Air chamber-type press filter-used diaphragm plate

A box-type filter press, diaphragm plate technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor sealing performance, shortened product service life, poor corrosion resistance, etc., to ensure sealing performance, Long service life and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

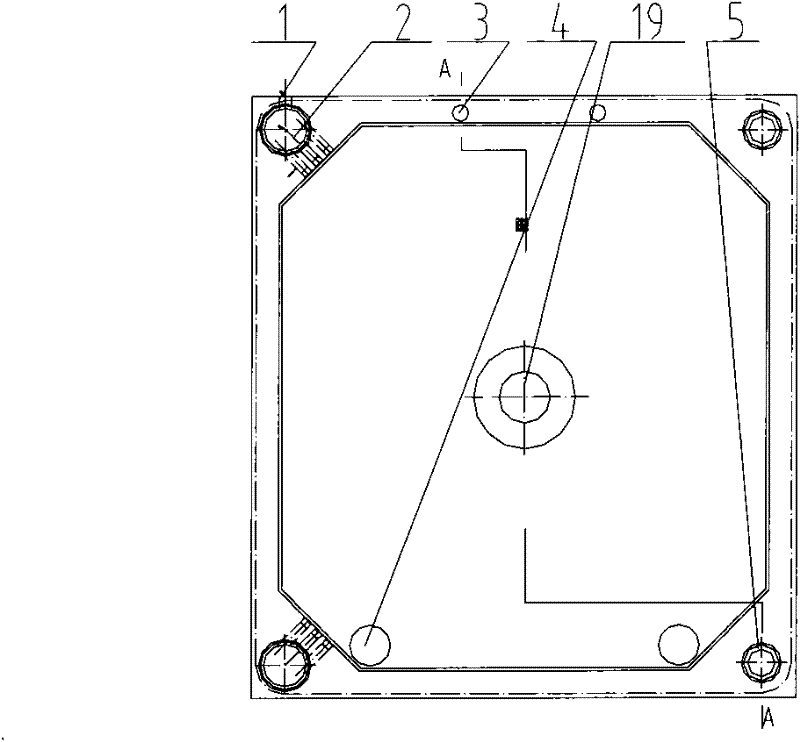

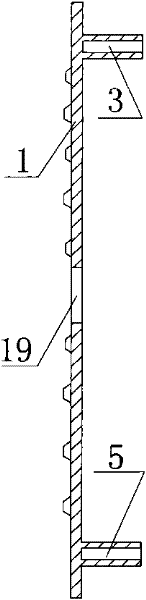

[0021] Embodiment 1: with reference to attached image 3 . Diaphragm for air chamber filter press, which includes diaphragm, means that on the basis of the existing diaphragm, the diaphragm is a sheet-shaped silica gel diaphragm 1 and the back of the four corners of the sheet-shaped silica gel diaphragm 1 is provided with a convex platform type liquid outlet 5 and a convex The table-type washing liquid channel 2 is provided with a convex table-type air channel 3 between the convex table-type washing liquid channel 2 and the convex table-type washing liquid channel 2 . There are one or more boss-type air passages 2 in the sheet-shaped silica gel diaphragm 1 and they are located on the sealing surface of the sheet-shaped silica gel diaphragm. There is no wrapping around the sheet-shaped silica gel diaphragm 1 . The center of the sheet-shaped silica gel diaphragm is the feeding port 19.

Embodiment 2

[0022] Embodiment 2: with reference to attached Figure 7 with 8 . Diaphragm for an air box filter press, which includes a diaphragm, and is characterized in that: a high-strength cloth 20 or mesh cloth or net is built around the feed port 19 and the liquid outlet 4 of the sheet-shaped silica gel diaphragm 1, or it is connected with a plate Core 6, boss 7, opposite sheet-shaped silica gel diaphragm, is equipped with high-strength cloth 21 or mesh cloth or net, or the feeding port 19 and liquid outlet 4 of the sheet-shaped silica gel diaphragm 1 are surrounded by built-in high-strength cloth 20 or Mesh cloth or net, the sheet-shaped silica gel diaphragm opposite with board core surface 6 bosses 7 faces are equipped with high-strength cloth 21 or mesh cloth or net.

Embodiment 3

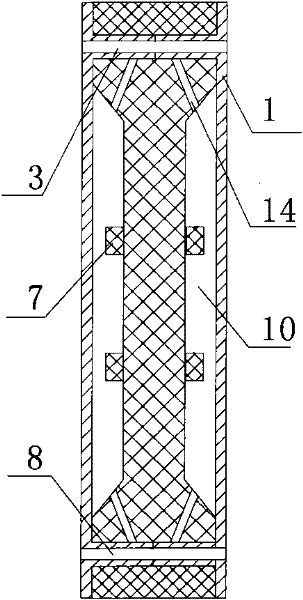

[0023] Embodiment 3: with reference to attached Figure 4 . The plate core for the air box filter press, which includes the plate core, means that on the basis of the existing plate core, the sealing surface of the plate core 6 has air holes 9 and communicates with the core chamber 10 of the plate core 6 ( Have channel 14), plate core 6 is provided with convex platform type washing solution channel 2, convex platform type liquid outlet channel 5, the core surface of plate core 6 is provided with three or more than three convex platforms 7 and convex platform 7 is distributed on plate core 6 around the liquid inlet. The core sealing surface 11 in the core 6 is lower than the surface of the boss 7 and can take any value within the range of 2-6mm including the end value. There are no bumps on the core surface of the core 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com