Heat-not-burn tobacco packing paper

A heat-not-combustible wrapping paper technology, applied in the fields of tobacco, non-woody plant/crop pulp, cigar manufacturing, etc., can solve the problems affecting the taste of tobacco, deviation from production requirements, limited heat production, etc., and achieve low toxicity, Promotes even heating and less smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

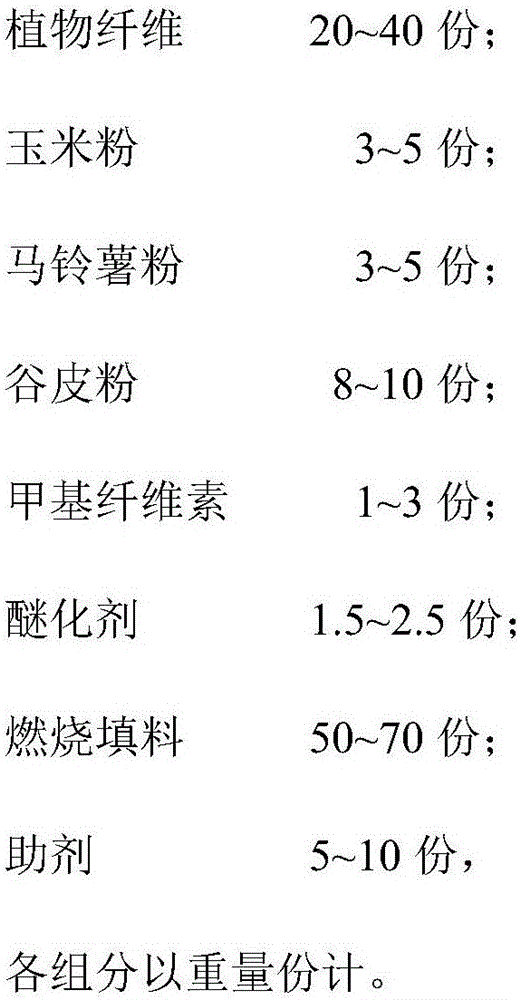

[0020] Embodiment 1: A heat-not-burn tobacco wrapper, comprising a combustion layer and a heat-conducting layer, the combustion layer and the heat-conducting layer are bonded together by composite glue, the combustion layer is a corrugated structure, and includes the following components:

[0021]

[0022] The heat conduction layer is composed of a base paper layer, a grid-like aluminum foil layer and a sheet-like aluminum foil layer. The sheet-shaped aluminum foil layer is in contact with the burning layer, the sheet-shaped aluminum foil layer is wrapped around the outside of the shredded tobacco, and the base paper layer includes the following components:

[0023]

[0024] The plant fibers are formed by mixing one or more of waste bamboo chips, waste cotton, corn stalks, straw, wheat stalks, cotton stalks, peanut stalks, potato residues, and bean curd residues.

[0025] The combustion filler is a mixture of carbon powder and calcium carbonate, and the mass ratio of car...

Embodiment 2

[0027] Embodiment 2: A heat-not-burn tobacco wrapper, comprising a combustion layer and a heat-conducting layer, the combustion layer and the heat-conducting layer are bonded together by composite glue, the combustion layer is a corrugated structure, and includes the following components:

[0028]

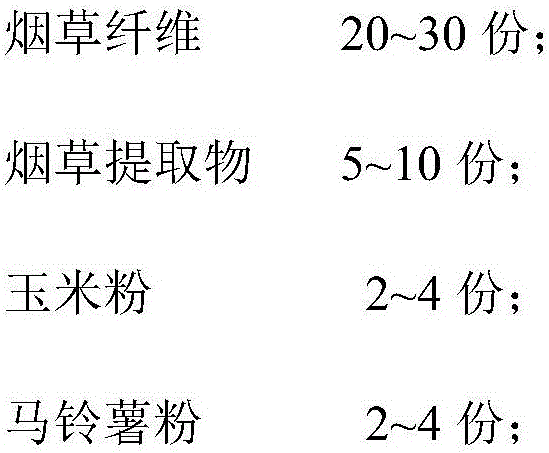

[0029] The heat conduction layer is composed of a base paper layer, a grid-like aluminum foil layer and a sheet-like aluminum foil layer. The sheet-shaped aluminum foil layer is in contact with the burning layer, the sheet-shaped aluminum foil layer is wrapped around the outside of the shredded tobacco, and the base paper layer includes the following components:

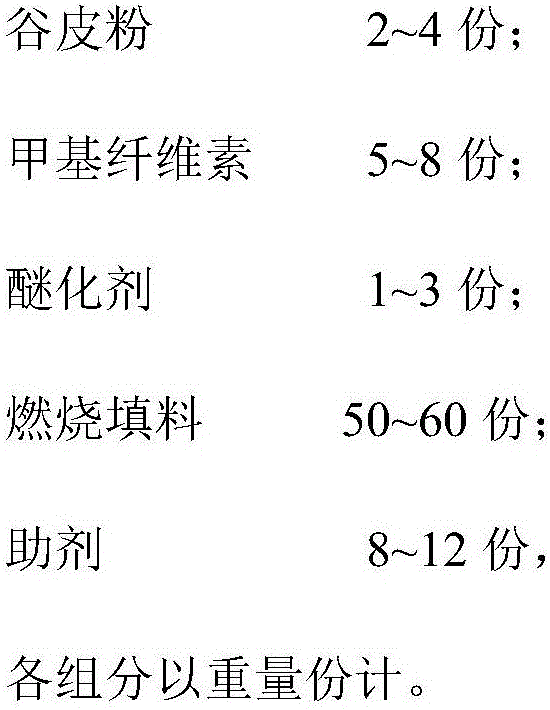

[0030]

[0031]

[0032] The plant fibers are formed by mixing one or more of waste bamboo chips, waste cotton, corn stalks, straw, wheat stalks, cotton stalks, peanut stalks, potato residues, and bean curd residues.

[0033] The combustion filler is a mixture of carbon powder and calcium carbonate, and the mass ...

Embodiment 3

[0035] Embodiment 3: A heat-not-burn tobacco wrapper, comprising a combustion layer and a heat-conducting layer, the combustion layer and the heat-conducting layer are bonded together by composite glue, the combustion layer is a corrugated structure, and includes the following components:

[0036]

[0037] The heat conduction layer is composed of a base paper layer, a grid-like aluminum foil layer and a sheet-like aluminum foil layer. The sheet-shaped aluminum foil layer is in contact with the burning layer, the sheet-shaped aluminum foil layer is wrapped around the outside of the shredded tobacco, and the base paper layer includes the following components:

[0038]

[0039] The plant fibers are formed by mixing one or more of waste bamboo chips, waste cotton, corn stalks, straw, wheat stalks, cotton stalks, peanut stalks, potato residues, and bean curd residues.

[0040] The combustion filler is a mixture of carbon powder and calcium carbonate, and the mass ratio of car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com