Patents

Literature

83results about How to "Improve brewing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beverage making method of horizontal type rotation beverage making machine

The invention discloses a beverage making method of a horizontal type rotation beverage making machine. The beverage making machine comprises a machine base with a brewing cavity, a brewing head, a water inlet pricking needle arranged at the brewing head, a leading-out pricking needle arranged at the brewing head, a liquid supply mechanism for supplying liquid to the brewing head and a brewing cup for containing a material bag; and one end of the brewing head is connected with the liquid supply mechanism, and the other end of the brewing head supplies the liquid to the interior of the material bag. The beverage making method includes the water inlet step, the making step and the beverage discharging step; a driving device is additionally used in the making step to drive the water inlet pricking needle to rotate, so that a jet flow area is formed by the water inlet pricking needle, beverage powder is flushed by liquid flow in the jet flow area so as to be mixed and dissolved, and therefore mixing dissolution of the liquid and the beverage powder is quickened; in addition, the beverage powder is sufficiently dissolved, residues are avoided, and the taste and the nutritive value of a beverage are improved; meanwhile, the rotation jet flow motion is formed by the water inlet pricking needle in the rotation process, dissolution of the beverage powder is better promoted, and the making efficiency and the taste of the beverage are improved.

Owner:JOYOUNG CO LTD

Flavor liquor and brewing method thereof

InactiveCN106939269AReduce the ratioShort cycleAlcoholic beverage preparationPulp and paper industryFood flavor

A flavored wine and a brewing method thereof, which belong to the technical field of wine making, are prepared by adding Chinese herbal medicines to wine-making raw materials according to the ratio of Chinese herbal medicine: wine-making raw materials = 0.05-0.1: 4.5-5, and brewed according to conventional wine-making methods. The brewing cycle is short, the brewing efficiency is high, and the cost of brewing is saved; and the use of animal and plant medicines and grains are co-fermented, organically integrated with wine, mellowed, naturally flavored, flavored, and fragrant, producing a rich and unique flavor. The complex smell of the drug itself, while retaining many biologically active components of the drug itself, improves the quality of liquor.

Owner:陈野

Method of making milky coffee drink with capsule drink machine

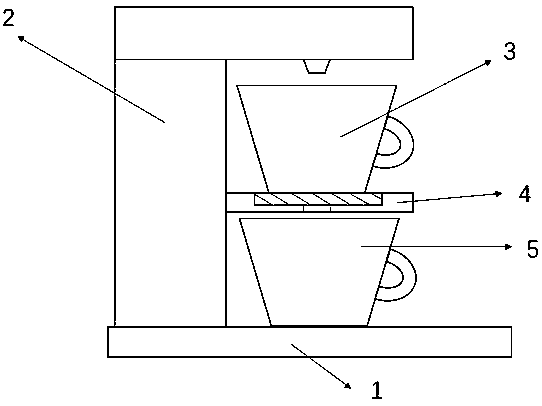

The invention provides a method of making a milky coffee drink with a capsule drink machine. The capsule drink machine comprises a base, a brewing chamber, a control panel, a brewing head, an inflow piercing needle, an extraction piercing needle, a liquid supply mechanism and a brewing cup for receiving milky coffee capsules; each milky coffee capsule includes a capsule body and a membrane and also includes a separator for liquid passage, the separator is arranged in the capsule body and divides an inner cavity of the capsule body into a first cavity and a second cavity, milk powder is arranged in the first cavity, and coffee powder is arranged in the second cavity; the method comprises the steps of emulsifying, extracting and mixing; sequentially, the milk powder is emulsified and brewed, the coffee powder is extracted and filtered, and milk and coffee liquids are mixed into a milky coffee drink; in the method, the milk and coffee liquids are mixed well, the milk liquid never floats on the surface of the coffee liquid, the taste of the milky coffee drink is enhanced, and the milky coffee drink has good color and appearance.

Owner:HONGYANG HOME APPLIANCES

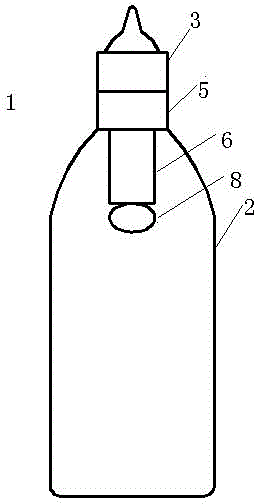

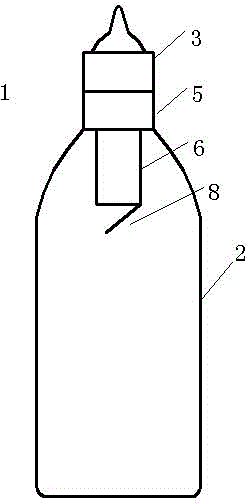

Baby feeding bottle

InactiveCN103054728AAvoid spillingShorten brewing timeFeeding-bottlesEngineeringStructural engineering

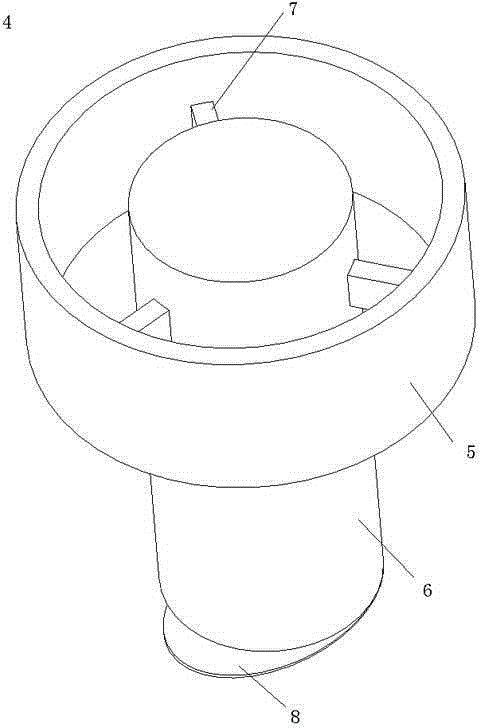

The invention discloses a baby feeding bottle (1) which comprises a bottle body (2) and a nipple (3), a device (4) for containing milk powder is built in the bottle body (2), the device (4) comprises a cylindrical connection piece (5) with an upper opening, a lower opening and a hollow cylindrical milk powder container (6), a circular movable cover plate (8) is arranged on the container (6), and the cover plate (8) is hinged with the lower end of the container through a hinge device. An iron sheet is embedded in the cover plate (8), a magnet is embedded in a cylindrical lateral wall of the container (6), the container (6) is vertically placed by setting size of the embedded magnet, and the cover plate (8) can still cling to a lower end face of the container (6) to enable the milk powder to be free of leakage from the container (6) due to magnetic attraction between the magnet and the iron sheet when the container (6) is full of milk powder. The baby feeding bottle can prevent the milk powder from losing and saves brewing time of the milk powder.

Owner:渭南高新区晨星专利技术咨询有限公司

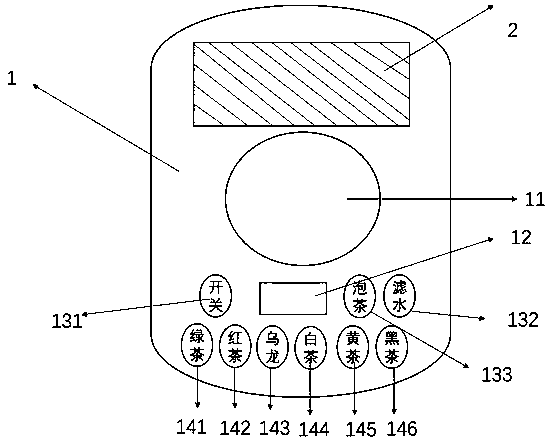

Intelligent tea drinking machine

The invention relates to the field of intelligent home, and particularly relates to an intelligent tea drinking machine. The intelligent tea drinking machine comprises a control base, a heating waterinjection device, a tea brewing cup, a tea filtering plate and a tea filtering cup, wherein the control base and the heating water injection device are connected into a whole; an instant heater and awater pump in the heating water injection device are controlled through selecting press keys on the base by a user; after being heated to a specific temperature, the water is injected into the tea brewing cup; after brewing for a certain time, through holes on the tea filtering plate are automatically opened to realize tea slag filtering; the tea water flows to the tea filtering cup; the control base carries the tea filtering cup and has a heat insulation function for a certain time. According to the invention, the brewing temperature and the brewing time can be automatically set by program according to different types of the tea; the best brewing scheme of green tea, black tea, oolong tea (light oolong), white tea, yellow tea and dark green tea is realized; the requirements of a drinker on the mouthfeel and the nutrition can be met to the maximum degree.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

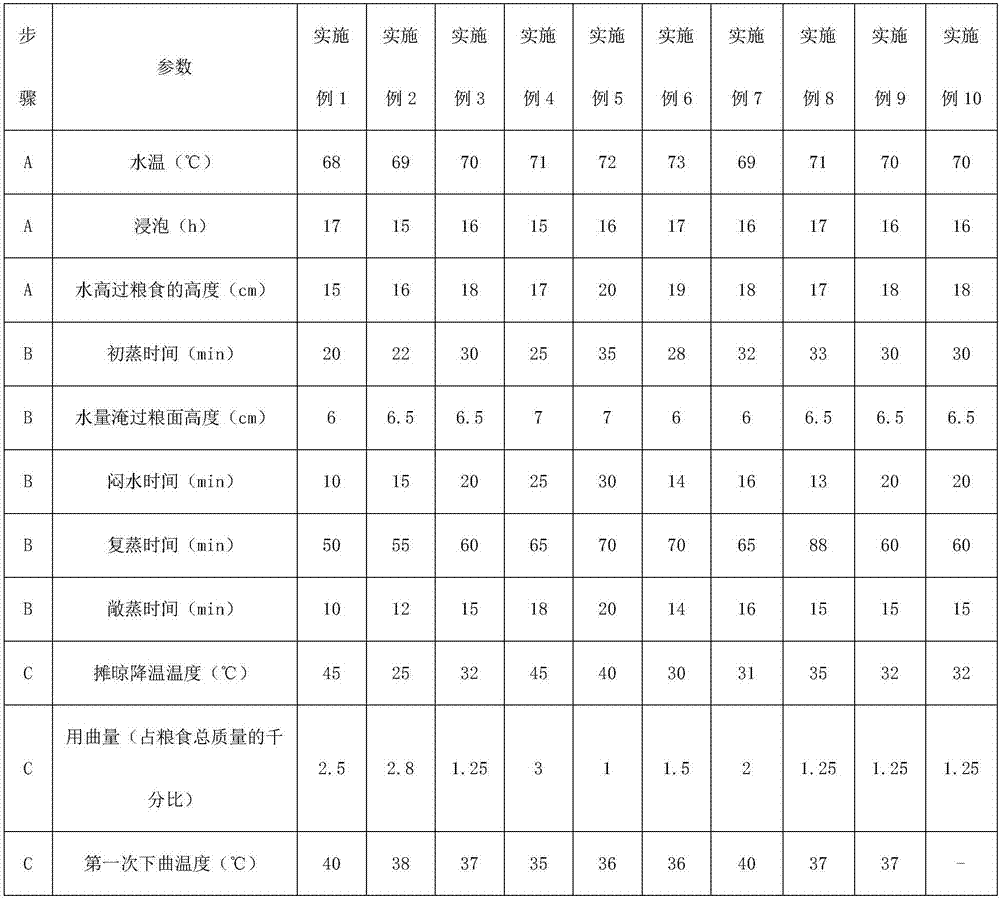

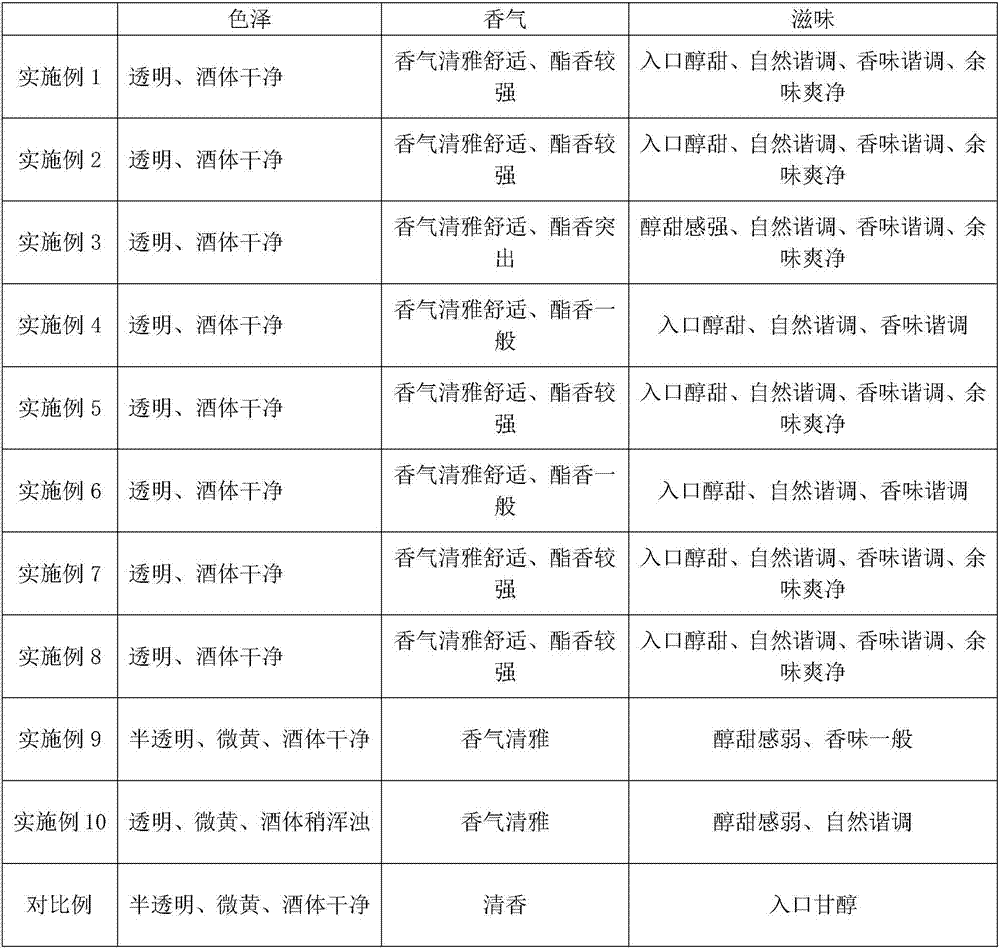

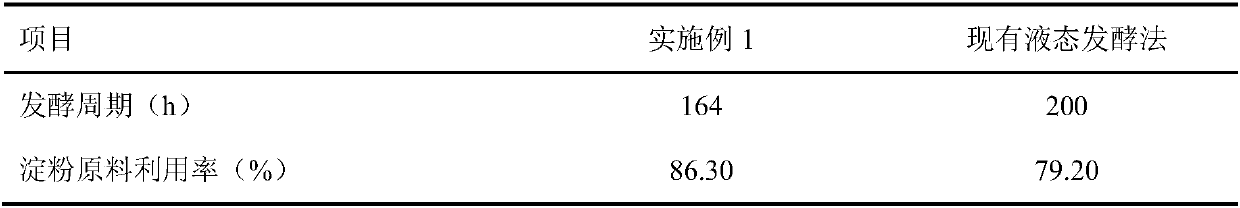

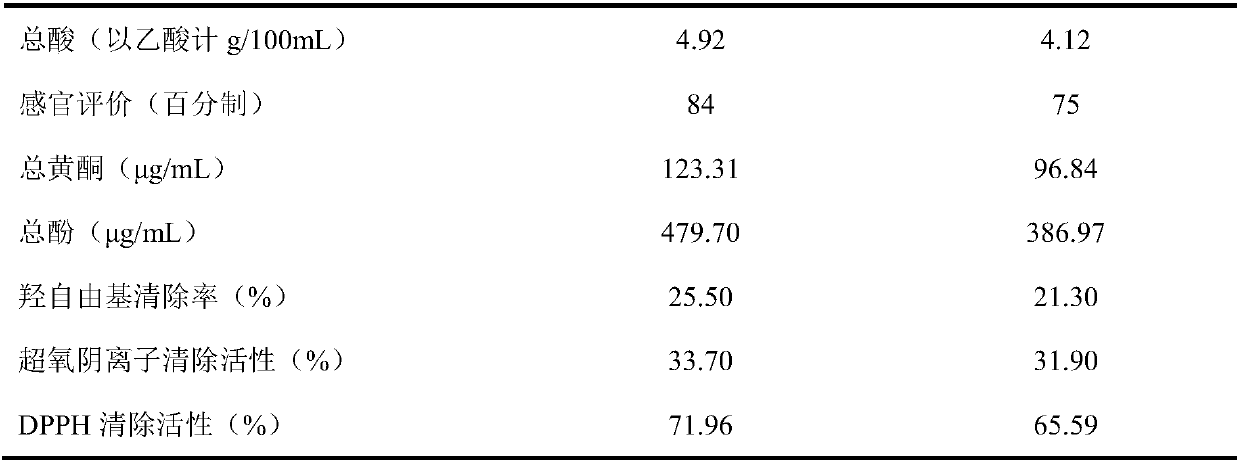

Simple brewing method of baijiu

ActiveCN107227237AIncrease return speedEnhanced transfer processAlcoholic beverage preparationAlcoholDistillation

The invention discloses a simple brewing method of baijiu, which comprises the following steps: A, soaking, B, cooking, C, low-temperature cultivation, D, low-temperature diastatic fermentation and E, distillation. Compared with the prior art, the baijiu produced by the simple brewing method of the baijiu has unique typical style characteristics of faint scent, purity, softness, elegance, comfort, soft, sweet and mellow taste, smoothness, nature, harmony and clear remaining taste; the baijiu with 'faint scent, purity, softness and tastiness' quality is very close to a style of international distilled liquor; however, the baijiu has the characteristics that the baijiu is soft, sweet, clear, pure, and comfortable, people are not drunk after drinking the baijiu, a drunkenness degree is low, and an alcohol effect is dispelled quickly; the baijiu is very popular with massive drinking consumers.

Owner:重庆江记酒庄有限公司

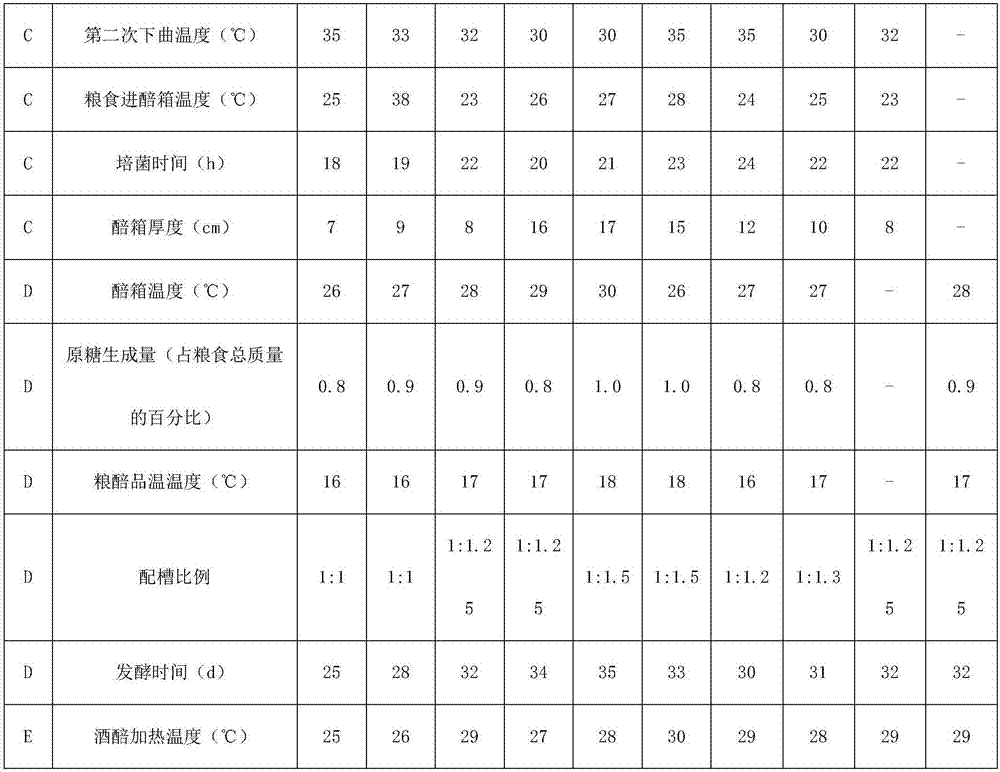

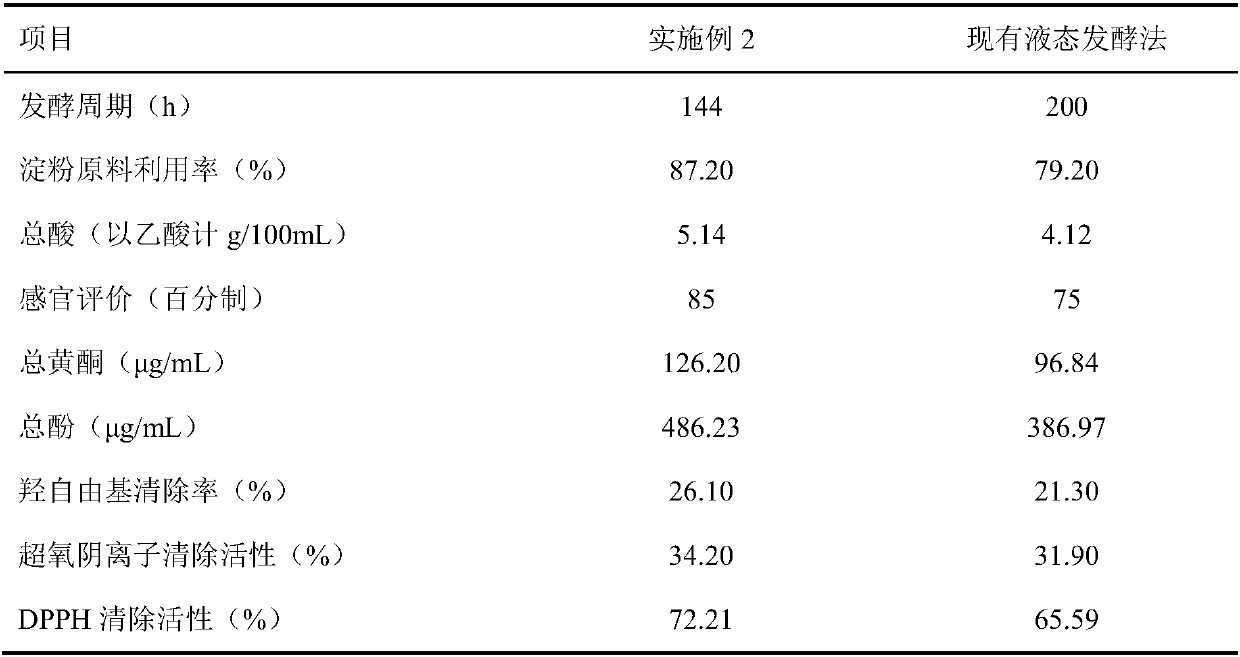

Method for fermenting vinegar by adding starter propagation Chinese herbal medicine

ActiveCN107904128AImprove brewing efficiencyTo promote metabolismAntinoxious agentsVinegar preparationFlavorFiltration

The invention provides a method for fermenting a vinegar by adding a starter propagation Chinese herbal medicine. The method comprises the following steps: (1) preparing a rhizoma polygonati extracting solution and red-knees herb extracting solution; (2) washing and soaking rice, performing filtration, cooking rice to be free from white cores, spreading for cooling, adding a koji mould spore suspension and the rhizoma polygonati extracting solution, performing stacking cultivation, and then performing ventilating cultivation to obtain rhizoma polygonati koji; (3) activating a brewer's yeast; (4) washing and soaking sticky rice, performing filtration, cooking sticky rice to be free from white cores, adding the rhizoma polygonati koji and an activated brewer's yeast suspension, performing fermentation till the alcoholic degree is stable, performing filtration, and performing wine boiling to obtain a fermented wine; and (5) adding the red-knees herb extracting solution into the fermentedwine, adding water to dilute the fermented wine, performing pasteurization, performing cooling, then adding an activated acetic bacteria suspension, charging into a fermentation tank, performing fermentation under stirring and ventilating conditions till the acidity no longer rises, performing filtration, and performing blending and disinfection to obtain the starter propagation Chinese herbal medicine. By adoption of the method, the vinegar fermentation production efficiency and the flavor of the vinegar are improved, and the health value of the vinegar is also improved.

Owner:SICHUAN UNIV

Saccharomyces cerevisiae strain for brewing aroma-enhancing wine and application and method

ActiveCN111363686AFermentation starts fastQuality controllableFungiMicroorganism based processesLeavening agentFermentation starter

The invention discloses a saccharomyces cerevisiae strain for brewing aroma-enhancing wine and application and a method. The saccharomyces cerevisiae strain is Clavispora lusitaniae lys 225, and the preservation number is CGMCC No. 18933. The saccharomyces cerevisiae strain can be used for preparing a fruit wine leavening agent and brewing wine.

Owner:HUNAN AGRICULTURAL UNIV

Method for preparing high-protein drink with capsule drink machine

The invention provides a method for preparing a high-protein drink with a capsule drink machine. The drink machine comprises a machine base, a brewing cavity, a control board, a brewing head, a water inlet pricking pin arranged on the brewing head, a lead-out pricking pin, a liquid supply mechanism supplying a liquid to the brewing head and a brewing cup for accommodating a material package, wherein the brewing cavity and the control board are arranged in the machine base, and high-protein drink powder is accommodated in the material package. The method for preparing the high-protein drink with the drink machine comprises a water injection step, a disturbance step and a drink discharge step, so that the height of a mixed solution is rapidly higher than a water outlet of the water inlet pricking pin within 2-8s, water injection is completed in shorter time, denaturation occurring after high-protein drink powder makes contact with water for a long time is prevented, the mixed solution churns in the material package to drive powder balls to impact water and a body of the material package in the churning process, and powder balls are more effectively scattered and dissolved. The taste of the drink is improved, the drink machine can prepare the high-protein drink, blocking of the pricking pins or a discharge outlet cannot be caused during preparation of the high-protein drink, thus, the blasting problem cannot be caused, and the safety during use of the drink machine is improved.

Owner:杭州九创家电有限公司

Acid control and efficiency improvement method for Daqu delicate fragrance liquor in hot season

ActiveCN104862167AReduce dosagePreserve the function of fermentation to produce wine and aromaAlcoholic beverage preparationFlavorRhizopus

The invention belongs to the technical field of liquor brewing, and provides an acid control and efficiency improvement method for Daqu delicate fragrance liquor in hot season, in order to solve the problems that the liquor produced by using Daqu as a saccharification fermentation agent goes rancidity easily in the hot season, and the liquor yield is affected. A Fen Daqu delicate fragrance Liquor brewage technology is employed, the consumption of Daqu is decreased, and rhizopus distiller's yeast, Saccharomyces cerevisiae and ester producing yeast are in cooperation; and sorghum is used as a raw material for fermentation liquor brewing. The dosage of the yeasts is as below: Daqu accounts for 2.5-7.5% of the raw material, rhizopus distiller's yeast accounts for 0.3-0.5% of the raw material, and Saccharomyces cerevisiae accounts for 0.05-0.01% of the raw material, and the ester producing yeast accounts for 0.05-0.1% of the raw material. The material and yeasts are subjected to ground tank fermentation for 13-15 days; and the initial fermentation temperature is controlled at 25-30 DEG C. The method effectively reduces the amount of Lactobacillus seed, ensures product flavor, presents novel style, greatly reduces the usage amount of the Fen liquor Daqu, lowers costs, and improves the efficiency of liquor brewing in the premise of effective acid control in the hot season. The liquor reserves the aroma function of Fen liquor Daqu, preserves complex composition, and guarantees the flavor characteristics of Fen liquor.

Owner:SHANXI XINGHUACUN FENJIU WINE FACTORY

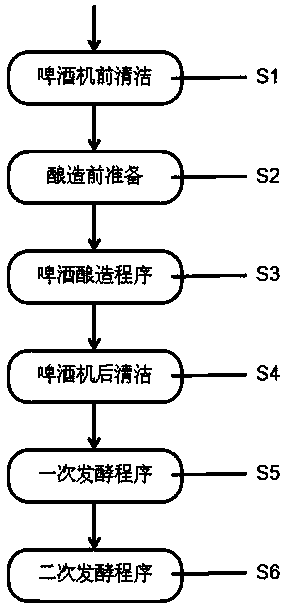

Beer brewing technology

InactiveCN108315117AImprove the level of brewing technologyImprove brewing efficiencyBeer brewingBrewingChemistry

The invention belongs to the technical field of beer brewing, and especially relates to a beer brewing technology, which comprises steps of beer brewing, first fermentation, and second fermentation. The beer brewing technology solves the problems that in the prior art, a conventional beer brewing technology is in a low level and the efficiency is low and has the advantages of high brewing efficiency, high finished product quality, good quality, high purity, and mellow taste.

Owner:天津丰逸科技有限公司

Chinese chestnut and sticky rice distilled liquor and brewing method thereof

InactiveCN105462774AGood health effectHigh in nutrientsAlcoholic beverage preparationNutritive valuesSorghum

The invention provides Chinese chestnut and sticky rice distilled liquor. With sticky rice being a main material and Chinese chestnuts being an auxiliary material, rough rice and sorghum are added, the usage quantities of all raw material components are adjusted and optimized, and then the Chinese chestnut and sticky rice distilled liquor is obtained through further brewing; in this way, on the basis of original sticky rice liquor, the flavor of the original sticky rice liquor can be adjusted, nutrient substances in the sticky rice liquor are further increased, and the health-care effect of the liquor is improved. Meanwhile, the invention provides a brewing method of the Chinese chestnut and sticky rice distilled liquor. In the method, through using the composition being the raw material, the Chinese chestnut and sticky rice distilled liquor having good flavor and nutritive value can be brewed. The Chinese chestnut and sticky rice distilled liquor has good flavor and is balanced and rich in nutrient.

Owner:束润涛

Technology for quickly producing yellow wine

PendingCN110734833AShorten the brewing cycleTraditional production process simplifiedAlcoholic beverage preparationProcess engineeringJaponica rice

The invention discloses a technology for quickly producing yellow wine, and belongs to the technical field of a technology for quickly producing yellow wine. The technology comprises the following steps of immersing good-quality polished round-grained rice for 18-20h, steaming rice, performing spreading for cooling, performing falling from a bar, performing prefermentation and adding water, performing loading in a pot, performing post fermentation, when alcoholic fermentative materials are cooked, performing squeezing, performing blending, and performing wine decoction to obtain finished products of the yellow wine. The yellow wine for brewing the yellow wine is simple in technological operation, the production cycle is shortened, and the obtained yellow wine is clear in wine quality and rich in wine fragrance.

Owner:安徽古南丰实业股份有限公司

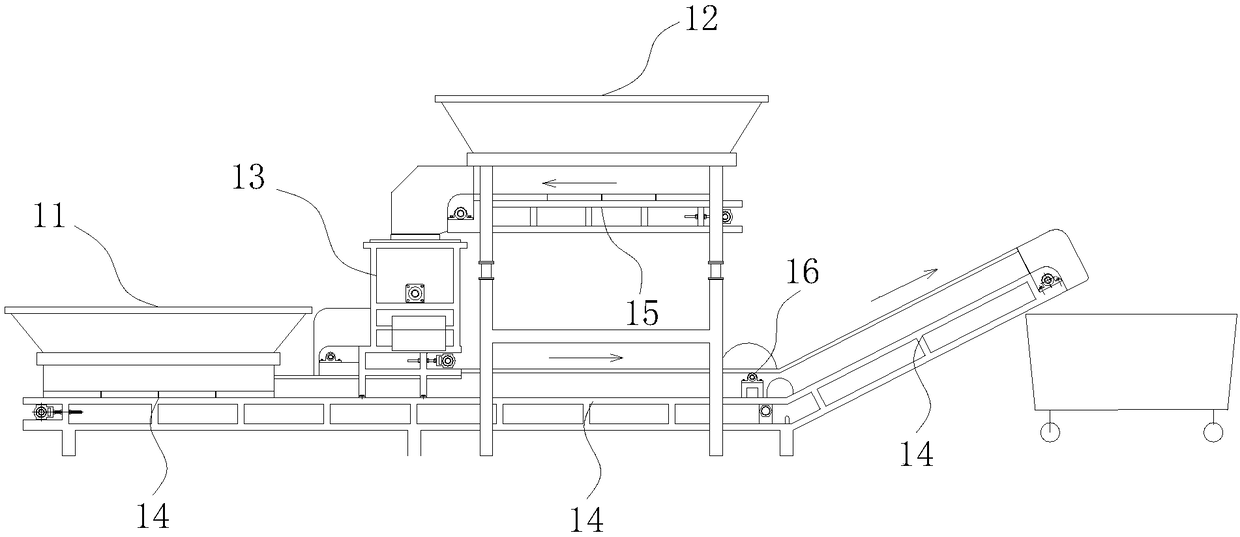

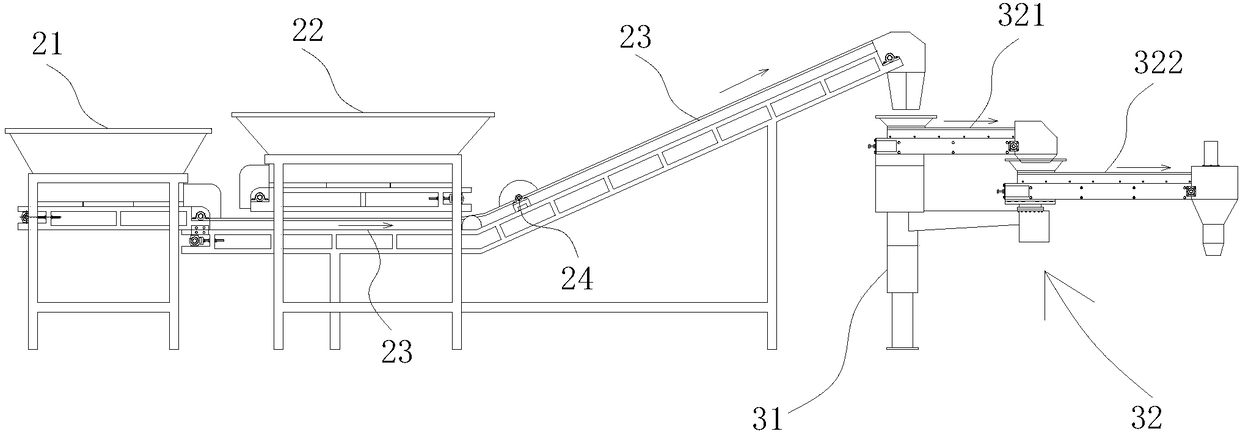

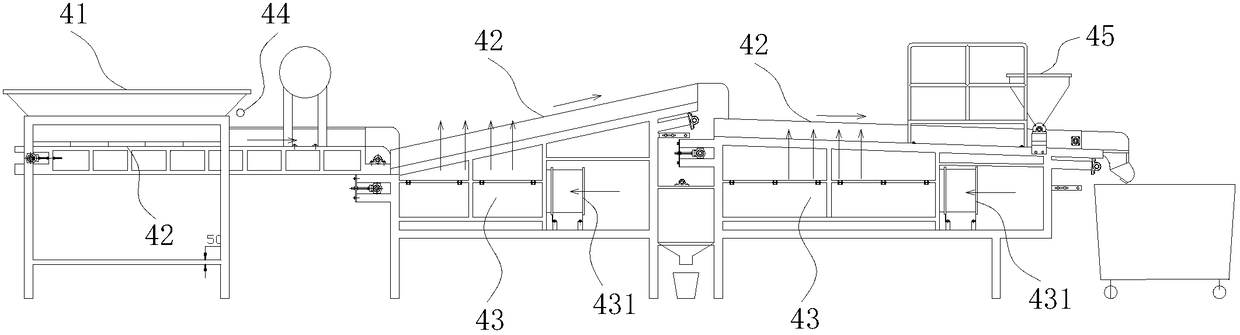

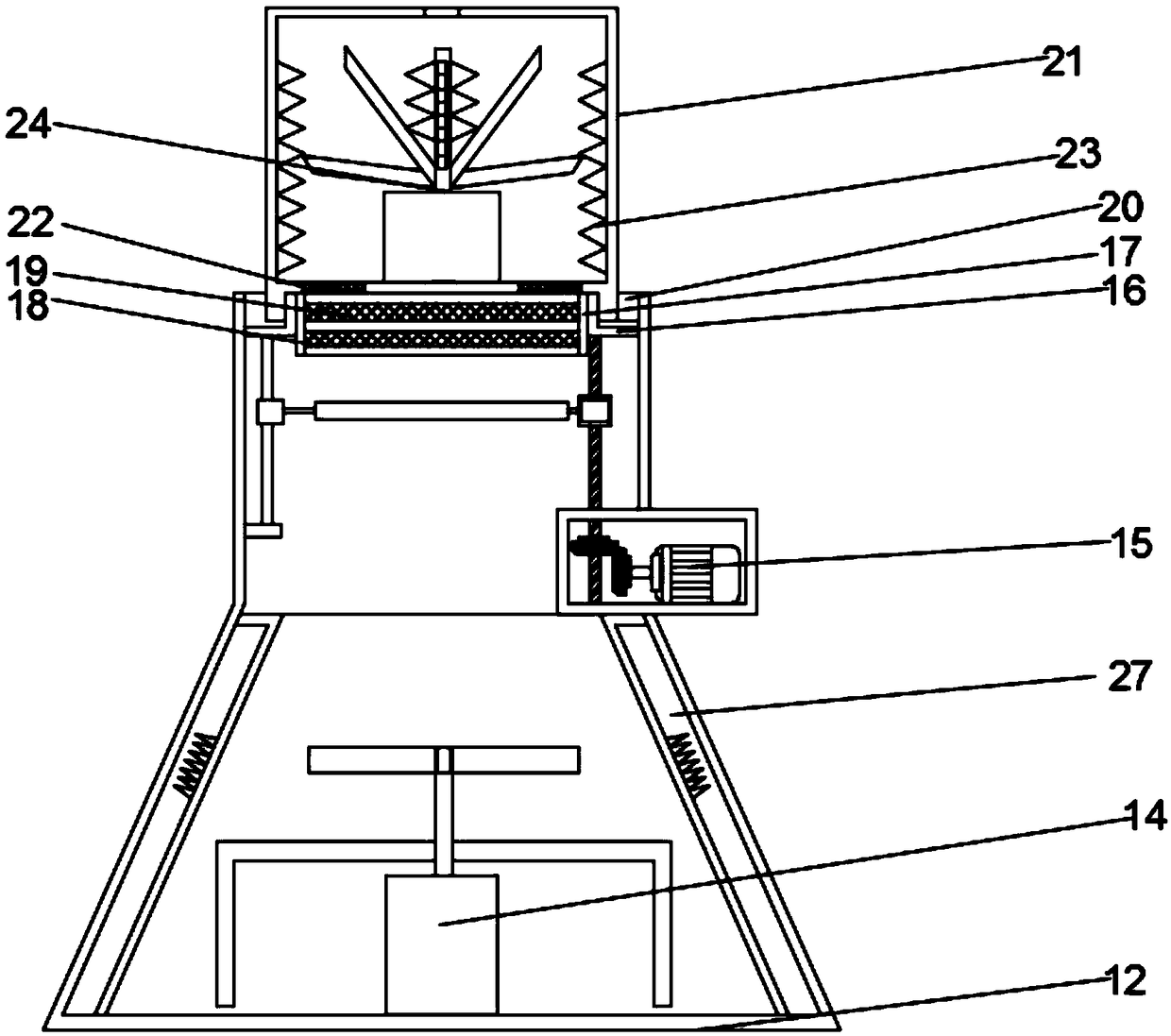

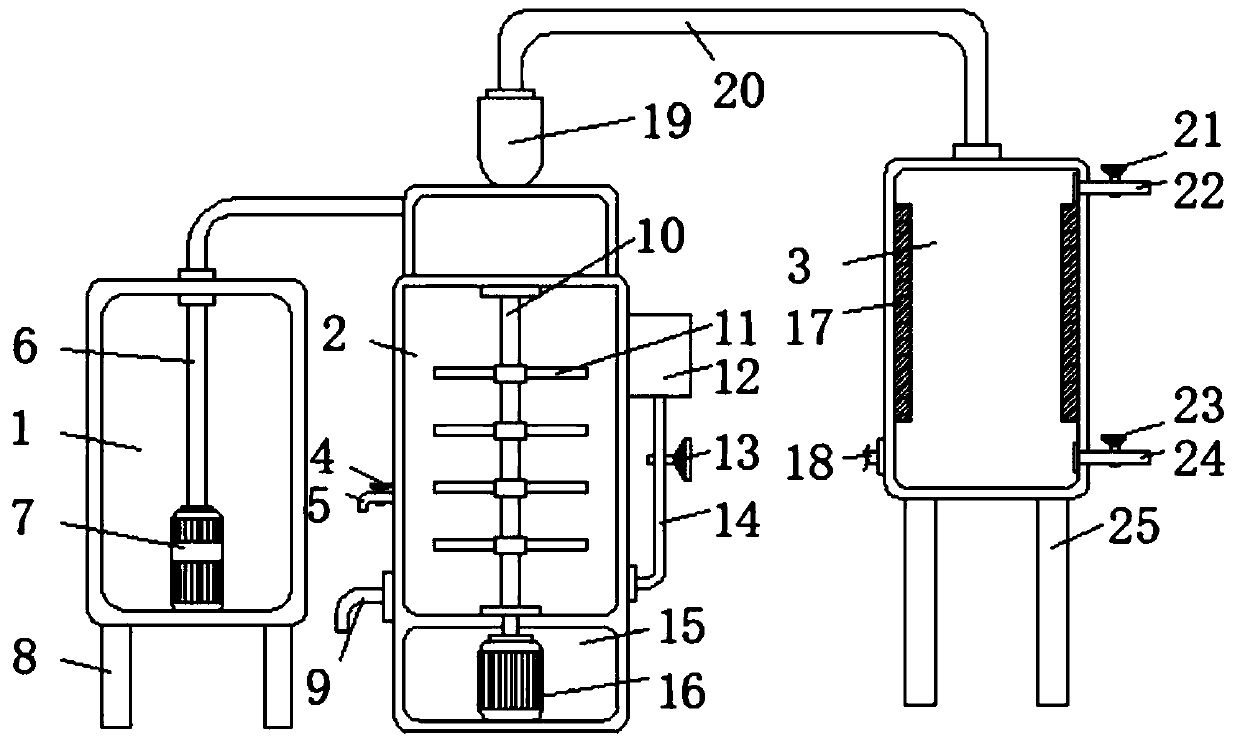

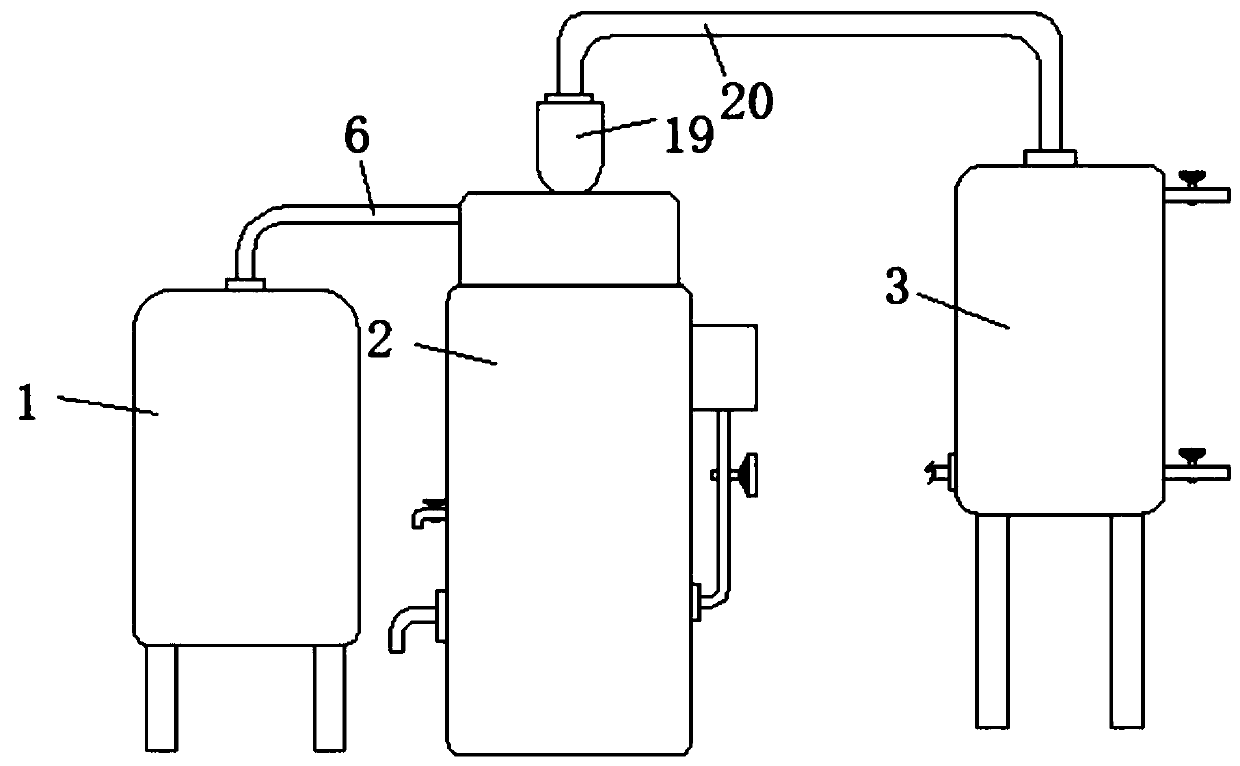

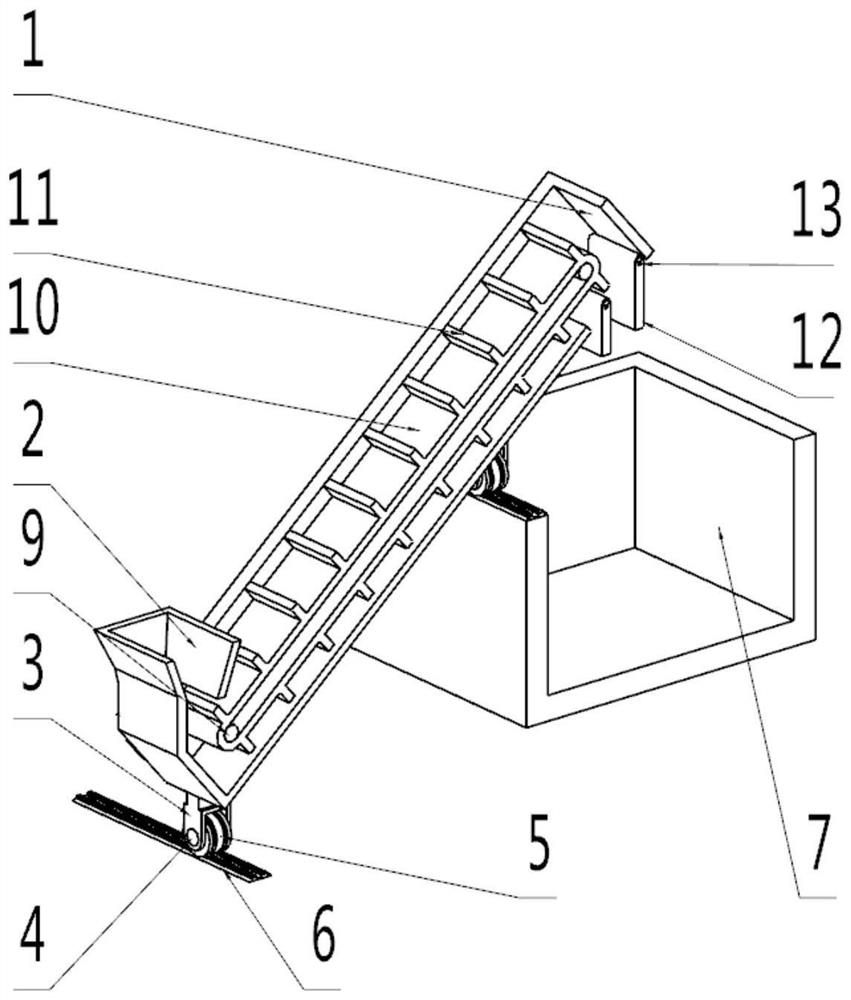

Intermittent intelligent wine brewing system and wine brewing method

InactiveCN108384699ALower installation heightAvoid uneven mixingAlcoholic beverage preparationCombustion chamberDistillation

The invention relates to an intermittent intelligent wine brewing system and a wine brewing method. The wine brewing system includes a first material stirring unit, a second material stirring unit, arice steamer storage unit, a mixed combustion vapor supply unit and a fermented grain airing and cooling unit; the first material stirring unit includes a fermented grain hopper, a grain hopper, a grain and water stirring device, a first conveyor belt and a second conveyor belt; the second material stirring unit includes a material mixing hopper, a bran hopper and a third conveyor belt; the rice steamer storage unit comprises a bracket and a spiral feeding mechanism for loading auxiliary materials into distillation rice steamers; the mixed combustion vapor supply unit includes a boiler for supplying vapor to the distillation rice steamers in which the auxiliary materials are stored; the boiler includes a combustion chamber composed of an upper layer bran husk combustion cavity, a middle layer marsh gas combustion cavity and a lower layer coal combustion cavity; the fermented grain airing and cooling unit includes a fermented grain hopper, a fourth conveyor belt and a blowing box. By means of the wine brewing system and the wine brewing method, not only can materials be uniformly blended, correspondingly the wine discharging amount is greatly increased, and the wine brewing qualityis ensured; moreover, continuous automatic operation can also be achieved, and the wine brewing efficiency is greatly improved.

Owner:ANHUI YINGJIA TRIBUTE WINE

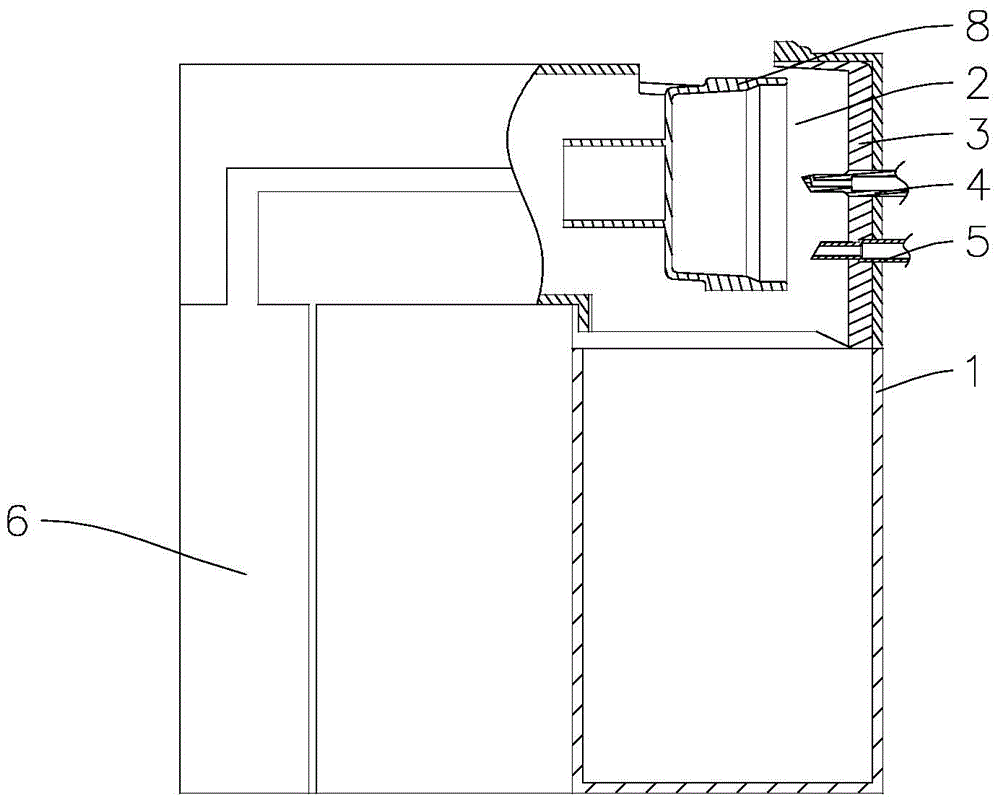

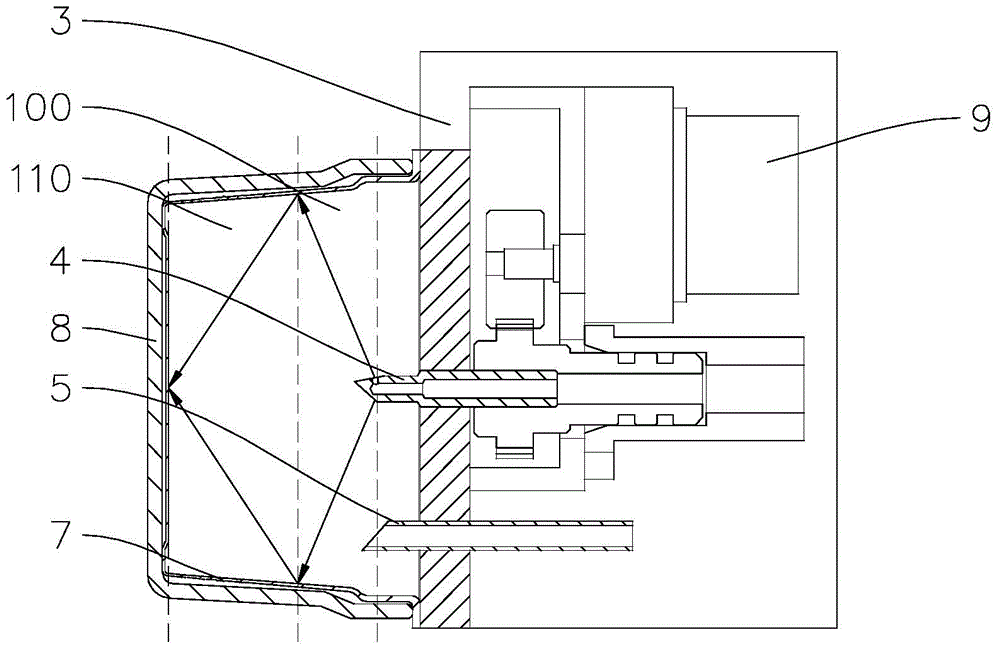

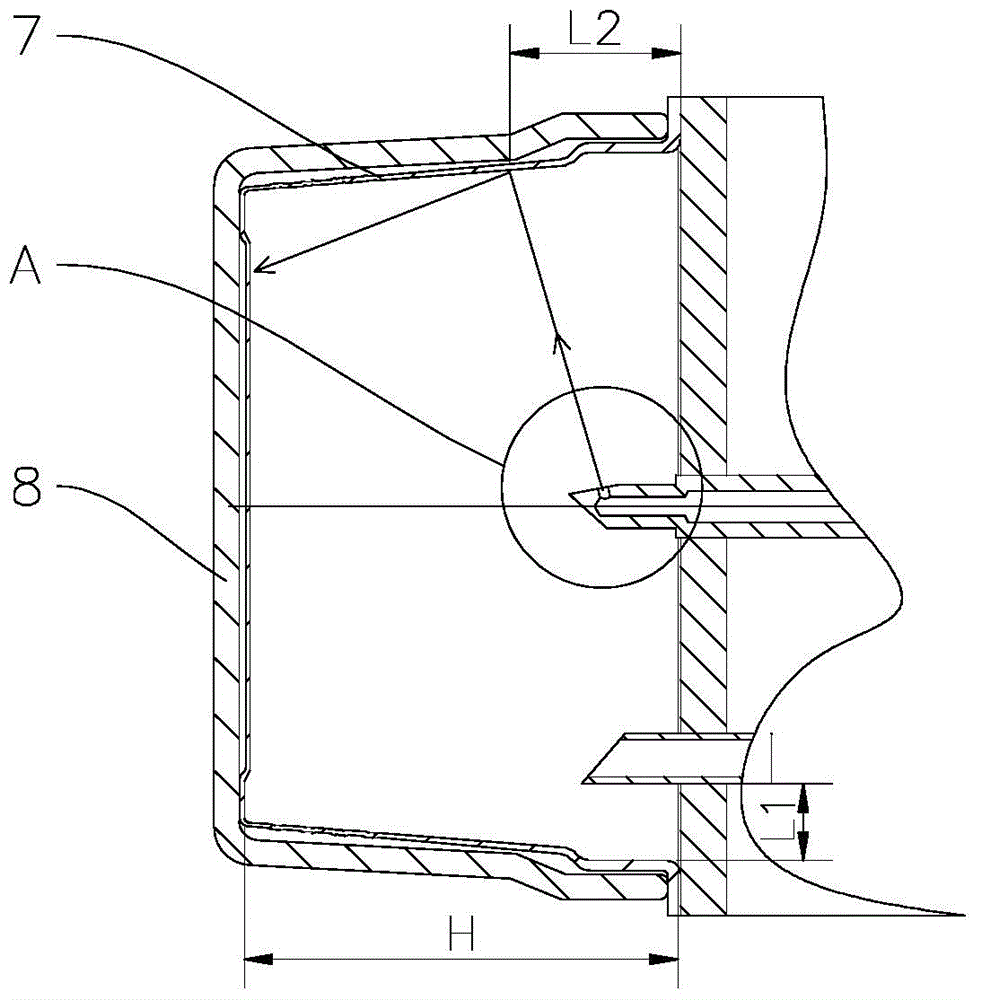

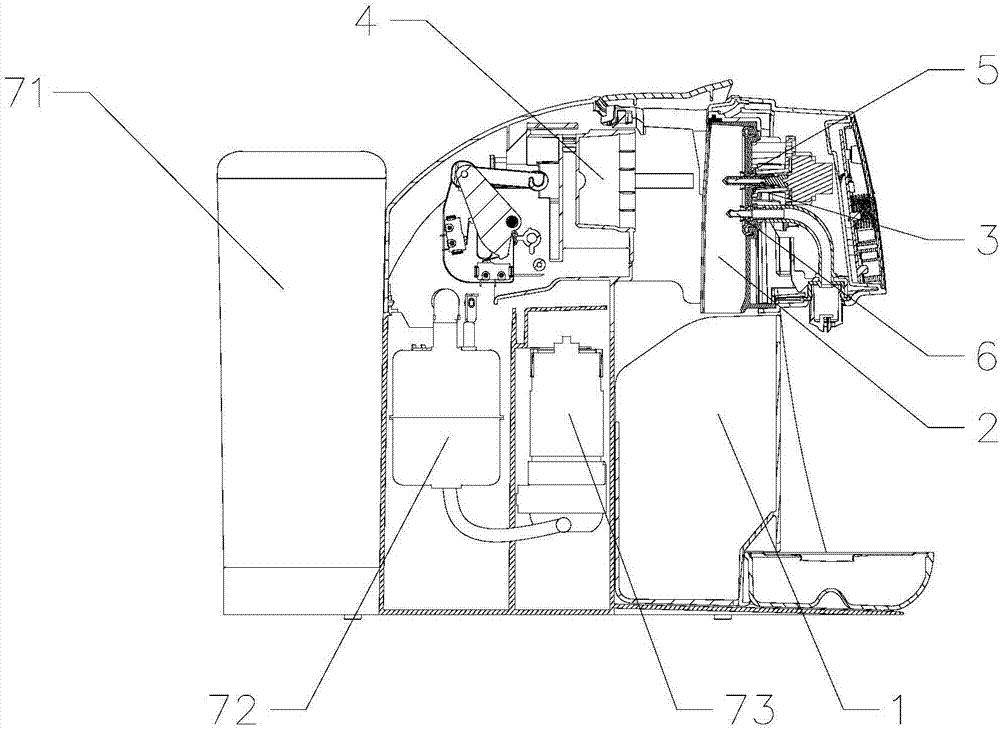

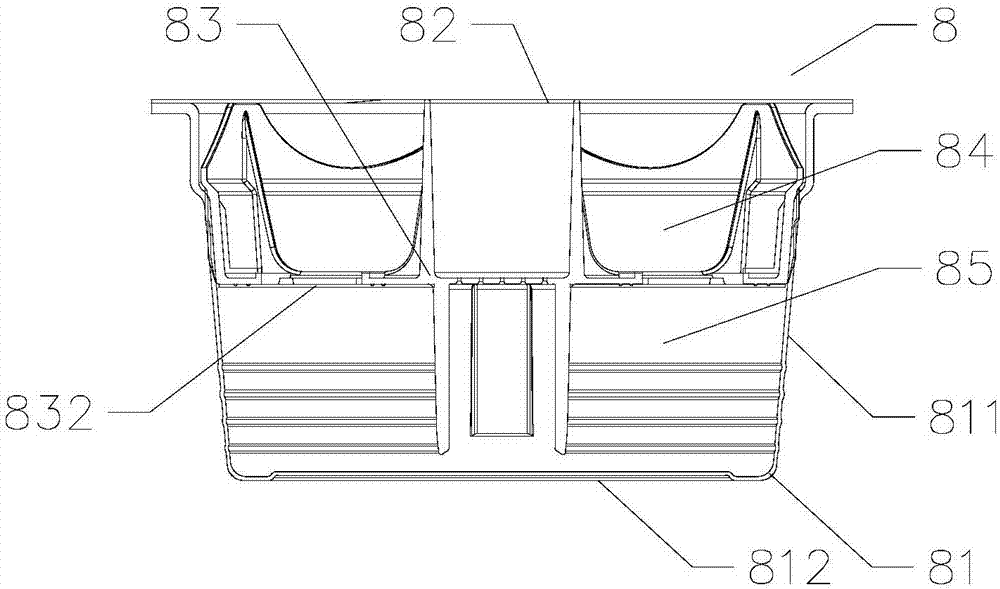

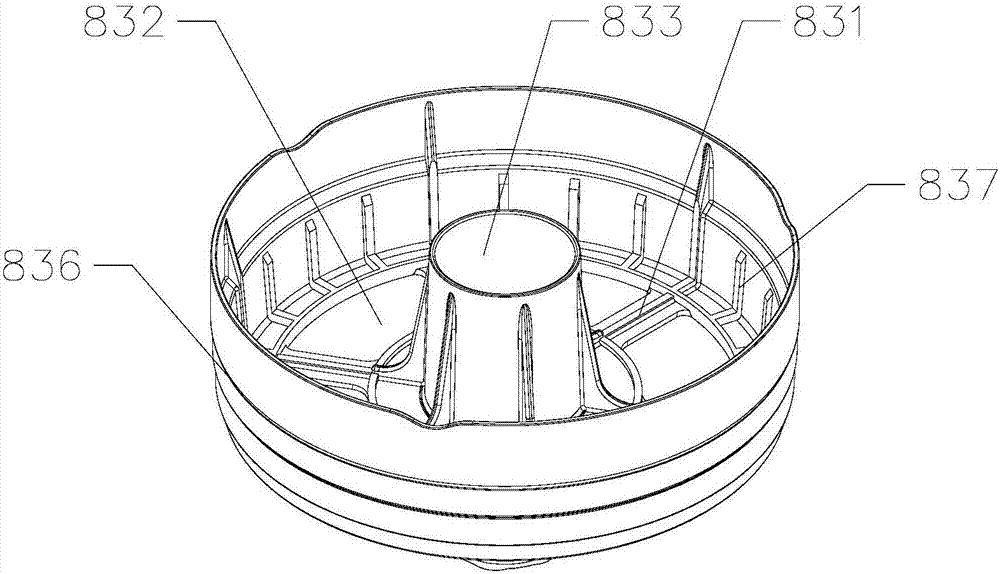

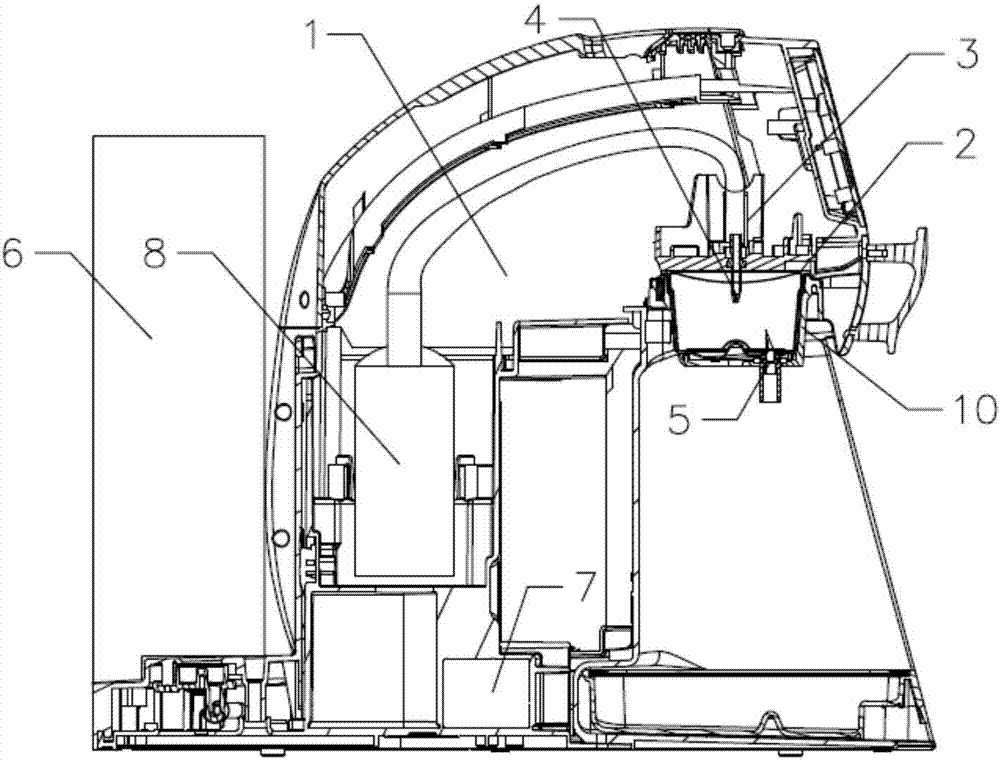

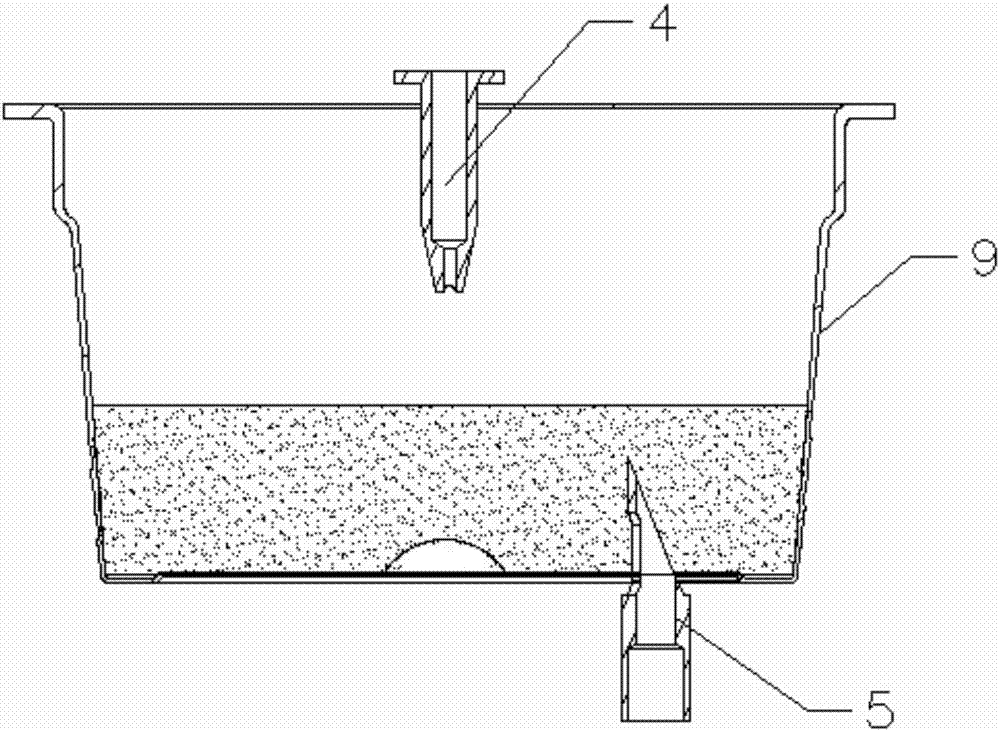

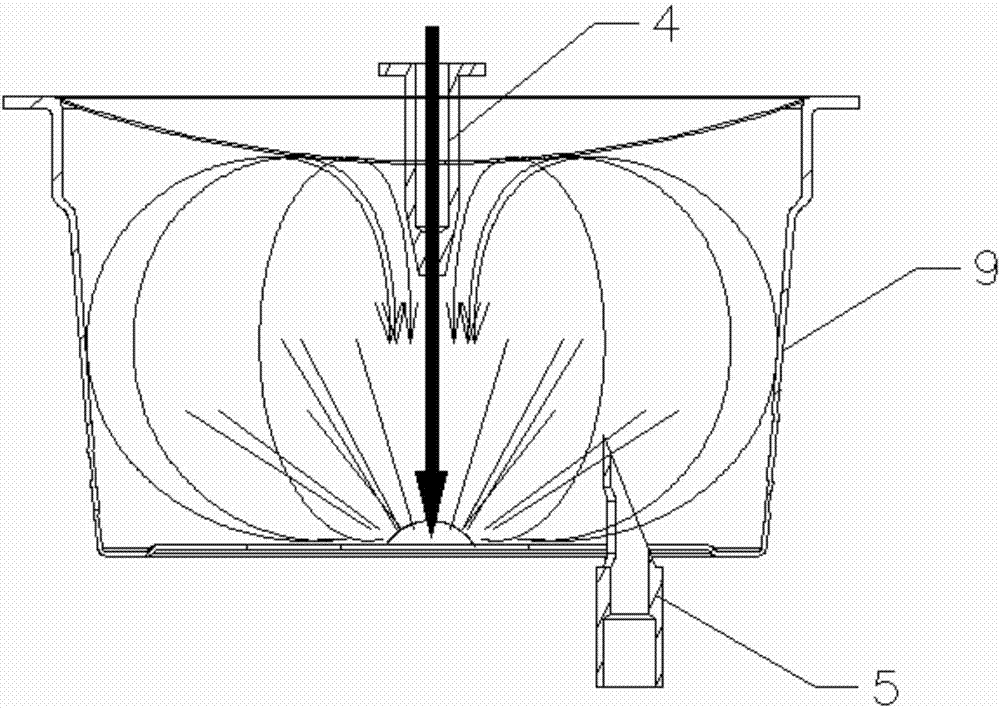

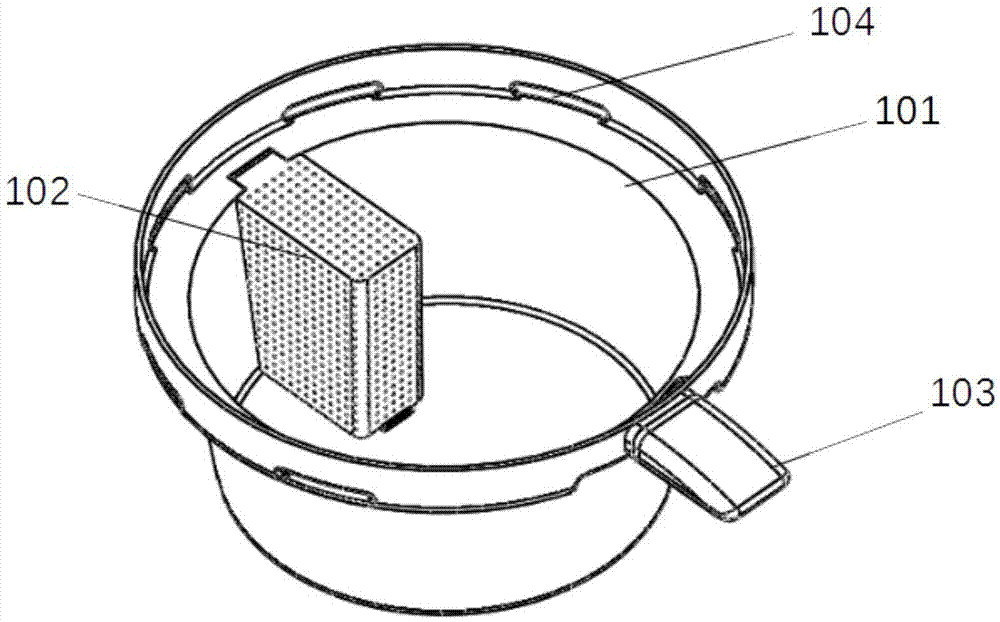

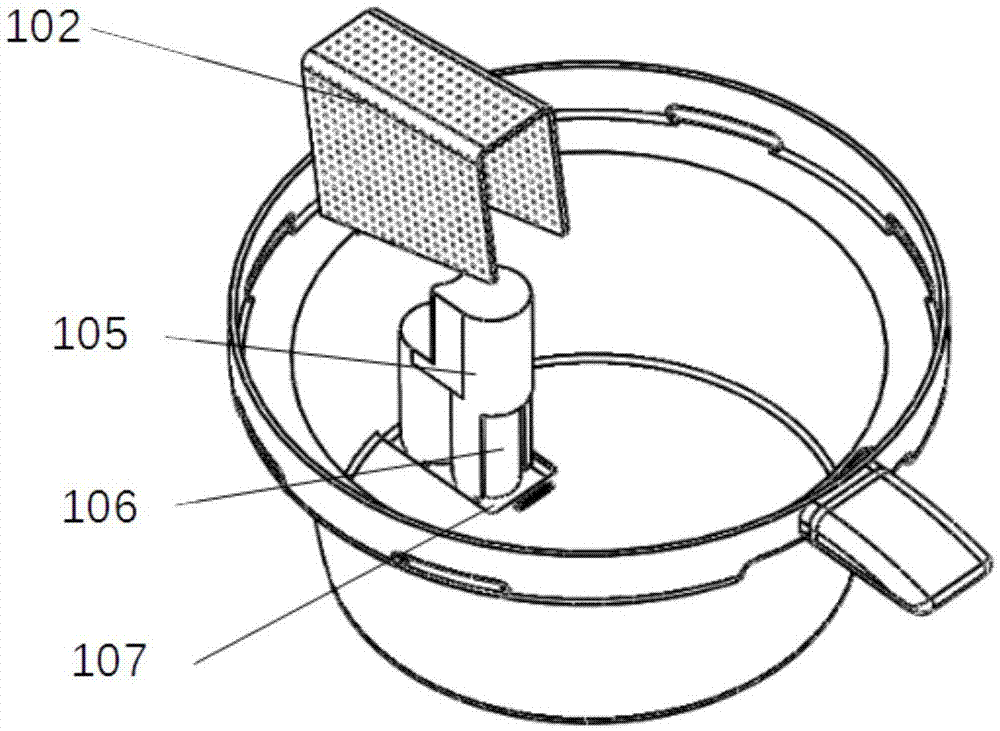

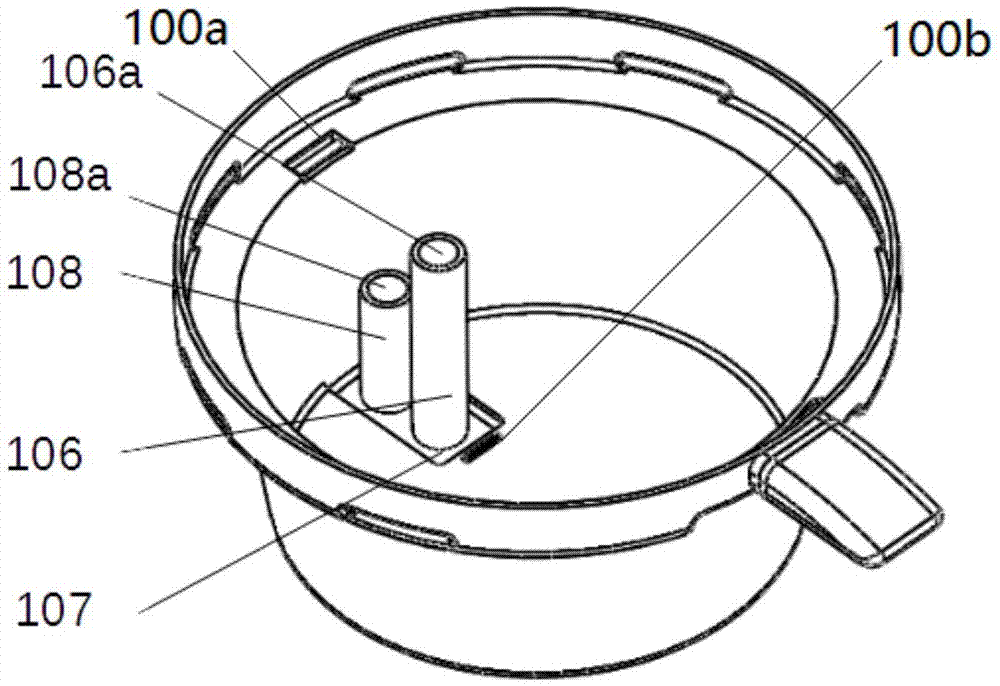

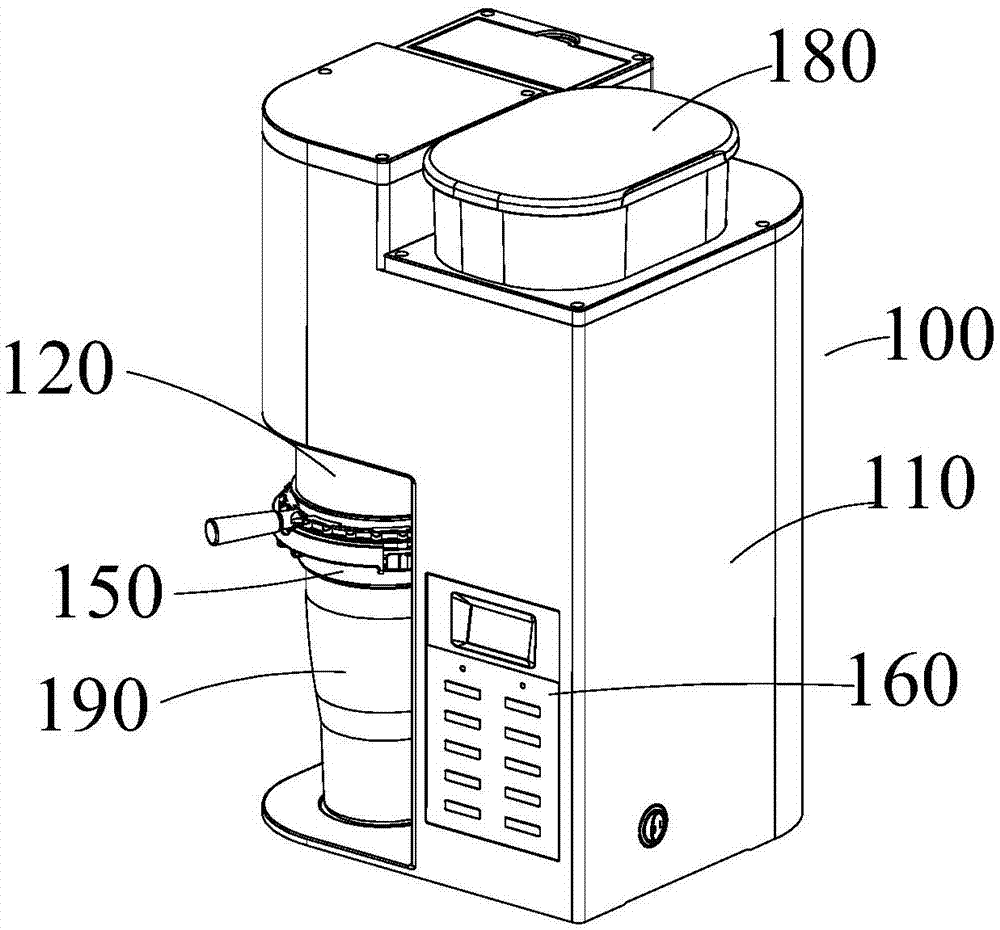

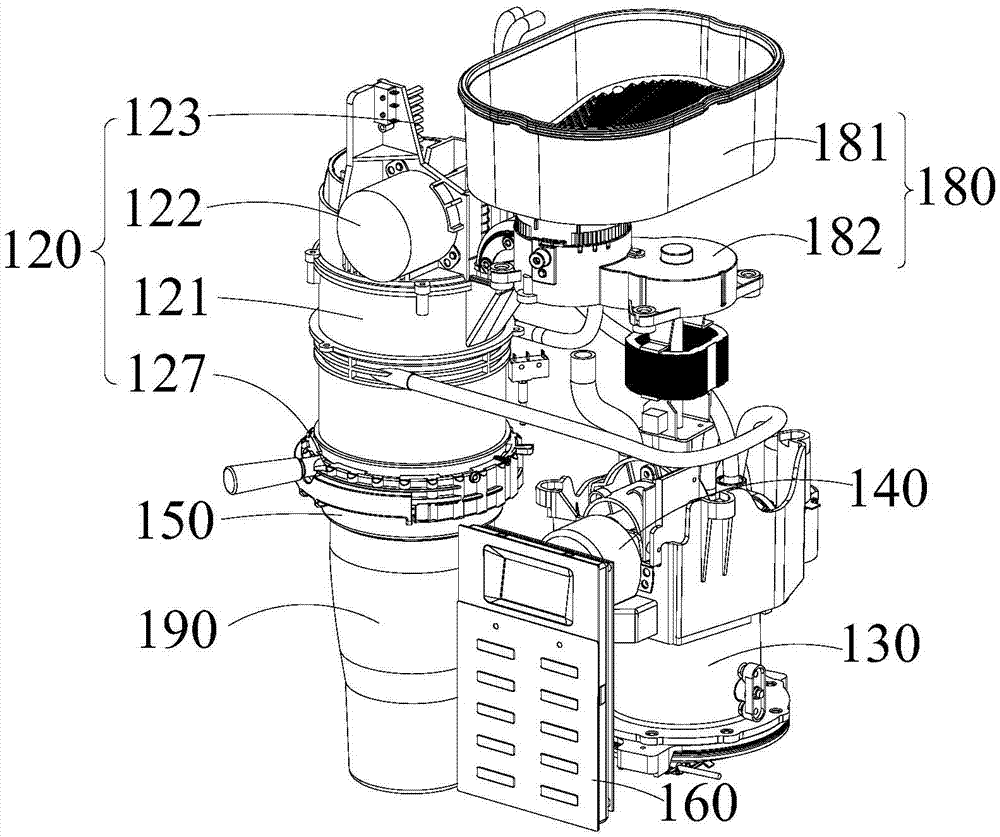

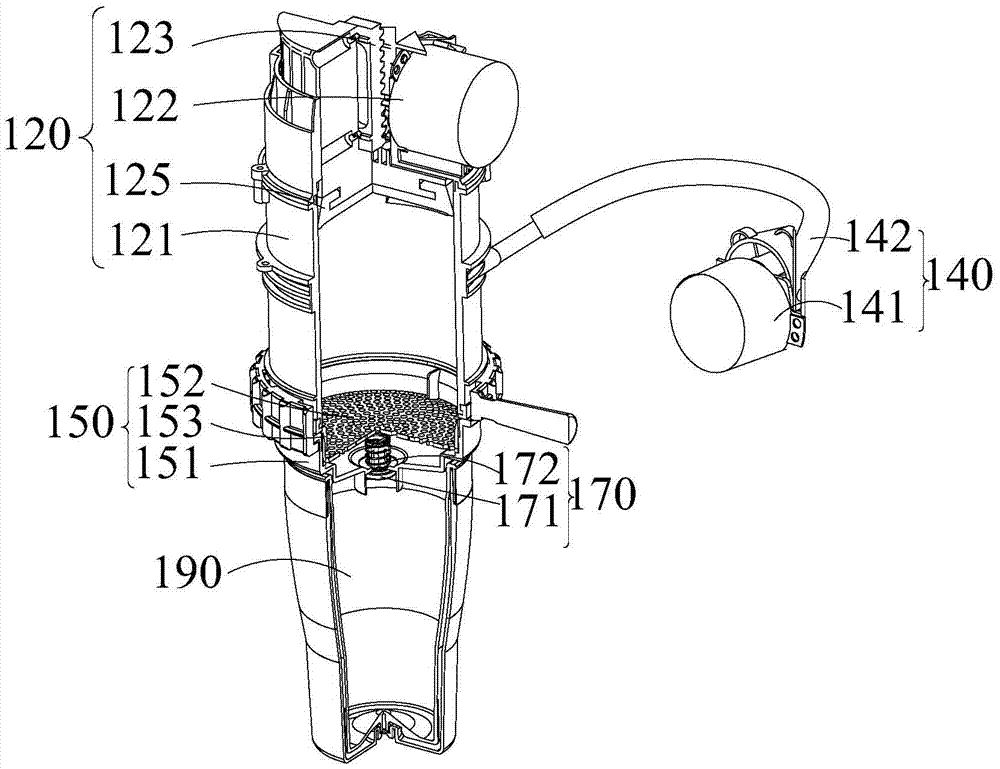

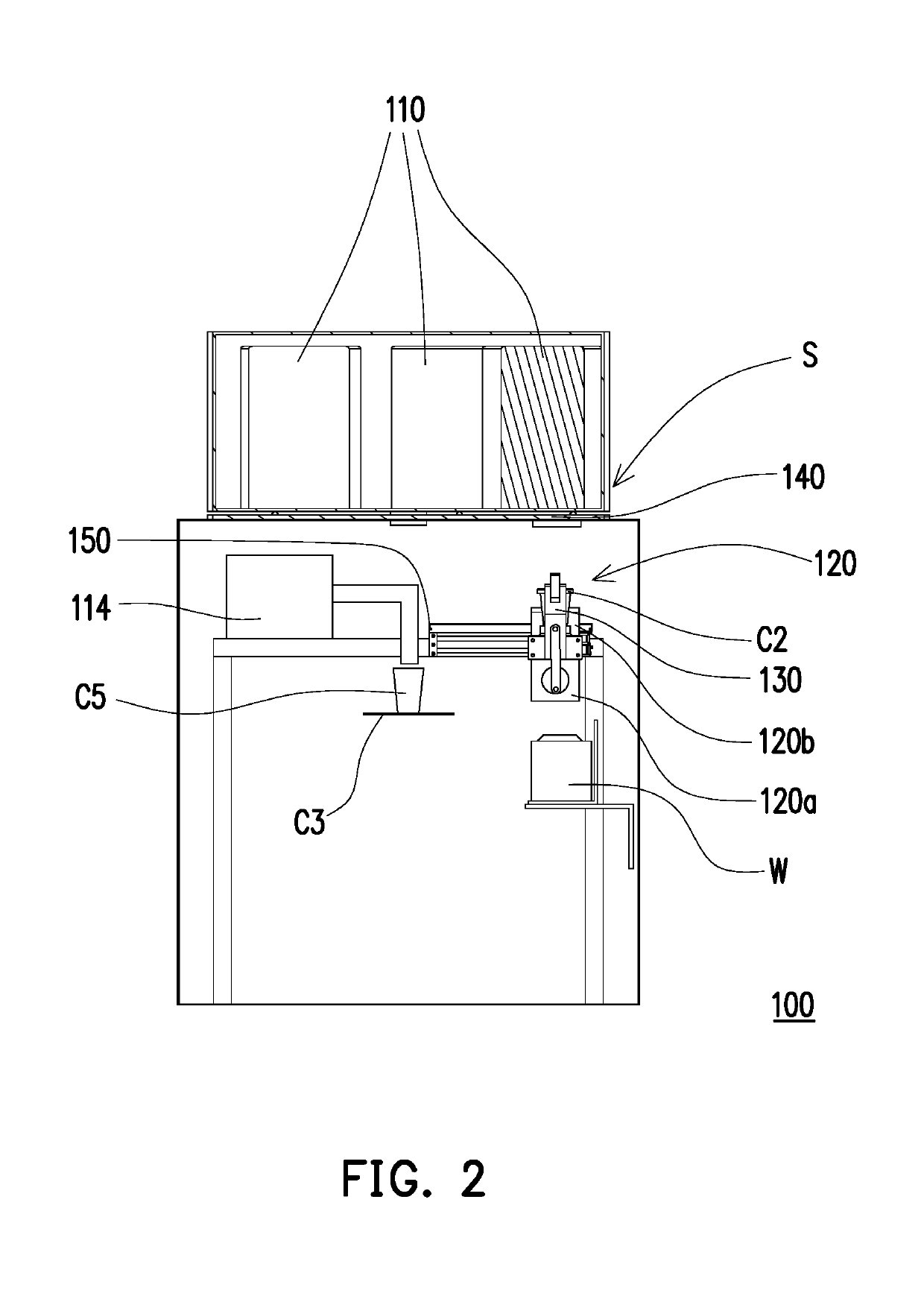

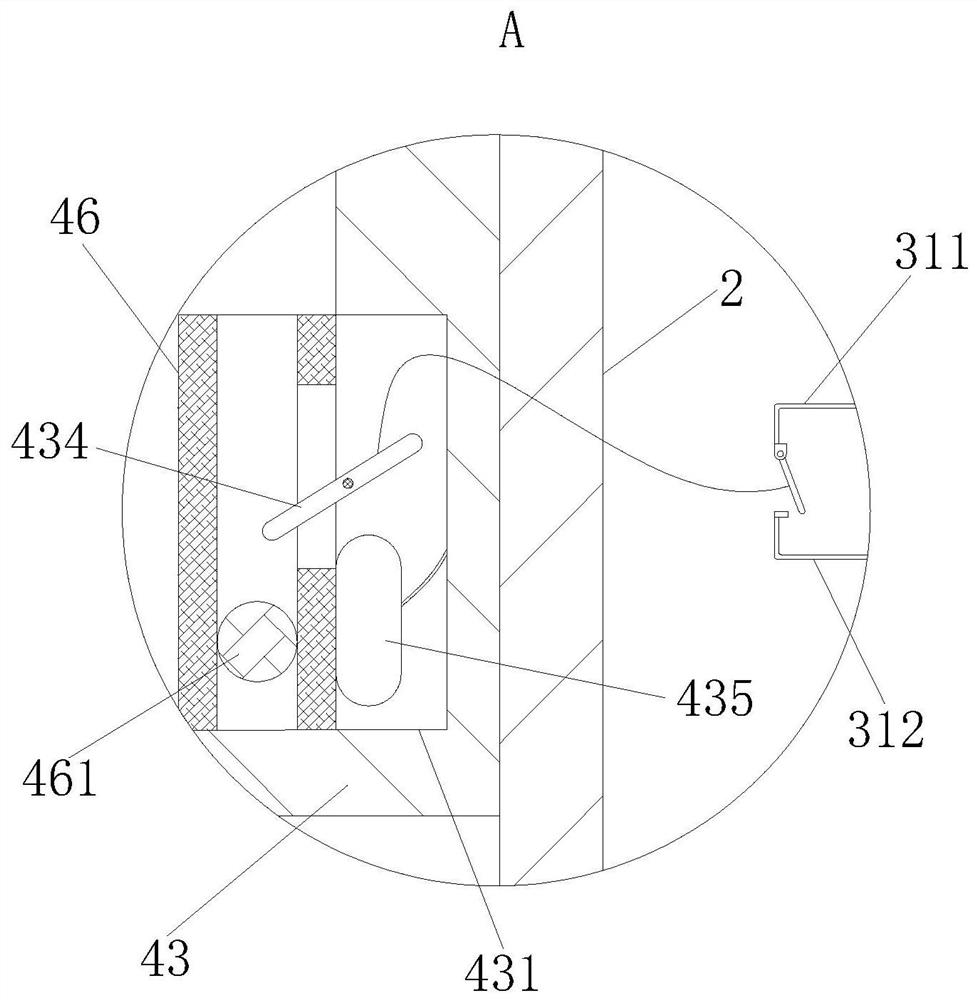

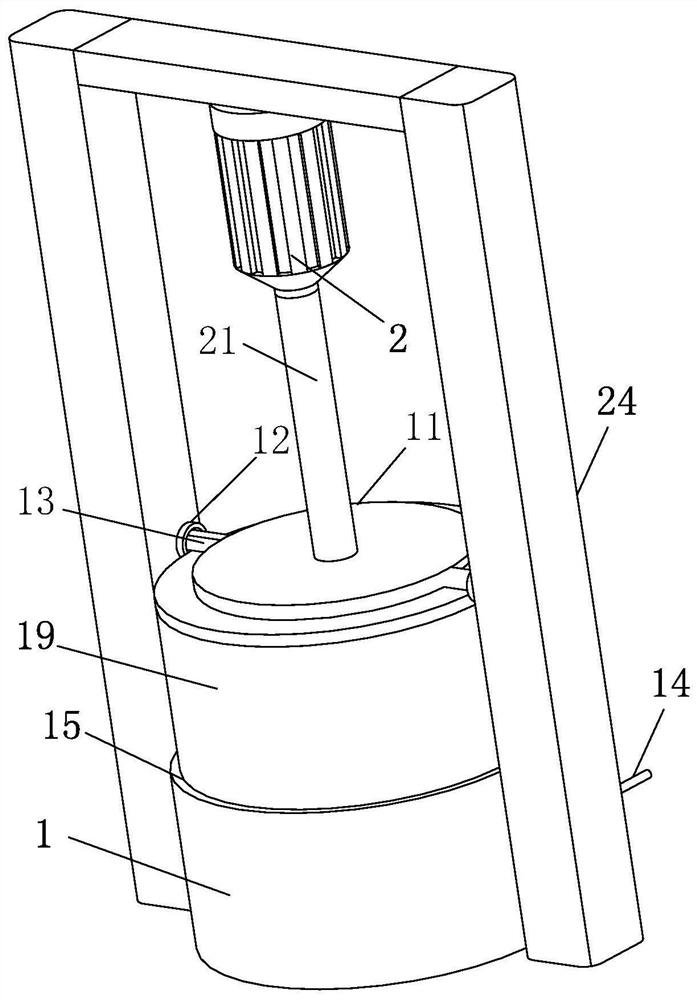

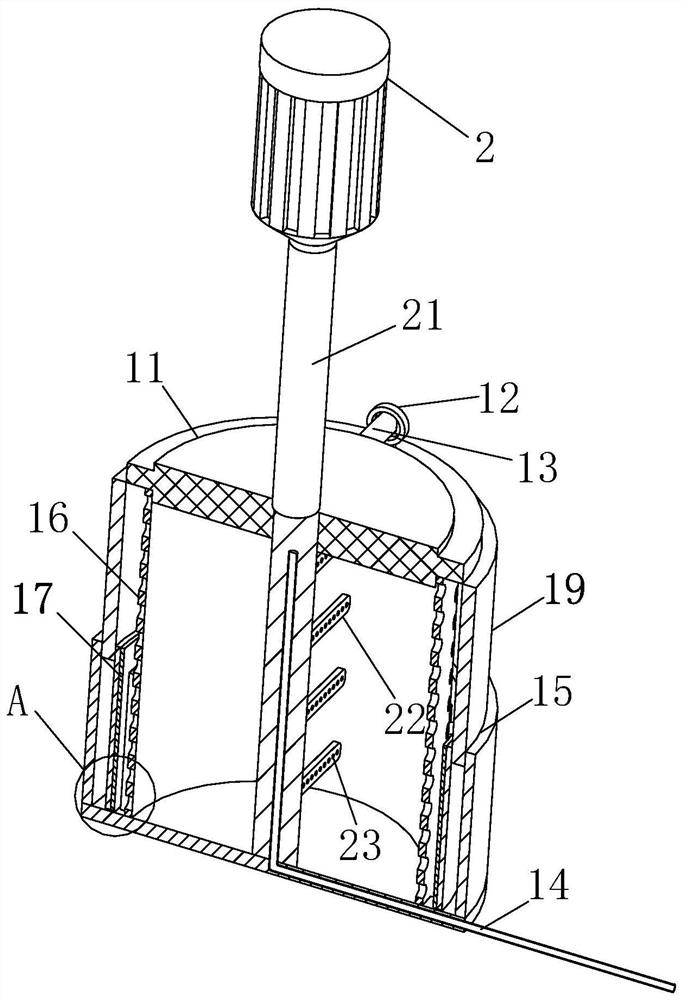

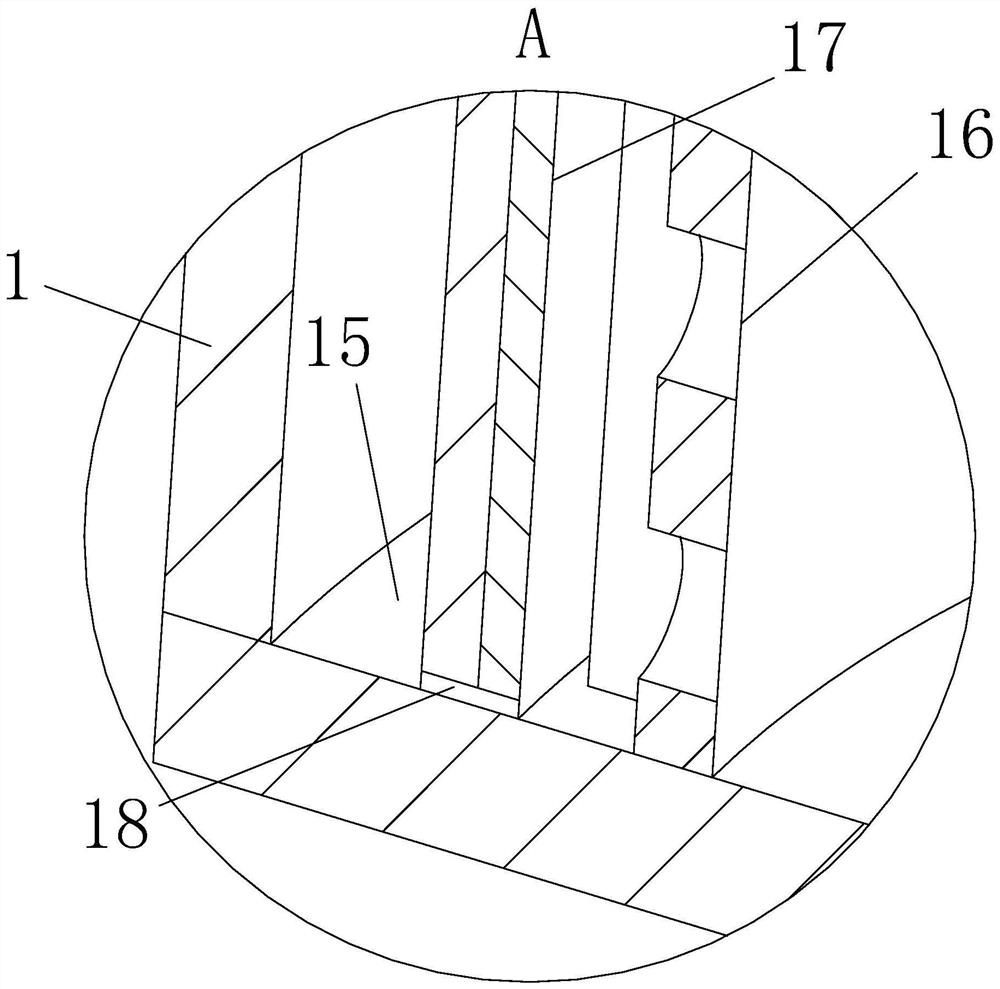

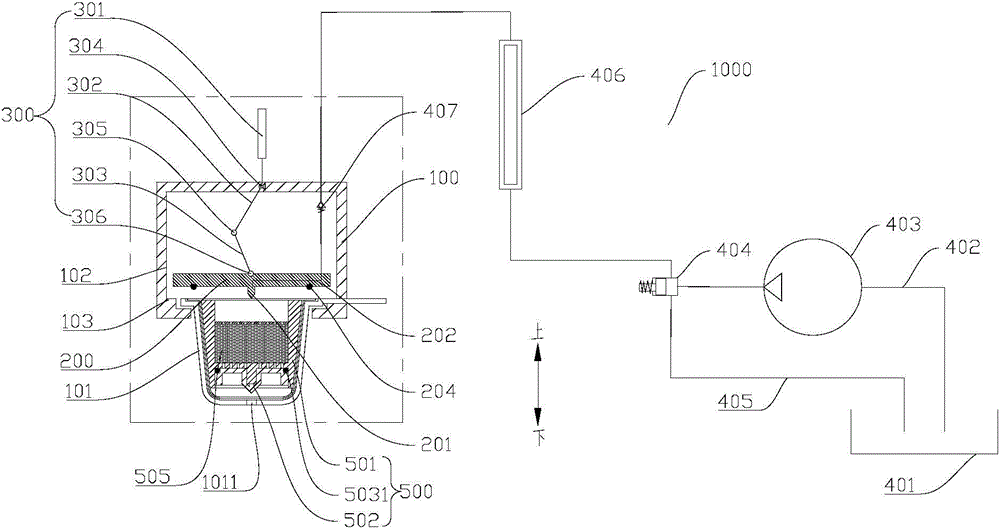

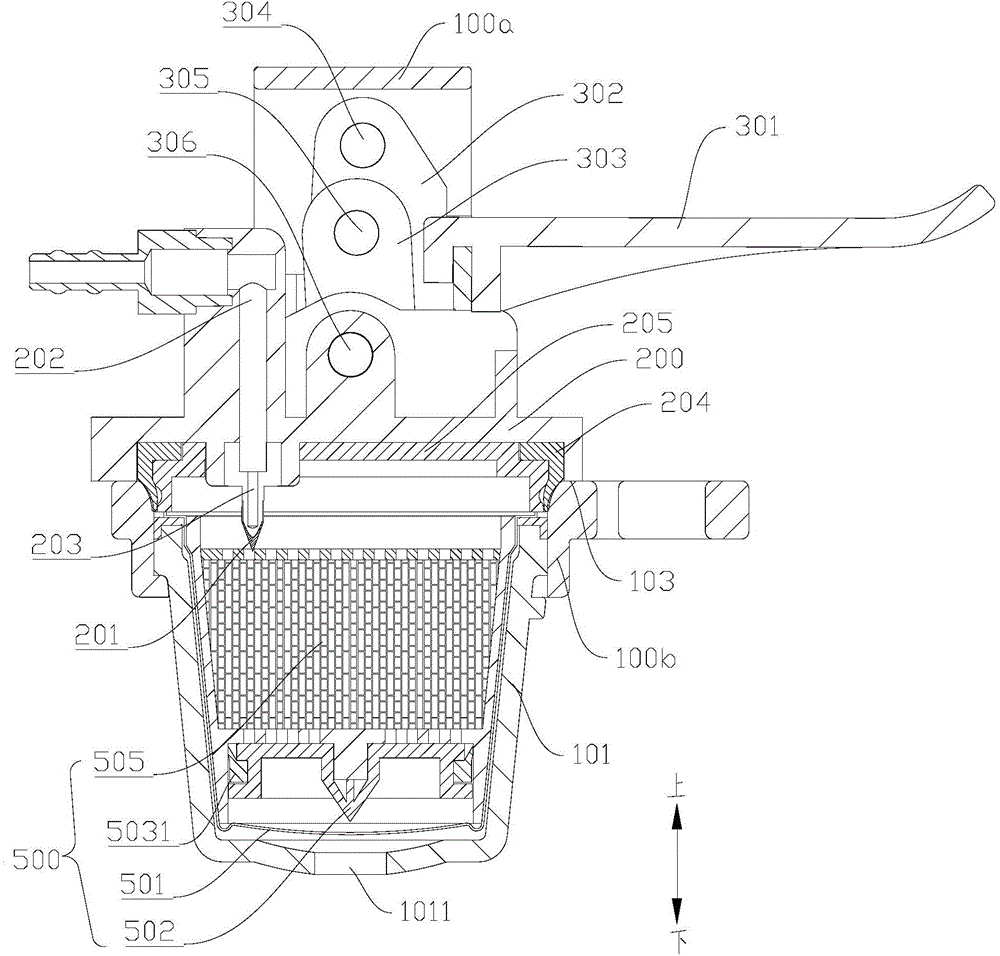

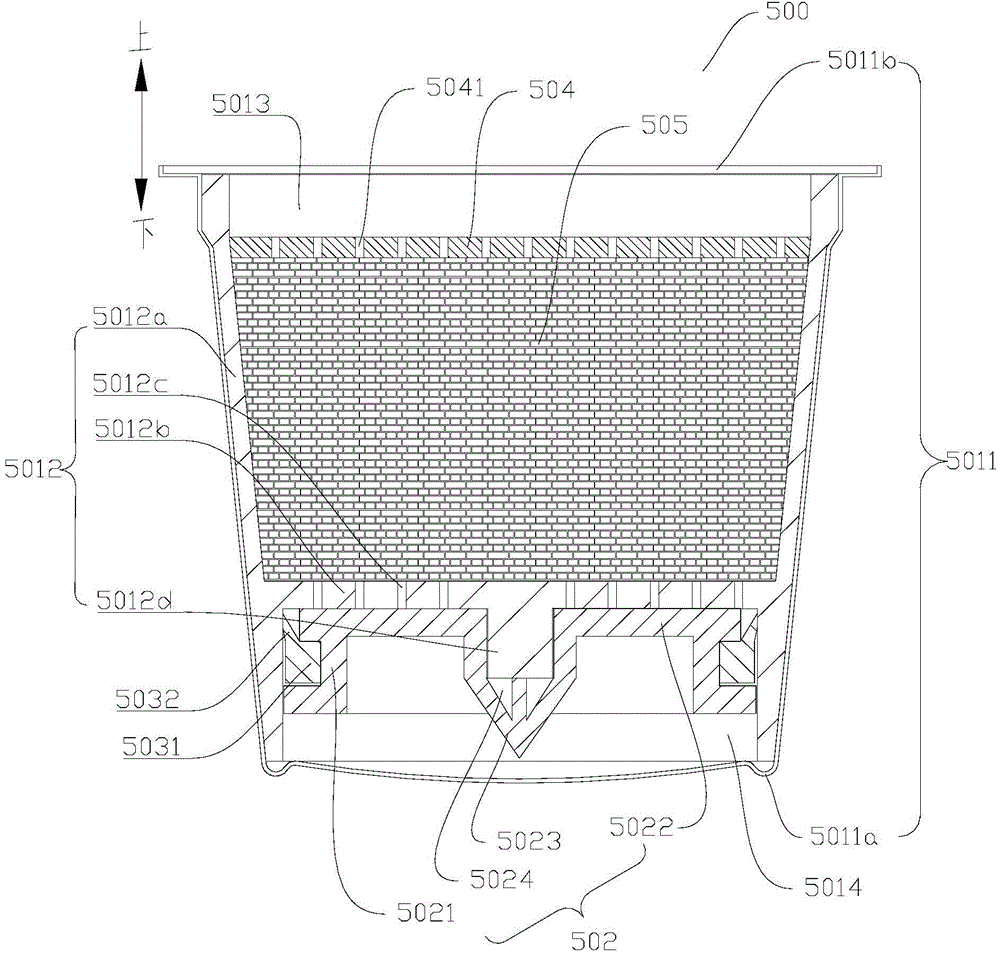

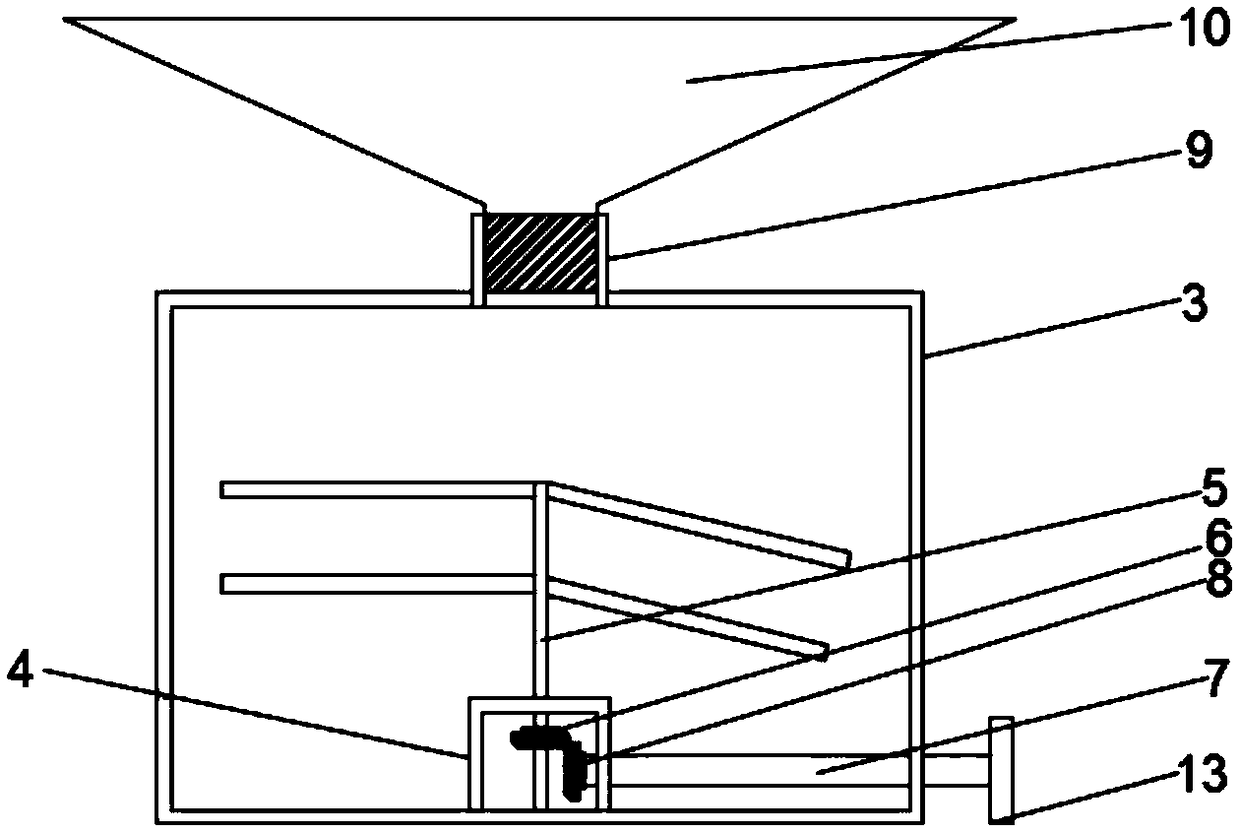

Discharging device, brewing device including same, and drink manufacturing machine

ActiveCN107136935ARealize dynamic brewingImprove brewing efficiencyBeverage vesselsSiphonAgricultural engineering

The invention relates to a drink manufacturing machine, concretely provides a discharging device, a brewing device including the same and a drink manufacturing machine, and aims to solve a problem of failure of dynamic brewing of a discharging device of a drink manufacturing machine in the prior art. To achieve the aim, the drink manufacturing machine comprises a container, a brewing device and a discharging device disposed in the brewing device, wherein the discharging device has a vertical pipe assembly and a siphon cover covering the vertical pipe assembly, wherein the vertical pipe assembly passes through the brewing device and arranged on the bottom of the brewing device and comprises a first high-position vertical pipe and a second low-position vertical pipe; the siphon cover has a first high-position part and a second low-position part; when the siphon cover covers the vertical pipe assembly, the first high-position part covers the first high-position vertical pipe; and the second low-position part covers the second low-position vertical pipe. With the above structure, a liquid level of the brewing device can dynamically change between the top end of the high-position vertical pipe and the top end of the low-position vertical pipe, so the liquid level can be adjusted according to components for different brewing flavors and brewing effect can be improved.

Owner:KEYWAY INNOVATIOS (SHANGHAI) CO LTD

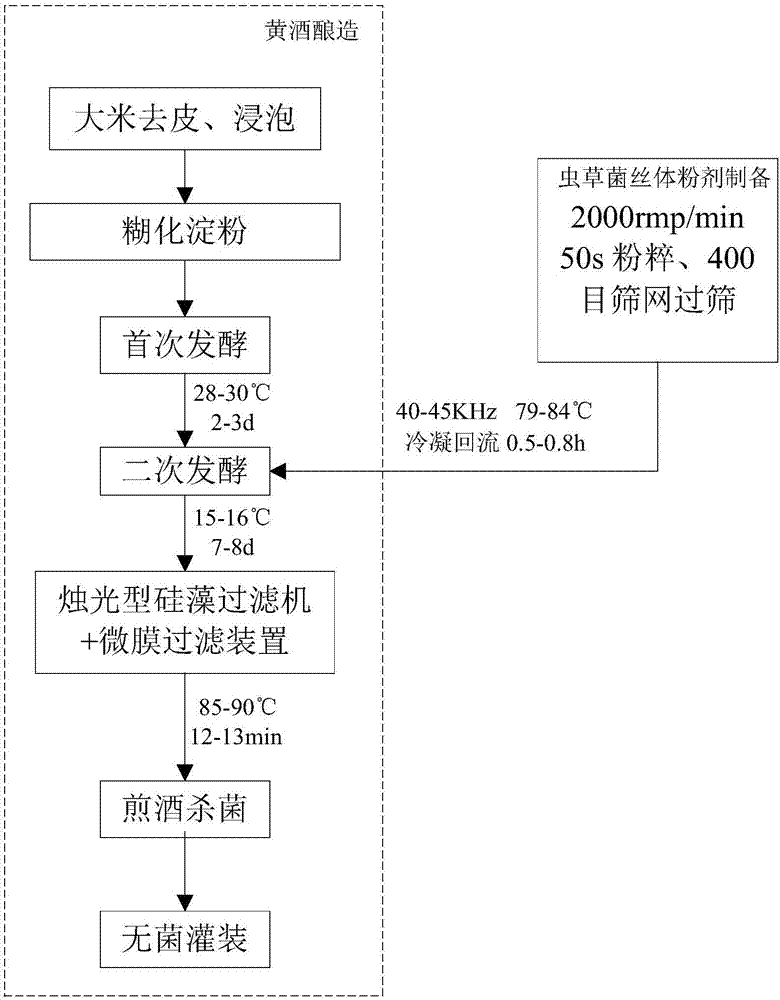

Method for making healthcare rice wine from cordyceps sinensis mycelia as raw material

The invention provides a method for making healthcare rice wine from cordyceps sinensis mycelia as a raw material. The method mainly comprises the following steps: cleaning cordyceps sinensis mycelia, performing freeze-drying, sterilizing in a sterilization cabinet, and crushing into powder in a crushing machine for later use; peeling rice; cleaning the rice, draining off water, putting the rice into a jar, adding water till the rice is completely immersed, and soaking for 2-3 days; draining off water of the rice, and steaming for 30 minutes at normal pressure; putting steamed rice into a fermentation tank, adding water and wheat koji, uniformly mixing, adding lactic acid, and adjusting the pH value; adding distiller's yeast, stirring, putting into the jar, and performing fermentation so as to obtain fermented glutinous rice; moving the fermented glutinous rice into a glass container in different batches, adding cordyceps sinensis mycelium powder, and performing ultrasonic oscillation till cordyceps polysaccharides and cordycepin are dissolved in the wine, wherein the cordyceps sinensis mycelium powder accounts for 0.40-0.60% of the mass of the rice wine; pouring the wine into the fermentation tank, and leaving to stand for 7-8 days at 15-16 DEG C; filtering, boiling, and sealing the wine. The method has the beneficial effects that the design has the advantages of being short in brewing period, low in production cost, high in nutrition value and high in cordyceps sinensis utilization rate.

Owner:宜智萱(天津)生物科技有限公司

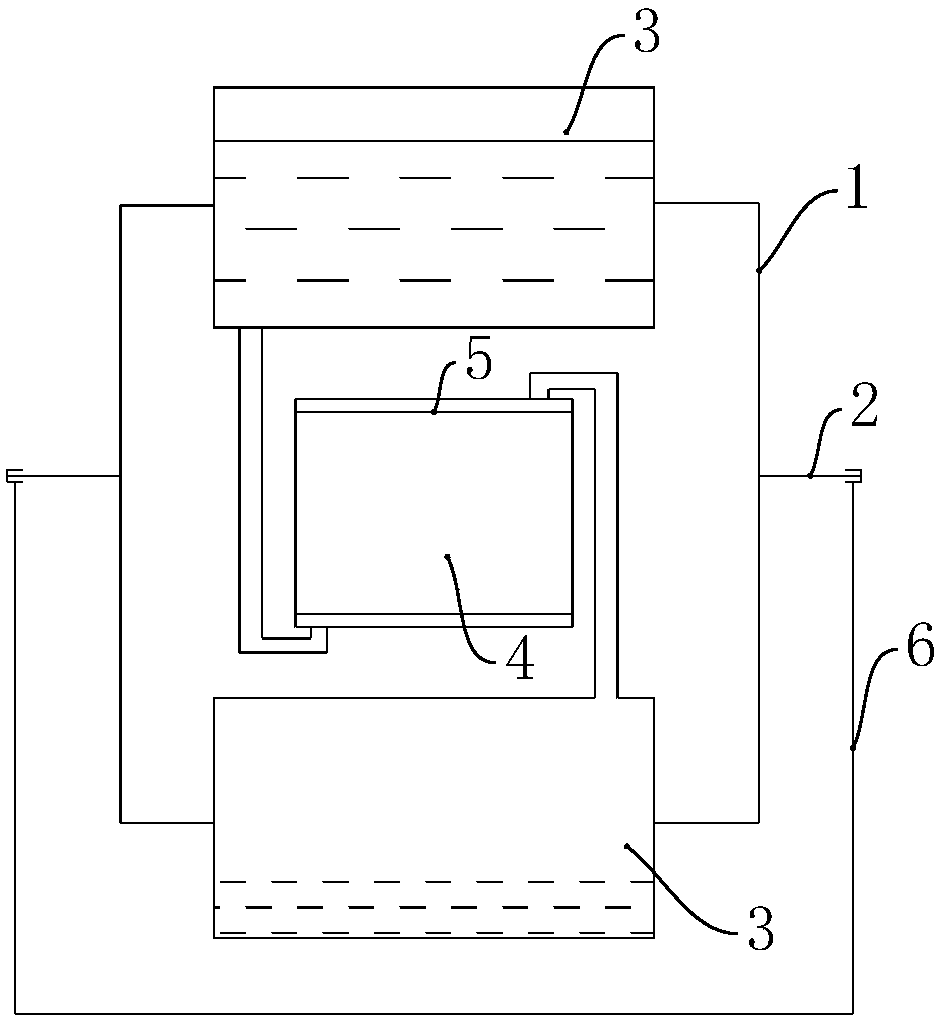

Quantitative beverage brewing device

ActiveCN106691194AAchieve quantitative brewingEasy dischargeBeverage vesselsAtmospheric pressureThermal water

The invention discloses a quantitative beverage brewing device, and relates to a beverage brewing device. The quantitative beverage brewing device comprises a water tank, a heating mechanism and a brewing cavity; the lower portion of the water tank is provided with a floater box and a heating box, the floater box and the heating box are connected through a starting valve (1), and the heating mechanism is arranged in the heating box; a side wall of the floater box is provided with a water inlet port, the water inlet port connects the floater box and the water tank, the floater box is provided with a floater, the floater is provided with a needle valve which can coordinate with the water inlet port; the upper portion of the heating box is provided with an exhaust pipe, and the exhaust pipe is provided with a one-way valve, the heating box and the brewing cavity are connected by the exhaust pipe, the brewing cavity is arranged at the upper portion of the heating box, the lower portion of the heating box is provided with a water suction pipe (1), the water suction pipe (1) connects the exhaust pipe with the heating box. In the quantitative beverage brewing device, water evaporates in large quantities after boiling, therefore the one-way valve is opened by increasing the pressure in the heating box, the water in the heating box is discharged, and therefore the water temperature is controlled, and hot water is quickly discharged.

Owner:重庆市嘉诺食品有限公司

Coffee maker and control method thereof

InactiveCN107149407AImprove solubilityImprove qualityBeverage vesselsCoffee extractionEngineeringProcess engineering

The invention provides a coffee maker. The coffee maker comprises a maker shell body, a brewing assembly, a light pressure applying assembly, a heating assembly and a filtering assembly. The brewing assembly comprises a brewing container, the brewing container is provided with a hollow containing cavity, and the containing cavity can contain a brewed object. The light pressure applying assembly comprises a booster pump and a pressure pipeline, and the booster pump can provide pressure for the brewing container. The heating assembly can provide hot water for the brewing container. The filtering assembly is communicated with the containing cavity. The hot water is added into the containing cavity through the heating assembly, coffee powder and the hot water are fully mixed, pressure is applied into the containing cavity through the light pressure applying assembly, matter in the coffee powder is extracted in a light pressure mode, the coffee powder can be fully dissolved in the hot water, high-quality brewed coffee liquid is obtained, the concentration, smoothness, taste and the like of the coffee liquid are improved, the brewing efficiency of the coffee liquid is improved, and the coffee maker is convenient to use by a user. The invention further provides a control method of the coffee maker.

Owner:GUANG DONG ELEC-TECH RETOP LED DISPLAY CO LTD

Alkaline type rapid brewing method of low-salt fish sauce

InactiveCN104642998AShorten the fermentation cycleImprove fermentation efficiencyFood preparationProtein proteinFermented fish

The invention discloses an alkaline type rapid brewing method of low-salt fish sauce. The method comprises the following steps: mixing marine fishes with general drinking water; adding table salt; uniformly mixing; adjusting pH to be 7.0 to 11.0 through an alkaline regulator; maintaining the temperature to ferment; agitating once every two days to promote rapid degrading of protein of the fish bodies; continuously fermenting the product obtained by the constant temperature fermenting for 30 to 60 days; agitating once at every 5 to 10 days to obtain completely fermented fish sauce; filtering to remove residues of the completely fermented fish sauce; after-ripening; removing the upper grease of the fish sauce to obtain the after-ripened and de-greased fish sauce; heating for sterilizing; filtering to remove incompletely-fermented protein and other impurities to obtain clear and transparent low-salt fish sauce which has a good taste. The method is short in fermenting cycle, high in fermenting efficiency, and low in salt in the fish sauce, and the value of low-value marine fishes is increased.

Owner:JIMEI UNIV

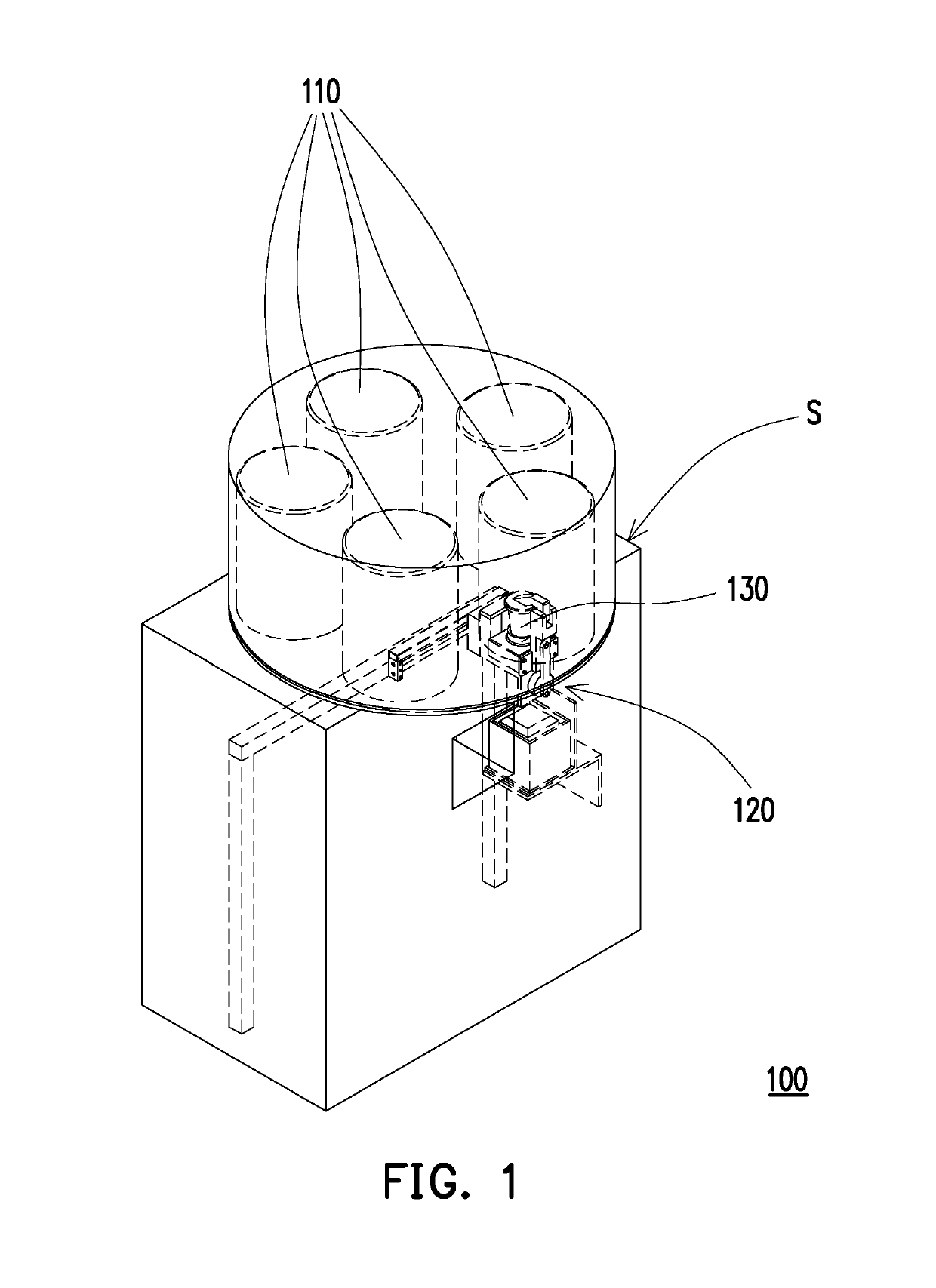

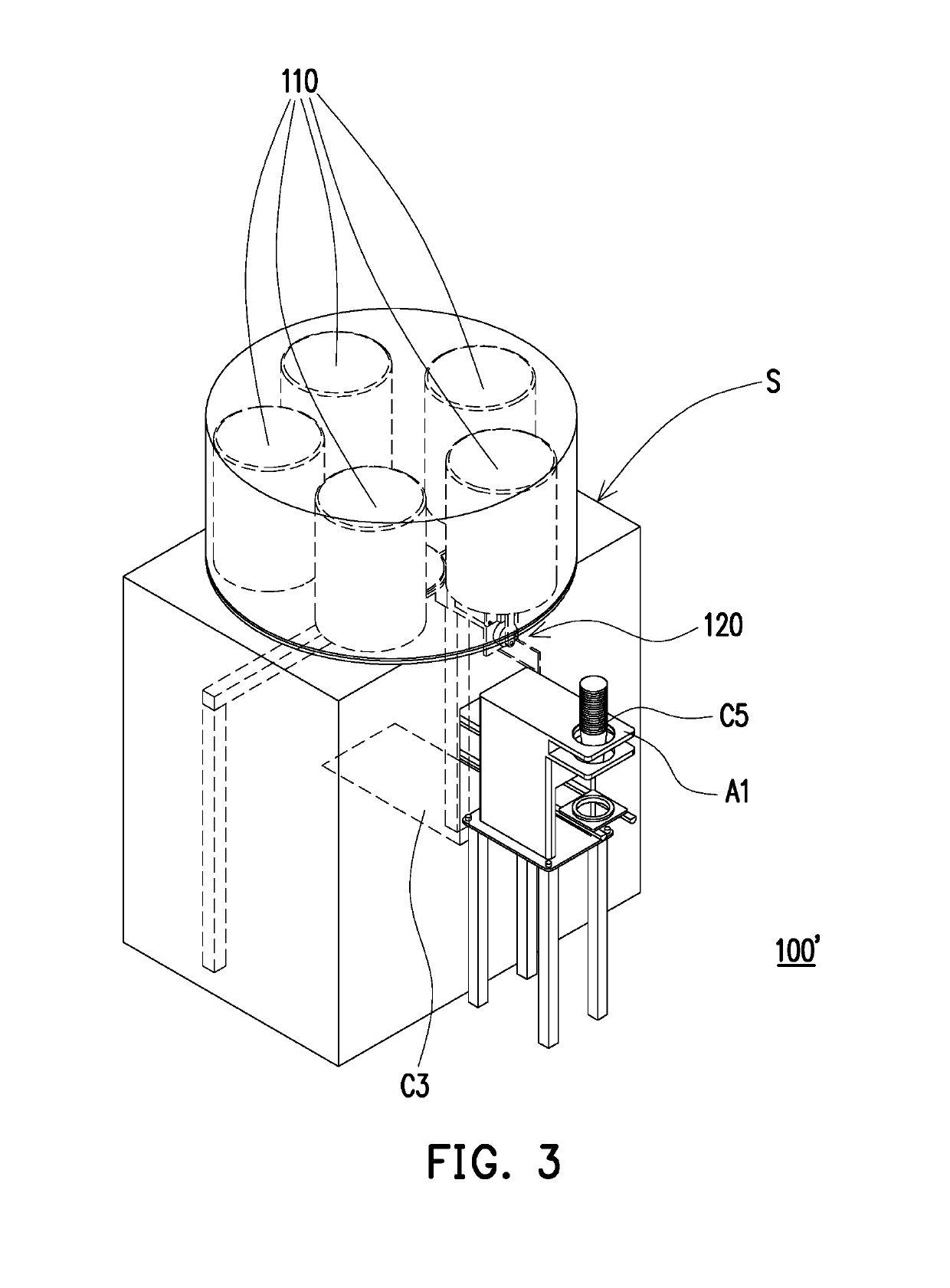

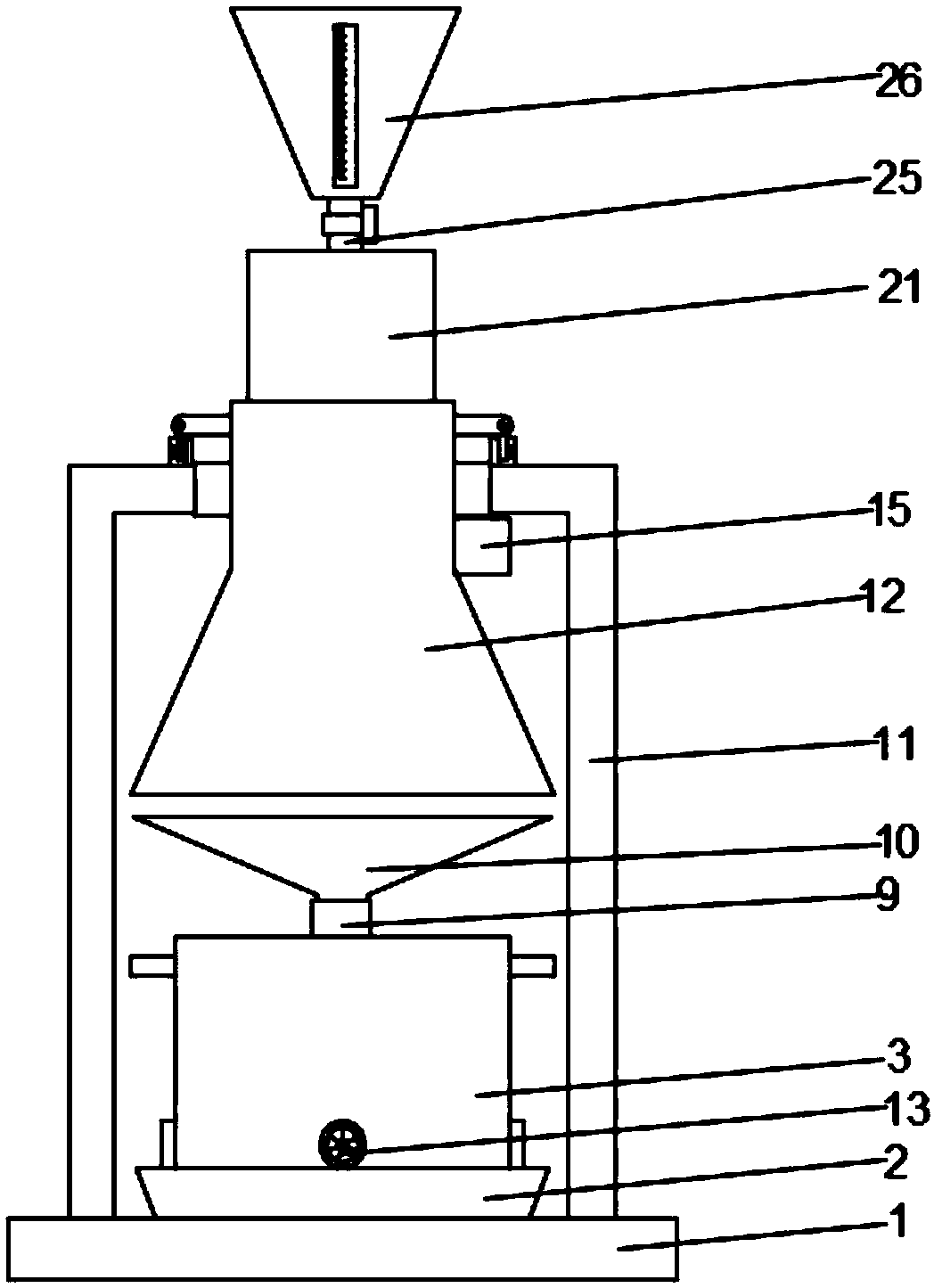

Beverage brewing apparatus

ActiveUS20190290070A1Enhances beverage brewing efficiencyReduce time costBeverage vesselsEngineeringBrewing

A beverage brewing apparatus includes at least one material storing unit, at least one brewing unit, at least one brewing cup and a matching system. The material storing unit is suitable for storing materials. The matching system is suitable for matching the brewing cup and the material storing unit, so that the brewing cup is suitable for receiving materials from the material storing unit. The matching system is suitable for matching the brewing cup and the brewing unit, so that the brewing unit is suitable for brewing materials in the brewing cup.

Owner:CENZ AUTOMATION

Blueberry Shuangyou dry red wine production equipment

PendingCN111909805AIncrease the intensity of crushingGrinding work thoroughlyWine preparationYield (wine)Electric machinery

The invention relates to the technical field of brewing, in particular to blueberry Shuangyou dry red wine production equipment. The blueberry Shuangyou dry red wine production equipment comprises a first motor, a crushing barrel, a crushing mechanism and an unfreezing mechanism. The unfreezing mechanism is mounted in the crushing barrel. The crushing mechanism is mounted in the crushing barrel and comprises a second motor, a first straight rod, a second straight rod, a conveying belt, a first roller, a second roller and a stirring mechanism. The second motor is fixedly connected to the outerside wall of a bottom plate. The first straight rod is fixedly connected to the output end of the second motor. The second straight rod is rotationally connected to the side wall of the crushing barrel. The first roller is fixedly connected to the first straight rod. The second roller is fixedly connected to the second straight rod. Under the action of the crushing mechanism and the unfreezing mechanism, the raw material pretreatment time is shortened, and the yield is increased.

Owner:YICHUN ZHONGZHI DASHANWANG WINERY

Preparation method of potato wine

InactiveCN110396460AReduce wasteEfficient heating and boiling stepsFood processingAlcoholic beverage preparationThroatFodder

The present invention relates to the technical field of wine making and discloses a preparation method of potato wine. The preparation method comprises the following steps: clean water is used to washpotatoes and straw clean, the potatoes are cut into slices and squeezed to obtain potato paste and potato juice, and the straw is cut into broken blocks; the potato paste is baked and taken out untilthe potato paste is burnt, the burnt potato paste, the straw broken blocks and water are mixed according to a ratio to obtain a mixture, the mixture is heated and boiled to obtain a fermentation rawmaterial, the fermented raw material is beaten to be dispersed, and temperature lowering is conducted; the temperature-lowered fermented raw material is put into a fermentation pool to be sealed and fermented to obtain fermented grains, and koji and the potato juice are preliminarily added into the fermentation pool; and the fermented grains are distilled to obtain potato wine and the distillers'grains. The manufactured potato wine prepared by the method retains burnt potato aroma, is mellow and pure in throat, and fragrant, and also has relatively high nutritional value. At the same time, the distillers' grains produced by the method can be directly used as a feeding feed for domestic livestock without processing.

Owner:王尉 +1

Wine brewing production line

PendingCN113789239AImprove cooking efficiencySmall footprintAlcoholic beverage preparationProcess engineeringBiology

The invention belongs to the technical field of wine brewing equipment, and particularly relates to a wine brewing production line which comprises a cooking barrel, a stirring unit and a conversion unit, the cooking barrel is cylindrical, and a sealing cover is mounted at the top of the cooking barrel; the conversion unit is used for converting the function of the cooking barrel from cooking to spreading cooling; the stirring unit is used for stirring in the cooking barrel; the stirring unit is rotationally connected into the cooking barrel, so that the stirring unit and the cooking barrel are integrated, the manufacturing cost of wine brewing equipment can be effectively reduced, the occupied area of a wine brewing production line is synchronously reduced, and the cooking efficiency of the cooking barrel is effectively improved by mounting the sealing cover at the top of the cooking barrel; and the stirring plate can stir the rice in the cooking barrel in the rotating process, so that the rice in the cooking barrel is uniformly and flatly placed in the inner space of the cooking barrel.

Owner:施裕杰

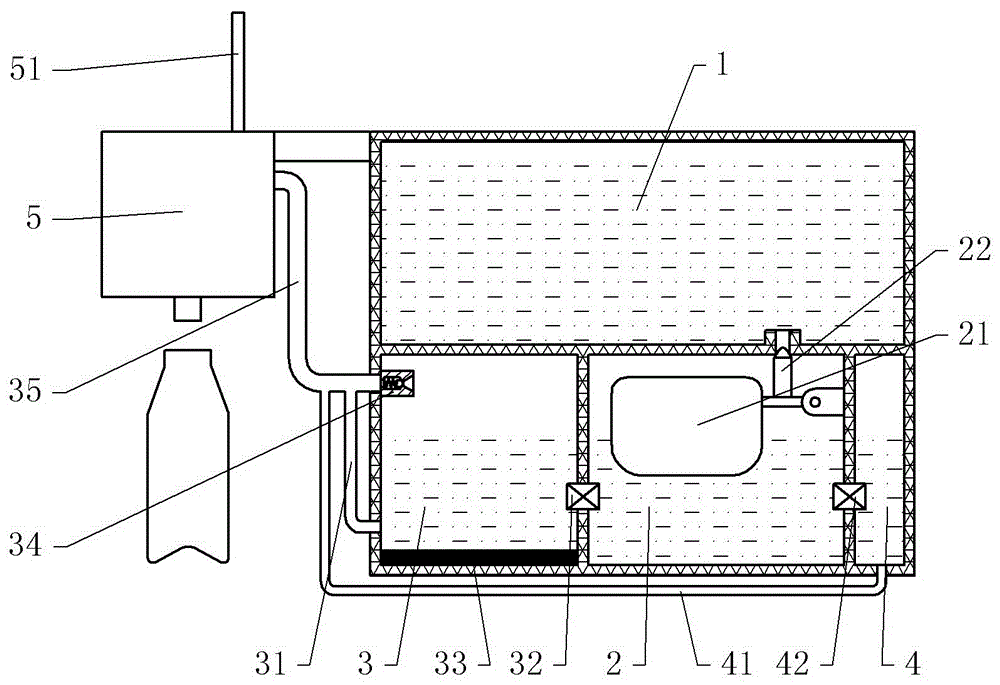

Beverage brewing system

The invention discloses a beverage brewing system which comprises a body, an upper piercing member, a drive mechanism, a liquid tank and a quartz heating pipe, wherein the upper piercing member is arranged in the body in an up-down moving manner and positioned above a brewing cavity; the drive mechanism comprises a drive member and a driven member; the drive member is pivotably arranged on the body; one end of the driven member is pivotably connected with the drive member, and the other end is connected with the upper piercing member to drive an upper piercing needle of the upper piercing member to pierce the top of a beverage capsule; the liquid tank is connected with the brewing cavity to supply the liquid in the liquid tank into the beverage capsule in the brewing cavity; and the quartz heating pipe is arranged between the liquid tank and the brewing cavity to heat the liquid entering the beverage capsule in the brewing cavity. According to the beverage brewing system disclosed by the invention, Italian high-pressure coffee as well as American low-pressure coffee can be brewed; and through the quartz heating pipe, the beverage brewing efficiency can be greatly improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Household beer brewing device convenient to disassemble

The invention discloses a household beer brewing device convenient to disassemble, and relates to the technical field of wine brewing. The household beer brewing device comprises a base; the top of the base is fixedly connected with an induction cooker; the top of the induction cooker is movably connected with a brewing tank through a positioning groove; a protective shell is fixedly connected tothe lower ends of the two sides of the inner wall of the brewing tank; a stirring rod is rotatably connected to the bottom of the inner wall of the brewing tank; and the top of the stirring rod penetrates through the protective shell and extends into the brewing tank. According to the household beer brewing device convenient to disassemble, the purposes that disassembly is facilitated, the size isdecreased, and the household beer brewing device is suitable for families and convenient to use are achieved, moving, cleaning and using are facilitated, and the life of people is convenient; a saccharifying tank can achieve dual purposes, can serve as a utensil for saccharification and gelatinization, and can also serve as a filtering device, thus a part special for filtration is omitted, the originally needed size for the device is decreased, and the cost is lowered; and the household beer brewing device is suitable for the families, the brewing efficiency is improved, manpower is saved, and using by people is convenient.

Owner:江苏龙河酒业有限公司

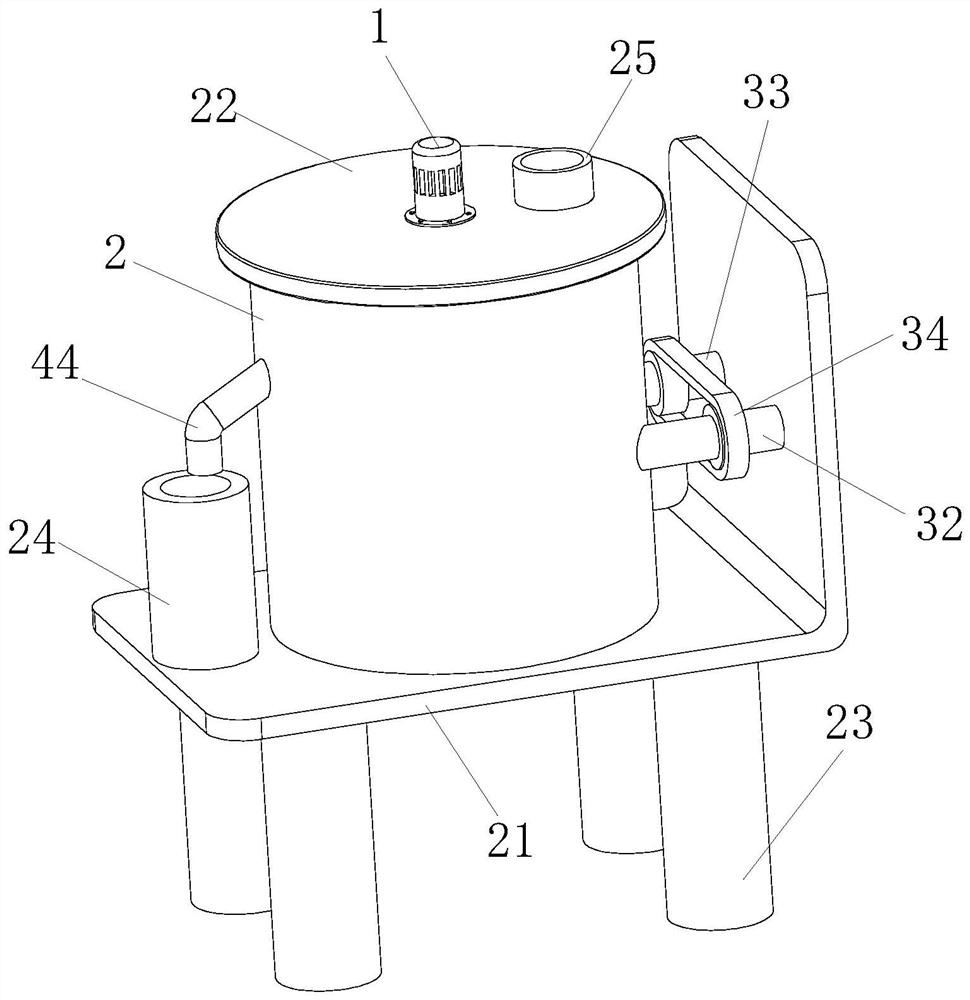

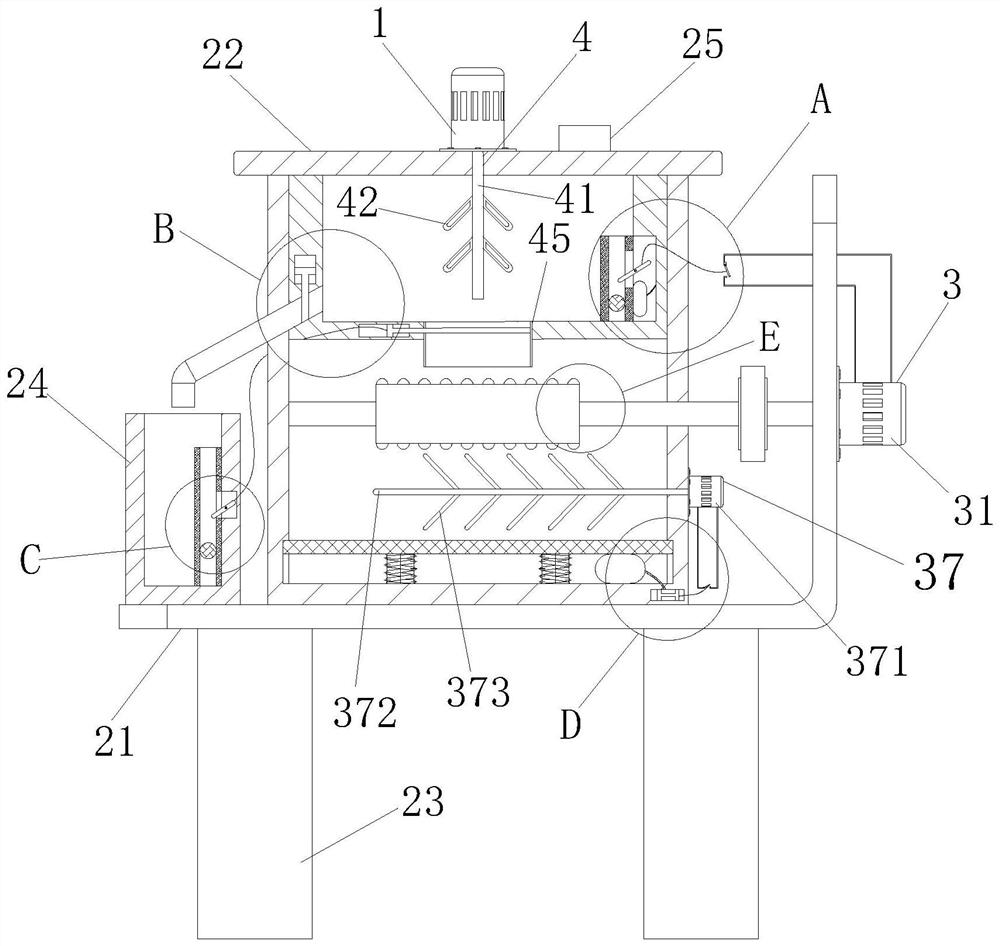

Automatic wine brewing device

InactiveCN109943453AShorten the timePromote precipitationAlcoholic beverage preparationAgricultural engineeringPrecipitation

The invention discloses an automatic wine brewing device. The device comprises a rotating bracket, raw wine containers and a medicinal material container; the rotating bracket is provided with a rotating shaft, and the rotating shaft is arranged on the fixing bracket through a bearing and connected with a motor; the rotating bracket is provided with the two raw wine containers, the two raw wine containers are symmetrically arranged at the two sides of the rotating shaft of the rotating bracket respectively, the medicinal material container is arranged between the two raw wine containers, and the two raw wine containers are connected with the medicinal material container separately. According to the automatic wine brewing device, the raw wine containers and the medicinal material containerare arranged, the flowing direction of wine is controlled through the rotating bracket, wine impacts medicinal materials in the continuous flowing process and is in full contact with the medicinal materials, the precipitation of medicinal components of the medicinal materials is accelerated, the brewing time of the medicinal wine is shortened, and the brewing efficiency is improved.

Owner:四川省宜宾市古叙酒业有限公司

Method for brewing lotus root vinegar

InactiveCN108624464AIncrease productivityShort fermentation cycleVinegar preparationAmylaseAcetic acid

The invention discloses a method for brewing lotus root vinegar, belonging to the technical field of food. The method comprises the following steps: (1) preparation of fermentation broth: smashing lotus roots, adding amylase for liquefaction, carrying out heating for enzyme deactivation after completion of liquefaction, then carrying out cooling and adding glucoamylase for saccharification so as to obtain the fermentation broth; (2) alcoholic fermentation: weighing active dry yeast, activating the active dry yeast, adding the activated active dry yeast into the fermentation broth prepared in the step (1), carrying out fermentation at 28-30 DEG C and terminating fermentation when the alcohol content of the fermentation broth is 7 to 8% (v / v) so as to obtain the fermentation broth having undergone alcoholic fermentation; and (3) acetic fermentation: adding Acetobacter rancens and auxiliary materials into the fermentation broth having undergone alcoholic fermentation in the step (2), carrying out fermentation at 28-30 DEG C, adding salt to terminate fermentation when the acetic acid degree of the fermentation broth having undergone alcoholic fermentation is no less than 3.5 g / 100 ml so as to obtain the fermentation broth having undergone acetic fermentation, and successively carrying out filtering, homogenization and sterilization so as to obtain the lotus root vinegar. The methodof the invention uses the lotus roots as a raw material and carries out alcoholic fermentation and acetic fermentation; and the prepared lotus root vinegar has good taste and rich nutrients, and thepreparation method is simple operation, short in fermentation cycle and high in efficiency.

Owner:HEBEI AGRICULTURAL UNIV.

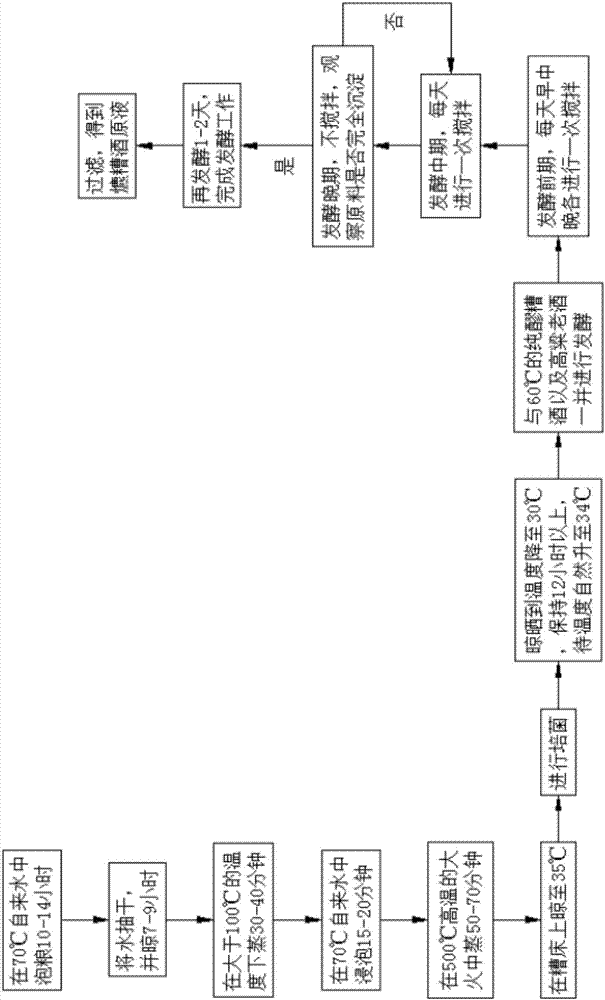

Brewing technology for cooked rice wine

InactiveCN107345184AImprove overall efficiencyProduct difference is smallAlcoholic beverage preparationSorghumBrewing

The invention discloses a brewing technology for cooked rice wine. The brewing technology comprises the following steps: firstly, soaking grains in the running water for 10-14 hours at 70 DEG C; dying the water and airing for 7-9 hours; steaming for 30-40 minutes under the temperature above 100 DEG C; soaking in the running water for 15 minutes at 70 DEG C and then steaming for 50-70 minutes with big fire; steaming and then airing to 35 DEG C on a wine instrument and cultivating fungus; after completely cultivating fungus, airing and reducing the temperature to 30 DEG C, keeping for more than 12 hours and naturally increasing the temperature to 34 DEG C; and putting into a fermenting tank together with pure fermented rice wine at 60 degrees and sorghum wine and fermenting for 6-8 days. According to the invention, any additives are not added, blending is not performed and the final product is the white spirit at low alcohol degree with the color of sorghum and has excellent color and taste; the alcohol degree is low, so that the white spirit is suitable for most people; the production period is short, the production standard is uniform, the batch fermenting production can be performed and the final products are low in difference.

Owner:合江县白沙镇燕坪酒厂

Yellow rice wine processing production device and method

InactiveCN110643456AReduce operating costsReduce labor intensityAlcoholic beverage preparationElectric machineryProcess engineering

The invention relates to the technical field of yellow rice wine production, and discloses a yellow rice wine processing production device and method. The yellow rice wine processing production devicecomprises a storage tank, a base is fixedly installed at the bottom of the storage tank, a pump is fixedly installed in an inner cavity of the storage tank, the other end of the pump is fixedly connected with a conveying pipe, the other end of the conveying pipe penetrates through the outer wall of the storage tank and extends to the outside of the storage tank to be fixedly connected to a stirring tank, a motor placing box is arranged at the bottom of an inner cavity of the stirring tank, the inner cavity of the motor placing box is fixedly provided with a motor, and an output shaft of the motor is fixedly connected with a main shaft. According to the yellow rice wine processing production device, the pump is installed in fermentation equipment, then the pump is used for conveying raw materials to a boiler, the situation that staff needs to pour the raw materials into the boiler for original equipment can be effectively improved by the device, manpower is effectively saved, and meanwhile, the efficiency of wine making is further improved, in turn, the operating costs of enterprises are saved, and the labor intensity of workers is further reduced.

Owner:浙江东方绍兴酒有限公司

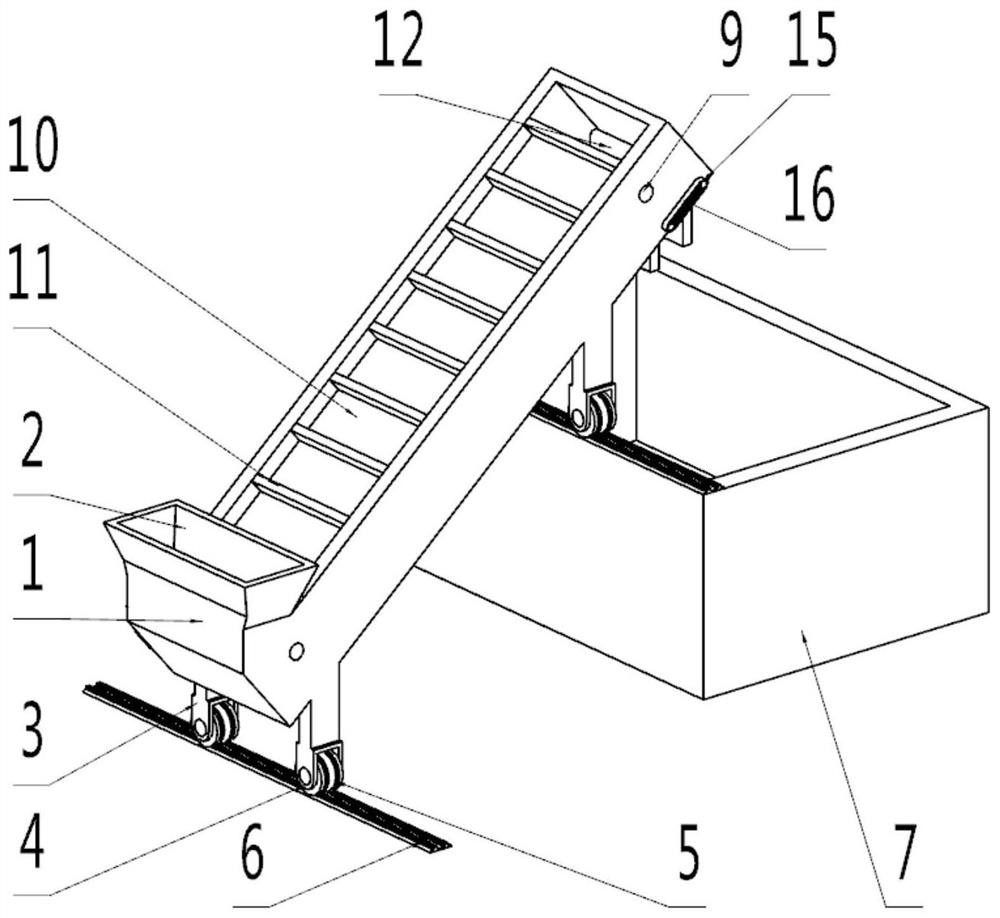

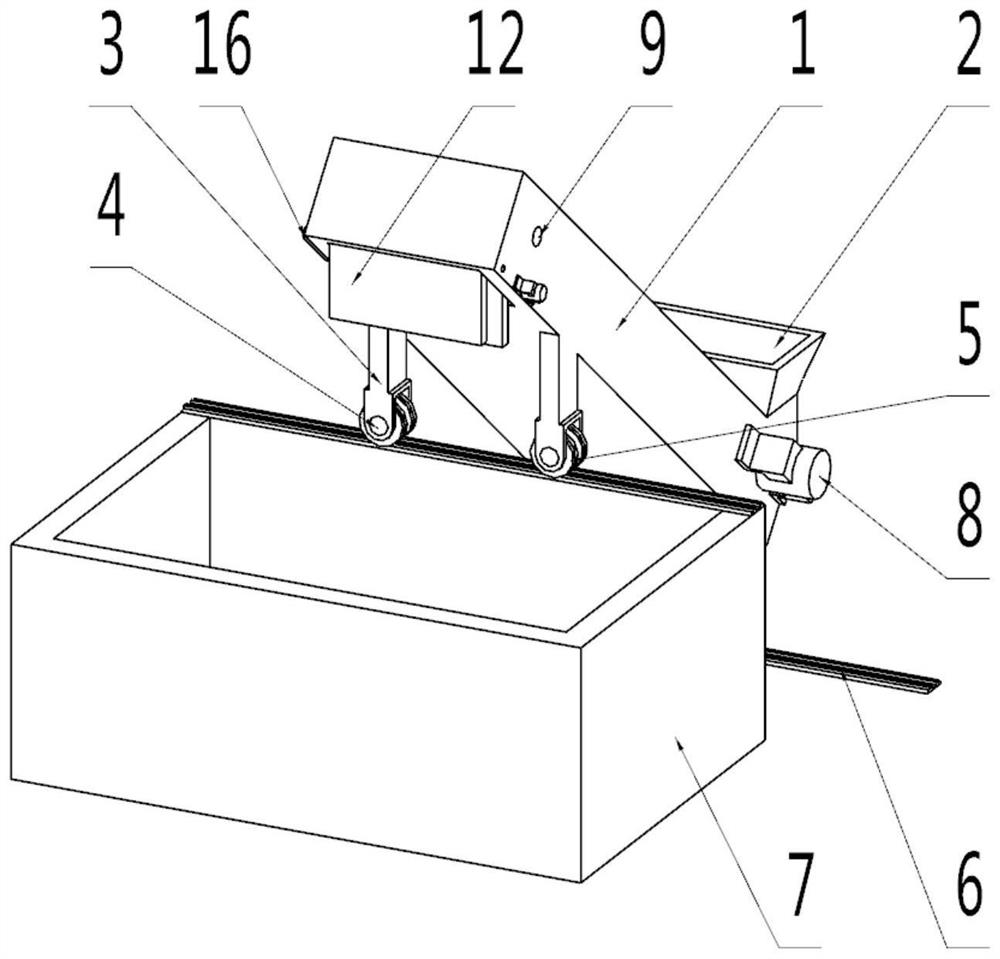

Automatic stacking raw material fermentation device for wine brewing processing

InactiveCN111849673AReduce exposureImprove food safetyAlcoholic beverage preparationBiotechnologyGear wheel

The invention discloses an automatic stacking raw material fermentation device for wine brewing processing. The device comprises a shell, a feeding port, a U-shaped supporting column, a straight toothgear and a gear belt. The feeding port is formed in the upper surface of the shell; the U-shaped supporting column is fixedly installed on the lower surface of the shell, a cylindrical pin is embedded in the inner surface of the U-shaped supporting column, meanwhile, a rolling wheel is installed on the inner surface of the cylindrical pin in a nested mode, a motor is fixedly installed on the outer surface of the shell, a bearing is fixedly connected to the edge end of the motor, and a conveying belt is installed on the outer surface of the bearing in a penetrating mode. According to the automatic stacking raw material fermentation device for wine brewing processing, the device for automatically transporting the raw materials is arranged, filling is conducted through the feeding port formed in the shell of the device, the raw materials are conveyed into the fermentation tank body through the conveying belt installed on the inner surface of the device, the conveyed materials are placedat multiple angles through the adjusting plate installed at the top end of the shell, manual contact can be reduced, the edible safety of wine brewing is improved, and the wine brewing efficiency is improved.

Owner:MOUTAI INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com