Blueberry Shuangyou dry red wine production equipment

A kind of production equipment and dry red technology, applied in the direction of biochemical equipment and methods, wine preparation, alcoholic beverage preparation, etc., can solve the problems of raw materials not meeting the processing requirements, incomplete crushing, reduced output, etc., and achieve accelerated crushing The effect of processing time, shortening the time of manual thawing, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

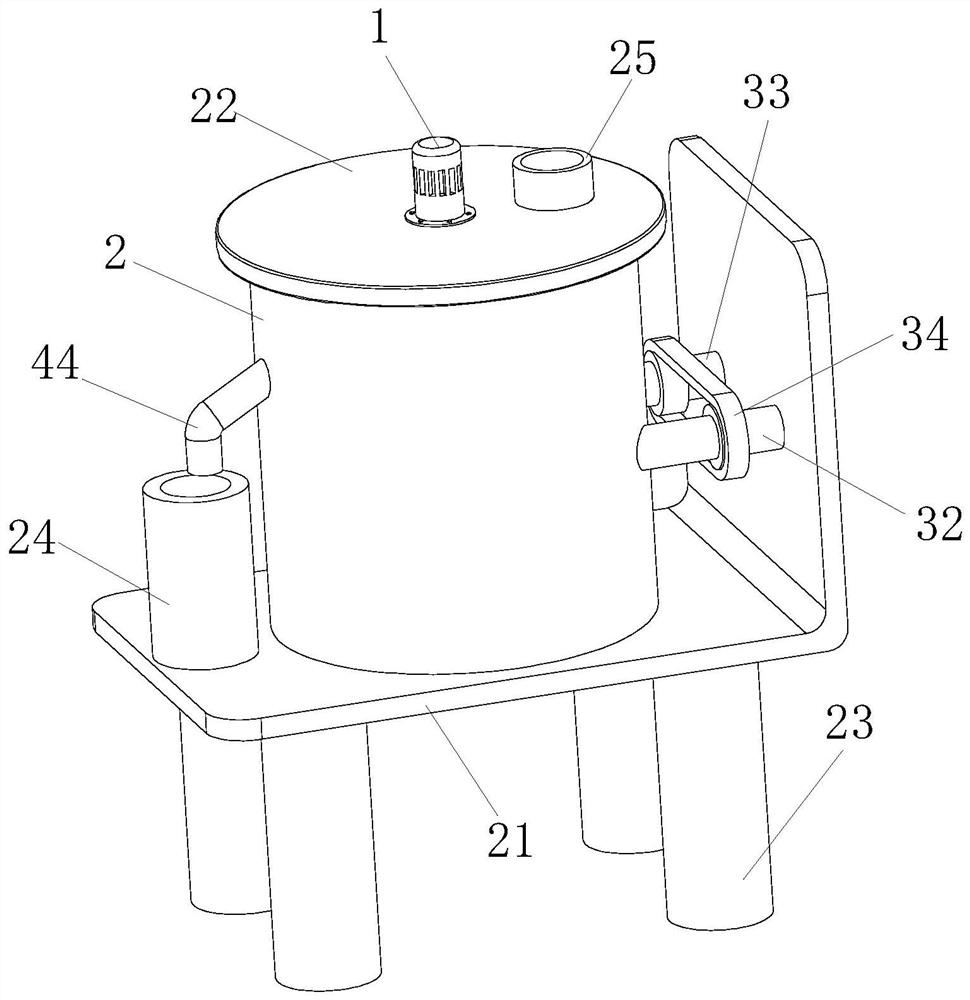

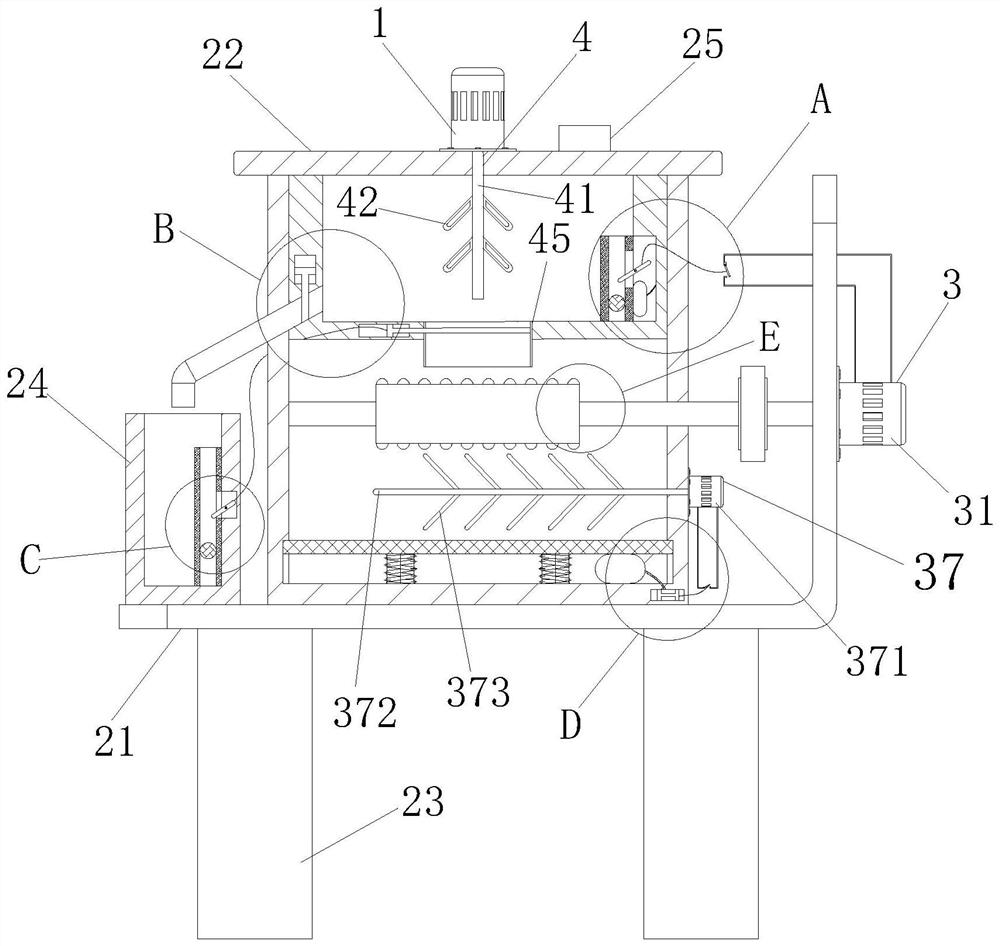

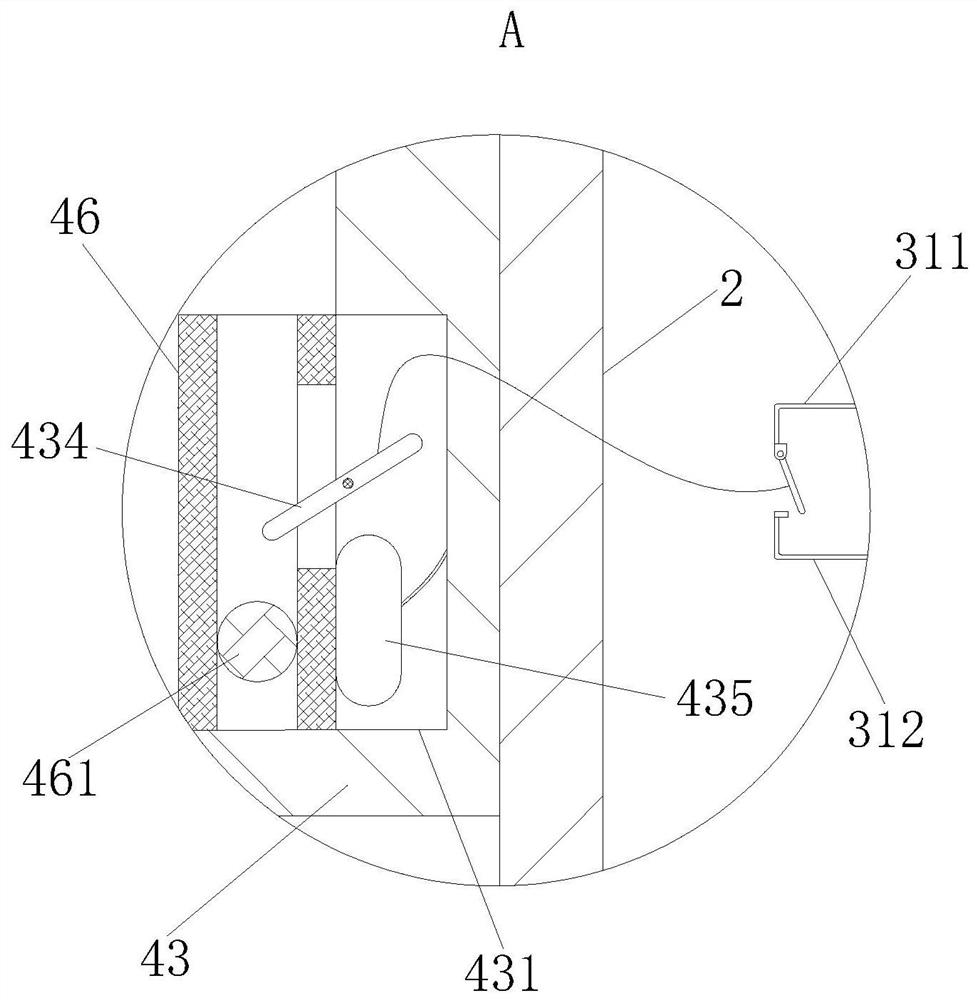

[0028] As an embodiment of the present invention, the thawing mechanism 4 includes a rotating rod 41, a heating block 42, a thawing barrel 43 and a liquid outlet pipe 44; the thawing barrel 43 is fixed on the inner wall of the crushing barrel 2; the rotating The rod 41 is affixed to the output end of the first motor 1; the heating block 42 is affixed to the outer side wall of the rotating rod 41; the liquid outlet pipe 44 is affixed to the side wall of the thawing bucket 43 and communicated with the inside of the thawing bucket 43; When working, put unthawed raw materials into the crushing bucket 2, start the first motor 1, and make the rotating rod 41 rotate, so that the heating block 42 can heat the raw materials during the rotation process, so that the frozen raw materials can be heated in the heating block. Under the double function of 42 stirring and heating, it can thaw quickly, thus shortening the time of artificial thawing and speeding up the time of raw material pretre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com