Maotai-flavor rice wine and preparation process thereof

A preparation process and rice technology, applied in the preparation of alcoholic beverages, biochemical equipment and methods, microorganisms, etc., can solve problems such as complex activation and rejuvenation methods of high-temperature koji, undisclosed alcohol yield, research on sauce-flavored rice wine, etc. Achieve the effects of enhancing market competitiveness, improving adaptability to the crowd, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

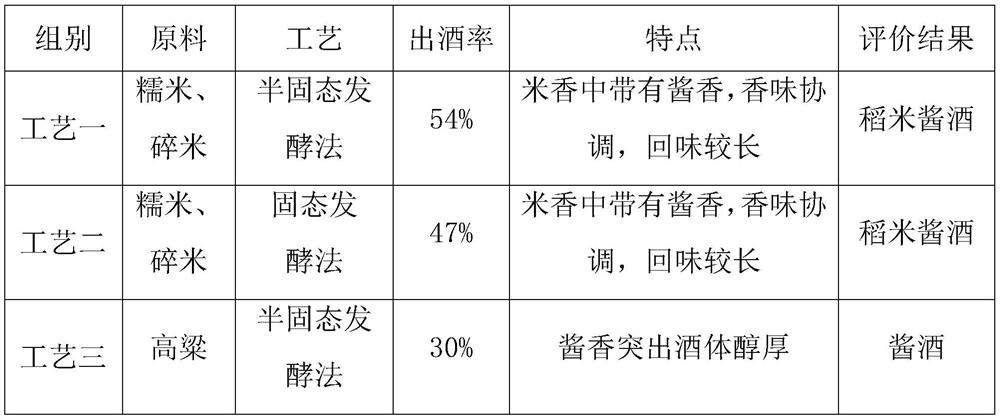

Method used

Image

Examples

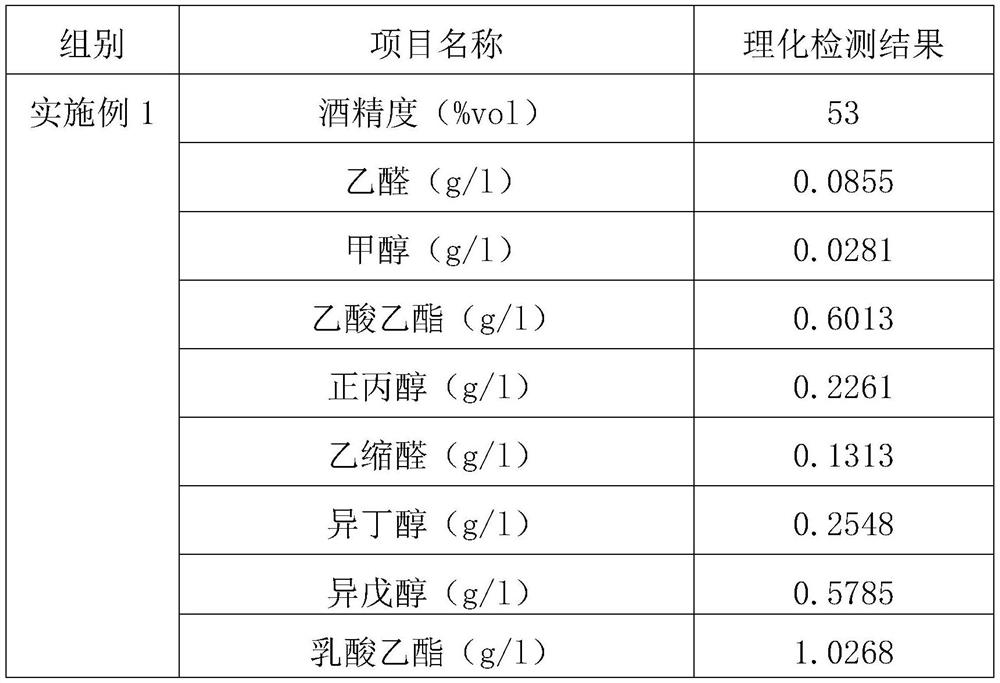

Embodiment 1

[0041] 1. Recipe for sauce-flavored rice wine:

[0042] Weigh 10kg of raw glutinous rice, 5kg of broken rice, the weight ratio of auxiliary materials Maotai-flavor Daqu and Q303 Rhizopus koji is 25:1, and the amount of auxiliary materials added is 10% of the weight of raw materials.

[0043] 2. The preparation process of sauce-flavored rice wine:

[0044] (1) Preparation of mixed koji: After pulverizing the Maotai-flavored Daqu, mix the Maotai-flavored Daqu and Q303 Rhizopus koji in proportion.

[0045] (2) Soaking of raw materials: take raw glutinous rice and broken rice, mix them in proportion, add water to soak for 11 hours, and filter;

[0046] (3) Cooking: steam the glutinous rice and broken rice mixture after soaking for 1 hour until the raw materials are cooked;

[0047] (4) Saccharification and fermentation: cooling the above-mentioned steamed raw materials to 30-40° C., adding mixed koji, and carrying out saccharification and fermentation;

[0048] (5) Sealed ferme...

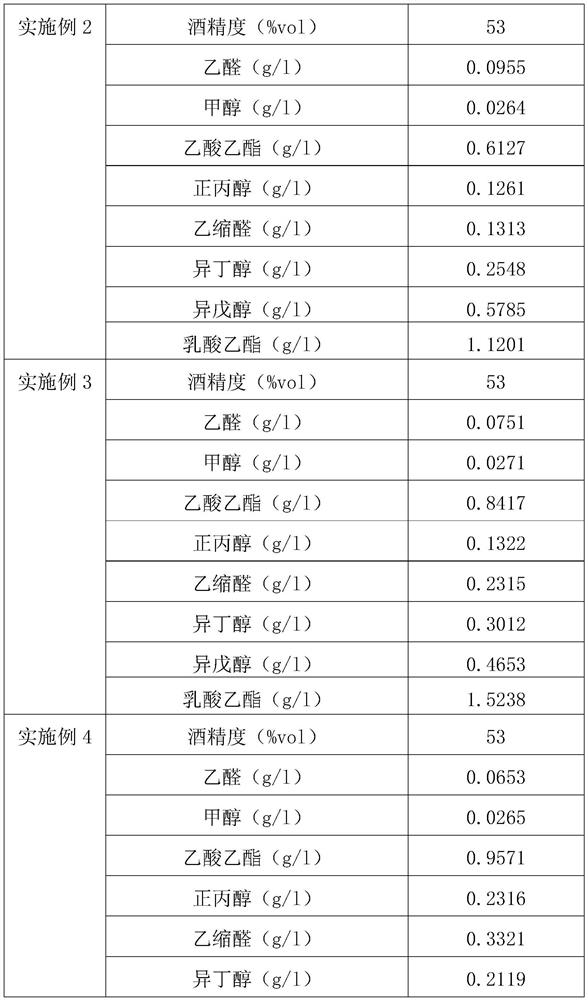

Embodiment 2

[0052] 1. Recipe for sauce-flavored rice wine:

[0053] Take by weighing 10kg of raw glutinous rice, 10kg of broken rice, the weight ratio of auxiliary materials Maotai-flavored Daqu and Rhizopus koji is 27.5:1, and the amount of auxiliary materials added is 12.5% of the raw material weight.

[0054] 2. The preparation process of sauce-flavored rice wine:

[0055] (1) Preparation of mixed koji: After pulverizing the Maotai-flavored Daqu, mix the Maotai-flavored Daqu and Q303 Rhizopus koji in proportion.

[0056](2) Raw material soaking: take the raw material glutinous rice and broken rice, after mixing in proportion, add water to soak, the soaking time is 11.5h, filter;

[0057] (3) Cooking: steam the mixture of glutinous rice and broken rice after soaking for 1.25 hours until the raw materials are cooked;

[0058] (4) Saccharification and fermentation: cooling the above-mentioned steamed raw materials to 30-40° C., adding mixed koji, and carrying out saccharification and ...

Embodiment 3

[0063] 1. Recipe for sauce-flavored rice wine:

[0064] Take by weighing 10kg of raw glutinous rice, 15kg of broken rice, the weight ratio of auxiliary materials Maotai-flavor Daqu and Rhizopus koji is 30:1, and the amount of auxiliary materials added is 15% of the raw material weight.

[0065] 2. The preparation process of sauce-flavored rice wine:

[0066] (1) Preparation of mixed koji: After pulverizing the Maotai-flavored Daqu, mix the Maotai-flavored Daqu and Q303 Rhizopus koji in proportion.

[0067] (2) Soaking of raw materials: take raw glutinous rice and broken rice, mix them in proportion, add water to soak for 12 hours, and filter;

[0068] (3) Cooking: steam the glutinous rice and broken rice mixture after soaking above for 1.5 hours until the raw materials are cooked;

[0069] (4) Saccharification and fermentation: cooling the above-mentioned steamed raw materials to 30-40° C., adding mixed koji, and carrying out saccharification and fermentation;

[0070] (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com