Water supply valve control system for optimizing production

A technology of valve control and water delivery pipes, which is applied in water supply pipeline systems, water supply devices, water supply main pipelines, etc., can solve the problems of low safety factor in the operation of the staff, burns and falls of the staff, and achieve convenient data statistics and The effect of measuring, eliminating burns, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

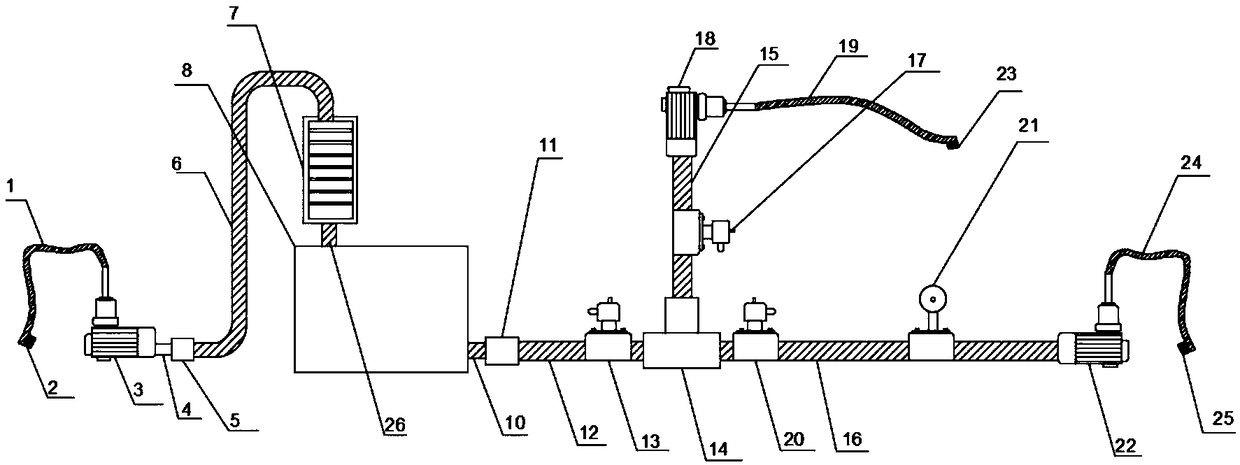

[0023] The present invention provides such Figure 1-2 The shown a kind of optimized production water supply valve control system comprises a water suction pipe 1, a first counterweight 2 is provided at one end of the water suction pipe 1 and a first water pump 3 is provided at the other end, and a first water pump 3 is provided at one end of the first water pump 3 A first connecting pipe 4 is provided, the end of the connecting pipe is provided with a first inner wire connecting pipe 5, and one end of the first inner wire connecting pipe 5 is provided with a first water delivery pipe 6, and the first water delivery pipe 6 ends A thin-film filter 7 is arranged at the top of the thin-film filter 7, and a heating box 8 is arranged at the bottom of the thin-film filter 7. A second connecting pipe 10 is arranged on one side of the heating box 8, and a second inner wire is arranged at one end of the second connecting pipe 10. A connecting pipe 11, one end of the second inner wire c...

Embodiment 2

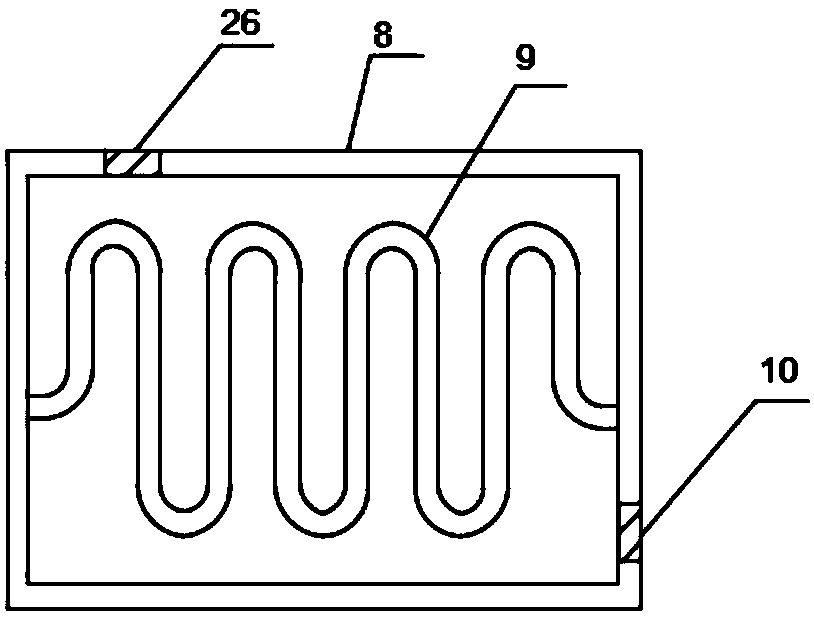

[0028] Such as figure 2 In the shown optimized production water supply valve control system, the inner cavity of the heating box 8 is provided with a heating tube 9, and the heating tube 9 is arranged in the inner cavity of the heating box 8 in a serpentine shape, so that the heating tube 9 and the heating box 8 The contact area of the water source in the interior reaches the maximum, and the heating rate is high. The bottom end of the connecting pipe 26 and the end of the second connecting pipe 10 both pass through the heating box 8 and extend to the inner cavity of the heating box 8. The connecting pipe 26 connects the membrane filter 7 The water source filtered inside is transported to the heating box 8 for heating, and then transmitted to the outside of the heating box 8 through the second connecting pipe 10 .

[0029] The working principle of the present invention: when the device is working, the pumping pipe 1 is put into the reservoir of the water treatment station i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com