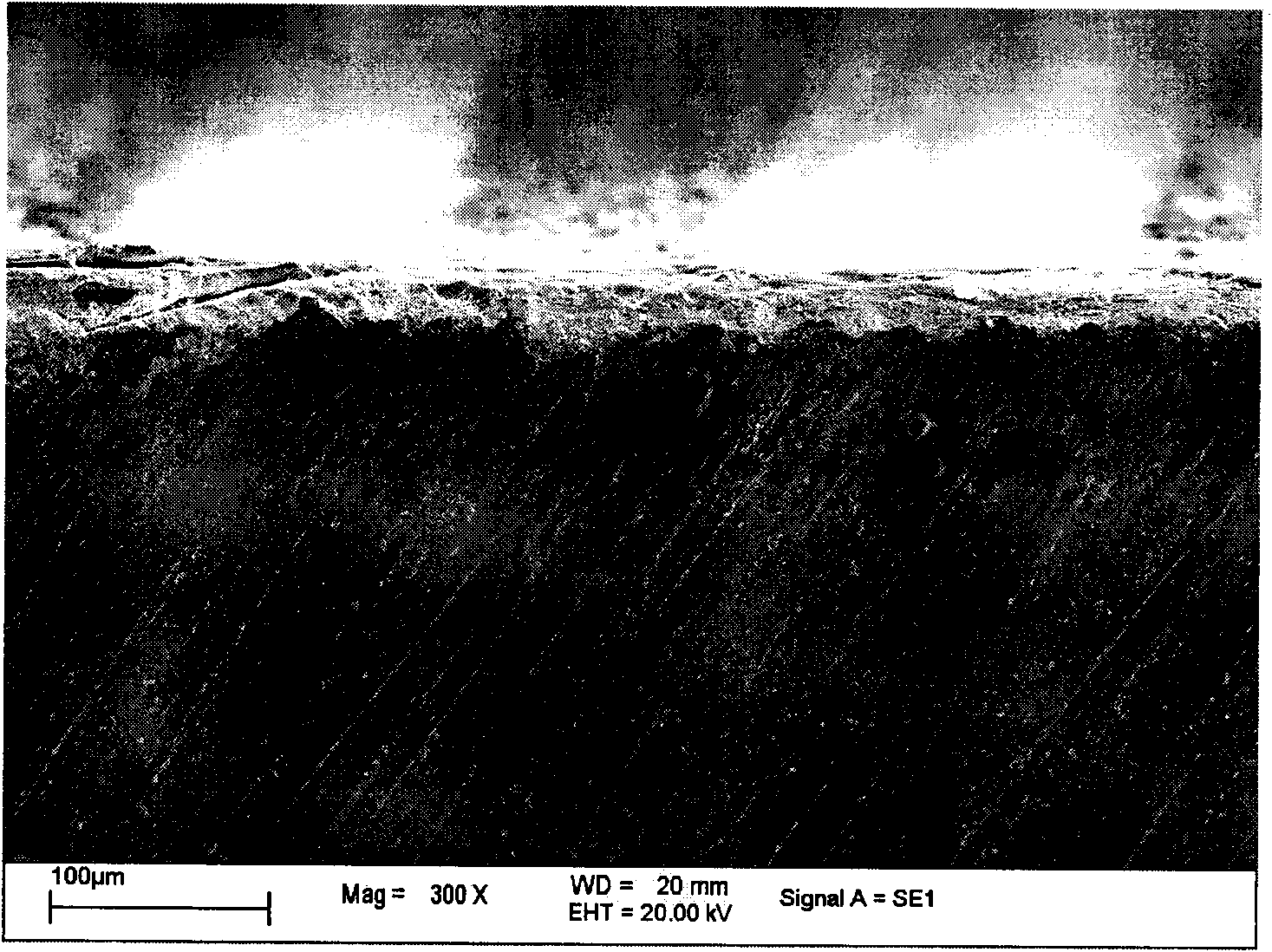

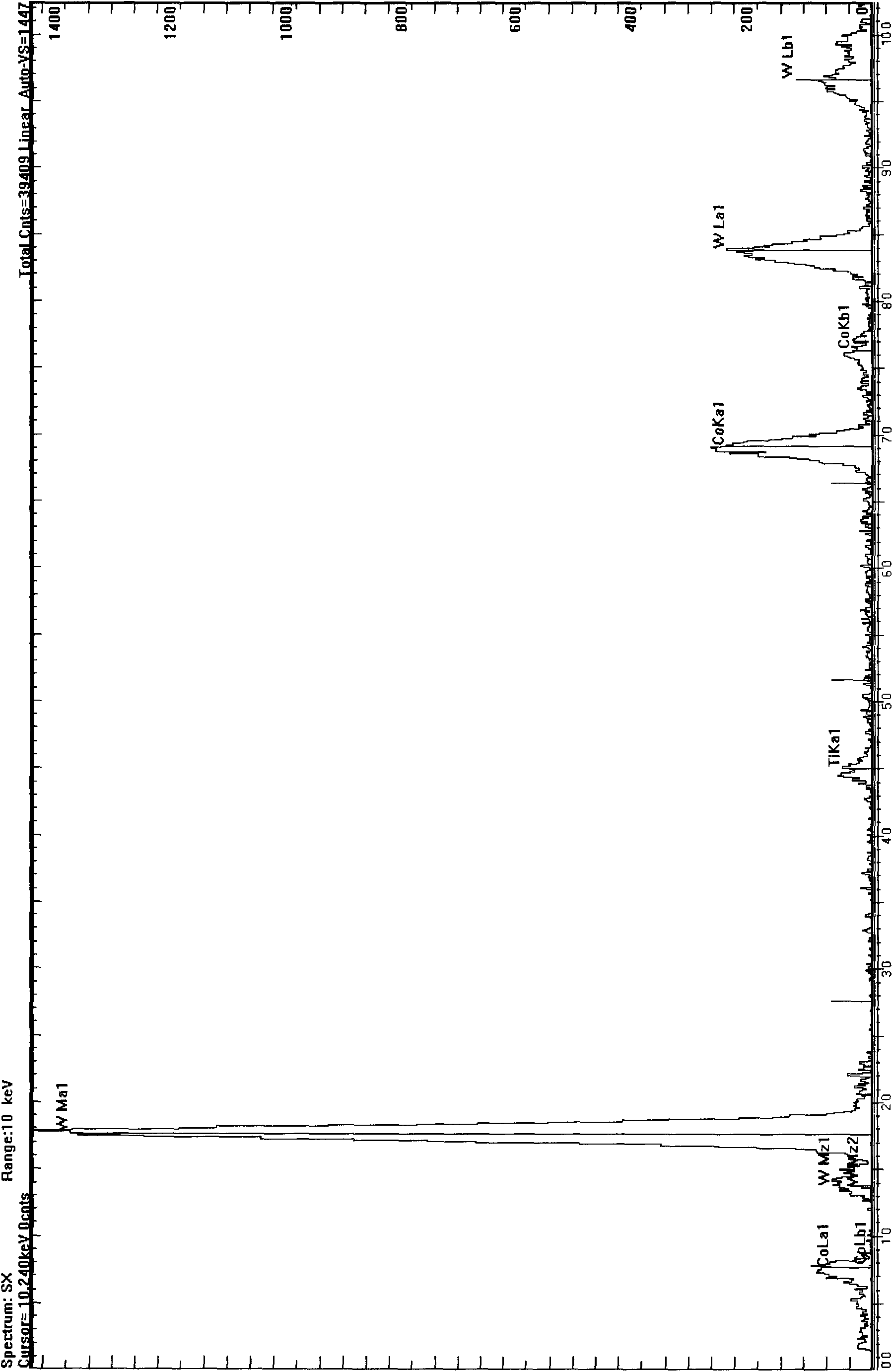

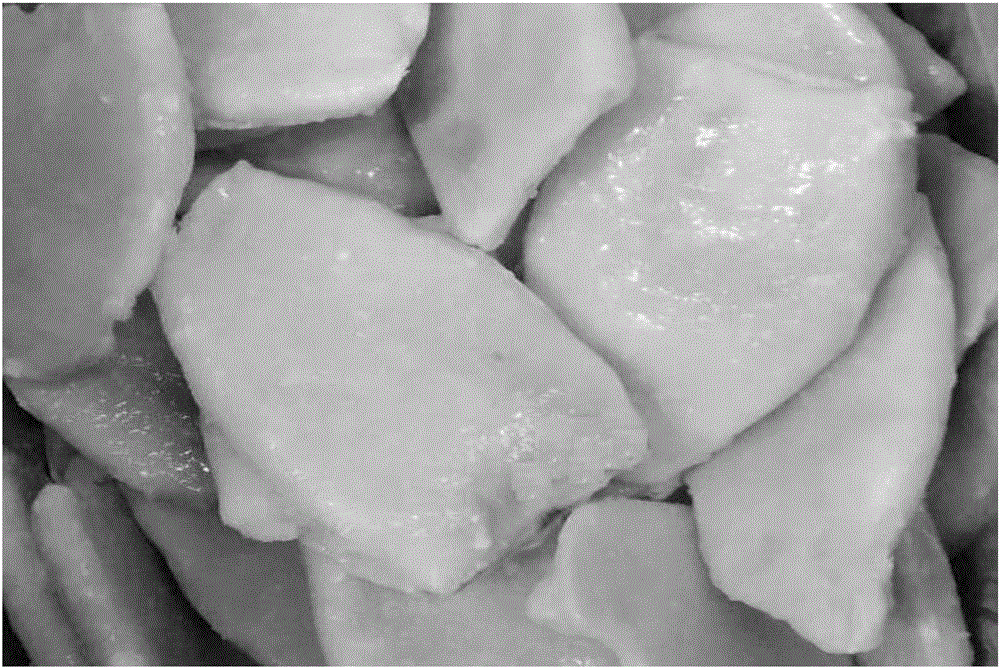

Technology method for pulse laser etching cobalt melting and fusing enhancing hard alloy

A technology method for pulse laser etching cobalt melting and fusing enhancing hard alloy relates to the laser surface processing technique of a hard alloy cutter and belongs to the technical field of the laser processing. The surface enhanced technology which is based on guaranteeing the toughness of the hard alloy appears in the practical production; generally coating is less than 10mu m; the bonding strength between the coating and the matrix of the hard alloy is lower; therefore, the service life of the hard alloy can not be substantially increased. The technology method carries out laseretching cobalt melting and fusing treatment on the external surface of the hard alloy (the mass percent of the cobalt is 10-30%); the wave length of the pulse laser is 248nm-1060nm; the power densityranges from 1.0*10<6>-9.9*10<7>W / cm<2>; the pulse width is 10 picosecond (ps)-90 nanosecond (ns); the numbers of the pulse is 10-500; and the pulse frequency is 1-20Hz. The thickness of the laser melting and fusing layer is 20-60mu m; the cobalt content in the melting and fusing layer is 3-9%; binder of Co, Ni, Cr and the like and matrix materials are of fast freezing tissues; and the hard alloycan be a cutter or a saw bit and used for processing materials such as metal, wood, etc.

Owner:BEIJING UNIV OF TECH

Watermelon enzyme and preparation method thereof

InactiveCN106307500AKeep the flavorRich in nutritional valueYeast food ingredientsNatural extract food ingredientsFiltrationSugar

The invention discloses a watermelon enzyme and a preparation method thereof. The preparation method of the watermelon enzyme comprises the following steps: separating watermelon peels and watermelon fleshes, and then separating white peels and green peels of the watermelon peels; pulverizing the green peels into watermelon green peel powder; fast freezing the watermelon fleshes, and cutting into fruit granules; fast freezing the white peels, and cutting into peel granules for later use; uniformly mixing the peel granules and the watermelon green peel powder, and performing enzymolysis reaction; mixing the enzymolysis product with the fruit granules to obtain a second mixture; alternately spreading white sugar and the second mixture, and performing primary fermentation to obtain a primary fermentation product; filtering the primary fermentation product to obtain a filtration product and a filtrate, fast freezing the filtration product, pulverizing, mixing with the filtrate, lemon powder and honey, performing secondary sealed fermentation, filtering, pasteurizing, and performing low-temperature preservation to obtain the watermelon enzyme finished product. According to the invention, different parts of a watermelon are subjected to the separation treatment and the multiple fermentation treatments through the method, thus obtaining the watermelon enzyme having a pure taste.

Owner:邓志翔

Method for producing frozen squid

ActiveCN106577979AImprove frost resistanceKeep freshMeat/fish preservation by freezing/coolingSodium lactateMANNITOL/SORBITOL

The invention provides a method for producing frozen squid. The method comprises S1 squid pretreatment: removing head, ear, cartilage, peel, lips and internal organs of squids, cleaning the squids, and carrying out drainage to obtain squid torsos, S2 squid torso soaking: soaking the squid torsos in an antifreezing agent aqueous solution for 4-8h, wherein the antifreezing agent comprises, by weight, 2 to 8 parts of Konjak refined powder, 1 to 4 parts of sodium polyacrylate, 0.5 to 2 parts of mannitol and 1 to 5 parts of sodium lactate, and S3 squid torso freezing: rapid cleaning the soaked squid torsos, draining the squid torsos, pre-freezing the squid torsos, and fast freezing the squid torsos at a fast freezing temperature of -38 to -45 DEG C to obtain frozen squids. The method belongs to the technical field of aquatic product processing, can remarkably improve the storage performance of the frozen squid, can reduce the loss of nutrients and flavoring substances during freezing and storage, and can maintain the freshness of the frozen squid.

Owner:广东环球水产食品有限公司

Fuel cell startup method for fast freeze startup

ActiveUS8835065B2Convenient timeMinimize timeFuel cell heat exchangeConverter typesFuel cellsStart time

A method for starting a cold or frozen fuel cell stack as efficiently and quickly as possible in a vehicle application is based upon a state of charge of a first power source such as a high voltage battery. Power flow between the first power source and fuel cell system is coordinated in conjunction with a specific load schedule and parallel control algorithms to minimize the start time required and optimize system warm-up.

Owner:GM GLOBAL TECH OPERATIONS LLC

Dried fermented meat and processing method thereof

InactiveCN105901554AGlossyLactobacillusFood ingredient as flavour affecting agentFermentationDried meat

The invention discloses dried fermented meat. Fermentation agents are used for fermenting pickled meat; the mould is filled with the fermented meat, the fermented meat is pressed into meat blocks, and is fast frozen under the condition of -18 DEG C; a slicing machine is used for cutting the frozen meat blocks into slices; after the low-temperature treatment on the meat slices, high-temperature curing is performed. The dried meat produced by the method provided by the invention has the advantages that the taste is unique; fragrant crispy and delicious effects are achieved; the mouthfeel is uniform and consistent; meanwhile, the fermented special fragrance is realized; the color is greasy and bright; the dried meat belongs to the novel supplement of leisure meat products.

Owner:CHACHA FOOD CO LTD

Processing and quality-keeping method capable of keeping natural color of purple yam for long time

InactiveCN105995742AEasy to storeConvenient for long-distance transportationFood freezingFood thermal treatmentMicroorganismChange color

The invention relates to a processing and quality-keeping method capable of keeping the natural color of purple yam for a long time. The method includes: cleaning purple yam tubers to remove dust and silt; using a knife or a bamboo chip to peel the purple yam tubers; cutting the peeled purple yam tubers into small pieces, cubes, slivers or slices; blanching, to be more specific, allowing the cut purple yam to pass a blanching water tank or a steam chamber with a conveying belt so as to inhibit enzyme activity and reduce microorganisms, wherein the temperature is kept at 90-100 DEG C and the blanching time is 1-3 minutes; draining water and mucilage attached to the purple yam; fast freezing the drained purple yam under 35-40 DEG C for 5-15 minutes to allow the internal temperature of the purple yam to reach 18 DEG C; then packaging the purple yam under 0-5 DEG C, and storing the purple yam under 18-25 DEG C. The processing and quality-keeping method has the advantages that manners such as blanching and draining are used to eliminate the activity conditions of enzyme and fast freezing fixing and cold storage are performed, so that the natural color and nutrition of the purple yam can be kept for a long time, and the purple yam does not change color and deteriorate in two years; the processed purple yam is delicious, sticky and tasty and refreshing after being cooked, and conditions are created for the large-scale development and utilization of the purple yam.

Owner:红河金城生物科技有限公司

Grinding method for producing fine ground medicinal materials

The invention provides a grinding method for producing fine ground medicinal materials and relates to the technical field of medicinal material smashing. The grinding method for producing the fine ground medicinal materials includes the following steps that raw material medicinal materials are picked and chosen, and cleaned to enter a drying processing device to be dried for standby use; the raw material medicinal materials after being dried enter an impacting type smashing unit to be smashed for 30 s and pass through a 40-mesh screen net; secondly; the raw material medicinal materials after rough screening enter a pre-cooling cavity to be pre-cooled for 3-5 min, till the temperature reaches -35 DEG C, the pre-cooled raw material medicinal materials enter a freezing bin to be fast frozen to -90 DEG C within 30 s; thirdly, the brittle raw material medicinal materials after being cooled enter an ultra low temperature smashing machine (filled with liquid nitrogen in advance), and are smashed under the ultra low temperature condition that the temperature is maintained at -90 DEG C; and fourthly, the materials after being smashed enter a cyclone separator to be separated, solid powder materials after being screened enter a storing tank, and finished products are obtained after packaging. The smashing effect is good, the operation cost of production can be lowered, meanwhile, losingof effective components can be effectively prevented, and the quality of the products is improved.

Owner:BOZHOU VOCATIONAL & TECHNICAL COLLEGE

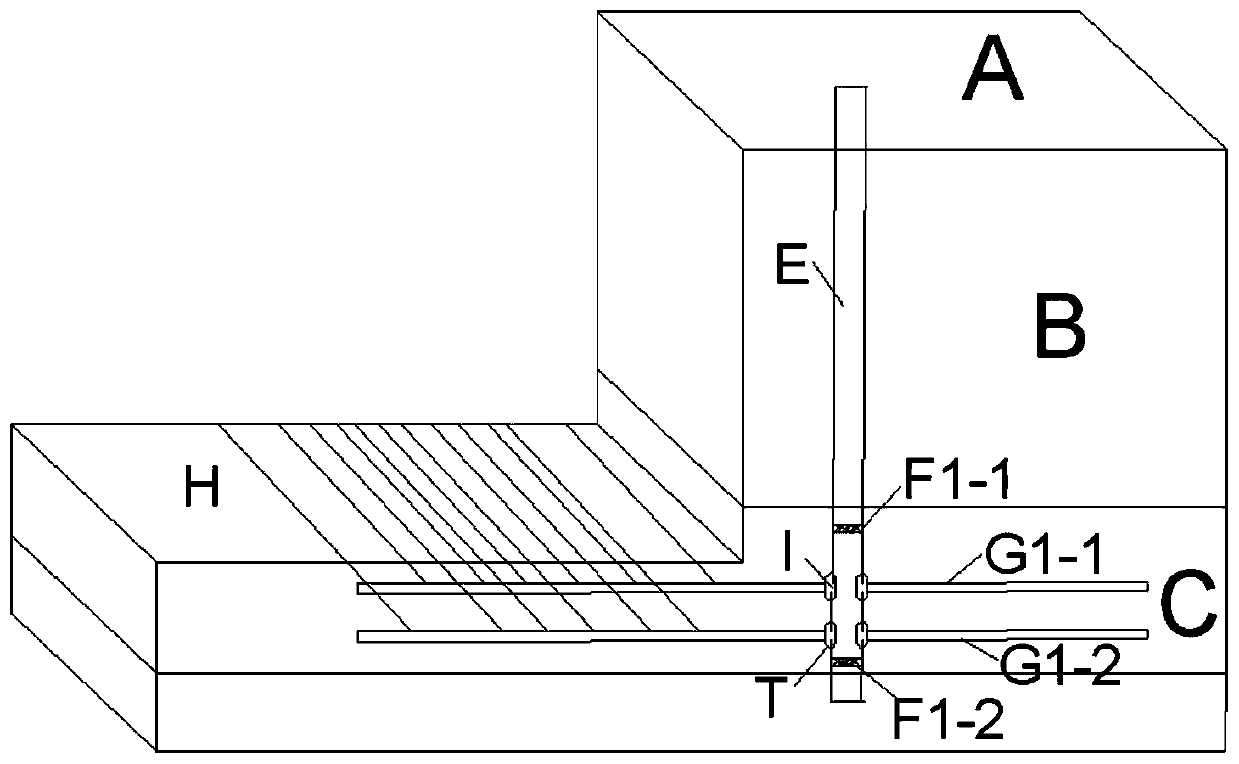

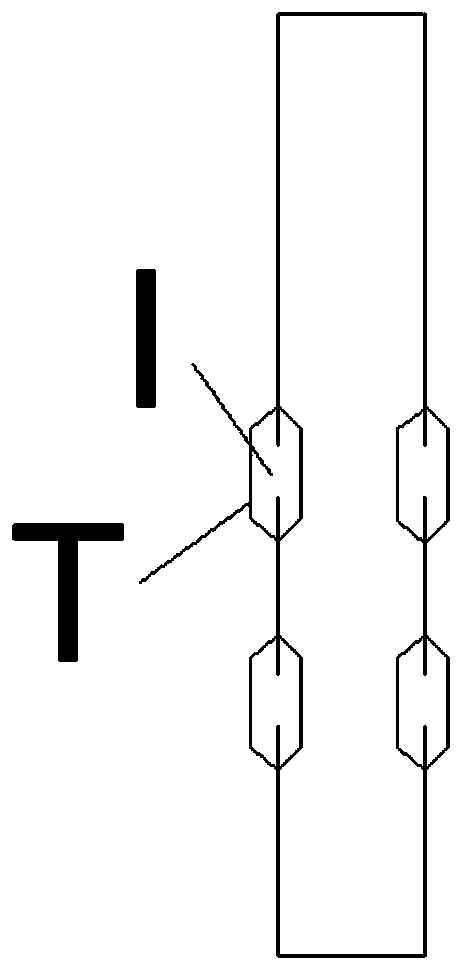

Freezing method of vertical hole treelike freezing wall

InactiveCN110735439ASolve the disadvantages of inconvenienceSolve the waste situationFoundation engineeringThermodynamicsEngineering

The invention relates to a freezing method of a vertical hole treelike freezing wall, and belongs to the technical field of freezing reinforcement. The freezing method comprises the following steps ofS1, drilling a through-layer drill to form a vertical hole on to-be-frozen ground; S2, installing a vertical freezing pipe reserved with a turning hole in the vertical hole; S3, carrying out self-advancing drilling to form a primary treelike branch drill hole along the direction of a required frozen layer through the turning hole reserved in the vertical freezing pipe at a required frozen layer section; S4, installing a primary treelike freezing pipe in the primary treelike branch drill hole; S5, carrying out lf-advancing drilling to form secondary treelike branch drill hole along the direction of the required frozen layer through a turning hole reserved in the primary treelike freezing pipeline; S6, installing a secondary treelike freezing pipe in the secondary treelike branch drill hole; S7, after the installation of the freezing pipes, installing a temperature insulation material according to the freezing requirement; and S8, checking pipeline installation and sealing conditions, and carrying out freezing construction and freezing temperature monitoring. The freezing method of the vertical hole treelike freezing wall realizes quick freezing and reduces unnecessary economic loss.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

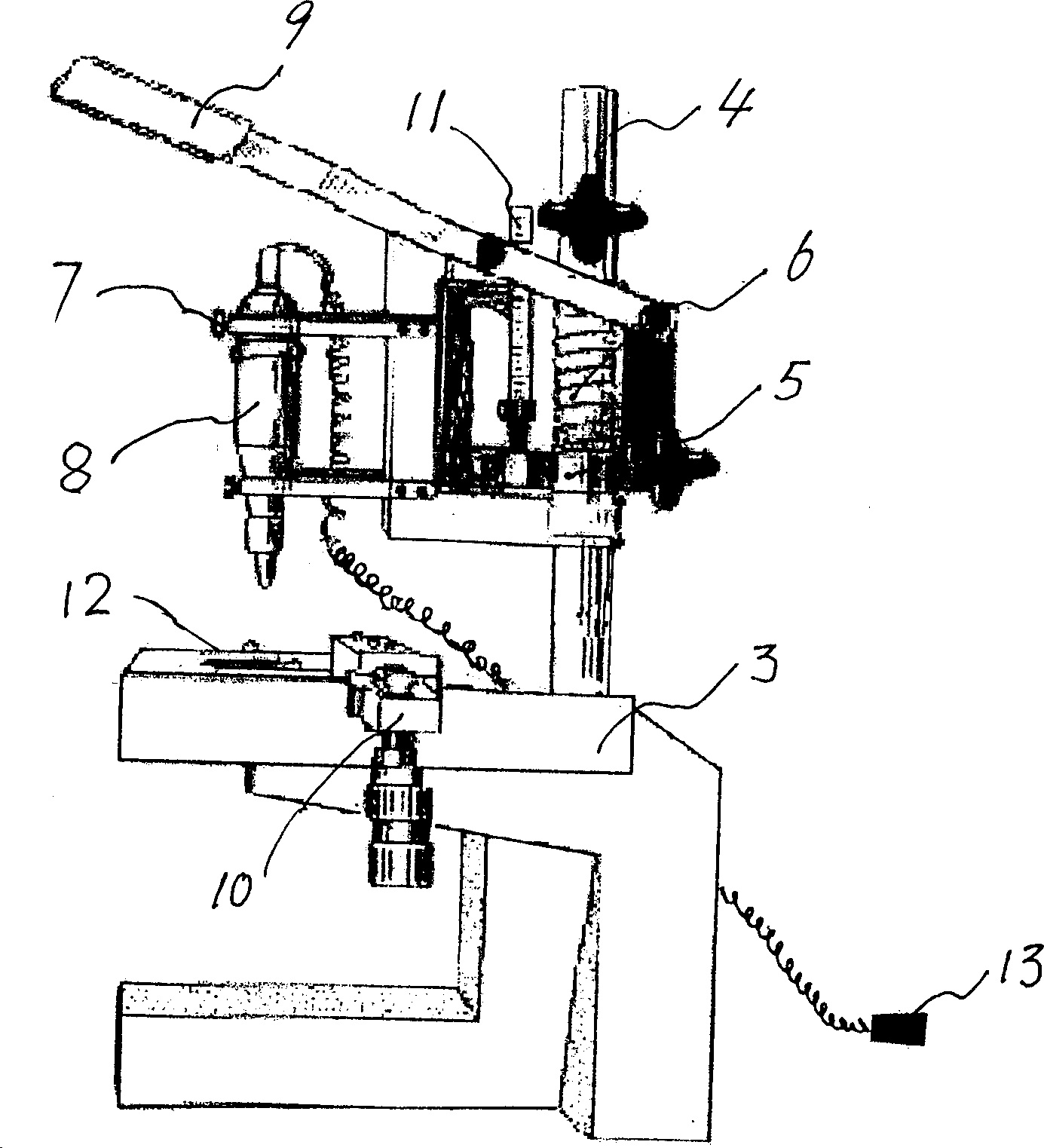

Special equipment for fabricating frozen tissue micro array carrier

InactiveCN1605849AReduce work intensityReduce sheddingPreparing sample for investigationEngineeringSmall hole

The present invention is apparatus specially for making frozen tissue micro array carrier, which has base body of freeze treated chicken gizzard with holes. The making process includes ultra-low temperature fast freezing fresh chicken gizzard in liquid nitrogen; shaping the fast frozen chicken gizzard in -35~-20 deg.c to form the base body; and drilling holes in the base body at -85~-75 deg.c. The special drilling apparatus may be a reformed drilling machine with base body fixture with coordinates and capable of moving horizontally. The present invention has frozen tissue micro array carrier with low cost, high density of holes and other advantages, and can produce great amount of detected specimens.

Owner:大连高新园区全国高技术产业化微生态中试基地

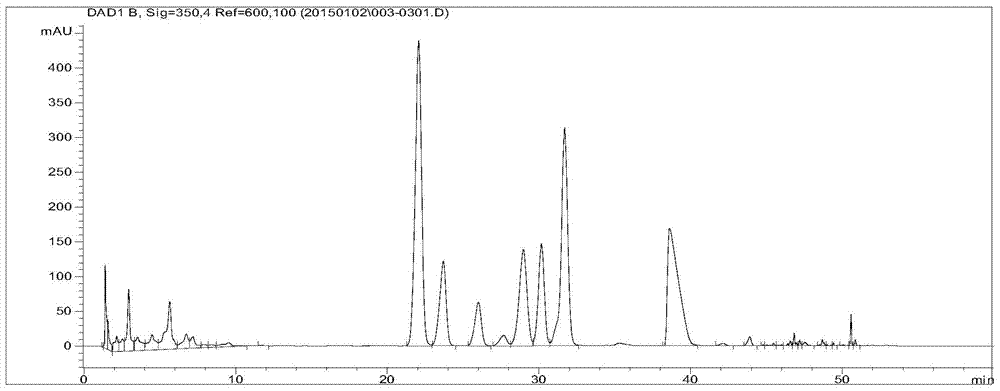

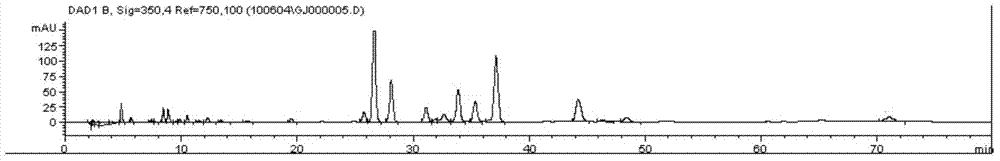

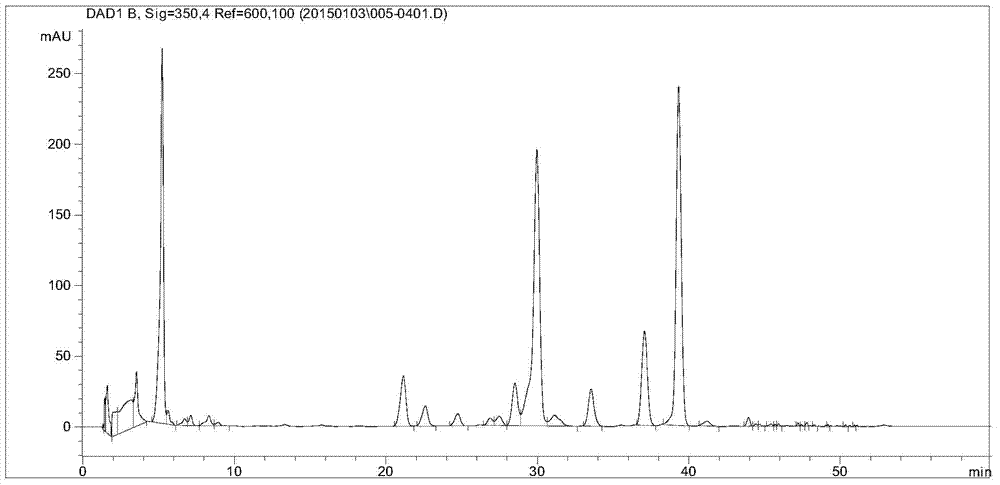

Method of measuring anthocyanins in ornamental Chinese flowering apple

The invention discloses a method of measuring anthocyanins in ornamental Chinese flowering apple and belongs to the field of flower measurement. The method includes the steps of 1, placing leaves of ornamental Chinese flowering apple which is fast-frozen with liquid nitrogen into a mortar, adding silica sand and insoluble PVPP, and adding liquid hydrogen before grinding to obtain powder; 2, transferring the powder into a test tube, adding anthocyanins extract, performing ultrasonic extraction at 45 DEG C for 60 minutes to obtain extracted anthocyanins liquid; 3, purifying the extracted anthocyanins liquid, centrifuging at the speed of 12000 / m for 3 minutes to obtain supernate, and loading the supernate in an Agilent feeding bottle for HPLC detection; 4, feeding a sample, subjecting the Agilent feeding bottle to HPLC-DAD, and acquiring results of measurement of anthocyanins in ornamental Chinese flowering apple. The method has the advantages that extraction time is short, less than 2h, the problem that measurement results are affected after the extract is placed overnight for a long period of time is solved, and in terms of computer practice, time is saved greatly and unnecessary waste of reagents is reduced.

Owner:BEIJING UNIV OF AGRI

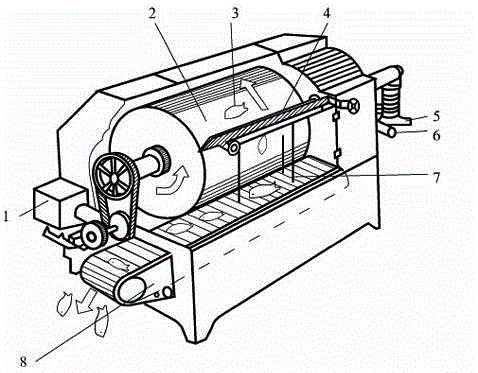

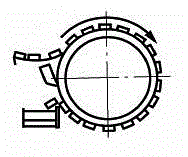

Roller type freezing device

InactiveCN104522840ACompact structureSmall footprintFood preservationEngineeringMechanical engineering

The invention discloses a roller type freezing device which aims at solving the problems of large occupied area and difficult transferring in the existing belt-type fast freezing device. The roller type freezing device is characterized in that a horizontal roller is arranged in a freezing chamber and is fixed on a hollow rotating shaft; the rotating shaft is driven by power; one end of the rotating shaft is provided with a refrigerant feeding pipe, and the other end of the rotating shaft is provided with a refrigerant outlet which is positioned in the roller; a refrigerant discharging pipe is arranged at one side of the roller and one side of the freezing chamber, close to the refrigerant feeding pipe; the outer wall of the roller is the freezing surface; a space for containing food is formed between the outer wall of the roller and the inner wall of the freezing chamber; a feeding hole of the food is formed in the side wall of the freezing chamber; a fed material conveying belt is arranged at the feeding hole and is positioned in the rotating tangential direction of the roller; a first scraping knife along the axial direction of the roller is arranged between the outer wall of the roller and the inner wall of the freezing chamber; the surface of the first scraping knife is vertical to the rotating tangent plane of the roller; and a discharged material conveying belt is arranged in the freezing chamber and under the first scraping knife.

Owner:CHONGQING QINFA FOOD

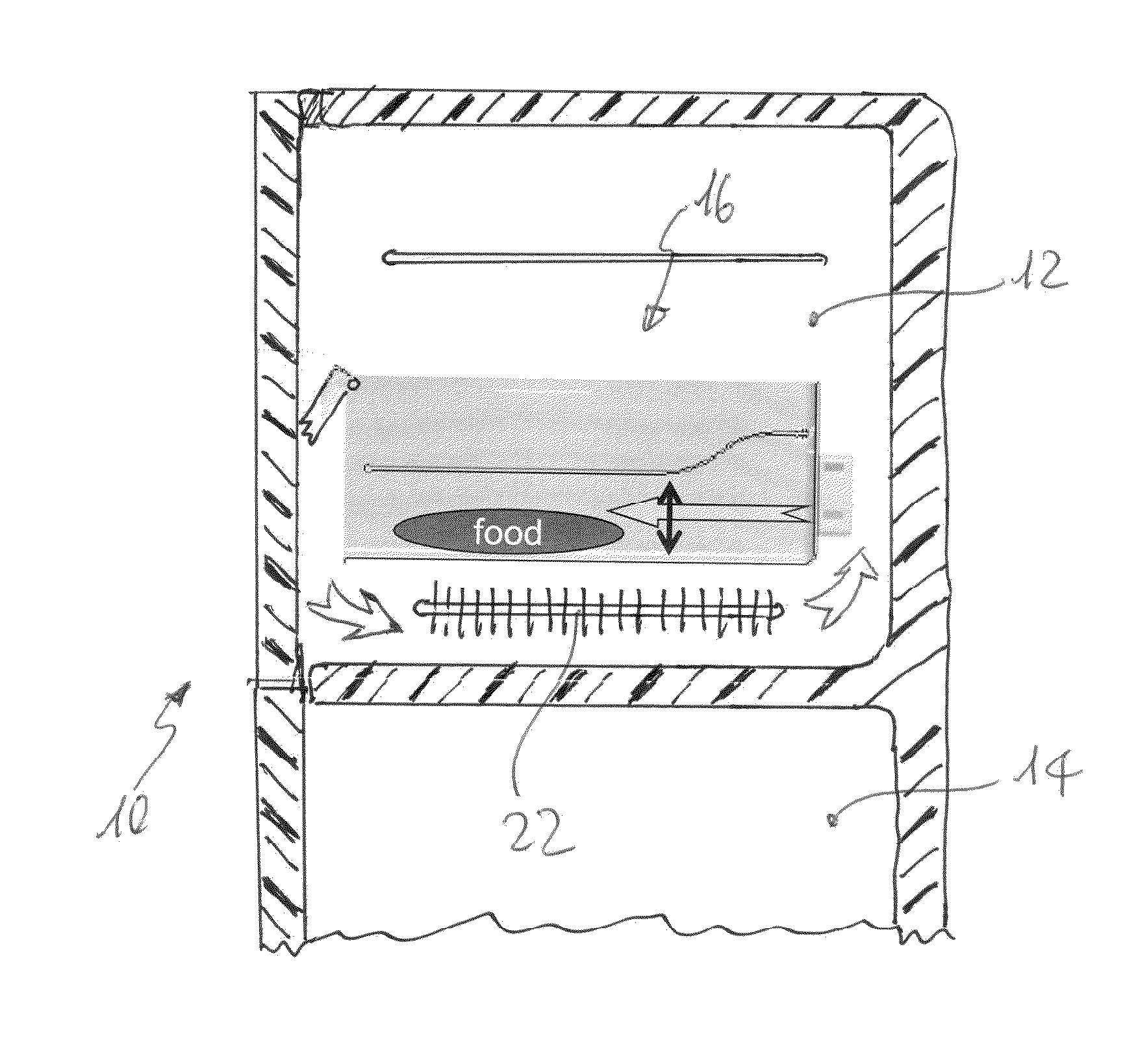

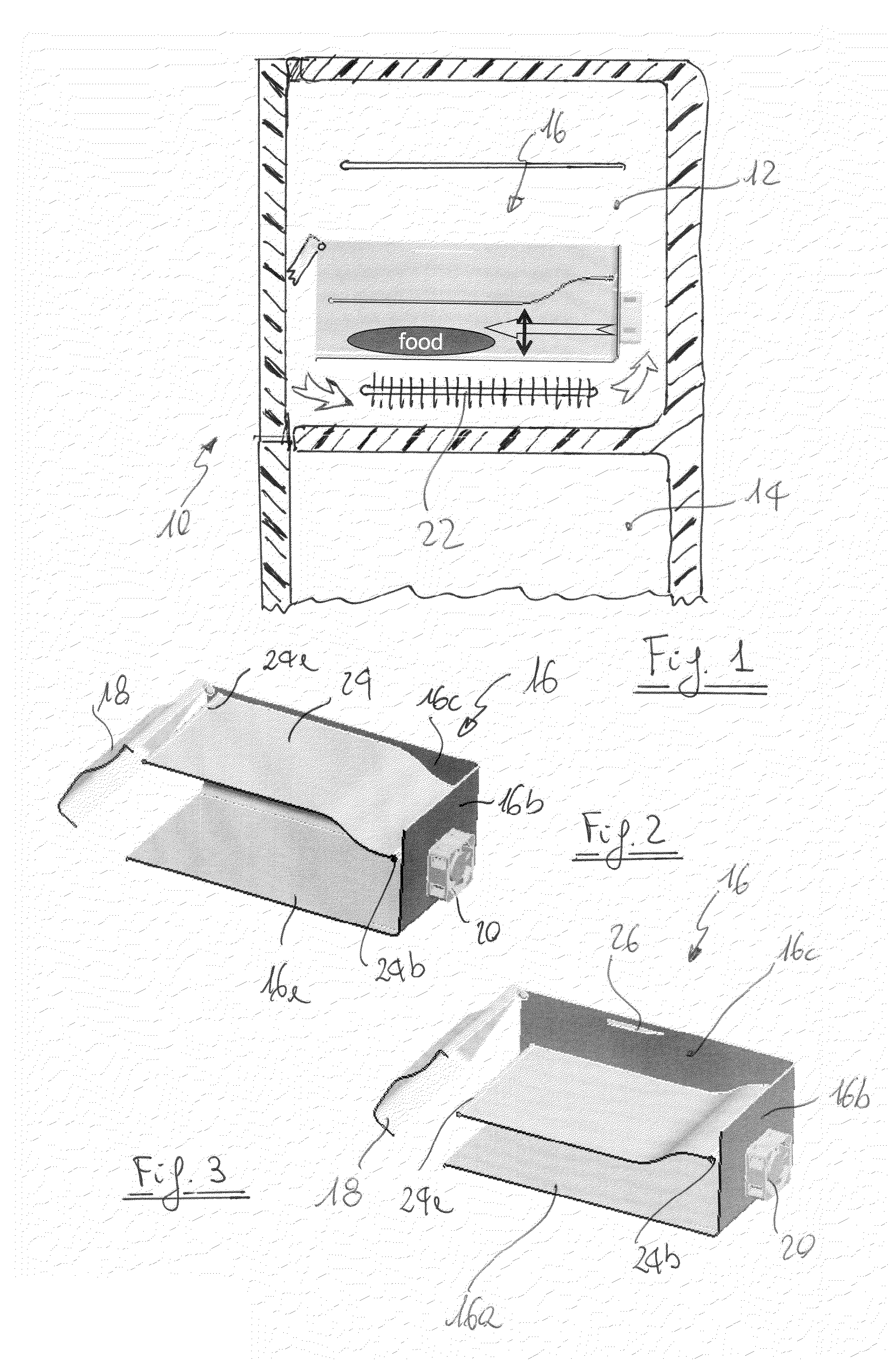

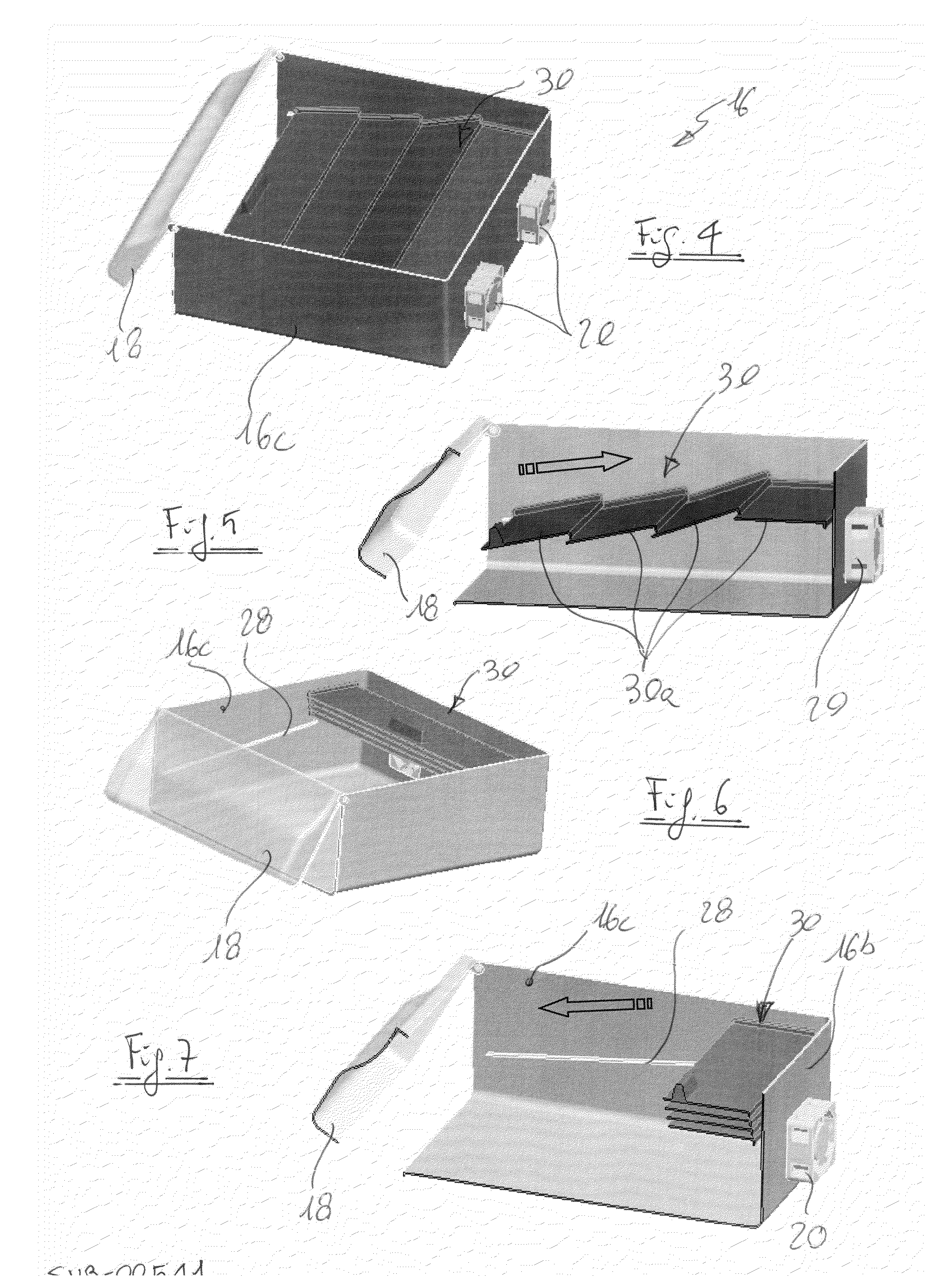

Adjustable shelf to be accomodated in freezer compartment to improve cooling process speed

InactiveUS20140152158A1Simply and cheap can be producedShorten the timeShow cabinetsLighting and heating apparatusCold airFresh food

A refrigerator with a fast freeze compartment is disclosed. The refrigerator comprises a no frost freezer compartment and a fresh food compartment. The refrigerator has a fast freeze compartment disposed within the fresh food compartment in which a food item can be placed, wherein the fast freeze compartment comprises an adjustable baffle adapted to change the cross section area of the air passage. The refrigerator further has a fan configured to propel cold air toward the fast freeze compartment, wherein the fast freeze compartment has a rear wall provided with at least one fan and a front swinging door, the adjustable baffle being located between side walls.

Owner:WHIRLPOOL CORP

Preparation method of high-calcium organic fertilizer

The invention relates to a preparation method of high-calcium organic fertilizer. The preparation method is characterized in that the low-temperature freeze drying technology is used to perform fast freeze drying on harvested Sedum aizoon L. which is a special plant extremely high in calcium content, the loss of calcium contained in the Sedum aizoon L. is prevented to a maximum extent, the calciumions contained in the Sedum aizoon L. are allowed to keep a free state, and accordingly the calcium ions can be easily absorbed and utilized by crops; the dried Sedum aizoon L. obtained after the freeze drying is crushed into power of 60-100 meshes to obtain high-calcium powder; according to different application manners, the high-calcium powder is added into thoroughly-decomposed farm manure toobtain base fertilizer, is directly added into edible fungi or soilless culture substrates to obtain high-calcium powder fertilizer or is soaked into water to obtain high-calcium liquid fertilizer after dregs are filtered and removed; high-calcium fertilizer produced according to organic standards is organic high-calcium fertilizer.

Owner:张晓峰

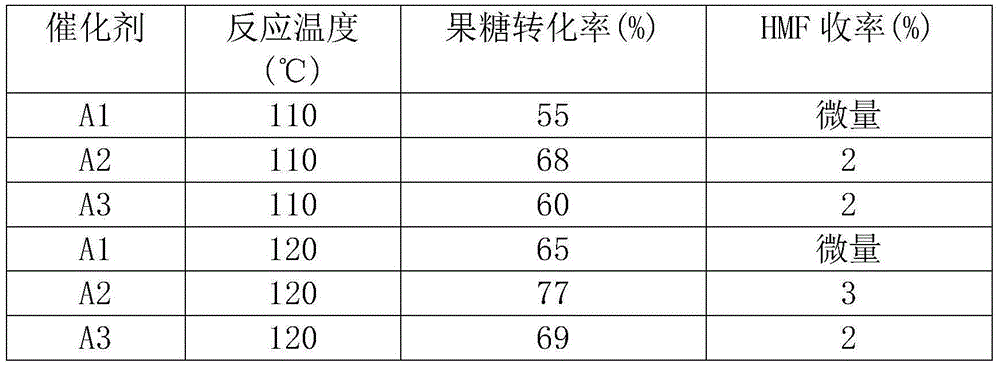

Method for preparing 5-hydroxymethylfurfural through fructose dehydration catalyzing

The invention relates to a method for preparing 5-hydroxymethylfurfural through fructose dehydration catalyzing. The method specifically comprises the steps that fructose is adopted as a raw material, a polar solvent is adopted as a reaction medium, boron-cerium compound oxide is adopted as a catalyst, reacting is carried out under mild conditions, and a high-yield target product is obtained. According to the boron-cerium compound oxide, a boron-containing compound and a cerium-containing compound are mixed and dissolved in a certain solvent, after the solvent is removed through rotary evaporation, solids are obtained through fast freeze drying, and then high-temperature roasting is carried out in air to obtain a solid oxide material. The catalyst synthesis method is simple, boron-cerium compound solid oxide is used for catalyzing fructose dehydration, 5-hydroxymethylfurfural is prepared, high activity and selectivity are shown under the mild conditions, and good application prospects are achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com