Technology method for pulse laser etching cobalt melting and fusing enhancing hard alloy

A cemented carbide and pulsed laser technology, applied in the field of laser processing, can solve the problems of not being able to greatly improve the service life of cemented carbide and low bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] (1) The grade of the cemented carbide to be processed is S4X7, which is a tungsten-cobalt-titanium cemented carbide. The typical application of this cemented carbide is a turning tool and a saw blade for cutting metal. The size of the material is length × width × height: 10 × 7×4mm, the surface is cleaned with alcohol before laser irradiation to remove the sundries and oil stains on the surface;

[0012] (2) The pulsed laser adopts a 248nm excimer laser with a pulse width of 25ns. The optical path of the laser beam is adjusted, and the laser beam is perpendicular to the workpiece, that is, the incident angle is 0°;

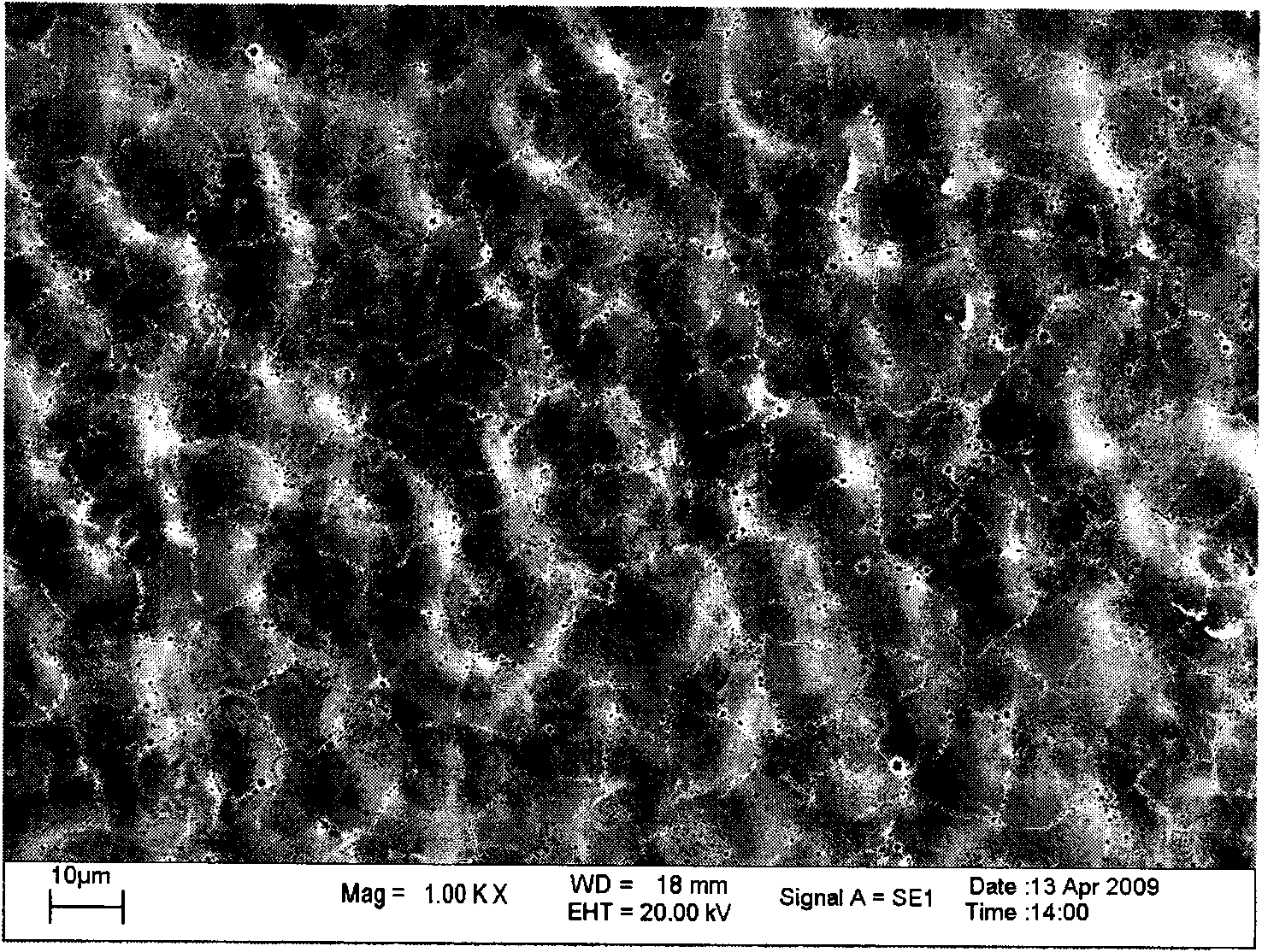

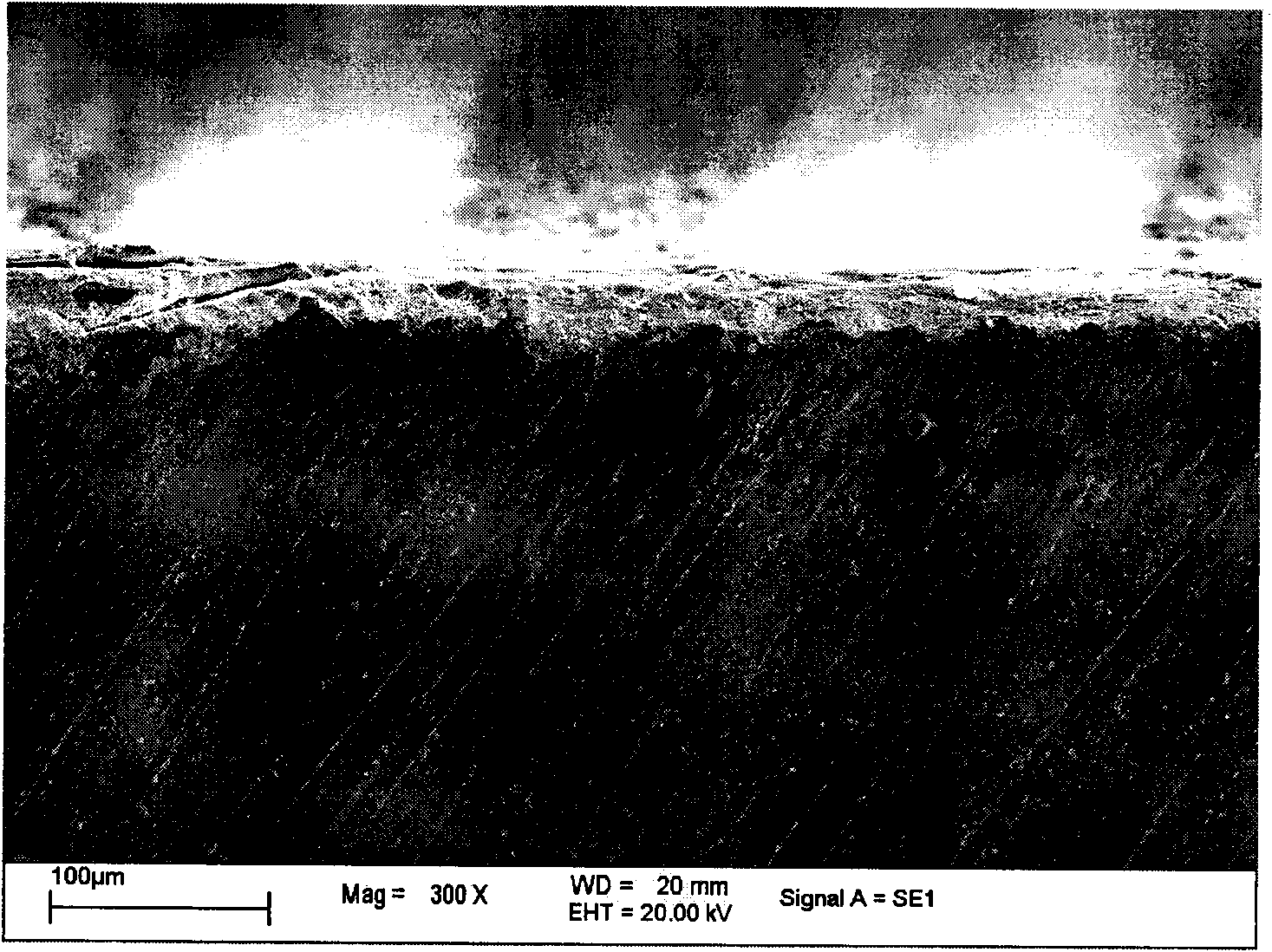

[0013] (3) The size of the laser beam obtained by shaping and homogenizing technology is 7×5 mm, and the laser beam of this size is used for laser irradiation in the tool tip area, and the power density of the laser is 9.9×10 7 W / cm 2 , the number of laser treatment pulses is 500, the laser pulse frequency is 20Hz, and a laser melting zone of 7×5mm is obta...

Embodiment 2

[0017] (1) The grade of the cemented carbide to be processed is Kcr06, which is a tungsten-cobalt cemented carbide. The typical use of this cemented carbide is turning tools or saw blades. The size of the material is 10.5×3.4×3.0mm. Clean the surface with alcohol before to remove the sundries and oil stains on the surface;

[0018] (2) The pulsed laser adopts a 1060nm YAG solid-state laser with a pulse width of 90ns, adjusts the optical path of the laser beam, and the incident angle of the laser beam relative to the workpiece is 45°;

[0019] (3) The laser beam is used to scan the area of 3.4×4.0mm at the tip of the tool, and the power density of the laser is 1.0×10 6 W / cm 2 , the number of pulses for laser processing is 10, and the laser pulse frequency is 10Hz;

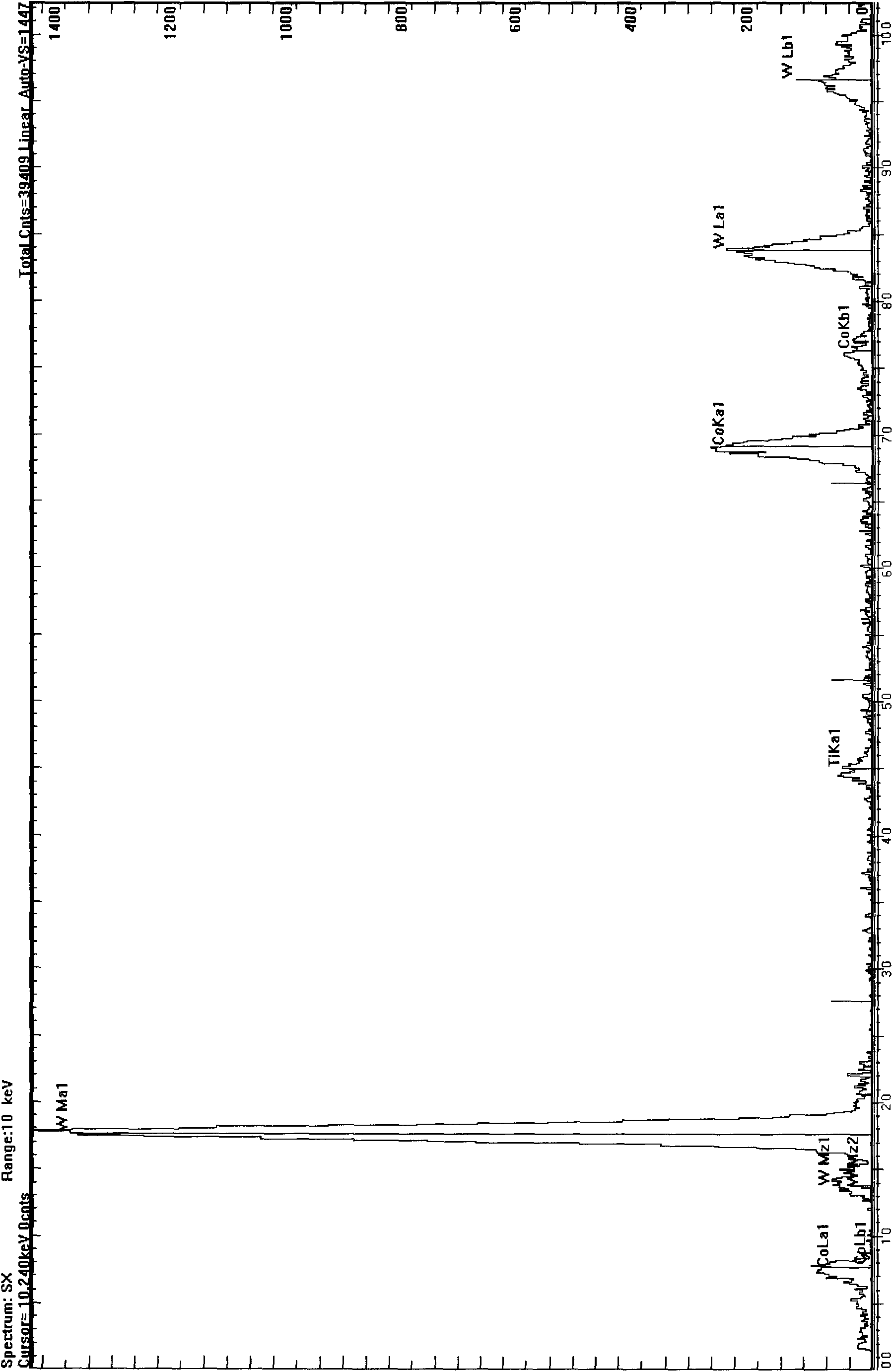

[0020] (4) Carry out quality inspection on the product after laser treatment, carry out EDS energy spectrum analysis to the cobalt content of cemented carbide before and after laser melting, the mass percentage ...

Embodiment 3

[0023] (1) The grade of the cemented carbide to be processed is Jcs03D, which is a cobalt-chromium-nickel-tungsten cemented carbide. The typical use of the cemented carbide is turning tools and saw blades. The typical size of the material is 10.5×3.4 in length×width×height ×3.0mm, the surface is cleaned with alcohol before laser irradiation to remove the sundries and oil stains on the surface;

[0024] (2) The pulse laser adopts a picosecond laser with a wavelength of 532nm and a pulse width of 15ps. The optical path of the laser beam is adjusted, and the incident angle of the laser beam relative to the workpiece is 20°;

[0025] (3) The laser beam is used to scan the area of 3.4×4.0mm at the tip of the knife, and the power density is 2.5×10 7 W / cm 2 , the number of laser treatment pulses is 300, the laser pulse frequency is 1KHz, and a laser melting zone of 3.4×4.0mm is obtained on the blade surface;

[0026] (4) Carry out quality inspection of the products after laser tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com