High-strength and high-elongation nodular cast iron alloy and preparation method thereof

A technology of nodular cast iron and high elongation, which is applied in the field of casting alloys. It can solve the problems of high cost of heat treatment, difficulty in improving material properties, and insufficient stability of as-cast materials, so as to achieve good graphite shape, promote clean iron, and pearlescent The effect of fine body-slice spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

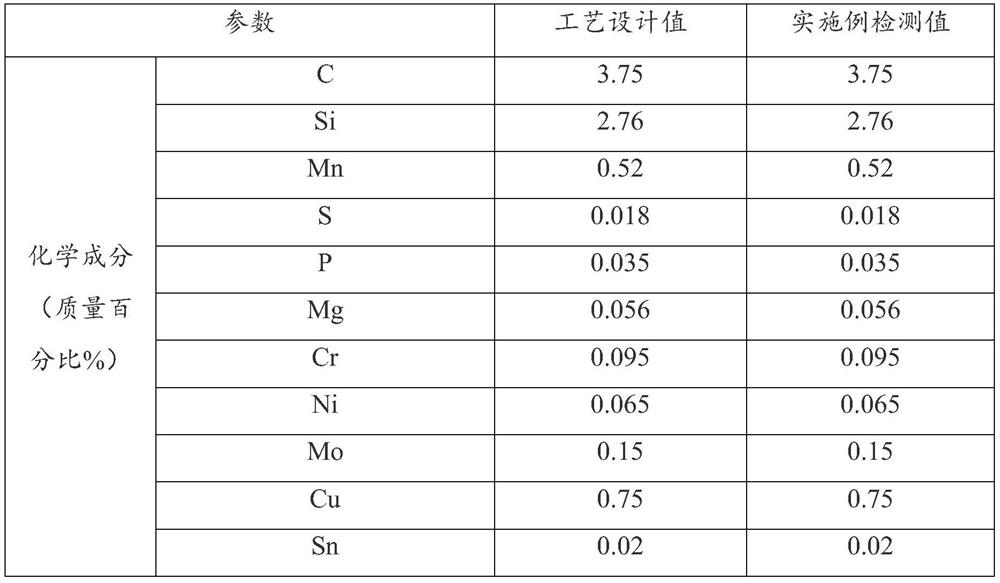

Embodiment 1

[0074]A heavy-duty tractor balance bridge support casting in this embodiment has a chemical composition ratio of C3.75%, Si2.76%, Mn0.52%, P0.035%, S0.018%, Mg0.056%, Cr0.095%, Ni0.065%, Mo0.15%, Cu0.75%, Sn0.02%, Al0.015%, Ti0.036%, V0.01%, Ba0.0025%, Ca0.0025%, RE0.002%, N0.003%, O0.0015%.

[0075] Prepare according to the following production process:

[0076] Step 1: Select high-quality pig iron with a carbon content of 4.5%, high-quality carbon, low-alloy and low-impurity briquette scrap, calcined high-purity silicon carbide, graphite-type low-sulfur carburizer, high-quality long-term special inoculant, high-magnesium spheroidized wire, Pearlitic inoculated filaments and high-strength ductile iron alloy additives are used as raw materials.

[0077] Step 2: Manufacture a special model for high-strength ductile iron castings and a sand box with adjustable temperature control film.

[0078] Step 3: The raw materials are smelted into molten iron in an intermediate frequenc...

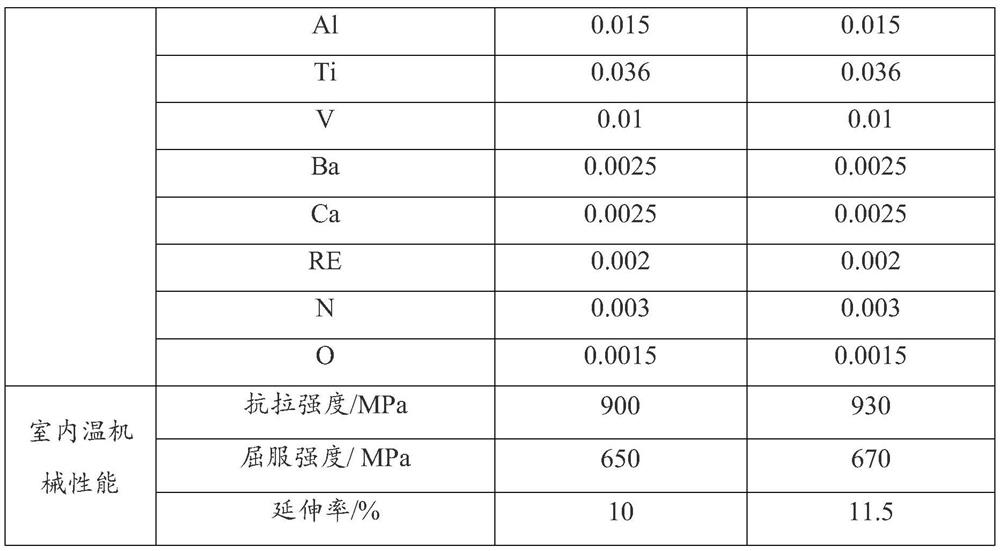

Embodiment 2

[0090] A heavy-duty tractor balance bridge support casting of this embodiment has a chemical composition ratio of C3.55%, Si2.7%, Mn0.50%, P0.035%, S0.018%, Mg0.050%, Cr0.09%, Ni0.06%, Mo0.12%, Cu0.7%, Sn0.01%, Al0.01%, Ti0.035%, V0.008%, Ba0.002%, Ca0.002%, RE0.018%, N0.0025%, O0.0012%.

[0091] Prepare according to the following production process:

[0092] Step 1: Select high-quality pig iron with a carbon content of 4.5%, high-quality carbon, low-alloy and low-impurity briquette scrap, calcined high-purity silicon carbide, graphite-type low-sulfur carburizer, high-quality long-term special inoculant, high-magnesium spheroidized wire, Pearlitic inoculated filaments and high-strength ductile iron alloy additives are used as raw materials.

[0093] Step 2: Manufacture a special model for castings of high-strength ductile iron heavy-duty tractor balance bridge bracket and a sand box with adjustable temperature control film.

[0094] Step 3: The raw materials are smelted int...

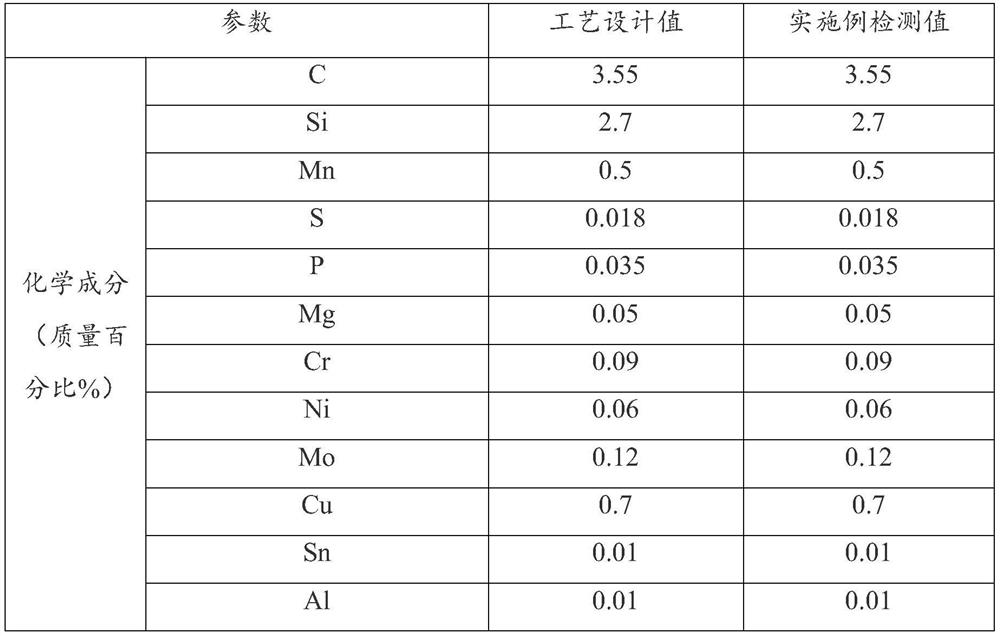

Embodiment 3

[0106] An engine mount bracket casting in this embodiment has a chemical composition ratio of C3.80%, Si2.8%, Mn0.55%, P0.035%, S0.018%, Mg0.058%, Cr0. 1%, Ni0.07%, Mo0.15%, Cu0.8%, Sn0.02%, Al0.02%, Ti0.038%, V0.01%, Ba0.003%, Ca0.003%, RE0. 002%, N0.003%, O0.0015%.

[0107] Prepare according to the following production process:

[0108] Step 1: Select high-quality pig iron with a carbon content of 4.5%, high-quality carbon, low-alloy and low-impurity briquette scrap, calcined high-purity silicon carbide, graphite-type low-sulfur carburizer, high-quality long-term special inoculant, high-magnesium spheroidized wire, Pearlitic inoculated filaments and high-strength ductile iron alloy additives are used as raw materials.

[0109] Step 2: Manufacture a special model for castings of high-strength ductile iron heavy-duty tractor balance bridge bracket and a sand box with adjustable temperature control film.

[0110] Step 3: The raw materials are smelted into molten iron in an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com