Garlic crusher

A technology of crusher and garlic, which is applied to household appliances, applications, kitchen utensils, etc., can solve the problems of loss of garlic juice and broken garlic, and achieve the effect of avoiding excessive loss and retaining the taste of particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

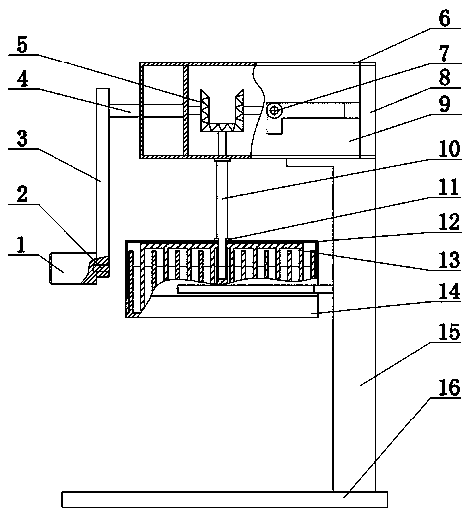

[0015] Below in conjunction with accompanying drawing, describe in detail:

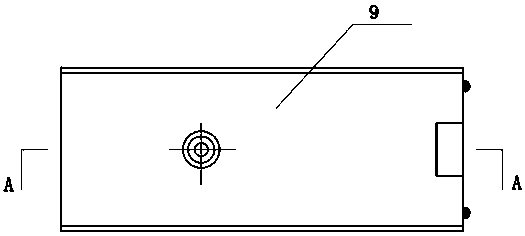

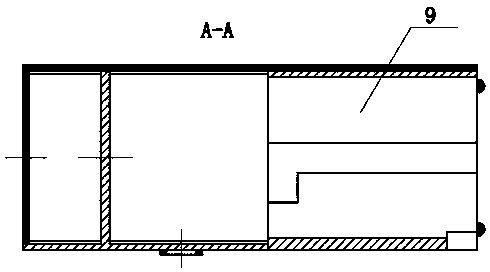

[0016] figure 1 The middle housing 9 and the upper cover 12 are fixed by the support 15, the support 15 and the support 16 are fixed together, the handle driving shaft 4 and the driven shaft 10 transmit motion through the bevel gear, and the motor 7 and the driven shaft 10 pass through The bevel gear is used to transmit the movement, the driven shaft 10, the upper cover 12 and the housing 9 are fixed and supported by bearings, the rotary knife 13 and the driven shaft 10 are fixed by threaded connection, the handle 1 and the handle arm 3 are connected by nails 2 connections. In the above, the rotary knife 13 is driven by the handle 1 or the motor 7 to rotate, and the granularity of the crushed garlic can be retained through the distance between the rotary knife 13 and the fixed reamer on the bottom cover 14, so as to realize the processing of garlic .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com