Rapid nutrient thawing method for frozen meat and refrigerator

A technology for freezing meat and nutrition, which is applied in household refrigerators, coolers, household refrigeration devices, etc., and can solve problems such as hindering internal ice crystals from absorbing microwaves, slowing down internal thawing, and degrading meat quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

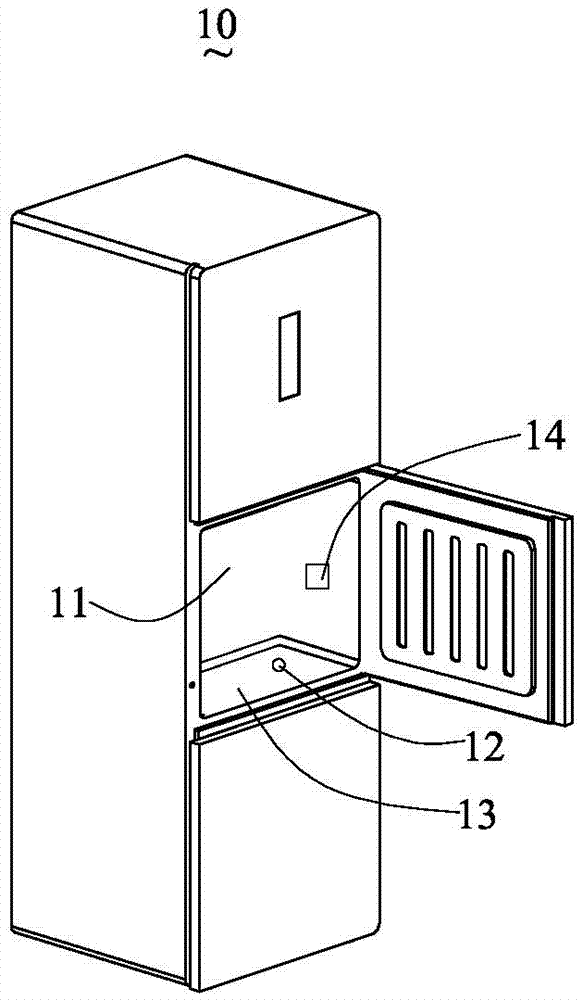

[0028] see figure 1 A schematic diagram of the refrigerator used in the first preferred embodiment of the method for rapid nutritional thawing of frozen meat, the refrigerator 10 includes a thawing chamber 11 and a control device (not shown), and the thawing chamber 11 is not higher than 0 ℃ and not lower than minus 3 ℃ negative temperature thawing chamber, the negative temperature thawing chamber is provided with a microwave generating device (not shown in the figure), and the microwave generating device is electrically connected to the control device.

[0029] In this embodiment, the negative temperature thawing chamber is also provided with a temperature detection device 12, a weight detection device 13, and a food type identification device 14. The temperature detection device 12, the weight detection device 13, the food type identification device 14 and the control device electrical connection.

[0030] A method for rapid nutritional thawing of frozen meat, a refrigerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com