Beverage making method of horizontal type rotation beverage making machine

A beverage machine and beverage technology, applied in beverage preparation devices, home appliances, applications, etc., can solve problems affecting beverage nutrition, taste, beverage powder residue, agglomeration, etc., to improve taste and nutritional value, improve taste, fully dissolved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The beverage preparation method of the present embodiment, its specific technological process is as follows:

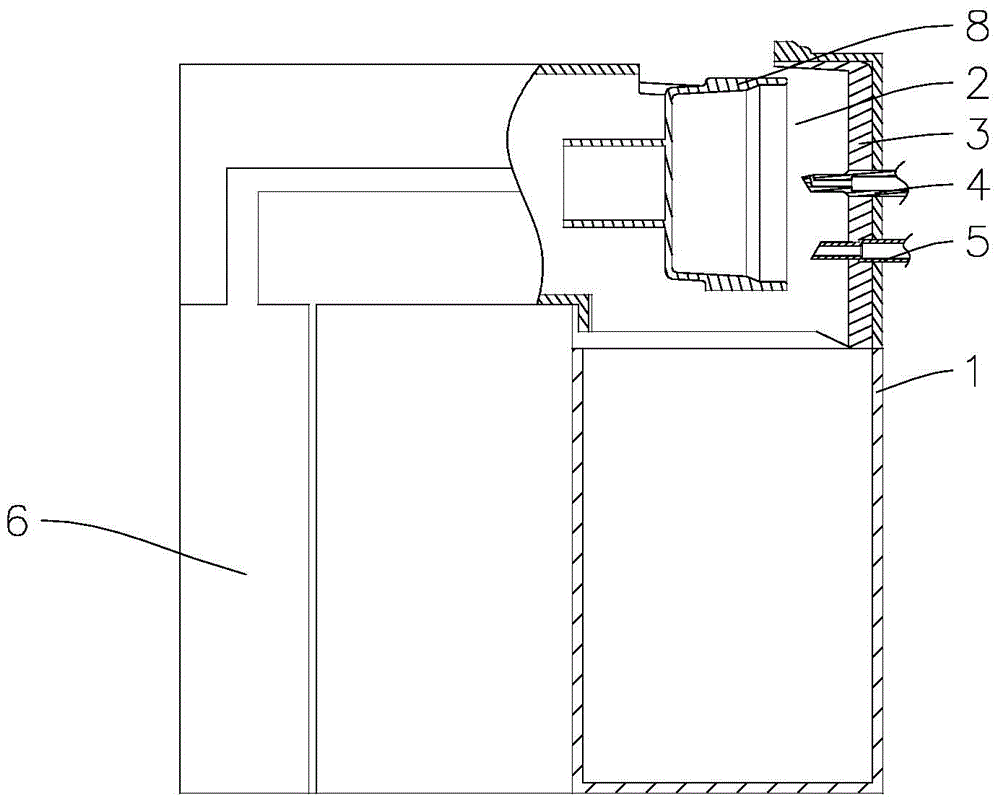

[0042] (1), the customer puts the material bag 7 into the beverage machine, presses the start button, and the beverage machine starts to work;

[0043] (2) Water inlet step: the water inlet needle 4 pierces the material bag 7, and provides the liquid into the material bag 7;

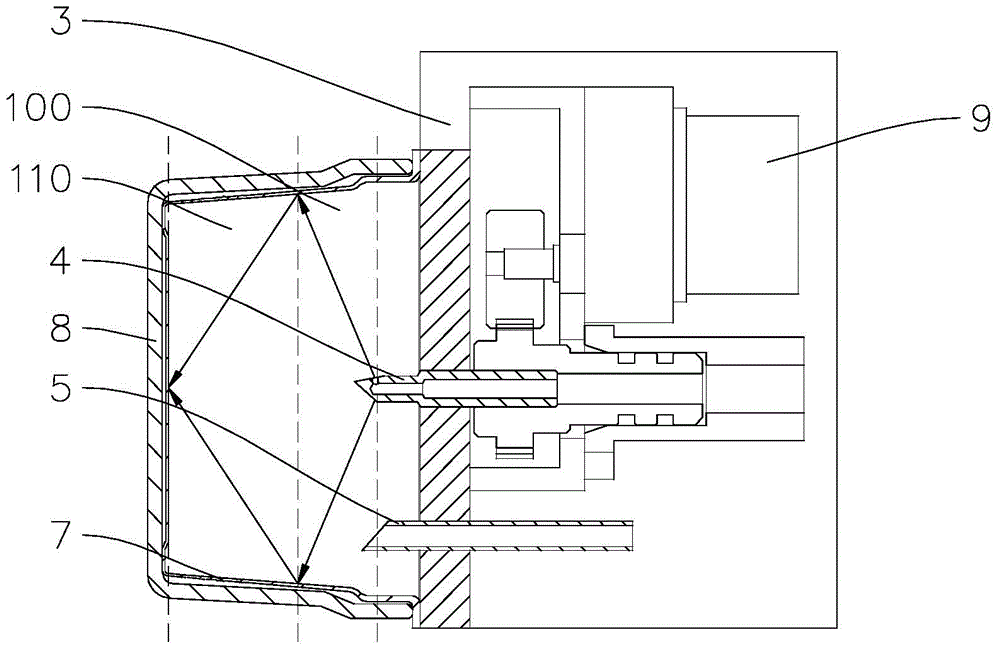

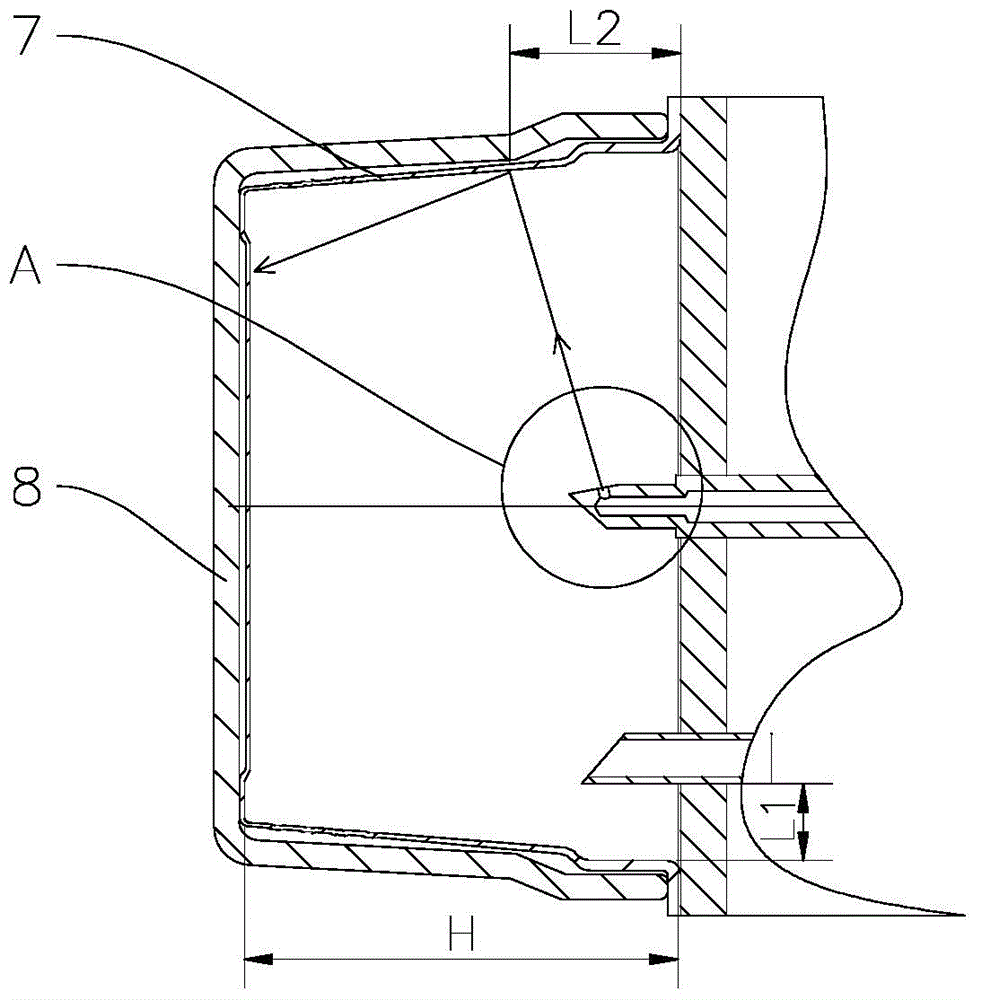

[0044] (3), brewing step: the driving device 9 drives the water inlet puncture needle 4 to rotate to form a conical straight jet flow area 100 with the water inlet puncture needle 4 as the center, and the beverage powder is washed by the liquid flow in the conical straight jet flow area 100 so that Mix to dissolve.

[0045](4) Beverage discharging step: the puncture needle 5 is drawn out to pierce the bag 7, so that the drink formed by the final dissolution of the beverage powder is led out of the bag.

[0046] The above beverage preparation method intersects the jet flow direction of t...

Embodiment 2

[0060] The difference between this embodiment and the first embodiment is that the brewing step also includes a dough forming process, a dough processing process and a dough dissolving process.

[0061] The beverage preparation method of the present embodiment, its specific technological process is as follows:

[0062] (1), the customer puts the material bag 7 into the beverage machine, presses the start button, and the beverage machine starts to work;

[0063] (2) Water inlet step: the water inlet needle 4 pierces the material bag 7, and provides the liquid into the material bag 7;

[0064] (3) Brewing step: the driving device 9 drives the water inlet needle 4 to rotate to form a conical straight jet flow area 100 centered on the water inlet needle 4. After part of the beverage powder is soaked, a paste layer is formed on the surface, and then The powder is formed, and the powder is continuously washed by the liquid flow in the conical straight jet flow area 100, and then th...

Embodiment 3

[0069] The difference between this embodiment and the second embodiment is that the jet area also includes a "V"-shaped reflection flow area.

[0070] The beverage preparation method of the present embodiment, its specific technological process is as follows:

[0071] (1), the customer puts the material bag 7 into the beverage machine, presses the start button, and the beverage machine starts to work;

[0072] (2) Water inlet step: the water inlet needle 4 pierces the material bag 7, and provides the liquid into the material bag 7;

[0073] (3), brewing step: the driving device 9 drives the water-inlet needle 4 to rotate to form a conical straight-jet flow area 100 centered on the water-inlet puncture needle 4, and the conical straight-jet flow area 100 passes through the side of the material bag 7 during the rotation process. The wall reflection forms a "V"-shaped reflection flow area 110, and the conical straight-jet flow area 100 and the "V"-shaped reflection flow area 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com