Wind driven generator

A technology for wind turbines and generators, which is applied in the directions of wind turbines, wind turbine combinations, and wind power generation, etc., can solve the problems of difficulty in removing tip ice, difficulty in heating, and difficulty in deicing blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

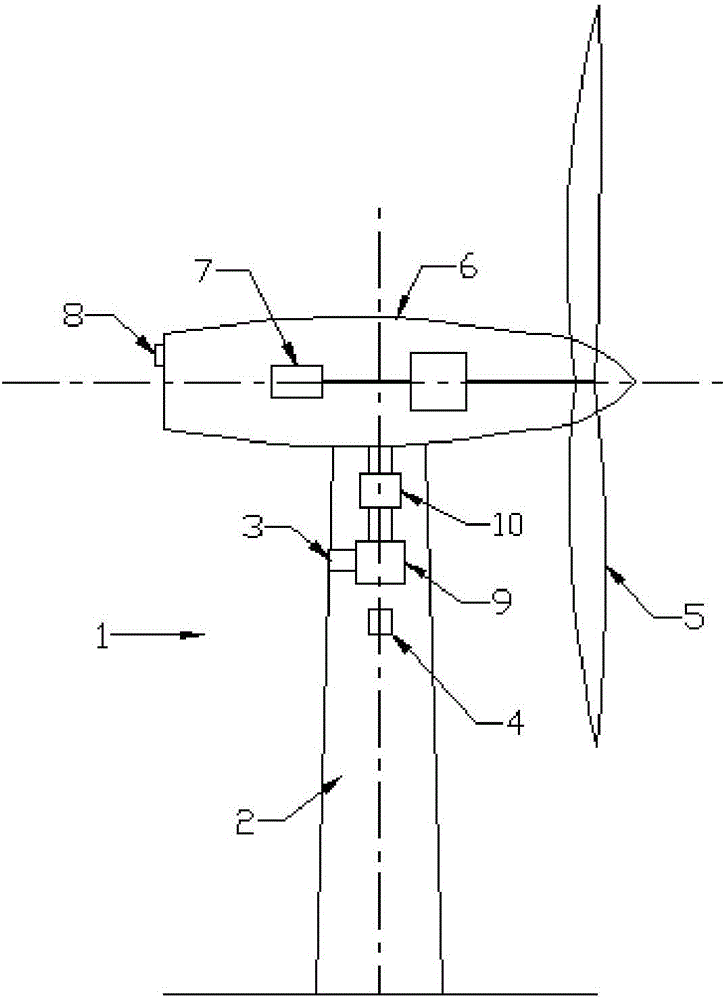

[0027] figure 1 is a perspective view of an exemplary wind turbine, showing various components of the wind turbine. Wherein the wind-driven generator 1 is a horizontal-axis generator, or may also be a vertical-axis generator. In this embodiment, the wind-driven generator 1 includes a tower 2 extending from a supporting surface, and the height of the tower 2 is usually tens of meters. The nacelle 6 installed on the tower 2, the generator 7 arranged in the nacelle, and the gearbox connected to the generator 7, the rotor of the wind power generator 2 is rotatably connected to the gearbox through the shaft, and the rotor includes a hub and an external Blade 5.

[0028] In this embodiment, the rotor comprises three rotor blades 5 . In an alternative embodiment, the rotor comprises more or less than three rotor blades 5 . Rotor blades 5 are spaced around the hub to facilitate rotation of the rotor, thereby converting kinetic energy from the wind into usable mechanical energy and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com