Filling process for ice cream containing large-particle mixed material

A technology of ice cream and large particles, which is applied in the field of mixing large particles inside ice cream, which can solve the problems of blocking the feeding nozzle and ensuring uniform and continuous mixing of particles, and achieves the effect of uniform output, good taste and accurate quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An ice cream pouring process comprising a large particle mix, comprising the steps of:

[0018] 1) After aging, the temperature of the ice cream material liquid is 2-5°C. The material liquid enters the ice cream freezer, and under the forced scraping action of the refrigeration system and the scraper and scraper, air is mixed into the ice cream and forms a semi-solid paste after puffing , the discharge temperature of ice cream reaches -4℃~-6℃;

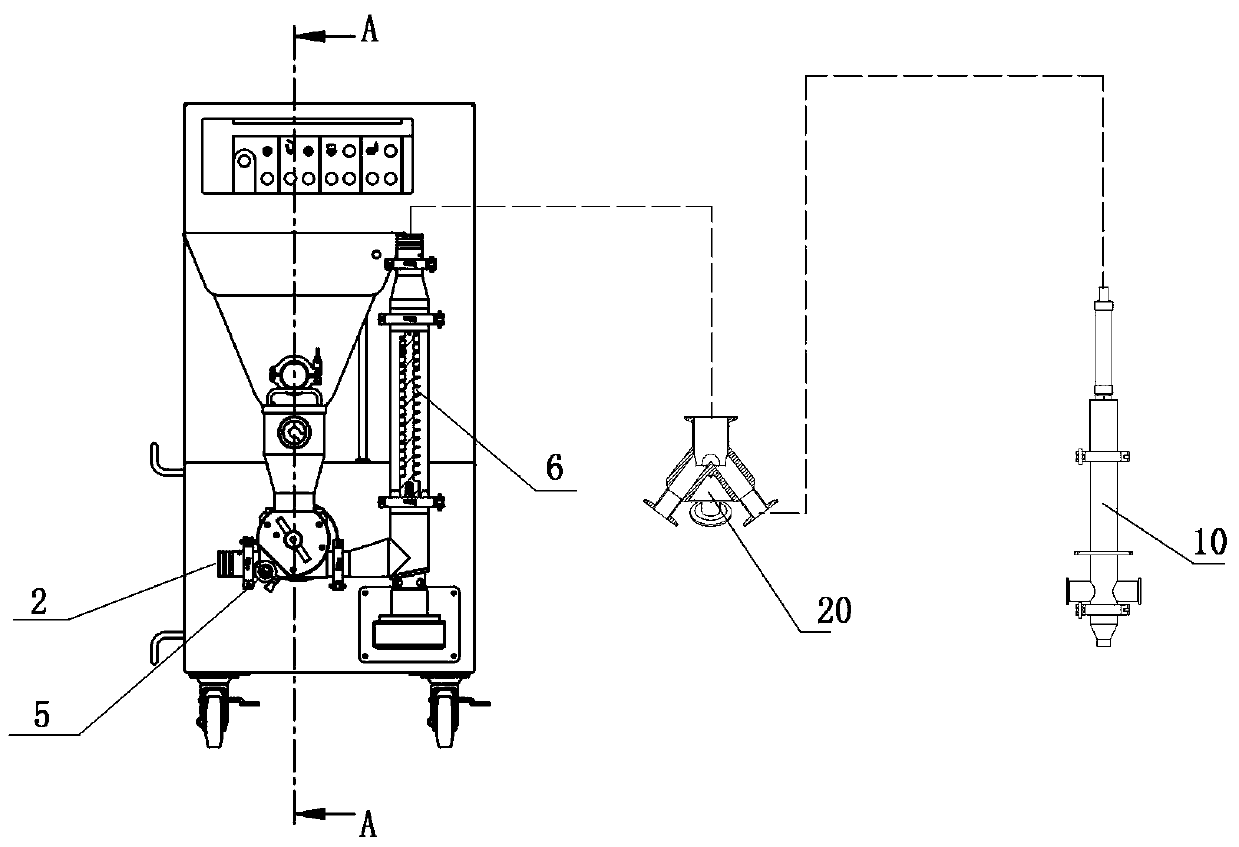

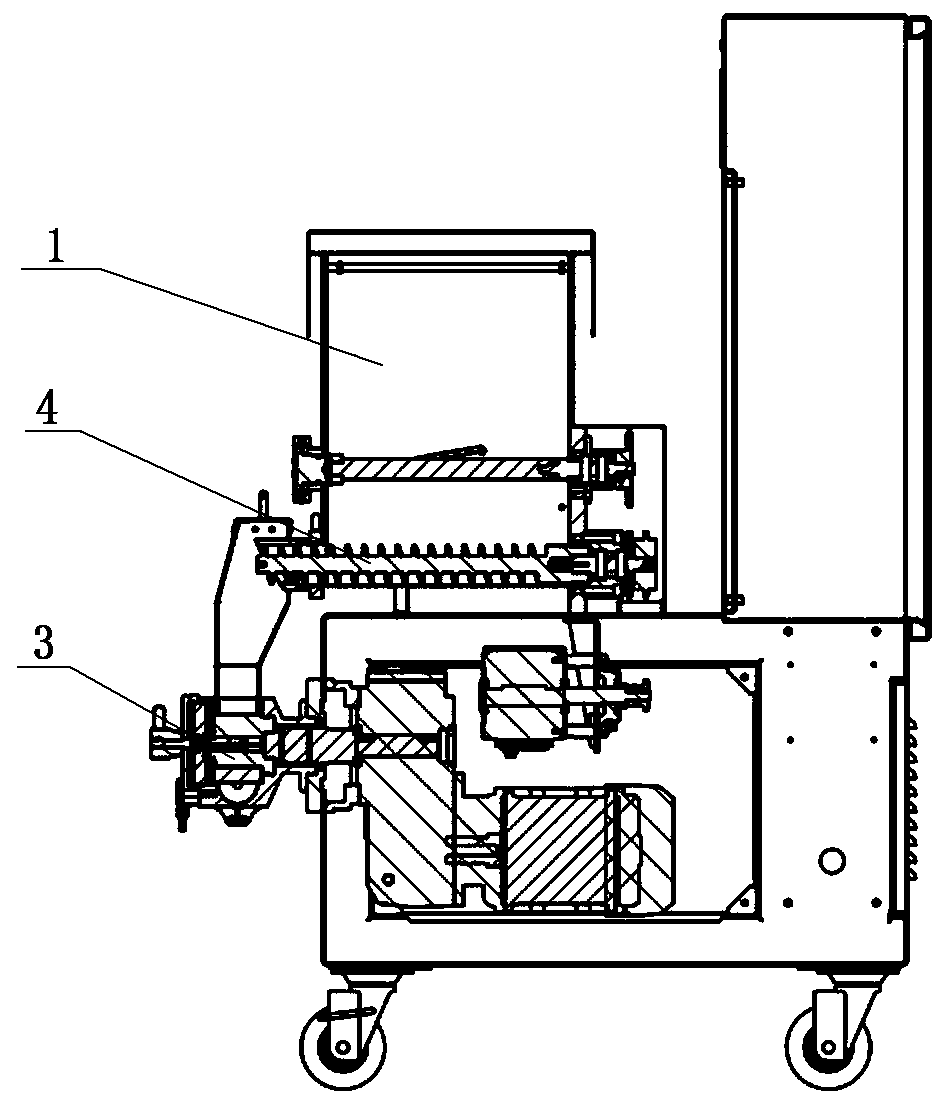

[0019] 2) if figure 1 As shown, the ice cream is connected from the outlet of the freezing machine to the ice cream inlet of the granule adding machine through a pipeline. The granule adding machine adopts the impeller to uniformly feed materials. The output speed ratio, the outlet of the mixing chamber uses spiral blades to export the mixed material;

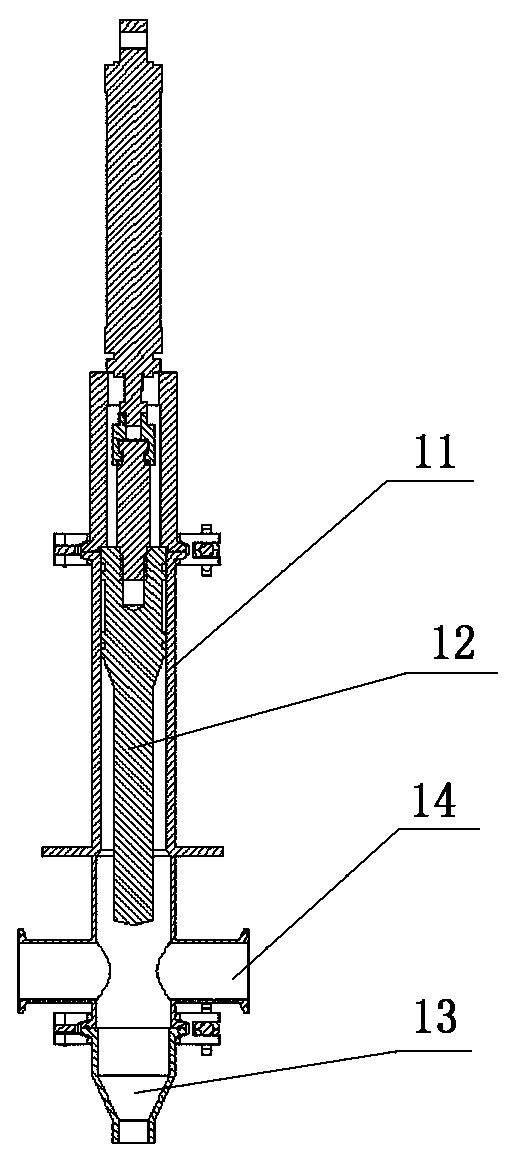

[0020] 3) Control the pressure of the outlet pipeline of the mixing chamber at 0.2-0.3Mpa, and distribute the material through the large-diameter distributor at the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com