A kind of high-strength, high-elongation ductile iron alloy and preparation method thereof

A ductile iron, high elongation technology, applied in the field of casting alloys, can solve the problems of difficult to improve material properties, high cost of heat treatment, unstable as-cast materials, etc., to promote clean molten iron, good graphite shape, pearlescent The effect of fine spacing between body pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

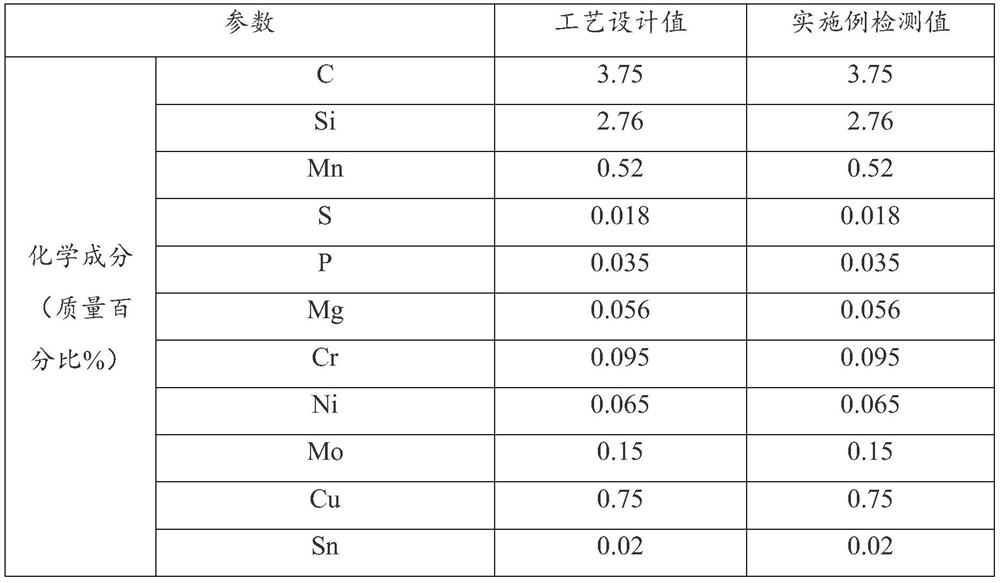

Embodiment 1

[0074]A heavy-duty tractor balance bridge support casting in this embodiment has a chemical composition ratio of C3.75%, Si2.76%, Mn0.52%, P0.035%, S0.018%, Mg0.056%, Cr0.095%, Ni0.065%, Mo0.15%, Cu0.75%, Sn0.02%, Al0.015%, Ti0.036%, V0.01%, Ba0.0025%, Ca0.0025%, RE0.002%, N0.003%, O0.0015%.

[0075] Prepare according to the following production process:

[0076] Step 1: Select high-quality pig iron with a carbon content of 4.5%, high-quality carbon, low-alloy and low-impurity briquette scrap, calcined high-purity silicon carbide, graphite-type low-sulfur carburizer, high-quality long-term special inoculant, high-magnesium spheroidized wire, Pearlitic inoculated filaments and high-strength ductile iron alloy additives are used as raw materials.

[0077] Step 2: Manufacture a special model for high-strength ductile iron castings and a sand box with adjustable temperature control film.

[0078] Step 3: The raw materials are smelted into molten iron in an intermediate frequenc...

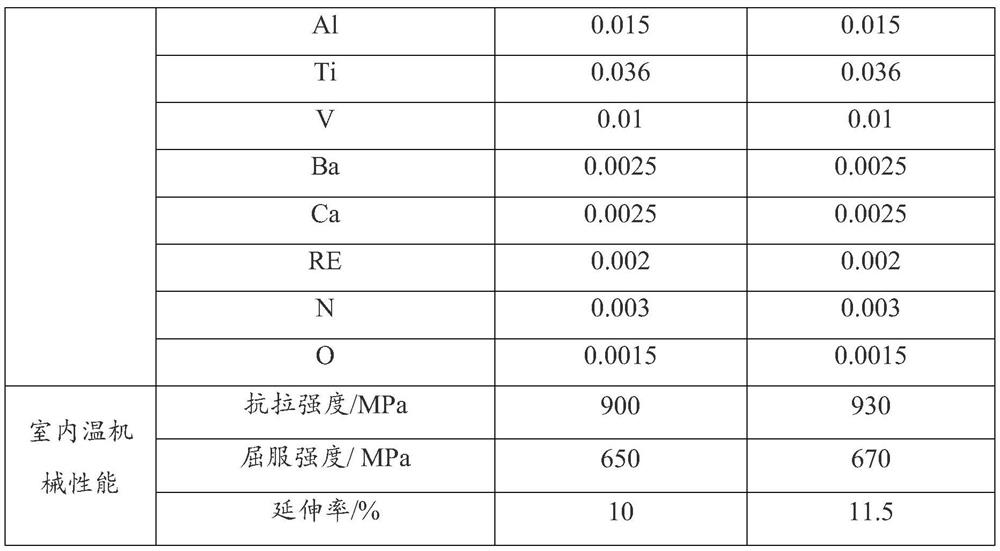

Embodiment 2

[0090] A heavy-duty tractor balance bridge support casting of this embodiment has a chemical composition ratio of C3.55%, Si2.7%, Mn0.50%, P0.035%, S0.018%, Mg0.050%, Cr0.09%, Ni0.06%, Mo0.12%, Cu0.7%, Sn0.01%, Al0.01%, Ti0.035%, V0.008%, Ba0.002%, Ca0.002%, RE0.018%, N0.0025%, O0.0012%.

[0091] Prepare according to the following production process:

[0092] Step 1: Select high-quality pig iron with a carbon content of 4.5%, high-quality carbon, low-alloy and low-impurity briquette scrap, calcined high-purity silicon carbide, graphite-type low-sulfur carburizer, high-quality long-term special inoculant, high-magnesium spheroidized wire, Pearlitic inoculated filaments and high-strength ductile iron alloy additives are used as raw materials.

[0093] Step 2: Manufacture a special model for castings of high-strength ductile iron heavy-duty tractor balance bridge bracket and a sand box with adjustable temperature control film.

[0094] Step 3: The raw materials are smelted int...

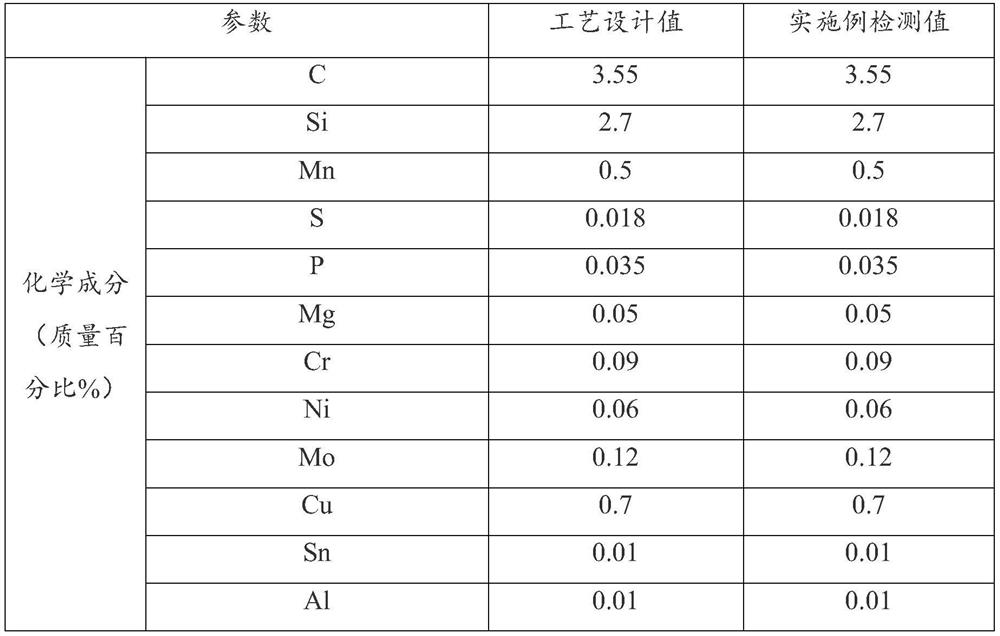

Embodiment 3

[0106] An engine mount bracket casting in this embodiment has a chemical composition ratio of C3.80%, Si2.8%, Mn0.55%, P0.035%, S0.018%, Mg0.058%, Cr0. 1%, Ni0.07%, Mo0.15%, Cu0.8%, Sn0.02%, Al0.02%, Ti0.038%, V0.01%, Ba0.003%, Ca0.003%, RE0. 002%, N0.003%, O0.0015%.

[0107] Prepare according to the following production process:

[0108] Step 1: Select high-quality pig iron with a carbon content of 4.5%, high-quality carbon, low-alloy and low-impurity briquette scrap, calcined high-purity silicon carbide, graphite-type low-sulfur carburizer, high-quality long-term special inoculant, high-magnesium spheroidized wire, Pearlitic inoculated filaments and high-strength ductile iron alloy additives are used as raw materials.

[0109] Step 2: Manufacture a special model for castings of high-strength ductile iron heavy-duty tractor balance bridge bracket and a sand box with adjustable temperature control film.

[0110] Step 3: The raw materials are smelted into molten iron in an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com