Marinating material recycling device used for producing and processing dried bean curd and using method

A technology of brine and dried tea, which is applied in the field of recycling and utilization of dried tea brine, can solve the problems of low efficiency, no vibration screening mechanism to enhance the filtering effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

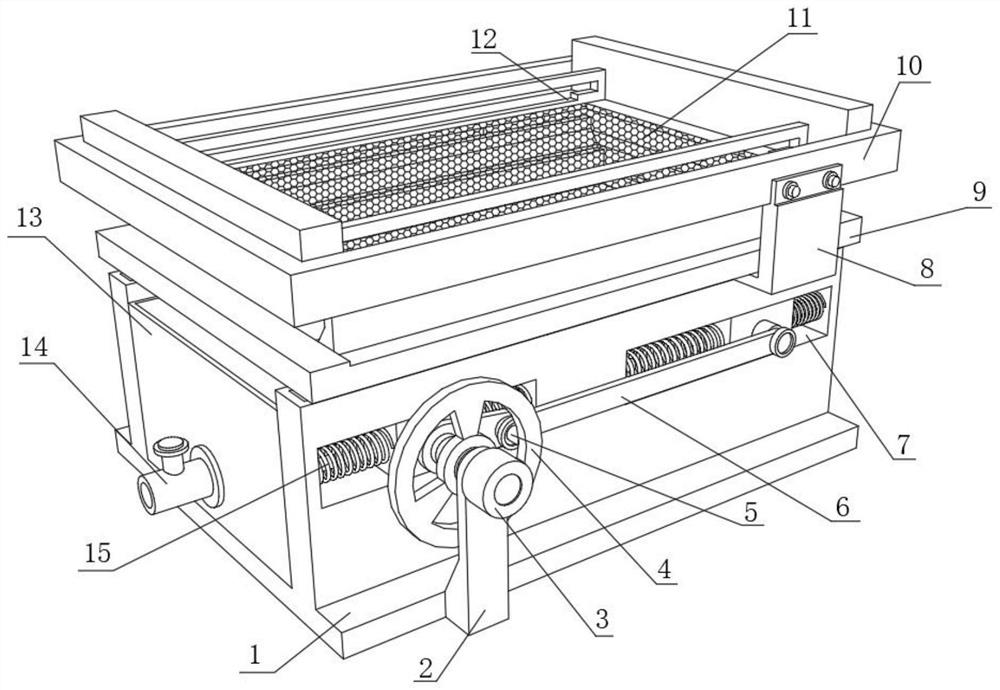

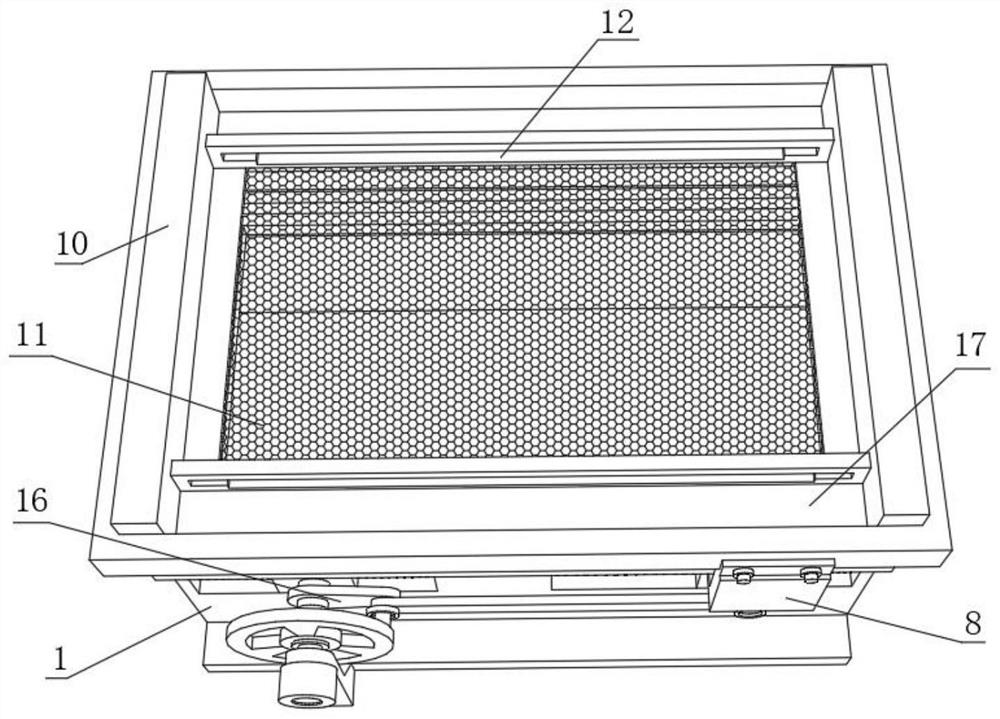

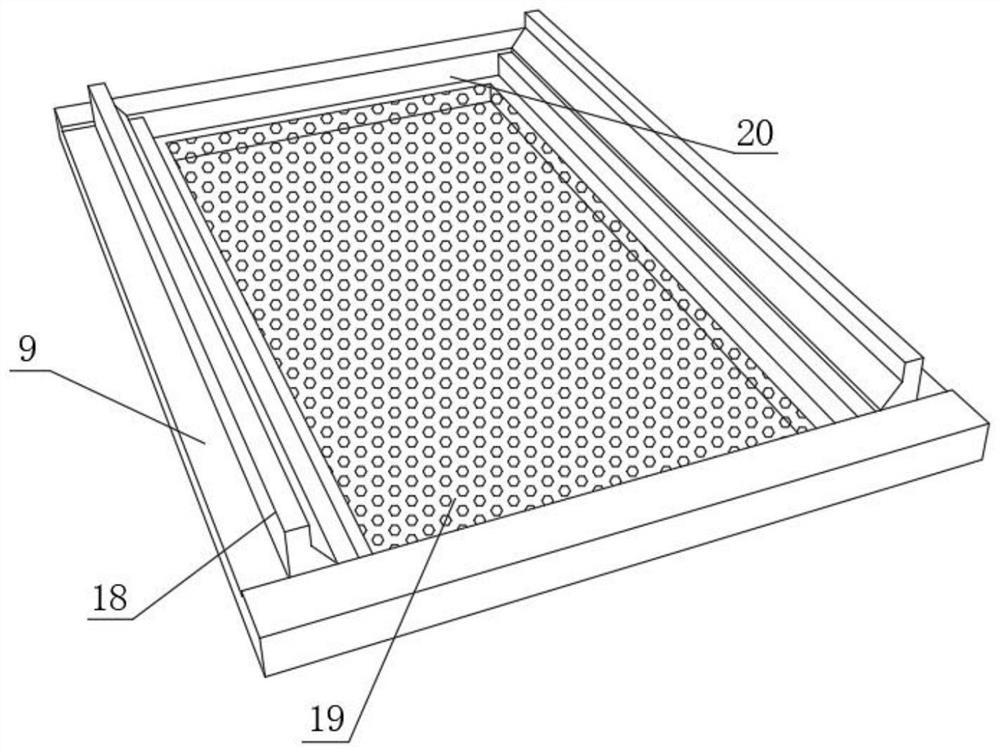

[0034] A kind of brine recycling device for dry tea production and processing, such as Figure 1-5As shown, including the base 1, the outer wall of the top of the base 1 has a placement groove, and the inner wall of the placement groove is placed with a storage box 13, and one side outer wall of the storage box 13 is threadedly connected with a liquid outlet pipe 14, and the base 1 is a The side outer wall is fixed with a fixed base 2 by bolts, and the outer wall on the top side of the fixed base 2 is connected with a motor 3 through a support plate, and the output end of the motor 3 is provided with a vibrating screen mechanism, and the top of the base 1 is slidingly connected with a bottom-up setting. The first filter plate 9 and the second filter plate 10, and the top inner wall of the second filter plate 10 has a guide hole, and the inner wall around the guide hole is fixed with a filter screen 11 by bolts, and the second filter plate 10 is close to both sides of the guide ...

Embodiment 2

[0039] A method for using a brine recycling device for dry tea production and processing, comprising the following steps:

[0040] A. import the brine material into the material guide groove 17 at the top of the second filter plate 10, and the brine material enters the second filter plate 10 from the diversion hole 12 on the dividing plate;

[0041] B. Immediately after starting the motor 3, the motor 3 drives the runner 4 to rotate, and the rotating runner 4 drives the fixed shaft 5 to make a circular motion, and the fixed shaft 5 promotes the rotation of the second connecting rod 16 and drives the first connecting rod 6 to swing up and down , so that the first slider 24 and the second slider 25 move in opposite directions, and compress the spring 15 in the first guide groove 7 and the second guide groove, and move back and forth on the first slideway 26 during the reset process of the spring 15 Slide in the second slideway 27, and simultaneously drive the first filter plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com