Method for altering metal surface color with ultra-short pulse laser

An ultra-short pulse laser and metal surface technology, which is applied in laser welding equipment, metal processing equipment, metal material coating technology, etc., can solve the problems of difficult to achieve color diversity and easy peeling of color layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below:

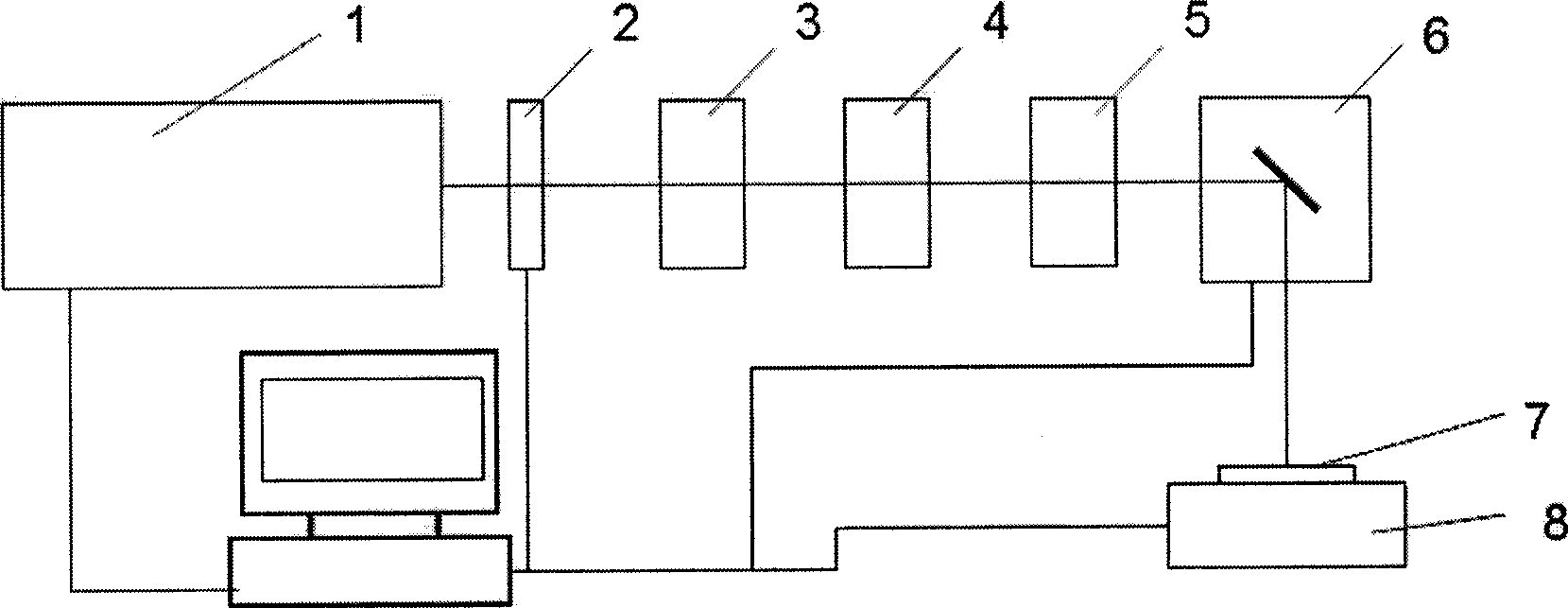

[0022] The selected metal materials should first be polished to obtain a bright and clean surface. According to different samples, various polishing processes such as mechanical polishing, chemical polishing, and vibration polishing can be used. The polished metal sample is placed on the translation stage 8, such as figure 2 shown. The pulsed laser light emitted by the ultrashort pulse laser 1 passes through the shutter 2 , the light intensity adjuster 3 , the spatial light intensity shaper 4 , the light polarization adjuster 5 , and the optical focusing system 6 in sequence, and then acts on the metal sample 7 .

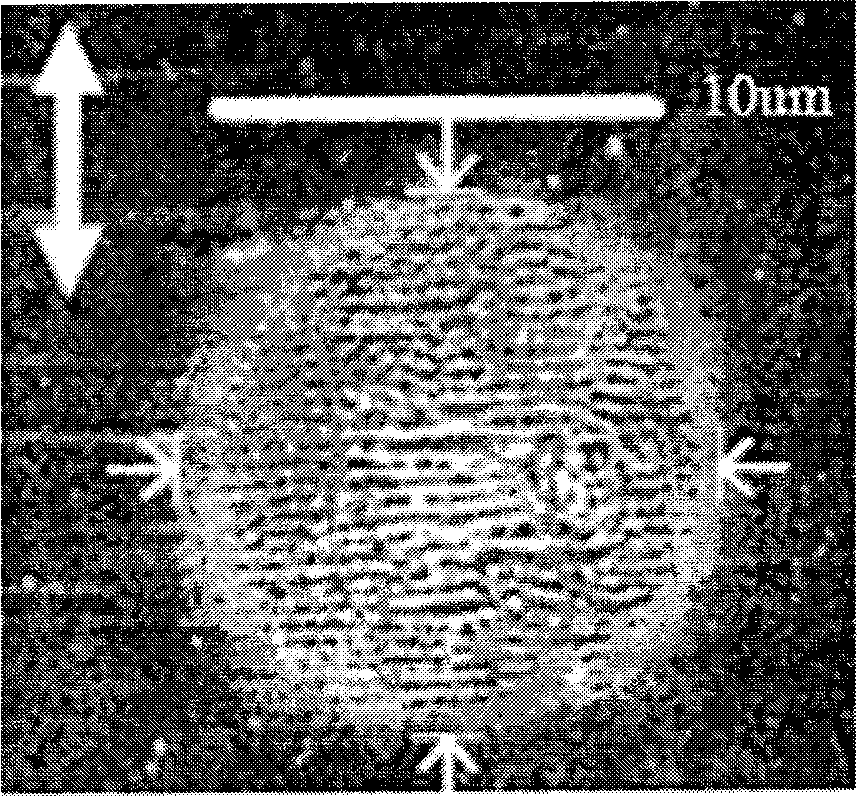

[0023] The metal sample in this embodiment is titanium, and the titanium sample is placed under a femtosecond pulsed laser. The femtosecond pulsed laser selected in this embodiment has a center wavelength of 800nm, a bandwidth of 80nm, a pulse width of 15fs, and vertical linear polarization. A 200mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com