Mixing and stirring device

A mixing and stirring shaft technology, which is applied to mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve the problems of uneven mixing and low quality of finished coatings, and achieve the effect of ensuring quality and accurate proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

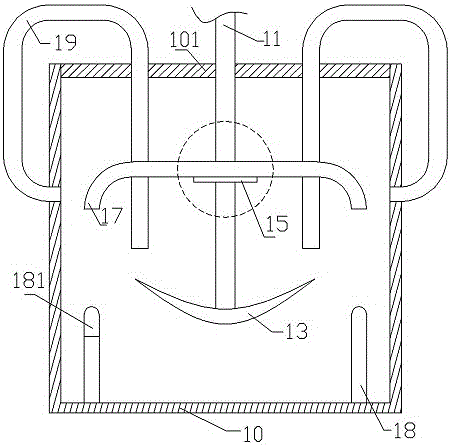

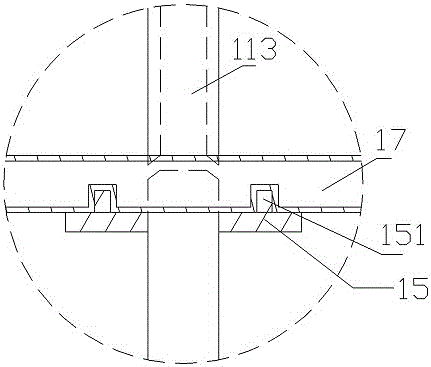

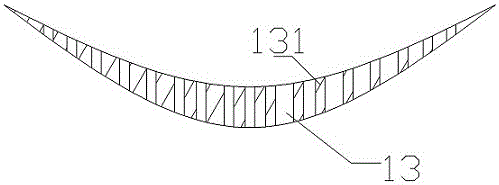

[0018] The reference numerals in the drawings of the description include: housing 10, upper cover 101, stirring shaft 11, feeding cavity 113, arc-shaped stirring blade 13, through hole 131, support plate 15, connecting column 151, feeding plate 17, Cylinder 18, stop switch 181, air pipe 19.

[0019] Such as figure 1 with figure 2 The mixing and stirring device shown includes a housing 10, a rotatable lifting stirring shaft 11 and an upwardly tilted arc-shaped stirring blade 13. The housing 10 is connected with an upper cover 101, and the upper end of the stirring shaft 11 is connected with a stepping motor. The lower end of the stirring shaft 11 passes through the upper cover 101 and is located inside the housing 10; the arc-shaped stirring blade 13 is fixedly connected to the lower end of the stirring shaft 11, as image 3 As shown, the arc-shaped stirring blade 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com