Urea storage system

a storage system and urea technology, applied in the direction of machines/engines, liquid transfer devices, positive displacement liquid engines, etc., can solve the problems of not having pumps and not being able to provide urea to the exhaust treatment system, and achieve the effect of quick freezing of frozen urea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

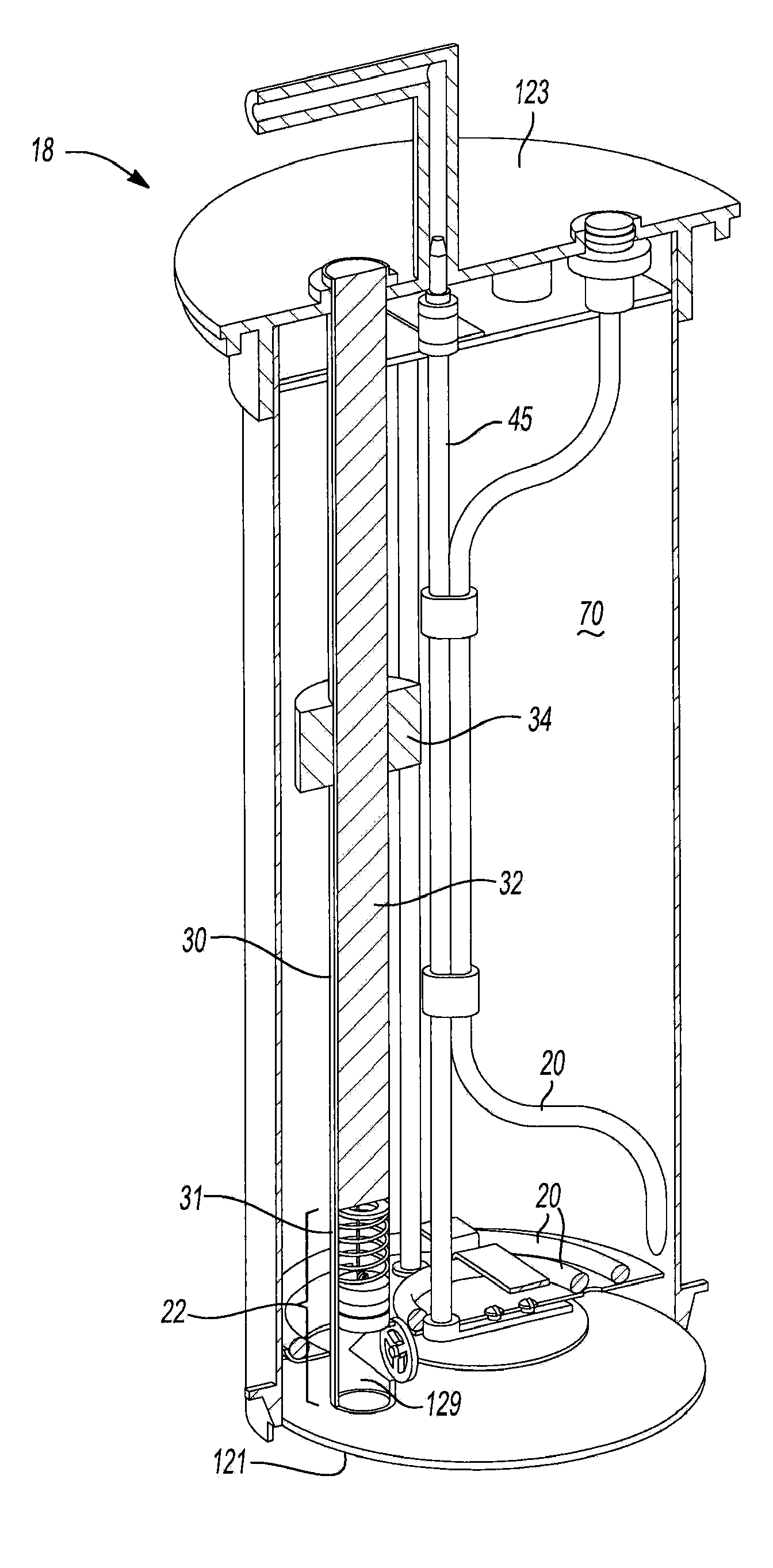

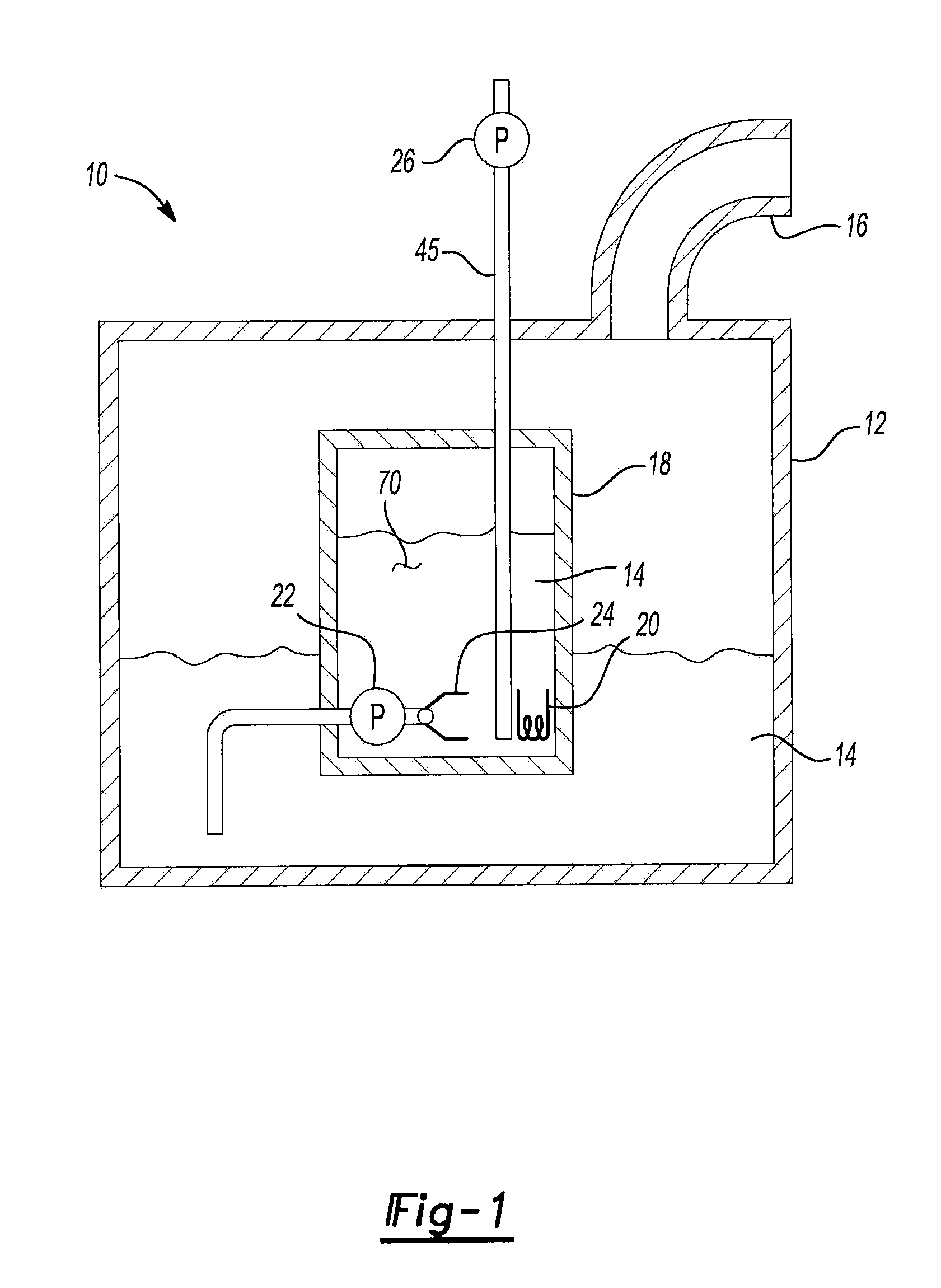

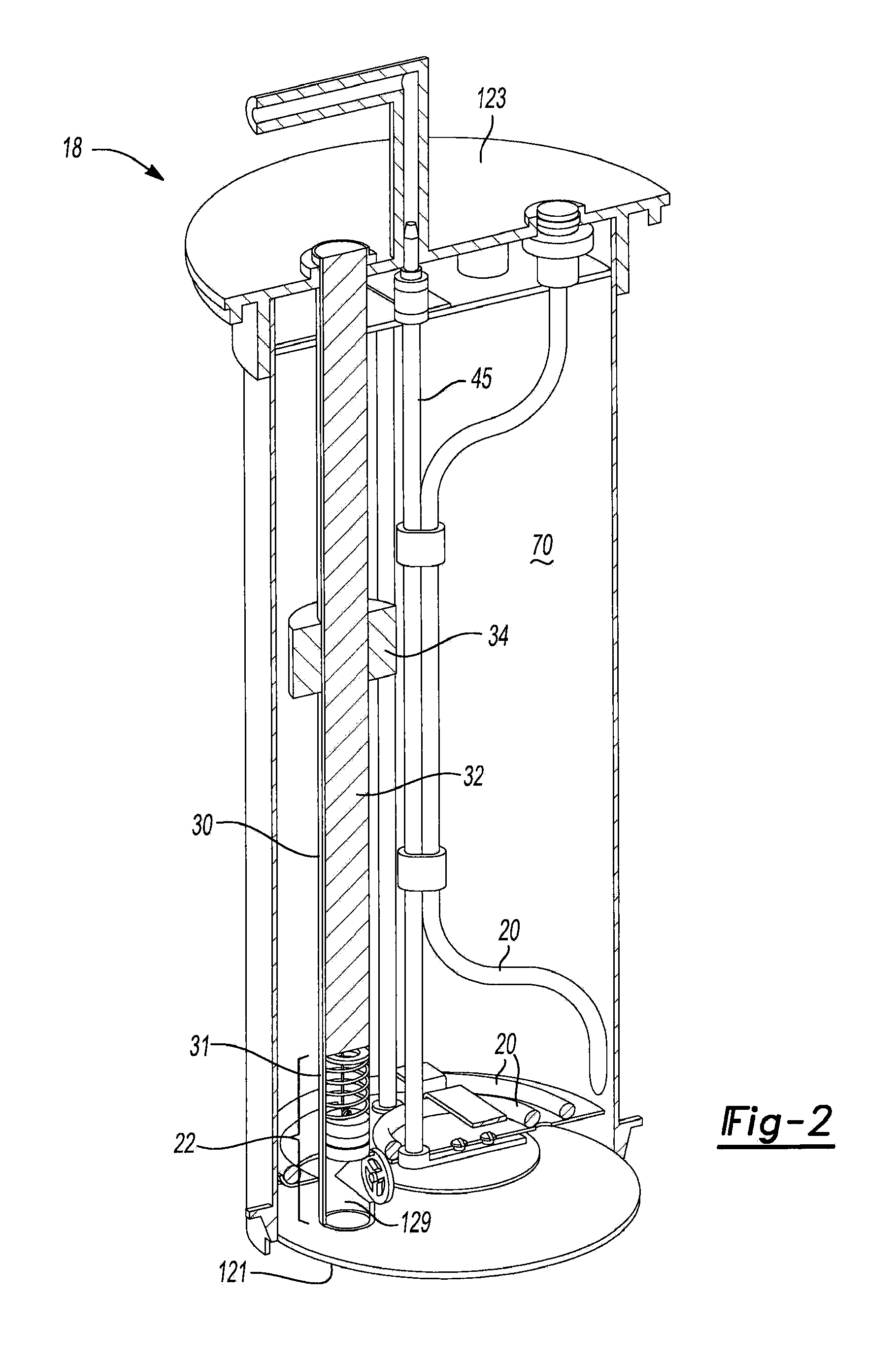

[0013]Referring now to FIG. 1, a functional block diagram is shown of a urea storage system 10. Storage system 10 includes a storage tank 12 that contains a urea solution 14. Urea solution 14 can be refilled via a filler opening 16. Storage tank 12 includes a reservoir 18. Reservoir 18 contains a portion of solution 14 within a volume that can be heated by a heater 20. A pump 22 pumps solution 14 into reservoir 18. The level of solution 14 can therefore be higher than the solution level in tank 12 providing a pressure load in reservoir 18 that is greater than the pressure head within tank 12. A check valve 24 prevents solution 14 from draining out of reservoir 18 and returning to storage tank 12. Another pump 26 transports solution 14 from reservoir 18 to a urea injection system that injects solution 14 into the engine exhaust stream.

[0014]Referring now to FIG. 2, one of several embodiments is shown of reservoir 18. Reservoir 18 includes a level sensing tube 30 that contains a print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com