Taste-improving agent for potassium-chloride-containing foods and beverages and process for producing potassium-chloride-containing foods and beverages

A manufacturing method and technology of potassium chloride, which are applied in the field of taste improvers, can solve the problems of unsatisfactory taste such as bitterness and astringency of potassium chloride, and achieve good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

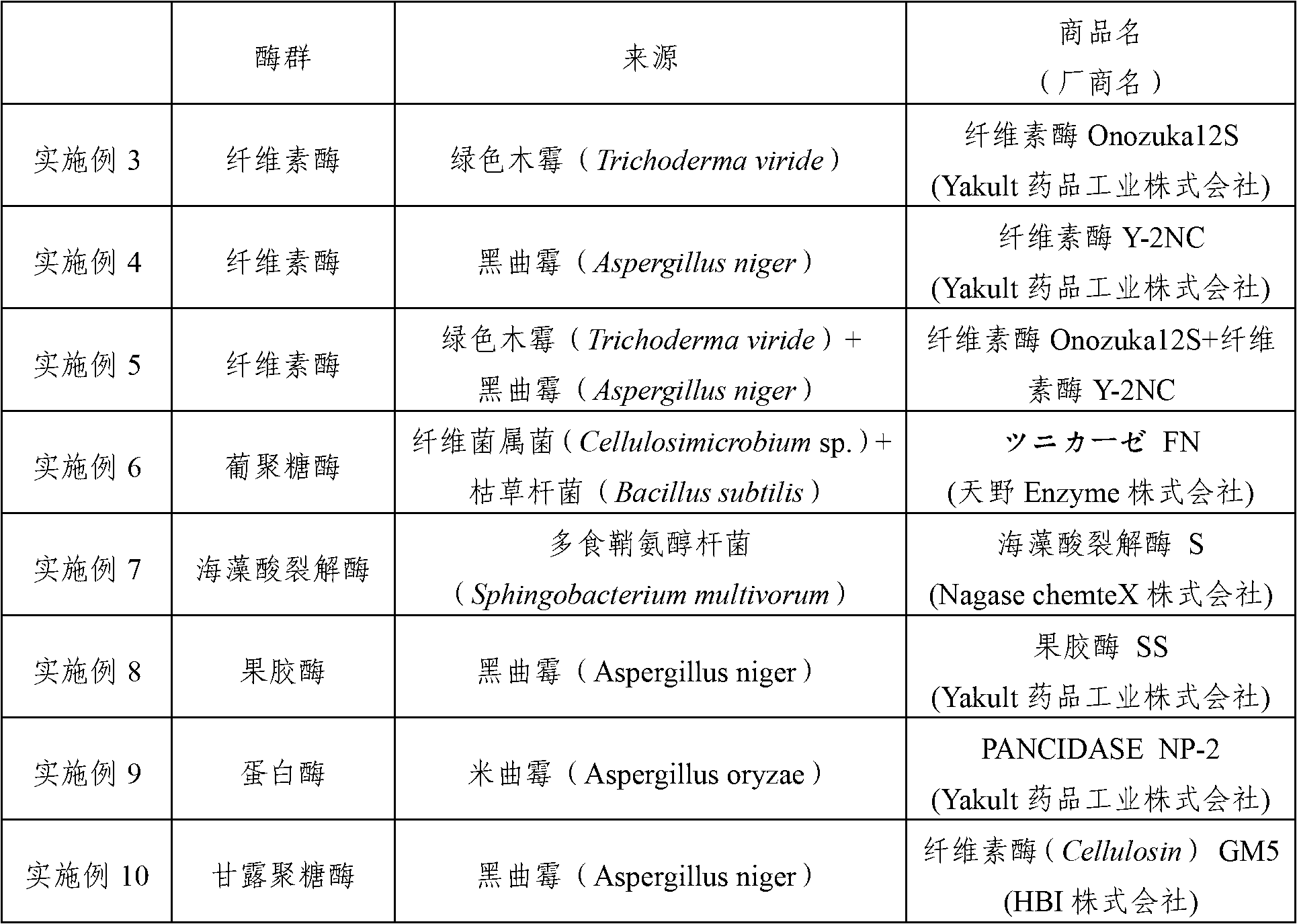

Examples

manufacture example 1

[0062] Manufacturing example 1 (preparation of seaweed hydrolyzate part 1)

[0063] Put 4000kg of water, 60kg of kelp micropowder (90 mass% of particles over 200 mesh), 60kg of wakame micropowder (over 60mesh but no more than 200mesh) into the tank, raise the water temperature to 85°C, and stir for 30 minutes . Next, the water temperature in the tank was lowered to 50° C., and then 2.5% by mass of the first cellulase (trade name: “cellulose Enzyme Y-2NC", produced by Yakult Pharmaceutical Co., Ltd.) and the second cellulase derived from Trichoderma viride (trade name: "Cellulase Onozuka12S", produced by Yakult Pharmaceutical Co., Ltd.). Then stir steadily and carry out enzymatic hydrolysis for 2 hours.

[0064] After enzymatic hydrolysis, raise the temperature of the water in the tank to 85°C to inactivate the enzyme within 10 minutes, then filter through a 154 μm (100 mesh) vibrating sieve to obtain seaweed enzymatic hydrolyzate as the filtrate. Thereafter, the water tempe...

manufacture example 2

[0065] Manufacturing Example 2 (Preparation of Salty Seasoning Part 1)

[0066] The savory savory was formulated at the addition levels shown in Table 1 below. That is, the powdered seaweed hydrolyzate obtained in Production Example 1 was mixed, and the raw materials were mixed to obtain the salty seasoning of Example 1. Moreover, instead of mixing the seaweed enzymatic hydrolyzate, sodium glutamate and sodium aspartate were mixed to obtain the salty seasoning of Comparative Example 1. Furthermore, the kelp extract powder was mixed instead of the seaweed enzymatic hydrolyzate, and the salty seasoning of Comparative Example 2 was obtained.

[0067] Table 1

[0068] Raw material (kg)

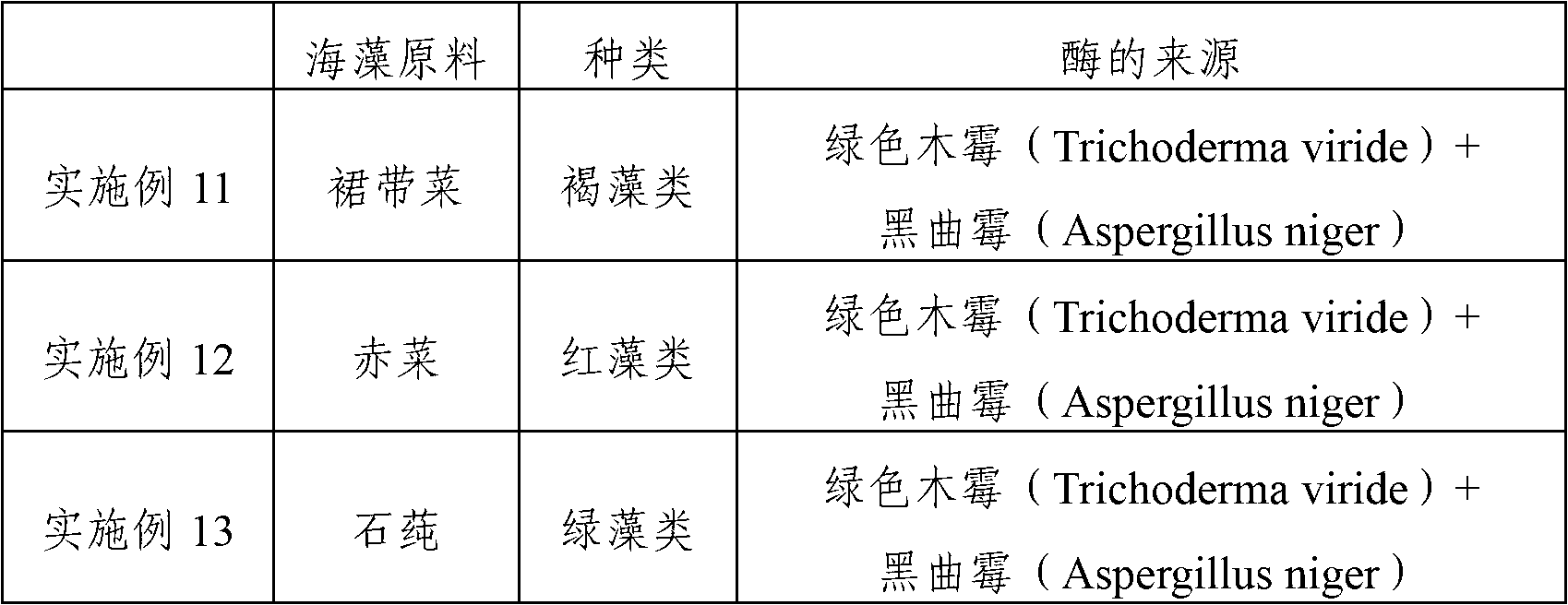

manufacture example 3

[0069] Production Example 3 (Preparation of Salty Seasoning Part 2)

[0070] The savory was formulated at the addition levels shown in Table 2 below. That is, the savory of Example 2 was obtained by adding fish peptide containing a basic amino acid and a basic peptide to the savory obtained in Example 1. Furthermore, fish peptide is made from bonito extract, and the basic amino acid adsorbed on the weakly acidic ion exchange resin (DIAIONWK-40, manufactured by Mitsubishi Chemical Co., Ltd.) is eluted with hydrochloric acid, then neutralized and powdered, and its composition is as follows: 80% salt, 4% anserine and 6% histidine as basic amino acids and basic peptides, 10% other ingredients.

[0071] Table 2

[0072] Raw material (kg)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com