Method of making milky coffee drink with capsule drink machine

A technology for capsules and milk coffee, applied in application, coffee, coffee extraction, etc., can solve the problems of increased packaging, insufficient aroma, complicated production, etc., and achieve the effect of reducing production and processing costs, reducing consumption costs, and reducing operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

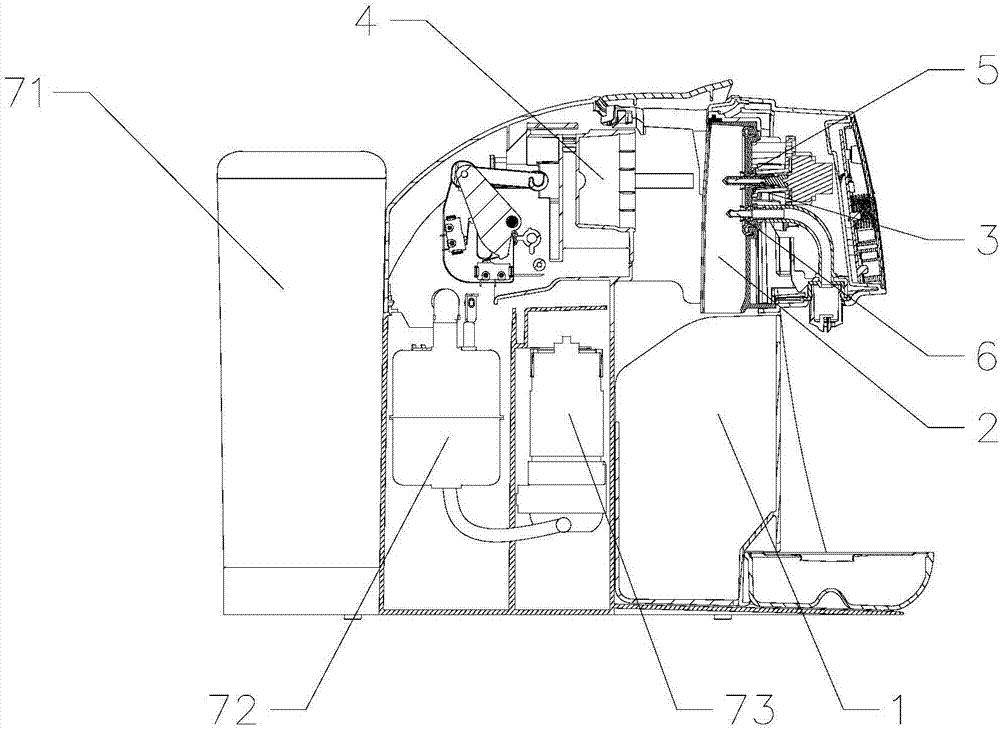

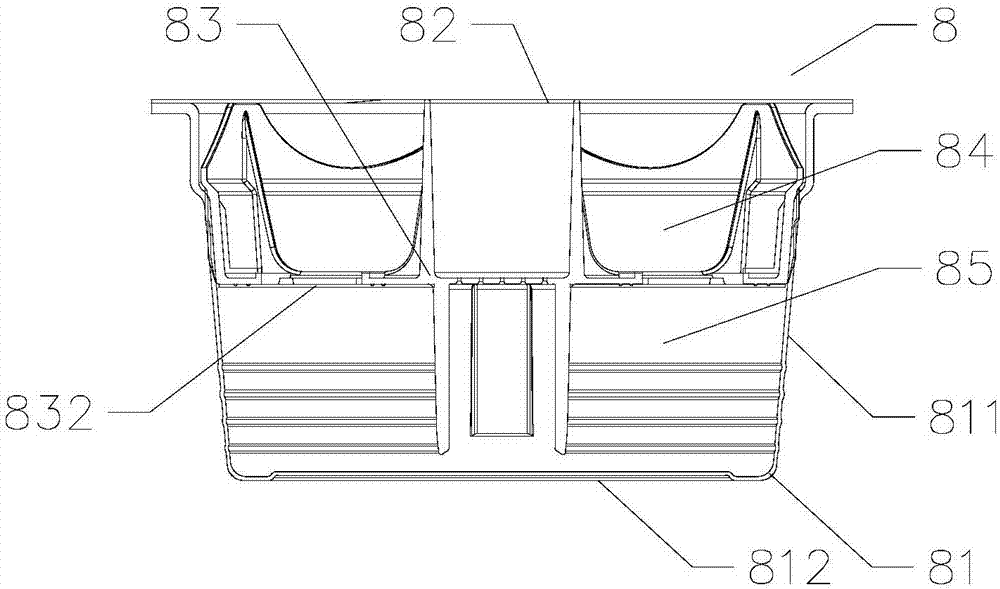

[0056] As a kind of capsule beverage machine for making milk coffee beverage according to the invention, such asfigure 1 As shown, it includes a machine base 1, a brewing chamber 2, a brewing head 3, a brewing cup 4, a water inlet needle 5, an extraction needle 6, a liquid supply mechanism and a control board (not shown in the figure). The brewing chamber 2 and the control board are arranged in the machine base 1, the brewing head 3 is arranged at one end of the brewing chamber 2, and the brewing cup 4 can move back and forth relative to the brewing head 3 in the brewing chamber. 3. One end is communicated with the liquid supply mechanism, and the other end provides water into the milk coffee capsule 8. In this embodiment, the water inlet needle 5 and the extraction needle 6 are arranged on the same side of the brewing head 3 and are arranged laterally, that is, the water inlet needle, the outlet needle 6 The central axes of the needles are arranged horizontally, which can also...

Embodiment 2

[0078] The difference between this embodiment and the first embodiment is that the extraction step is different, that is, the extraction step includes a staged extraction process.

[0079] In this embodiment, the extraction step includes a segmented extraction process: the liquid supply mechanism injects a certain amount of water and then stops for a period of time, and then continues to inject water. This cycle is N times, N≥2, and each segment of the extraction process in the segmented extraction process is stopped for a period of time. The interval time between is T, 0.1s≤T≤5s.

[0080] Specifically, S2 is 4ml / s, V2 is 88ml, N=11 times, T=2s, so that 88ml of water is injected into the second cavity 84 11 times, 8ml each time, and the interval time between each injection is 2s. The rest of the structure of the milk coffee capsule, the structure of the capsule drink machine and the effects of the present embodiment are the same as those of the first embodiment, and will not ...

Embodiment 3

[0085] The difference between this embodiment and the first and second embodiments is that the liquid supply mechanism further includes an air pump, and the mixing step includes an air blowing process.

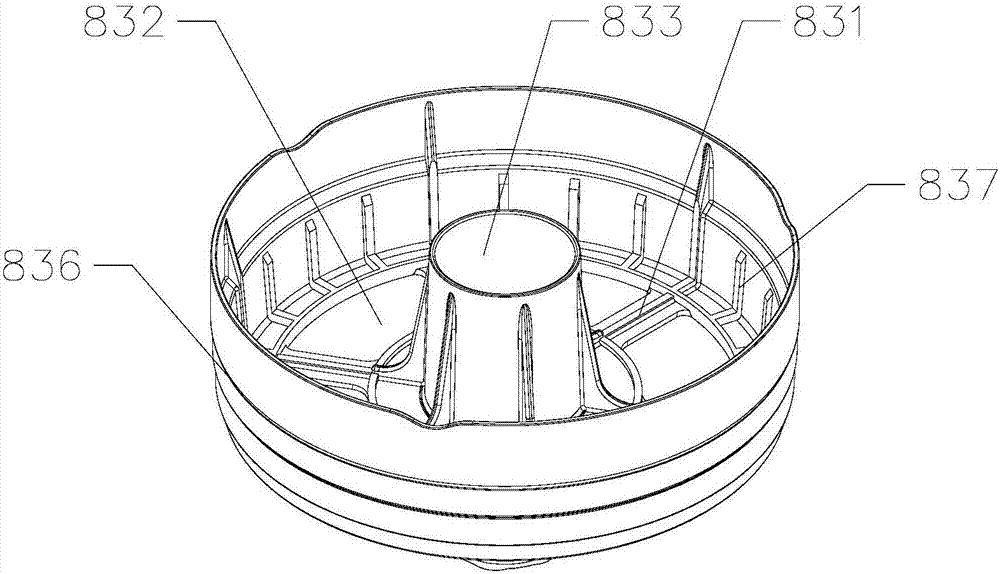

[0086] In this embodiment, the liquid supply mechanism includes an air pump. Specifically, the air pump is installed in the machine base and communicated with the water inlet needle through a pipeline. The air pump is electrically connected to the control board and is controlled by the control board. The mixing step also includes an air blowing process. : The control board controls the air pump to blow air, the air enters the second cavity from the water inlet needle, and pushes the coffee liquid to mix with the milk in the first cavity through the partition.

[0087] Specifically, the airflow speed in the blowing process is S4, 10ml / s≤S4≤30ml / s, specifically, S4 is 12.5m / s, blowing through the air pump, the gas quickly passes through the splitter plate of the middle ring and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com