Method for improving compressive strength of aerated recycled concrete

A technology for recycled concrete and air-entrained concrete, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve the problem of difficulty in controlling the ratio of waste glass fibers added to concrete, unqualified waste glass fibers broken, and waste glass fibers. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

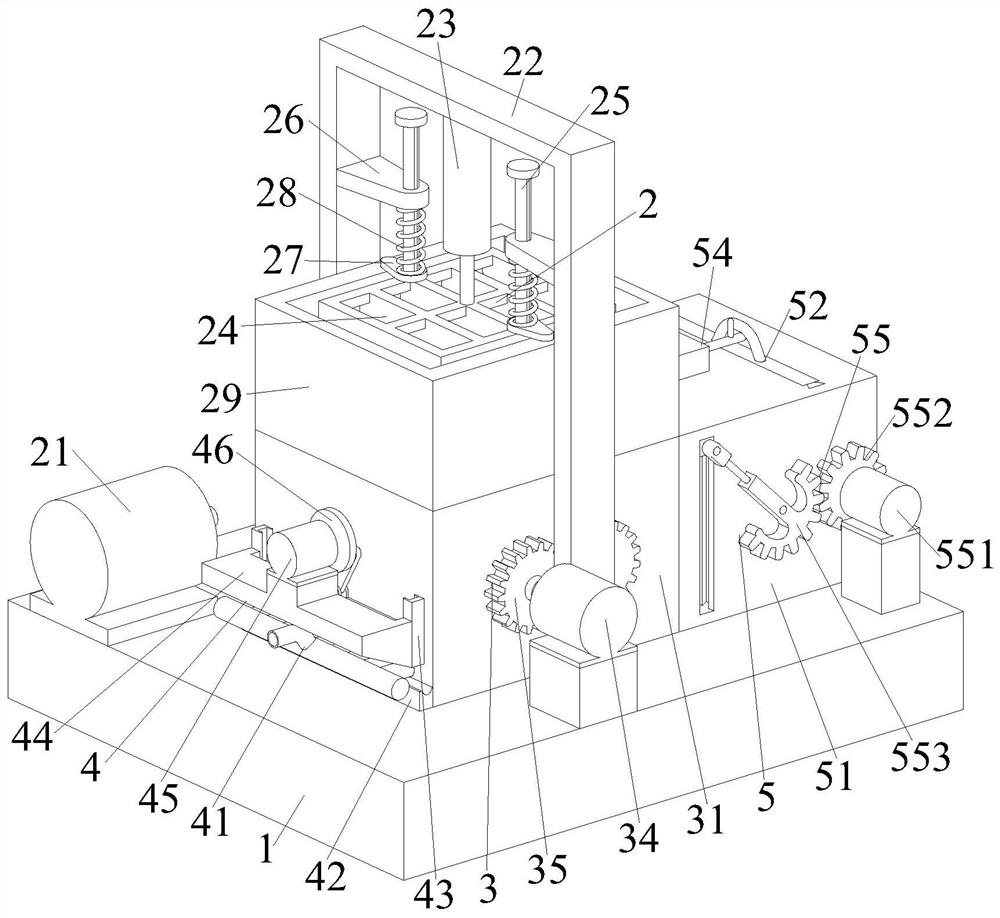

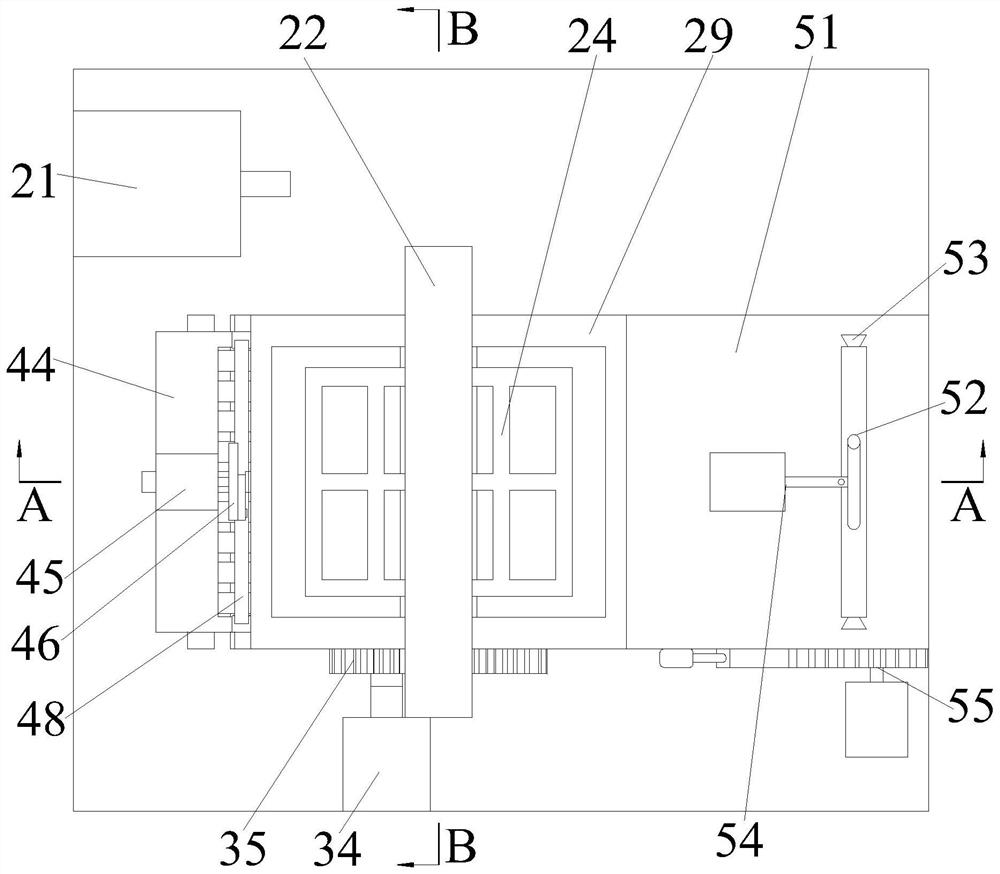

[0040] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

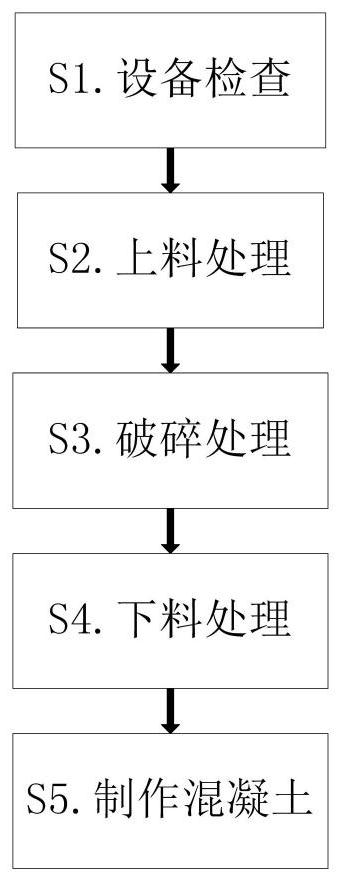

[0041] A method for increasing the compressive strength of aerated recycled concrete, specifically the method for improving the compressive strength of recycled concrete is as follows:

[0042] S1. Equipment inspection: check the equipment before using the equipment to increase the compressive strength of aerated concrete to make aerated concrete;

[0043] S2. Feeding treatment: After the equipment inspection is completed, manually put the waste glass fiber into the feeding device 2 for feeding treatment;

[0044] S3. Crushing treatment: After the feeding is completed, the waste glass fibers are blown and air-selected through the blowing device 4, and the crushing device 3 is used to crush the blown glass fibers;

[0045] S4. Blanking treatment: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com