A method for producing x65 acid-resistant pipeline steel plates used under low-cost and ultra-low temperature conditions by a coiling furnace

A coiling furnace, ultra-low temperature technology, applied in the direction of reducing gas emissions, can solve the problems of low-cost process, difficult to ensure the ultra-low temperature performance of thin acid-resistant steel plate, anti-HIC performance, and difficult to ensure use, etc., to ensure grain structure, excellent quality Ultra-low temperature and acid resistance, the effect of ensuring the final rolling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

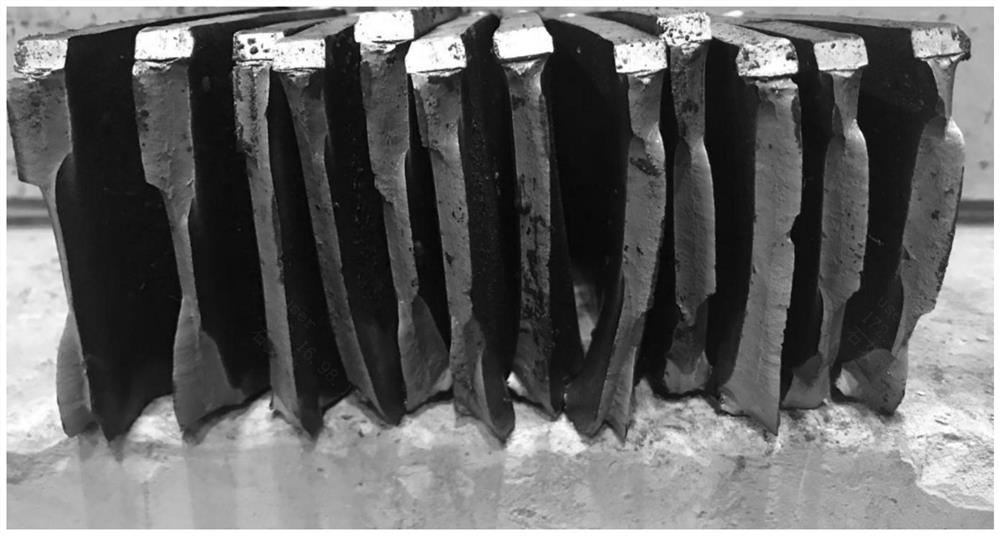

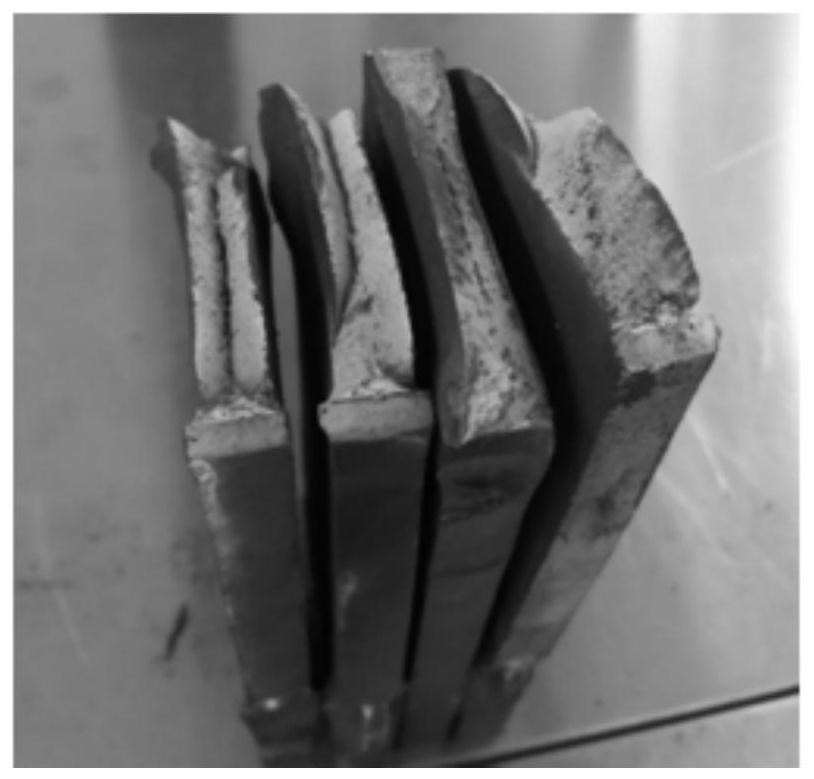

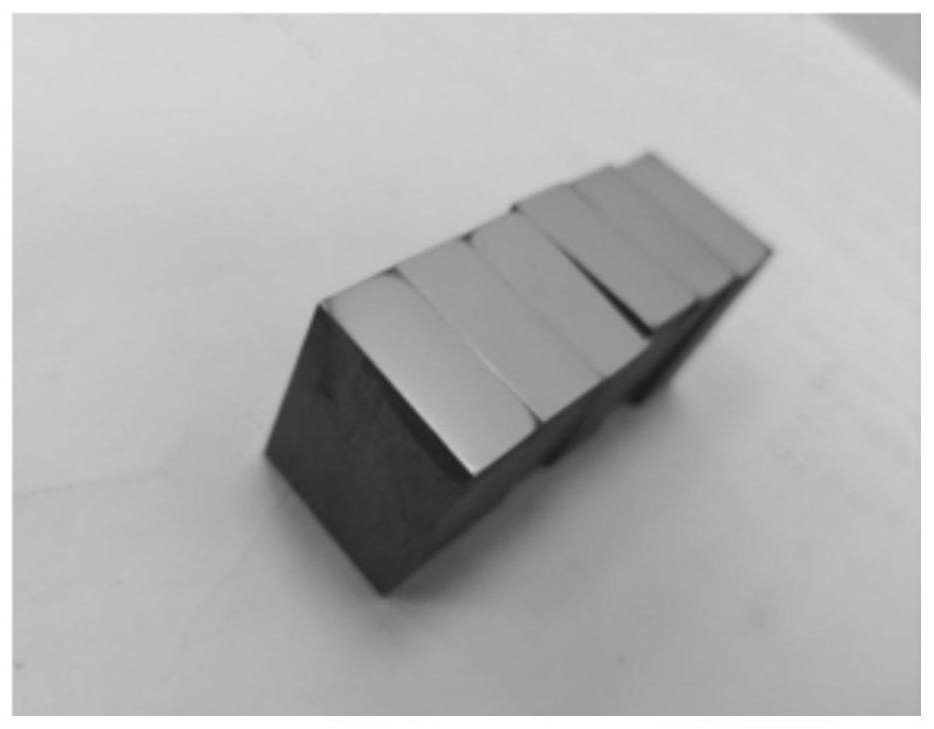

[0041] The manufacturing process of X65MS pipeline steel plate: KR molten iron pretreatment (preliminary desulfurization) - BOF smelting - RH vacuum degassing - LF refining - RH vacuum degassing - continuous casting into 150mm thick continuous casting billets - continuous casting billets with hood and slow cooling - Continuous casting billet inspection and cleaning - billet reheating - high pressure water descaling - rolling - flying shear segment - ACC cooling - straightening - steel plate shearing - inspection and storage, manufacture of X65MS acid-resistant pipeline steel plates used under ultra-low temperature conditions.

[0042] The specific process of the above heating, rolling and cooling is as follows: heating the continuous casting slab with a thickness of 150 mm to 1180 ° C, keeping the temperature in the soaking section for 50 minutes (Example 1) or heating the continuous casting billet with a thickness of 150 mm to 1180 ° C, and keeping the temperature in the soakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com