A method for manufacturing high-silicon nickel-based alloy cold-rolled sheet

A manufacturing method and technology of nickel-based alloys, applied in the manufacture of high-silicon nickel-based alloy cold-rolled plates, and in the field of plate heat exchangers, can solve problems such as high gas content, billet cracking, and low melting point, and achieve good room temperature performance and surface Good, high-performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below with examples, and examples are only a description of the best implementation mode of the present invention, and do not limit the scope of the present invention in any way.

[0037] The present invention is described in more detail by using three examples.

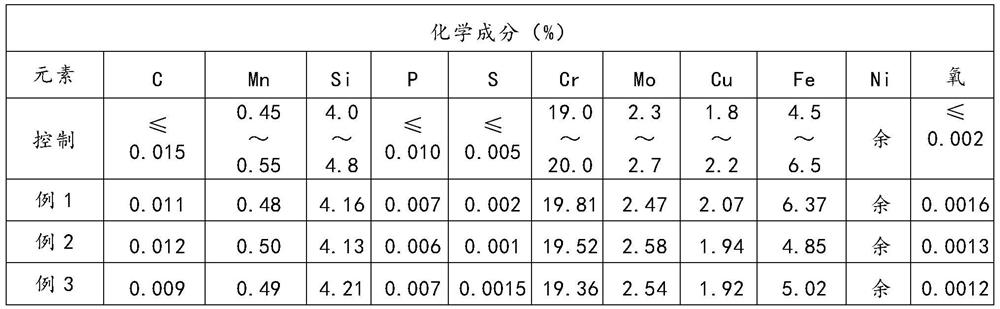

[0038] 1. See Table 1 for the mass percentages of the chemical components of the three examples.

[0039] Table 1 chemical composition

[0040]

[0041] 2. the production technology of embodiment is as follows:

[0042] ⑴Smelting: using VIM+ESR smelting

[0043] During the production of VIM, the main process parameters of the three cases are shown in Table 2.

[0044] Table 2 main process parameter list

[0045] batch Not greater than 5Pa, holding time (min) Vacuum degree during pouring (Pa) Pouring temperature (℃) example 1 45 36 1418 Example 2 49 25 1414 Example 3 57 28 1408

[0046] During ESR production, the cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com