Bitterness inhibitor, application, electronic atomized liquid and preparation method thereof

A bitterness inhibitor, electronic atomization technology, applied in application, electronic atomization liquid and its preparation, bitterness inhibitor field, can solve problems such as reducing bitterness and astringency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing an electronic atomization liquid in an embodiment includes the following steps:

[0047] Mix the base smoke liquid, nicotine, taste additives and bitterness inhibitors to prepare electronic atomization liquid. The bitterness inhibitors include: glucosyl steviol glycoside, β-cyclodextrin and erythritol, and glucosyl steviol glycoside, β-cyclodextrin -The mass ratio of cyclodextrin and erythritol is (1-10):(2-20):(5-100).

[0048] Specifically, the mass ratio of glucosyl steviol glycoside, β-cyclodextrin and erythritol is 1:2:5, 2:5:10, 5:10:20 or 10:20:100. Further, the mass ratio of glucosyl steviol glycoside, β-cyclodextrin and erythritol is (1-5):(5-10):(10-20). Furthermore, the mass ratio of glucosyl steviol glycoside, β-cyclodextrin and erythritol is 1:(2-2.5):(4-10).

[0049] Specifically, the basic e-liquid includes propylene glycol and glycerin. Nicotine includes benzoic acid and nicotine. The steps of mixing the base e-liquid, nicotine...

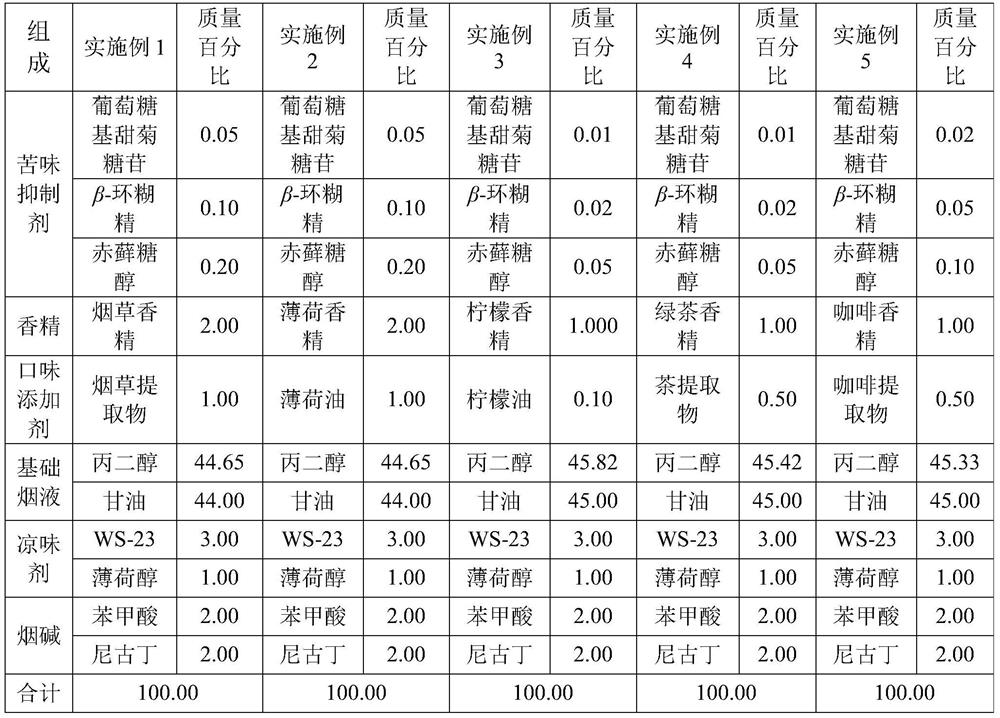

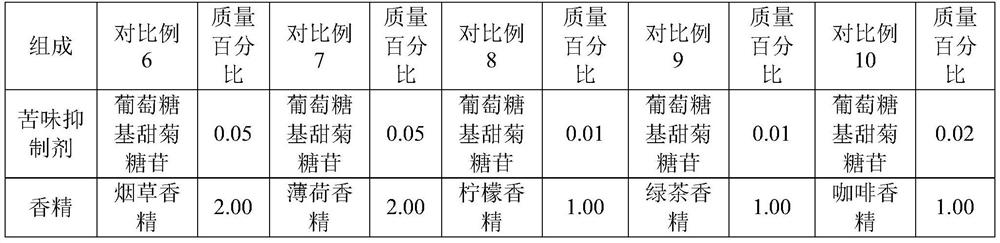

Embodiment 1~ Embodiment 5

[0057] The preparation process of the electronic atomization liquid in Examples 1 to 5 is as follows:

[0058] (1) According to the proportioning in Table 1, weigh each raw material.

[0059] (2) Mix propylene glycol and glycerin evenly to prepare the base e-liquid.

[0060] (3) Add WS-23, menthol, benzoic acid, nicotine and flavor additives to the base e-liquid in step (2) and mix well.

[0061] (4) Add glucosyl steviol glycoside and β-cyclodextrin to the mixed solution in step (3), stir until it is completely dissolved, then add erythritol until it is completely dissolved, and prepare the electronic mixtures of Examples 1 to 5. Atomized liquid.

[0062] Table 1 Composition and ratio of electronic atomization liquid in Example 1 to Example 5

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com