Novel manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel

A cold work die steel, high carbon and high chromium technology, applied in the field of cold work die steel forging round steel manufacturing, can solve the problem of serious eutectic carbide inhomogeneity, deterioration of carbide segregation, and increase of surface crack defects in large section forging materials and other problems, to achieve the effect of improving hot working plasticity, preventing crack defects and stabilizing melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The production size and shape are Φ300mm round steel.

[0046] EAF+LF+VD method is used for smelting, LF furnace uses 4.25 high alkalinity slag, [FeO] content in slag is 0.61%, white slag time is 35min; VD vacuum degree is ≤1mbar, keep it for 15min, and softly blow Ar gas for 10min before pouring , casting 5t ingots, the pouring temperature is 1471°C, and the 5t ingots are sent to the next branch factory.

[0047]The melting analysis results of the chemical composition of steel ingots are shown in Table 1.

[0048] Table 1 chemical composition

[0049]

[0050] The steel ingot is subjected to high-temperature homogenization treatment, the heating temperature is 1178°C, and the holding time is 4h.

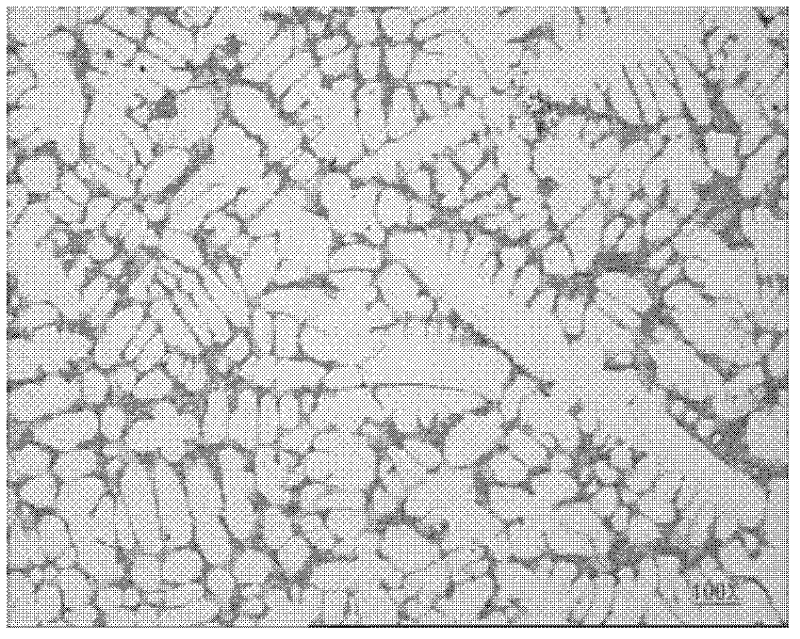

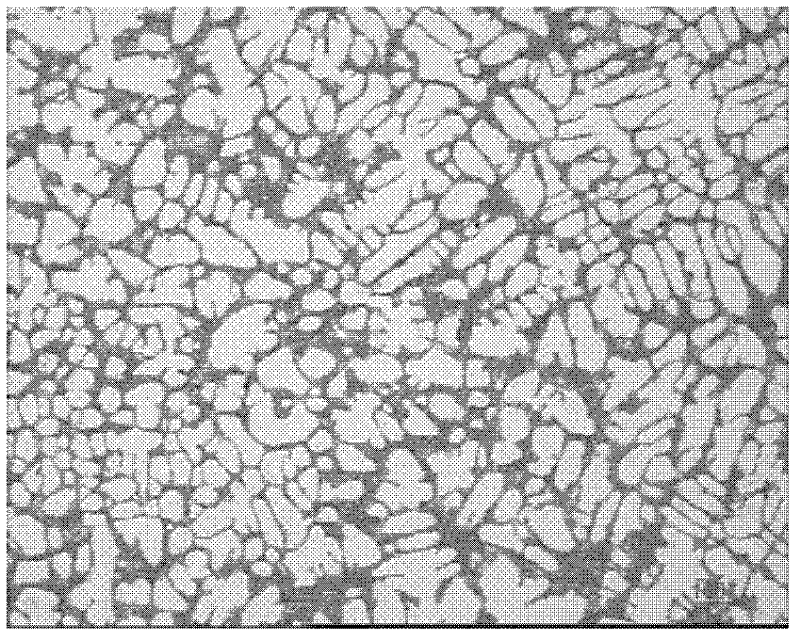

[0051] The steel ingot is forged with eight fires, which are divided into three steps: the first step is symmetrical deformation forging, the first three fires use the upper and lower equal width flat anvils to lightly press the steel ingot, the deformation of each pass ...

Embodiment 2

[0056] The production size and shape are Φ480mm round steel.

[0057] EAF+LF+VD method is used for smelting, LF furnace uses 4.21 high alkalinity slag, the [FeO] content in the slag is about 0.63%, and the white slag time is 33min; VD vacuum degree is ≤1mbar, keep it for 15min, and blow Ar gas softly before pouring In 10 minutes, 9t ingots were poured, the pouring temperature was 1468°C, and the 9t ingots were sent to the next branch factory.

[0058] The melting analysis results of the chemical composition of steel ingots are shown in Table 3.

[0059] Table 3 chemical composition

[0060]

[0061] The steel ingot is subjected to high-temperature homogenization treatment, the heating temperature is 1177°C, and the holding time is 6h.

[0062] The steel ingot is forged with nine fires, which is divided into three steps: the first step is symmetrical deformation forging, the first four fires use the upper and lower flat anvils to lightly press the steel ingot, the deformat...

Embodiment 3

[0067] The production size and shape are Φ510mm round steel.

[0068] EAF+LF+VD method is used for smelting, LF furnace uses 4.23 high alkalinity slag, the [FeO] content in the slag is about 0.62%, and the white slag time is 32min; VD vacuum degree is ≤1mbar, keep it for 15min, and blow Ar gas softly before pouring For 10 minutes, cast a Φ700mm round electrode rod, the pouring temperature is 1469°C, the electrode rod is red and annealed, and the annealing temperature is 890°C. Ternary slag-based CaF is used in electroslag remelting 2 : Al 2 o 3 : MgO=65%: 30%: 5%, the amount of remelting slag is 370kg, the remelting voltage is controlled at 75V ~ 82V, the remelting current is controlled at 16000A ~ 20000A, the electroslag remelting ingot type is Φ930mm electroslag ingot, The electroslag ingot is warmly sent to the next branch factory. The results of the chemical composition analysis of the electrode rod are shown in Table 5.

[0069] Table 5 Chemical Composition

[0070]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com