Method for improving frozen prepared fish fillets

A technology for frozen conditioning and fish fillets, which is applied in food science and other directions, can solve the problems of being easily broken, not forming, losing brittleness, and becoming smaller, so as to achieve a slightly brittle taste, no peculiar smell, no loss of raw material nutrition, and increased yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

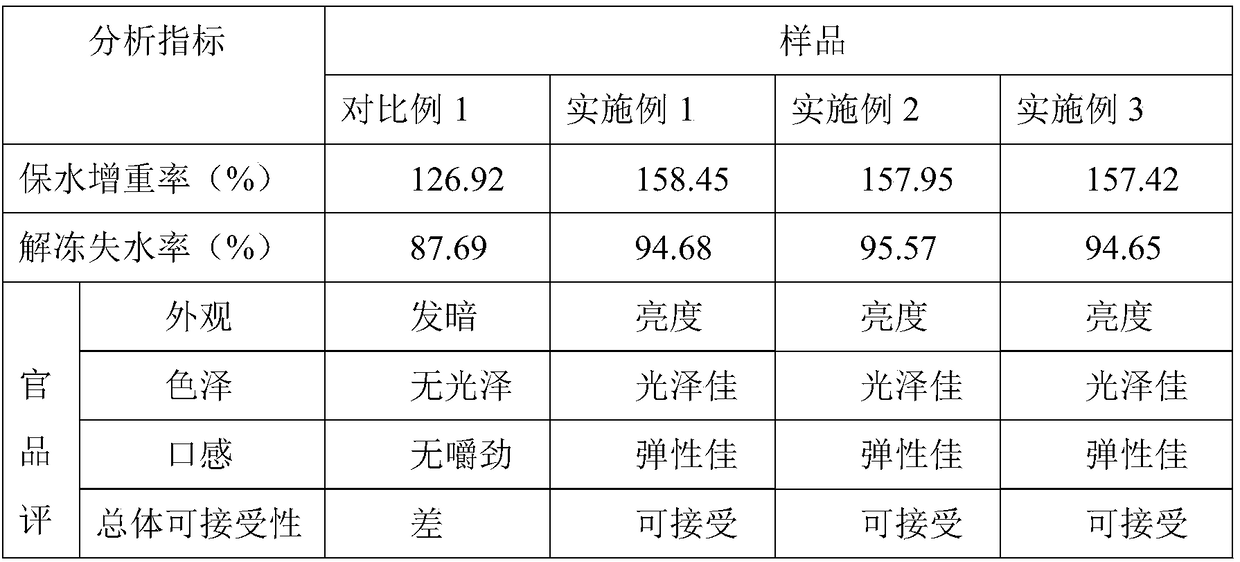

Examples

Embodiment 1

[0026] A method for improving frozen conditioning fish fillets, comprising the steps of:

[0027] Step 1. Raw material processing: select fresh black fish, remove the scales, head, viscera and bones, cut into 2-3mm fillets, wash and drain, and set aside;

[0028] Step 2, rolling and marinating: take 100 parts by mass of fish fillets, add 1.5 parts by mass of compound fish fillet tissue improver, then add 1.0 parts by mass of salt, 0.5 parts by mass of monosodium glutamate, 0.01 parts by mass of I+G, and 0.08 parts by mass of white Pepper powder, 3 parts by mass of starch, 30 parts by mass of ice water, vacuum tumbling and marinating for 15min at a speed of 2r / min; wherein, the compound fish fillet tissue improver includes the following components: 25 parts by mass of sodium carbonate, 16 parts by mass of Parts of sodium bicarbonate, 11 parts by mass of sodium citrate, 10 parts by mass of sodium tripolyphosphate, 5 parts by mass of sodium hexametaphosphate, 15 parts by mass of ...

Embodiment 2

[0034] A method for improving frozen conditioning fish fillets, comprising the steps of:

[0035] Step 1. Raw material processing: select fresh dragon fish, remove the scales, head, viscera, and bones, cut into 2-3mm fillets, wash and drain, and set aside;

[0036] Step 2, rolling and marinating: take 100 parts by mass of fish fillets, add 2 parts by mass of compound fish fillet tissue improver, then add 1.2 parts by mass of salt, 0.6 parts by mass of monosodium glutamate, 0.1 parts by mass of I+G, and 0.15 parts by mass of white Pepper powder, 8 parts by mass of starch, 65 parts by mass of ice water, vacuum tumbling and marinating for 15min at a speed of 2r / min; wherein, the compound fish fillet tissue improver comprises the following components: 33 parts by mass of sodium carbonate, 25 parts by mass of Parts of sodium bicarbonate, 23 parts by mass of sodium citrate, 15 parts by mass of sodium tripolyphosphate, 12 parts by mass of sodium hexametaphosphate, 17 parts by mass of...

Embodiment 3

[0040] A method for improving frozen conditioning fish fillets, comprising the steps of:

[0041] Step 1. Raw material processing: select fresh black fish, remove the scales, head, viscera and bones, cut into 2-3mm fillets, wash and drain, and set aside;

[0042] Step 2, rolling and marinating: take 100 parts by mass of fish fillets, add 1.5 parts by mass of compound fish fillet tissue improver, then add 1.2 parts by mass of salt, 0.6 parts by mass of monosodium glutamate, 0.05 parts by mass of I+G, and 0.1 parts by mass of white Pepper powder, 5 parts by mass of starch, 50 parts by mass of ice water, vacuum-tumbled and marinated for 15 minutes at a speed of 2r / min; wherein, the composite fish fillet tissue improver comprises the following components: 30 parts by mass of sodium carbonate, 20 parts by mass Parts of sodium bicarbonate, 16 parts by mass of sodium citrate, 12 parts by mass of sodium tripolyphosphate, 10 parts by mass of sodium hexametaphosphate, 16 parts by mass o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com