Apparatus for manufacturing ices

a technology for ice making apparatus and ice cream, which is applied in the field of apparatus for manufacturing ices, can solve the problems of considerable time and effort, complicated structure of the ice making apparatus, and difficulty in quickly manufacturing ices with ice creams or ice cakes which require higher cooling, etc., and achieves rapid ice thawing, rapid ice thawing, and easy melting and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

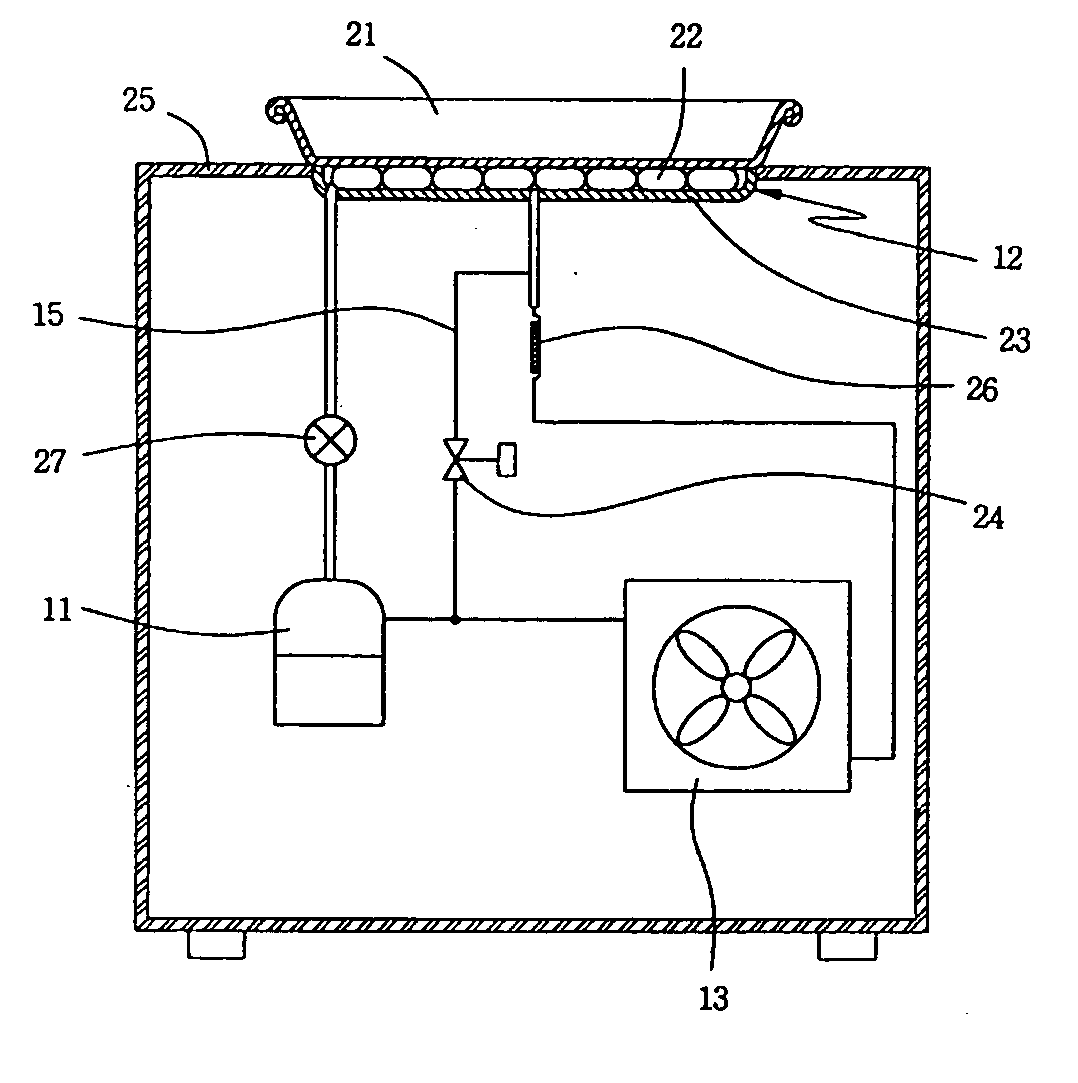

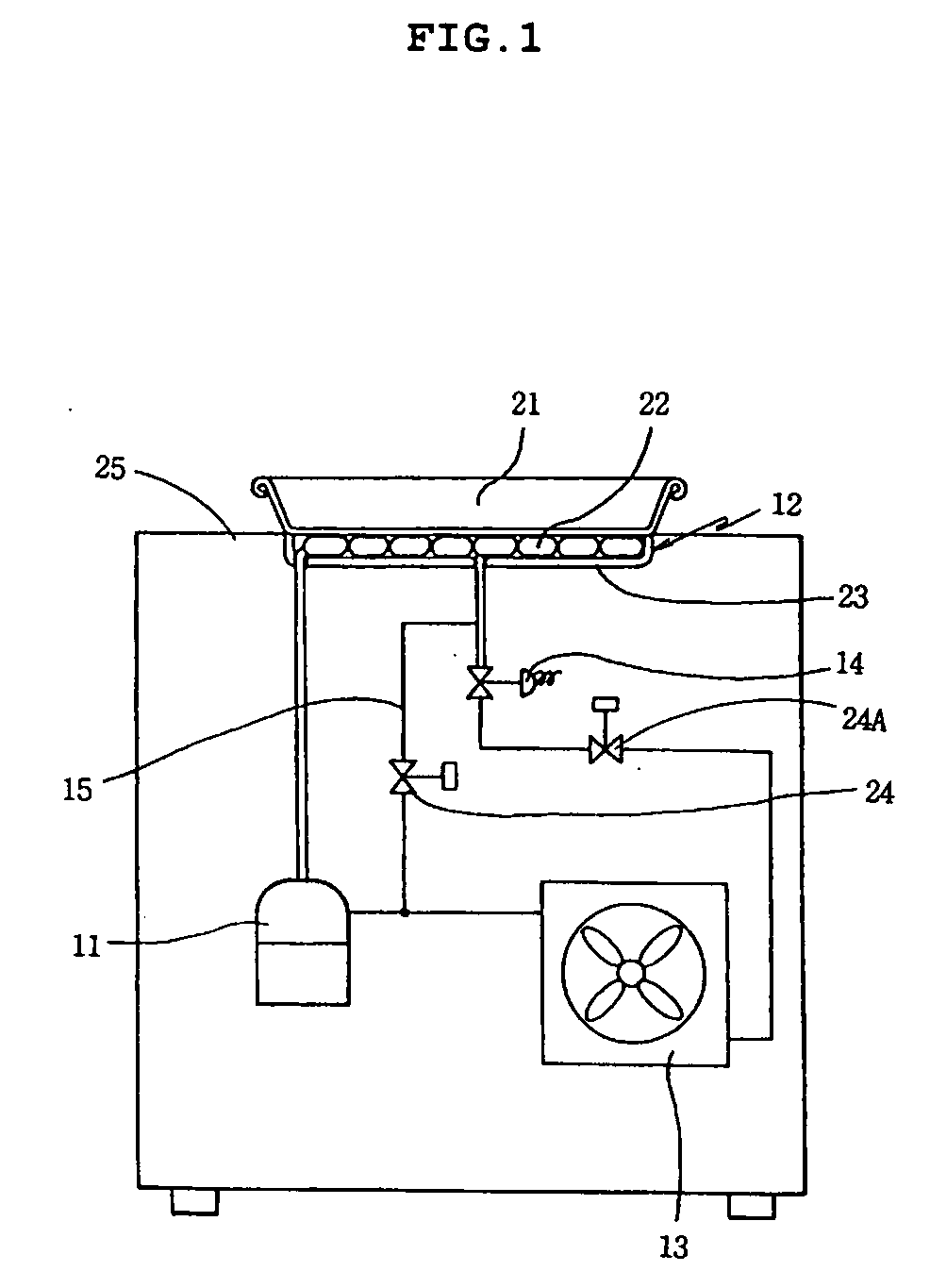

[0024] Hereinbelow, an apparatus for manufacturing ices via rapid ice facture and rapid ice thaw according to the present invention will be described with reference to the accompanying drawings.

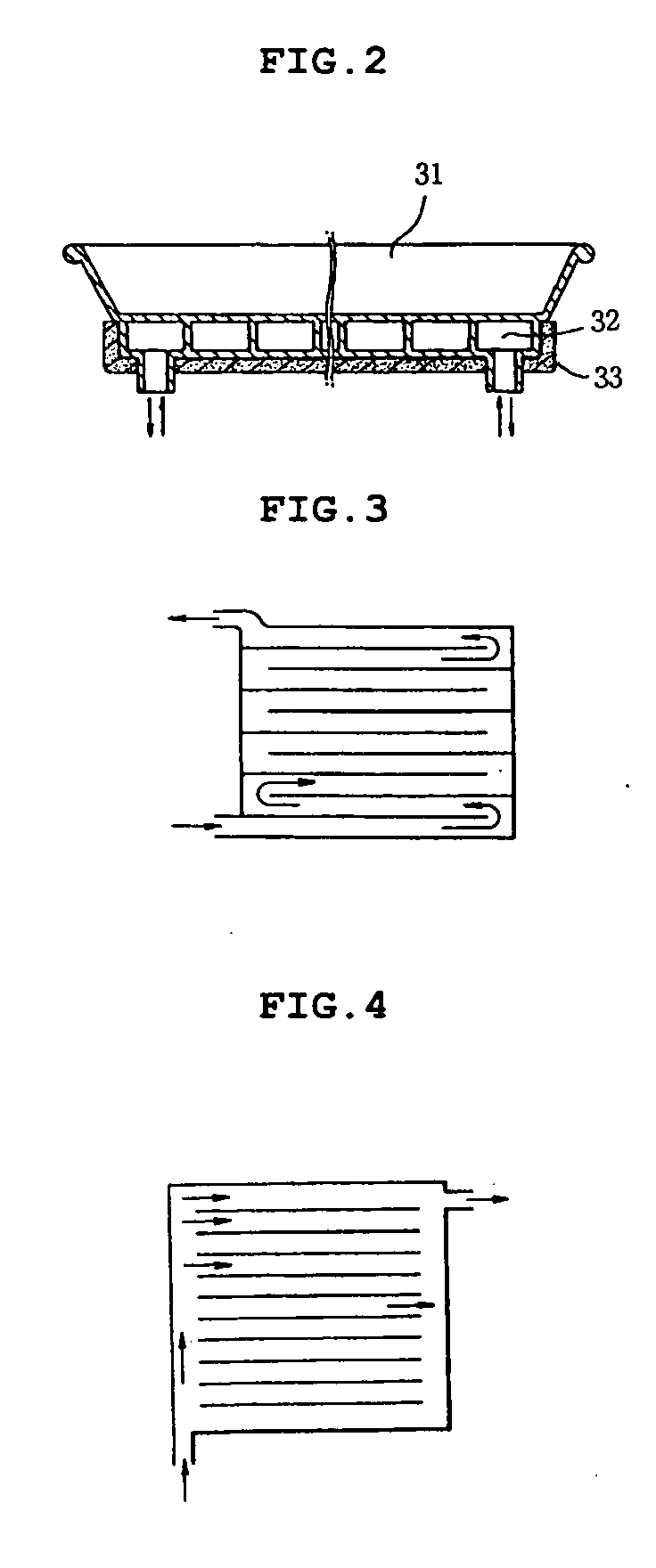

[0025]FIG. 5 is a piping diagram showing an ice making apparatus according to the present invention. FIGS. 6A and 6B are a partially enlarged view showing a preferred shape of a capillary tube, respectively.

[0026] As shown in FIG. 5, an apparatus for manufacturing ices via rapid ice facture and rapid ice thaw according to the present invention includes a compressor 11, a condenser 13, and an evaporator 12 all of which are installed in a box-shaped case 25 at the state of being connected with a coolant tube. A bypass tube 15 having an electronic valve 24 is connected between the coolant tube connecting the compressor 11 and the condenser 13 and the coolant tube connecting the condenser 13 and the evaporator 12. Also, the evaporator 12 is of a tray-shaped form and is installed so that a flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com