Special equipment for fabricating frozen tissue micro array carrier

A tissue microarray and special equipment technology, which is applied in the preparation of test samples and other directions, can solve the problems of high efficiency and high accuracy of medical research, difficulty in making high-density array carriers, and easy detachment of sample tissue points. To avoid the loss of sample tissue points, the production process is simple, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

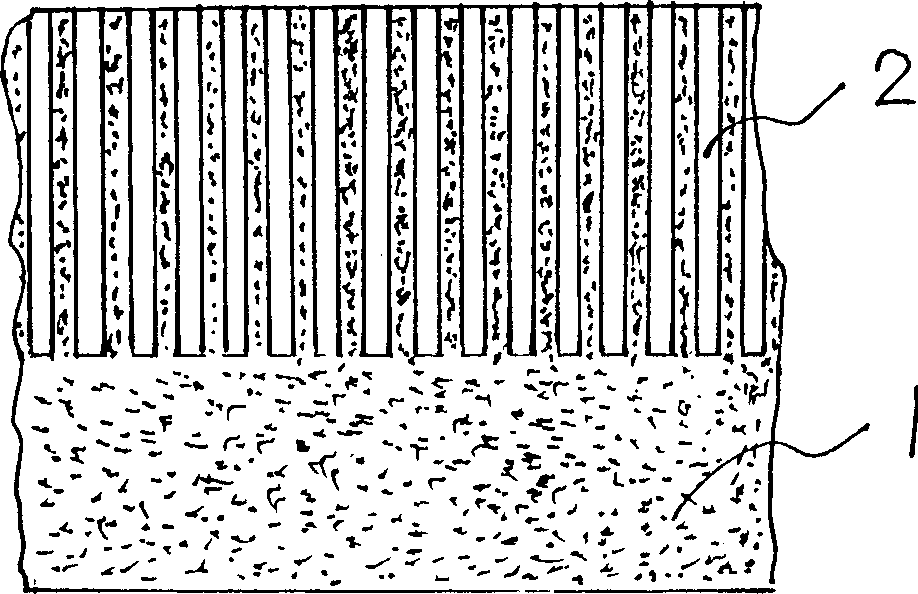

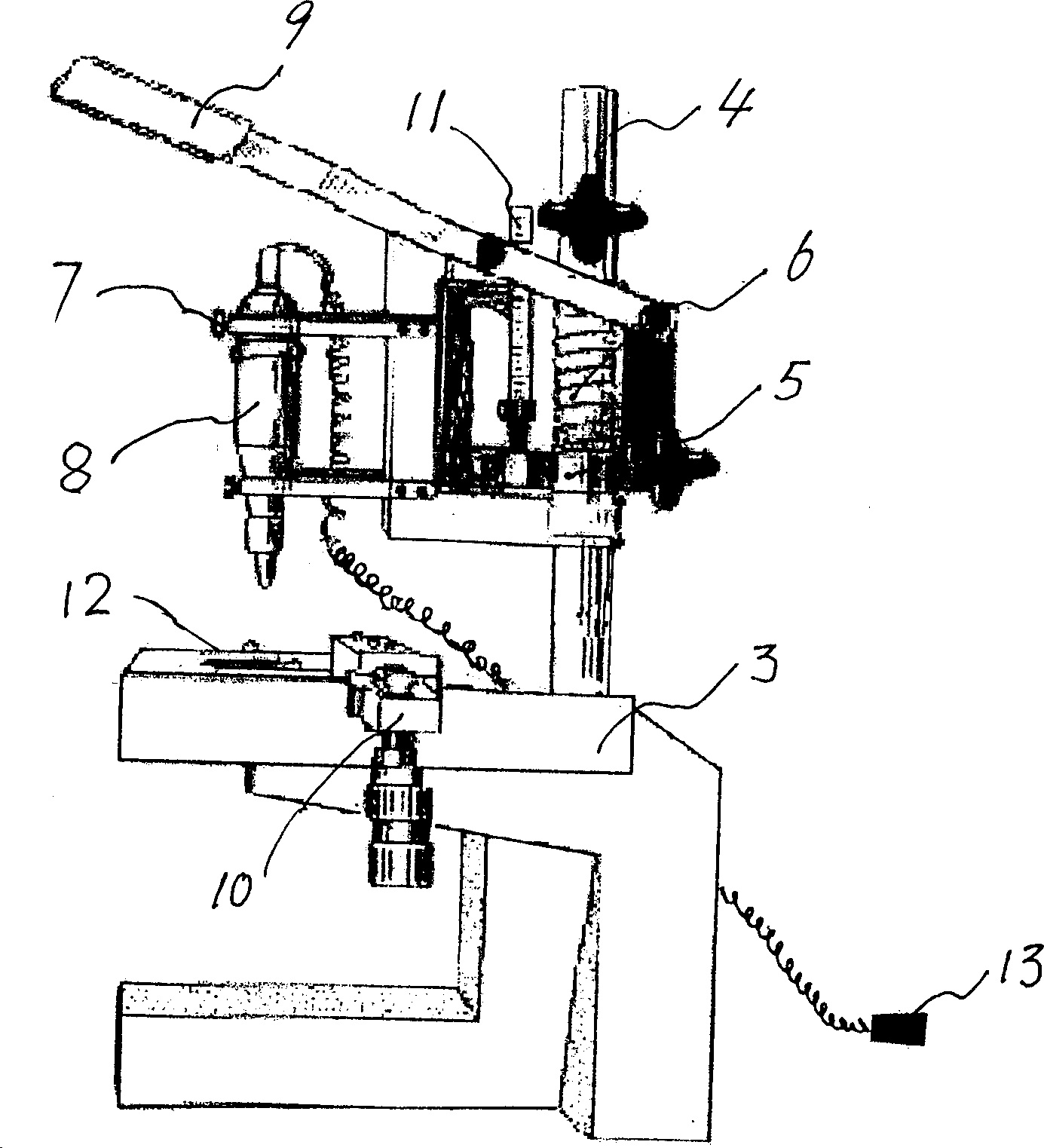

[0018] The specific embodiment of the present invention will be illustrated below in conjunction with the accompanying drawings: get fresh chicken gizzards, preferably chicken gizzards about 1 hour after slaughter, place them in liquid nitrogen for ultra-low temperature quick freezing, and then freeze the chicken gizzards after quick freezing at -20 Shaping is carried out in a frozen state at ~-35°C, that is, quick-frozen chicken gizzards are cut into small pieces with a size of 0.8cm×0.8cm×0.5cm or 0.6cm×0.6cm×0.5cm to form the matrix 1 . Then, in the frozen state of -75~-80℃, an array of small holes 2 with a diameter of 0.6 mm and a depth of 3 to 5 mm are drilled on the substrate 1, and the distance between the small holes 2 is 0.7 mm, thus forming a figure 2 Frozen tissue microarray vectors are indicated. Special equipment is required for drilling, and the structure of the special equipment is as follows: figure 2 As shown: a stage 3 is provided, and a lifting rod 4 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com