Substrate processing apparatus and substrate processing method

a substrate processing and processing apparatus technology, applied in the direction of cleaning processes and apparatus, chemistry apparatus and processes, cleaning using liquids, etc., can solve the problems of affecting the processing efficiency of substrates, so as to prevent damage to substrates, prevent clogging of flow passages, and improve throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

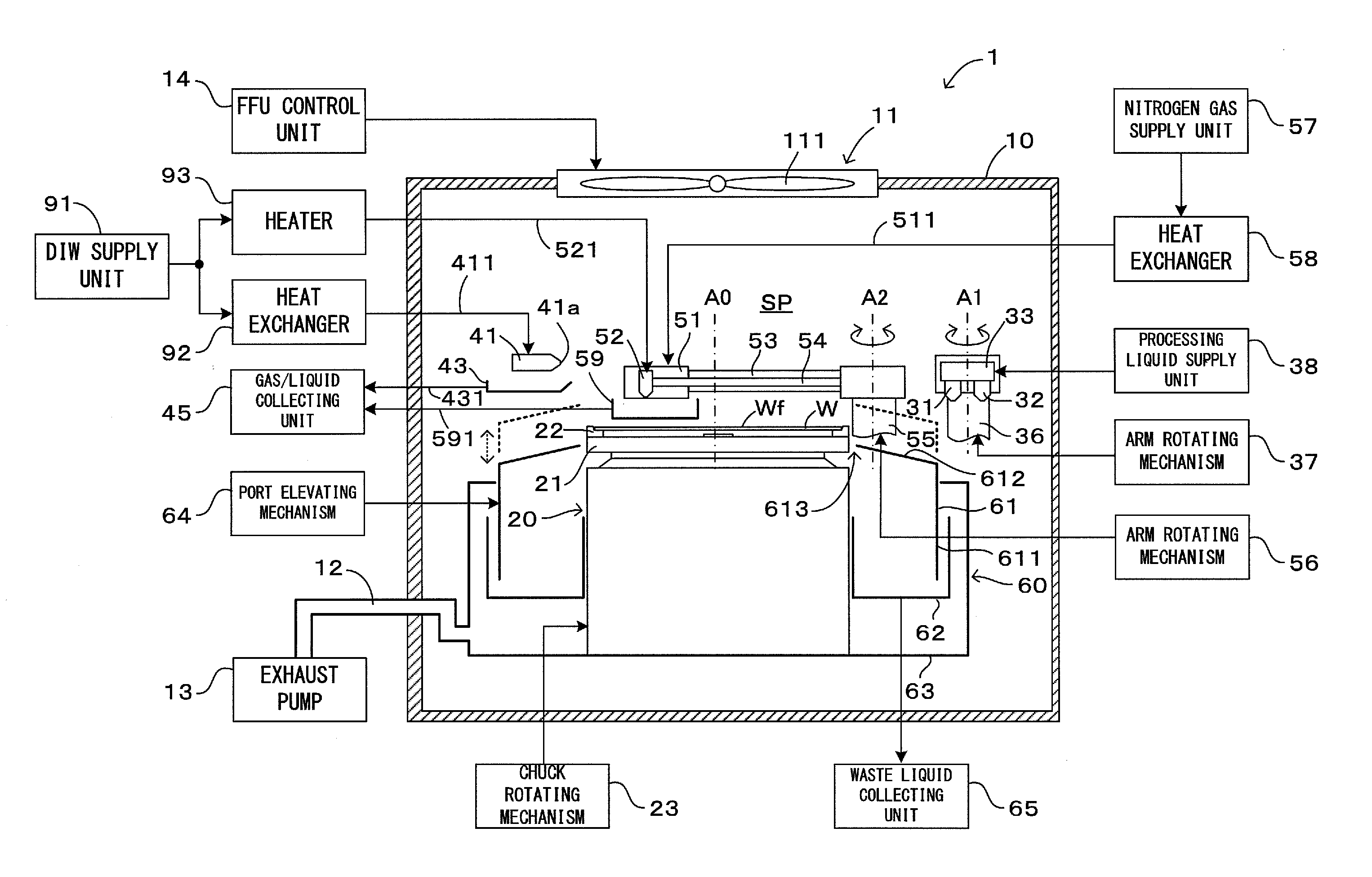

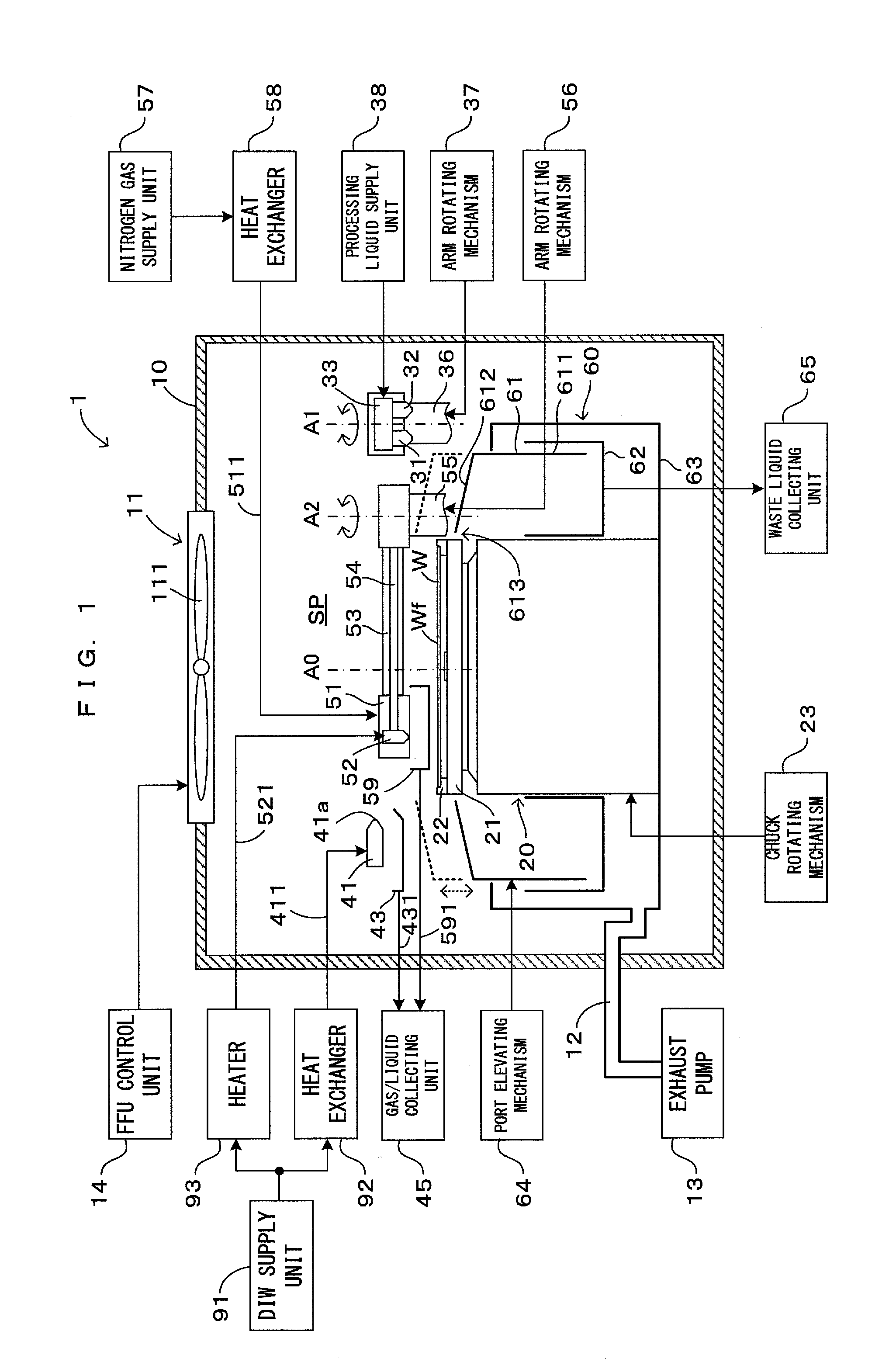

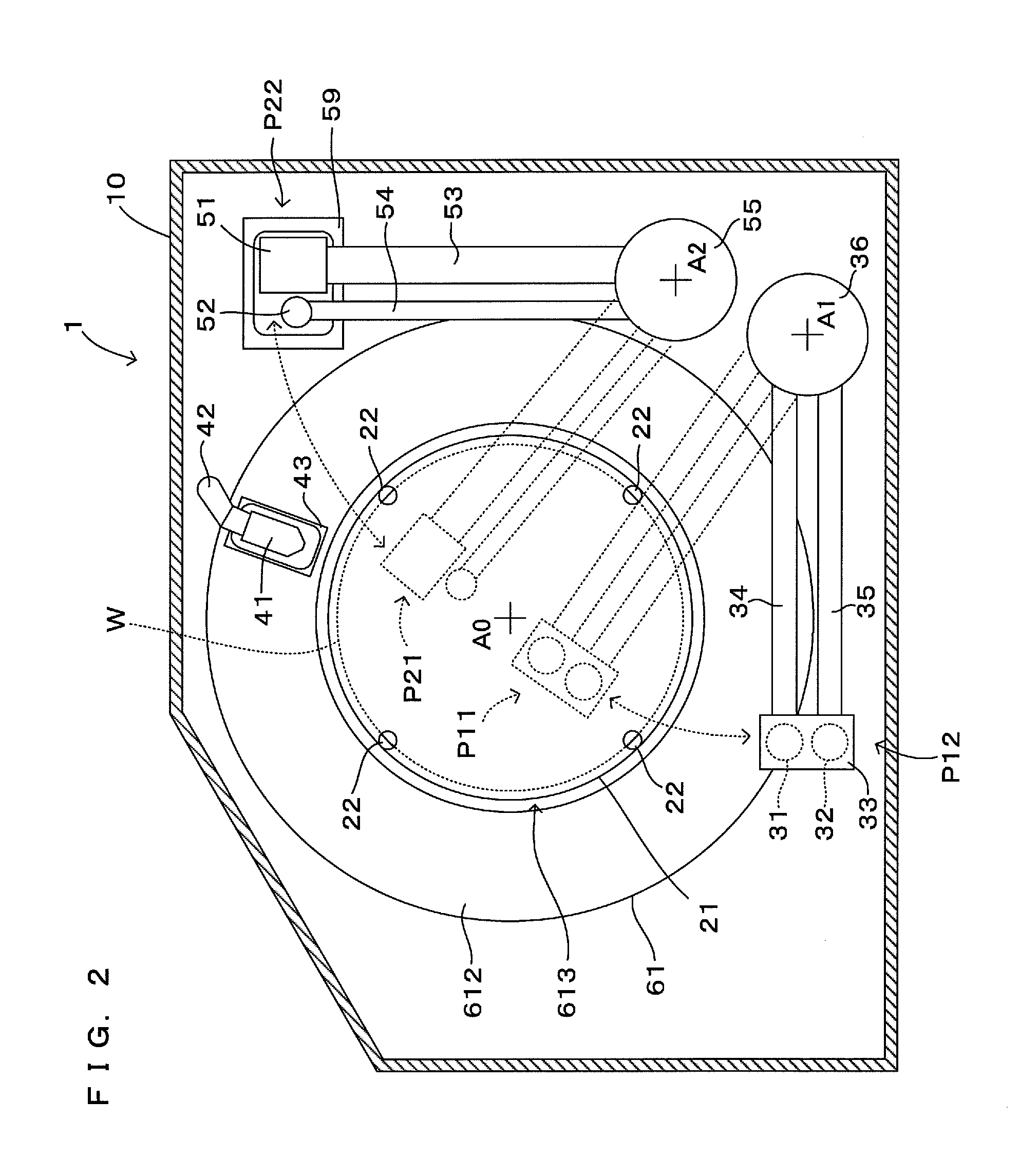

[0034]FIG. 1 is a side view diagrammatically showing one embodiment of a substrate processing apparatus according to the invention. FIG. 2 is a plan view showing the arrangement and moving modes of nozzles. This substrate processing apparatus 1 functions as a single-wafer substrate cleaning apparatus capable of performing a substrate cleaning process to remove extraneous matters such as particles adhering to a surface (pattern forming surface) Wf of a substrate W such as a semiconductor wafer. More specifically, this substrate processing apparatus 1 performs a freeze cleaning process of removing extraneous matters adhering to the substrate W together with a frozen film by removing the frozen film after forming a liquid film on the surface Wf of the substrate W and freezing the liquid film as the substrate cleaning process.

[0035]The substrate processing apparatus 1 includes a processing chamber 10 internally provided with a processing space SP in which a cleaning process is applied t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com