Shockproof colloid mill

A technology of colloid mill and anti-vibration pad, which is applied in the field of mechanical processing, and can solve problems such as the easy displacement of the mill body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

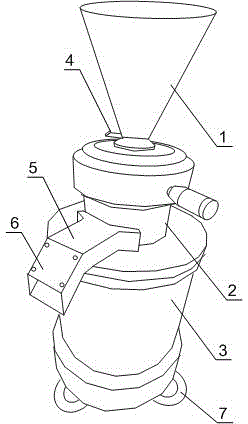

[0020] Such as figure 1 As shown, this embodiment includes a grinding head 2, a feed port 1, a discharge port and a driving mechanism, the feeding port 1 is arranged on the grinding head 2, the driving mechanism is connected with the grinding head 2, and the discharge port is set At the bottom of the grinding head 2, an insert 4 is provided at the bottom of the feed port 1, and the insert 4 is movably arranged at the bottom of the feed port 1; a plurality of anti-vibration feet 7 are also provided at the bottom of the driving mechanism. When working, the material enters the grinding head 2 through the feed port 1, and starts a series of dispersion, crushing, emulsification, homogenization, and uniform mixing operations under the drive of the driving mechanism; there is an insert 4 at the bottom of the feed port, The speed of material leakage in the feed port 1 can be adjusted according to the specific situation. When the insert 4 moves outward, the gap between the feed port 1 ...

Embodiment 2

[0023] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the discharge port includes an upper nozzle 5 and a lower nozzle 6, and the upper nozzle 5 and the lower nozzle 6 are connected. After a series of dispersing, crushing, emulsifying, homogenizing and uniform mixing operations are completed, the material is discharged from the discharge port. The discharge port is divided into an upper nozzle 5 and a lower nozzle 6. The connection between the upper nozzle 5 and the lower nozzle 6 forms an obtuse angle arc. When the material is thrown out of the discharge port due to inertia, the upper nozzle 5 will carry the material itself The impulsive force buffered is discharged by lower mouth 6 again.

Embodiment 3

[0025] Such as figure 1 As shown, the present embodiment is based on the embodiment 2, and the lower nozzle 6 includes a lower nozzle groove and a groove cover, and the groove cover is connected with the lower nozzle groove by bolts. The upper mouth 5 will accumulate a certain amount of material layer due to the mill working for a long time, if it is not cleaned regularly, it will also cause the discharge port to be blocked. The lower nozzle groove and the groove cover are connected by bolts, and the material residue in the upper nozzle 5 and the lower nozzle 6 can be cleaned well only by opening the groove cover during cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com