Cleaning device and cleaning method for high-cleanliness ultrasonic material belt

A high cleanliness and cleaning device technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as wear, cleaning effect decline, and mutual friction between them, so as to improve cleaning effect, The effect of controlling cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

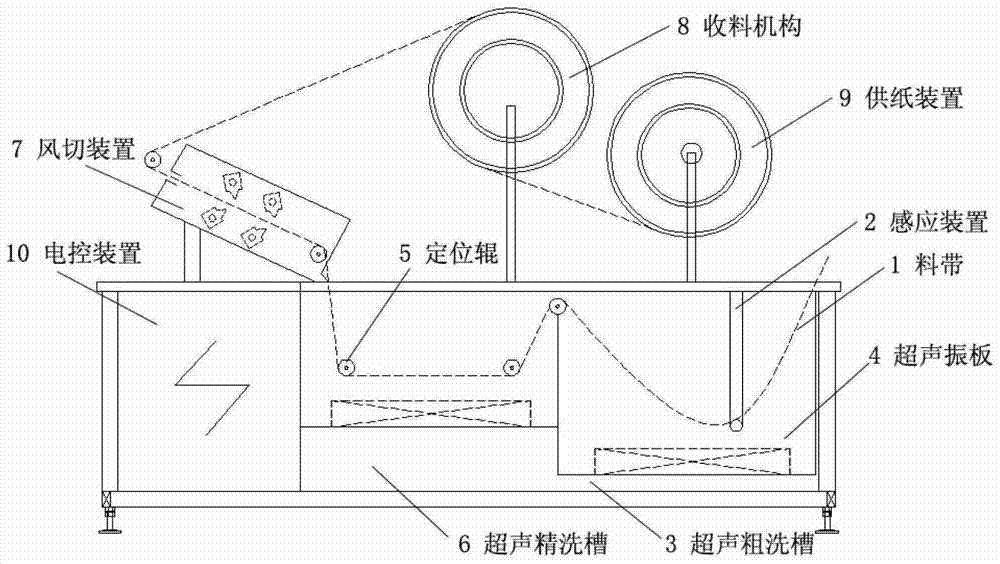

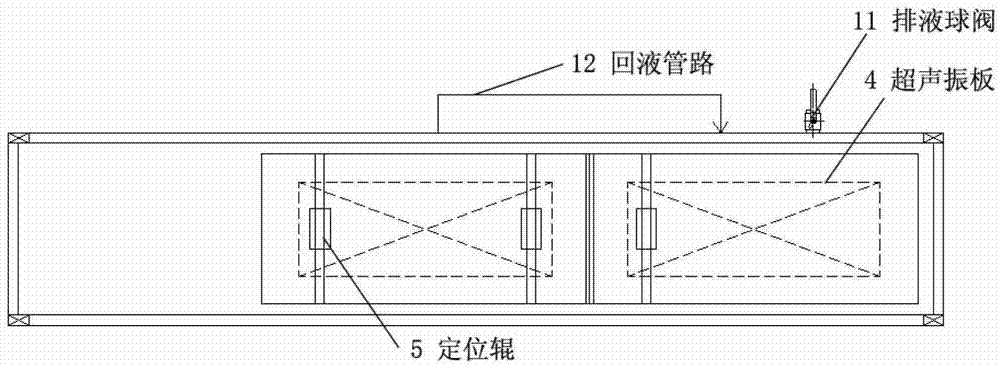

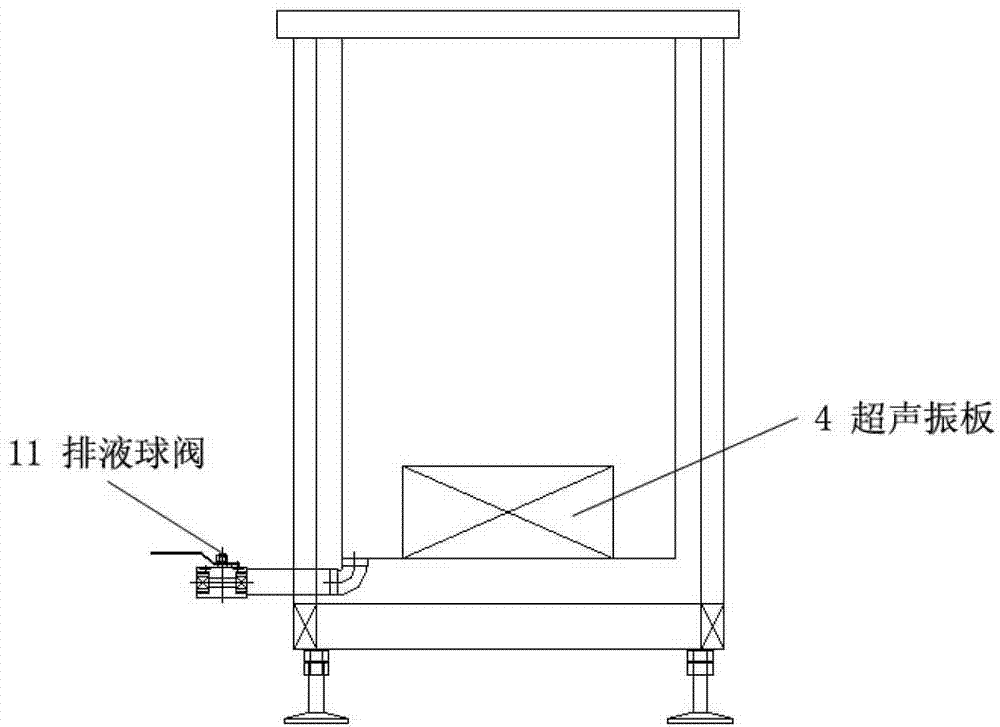

[0029] Such as Figure 1-Figure 3 As shown, after the material belt 1 enters the ultrasonic coarse cleaning tank 3, the induction device 2 is installed in the ultrasonic rough cleaning tank 3, the material belt 1 passes through the U-shaped induction device 2, and the material belt 1 passes in a U shape. This device adopts a unique The setting of two-stage cleaning tanks can greatly reduce the waste of cleaning agents and improve the smoothness of the material belt 1 after cleaning. The material strip 1 first enters the ultrasonic rough cleaning tank 3, and the bottom of the rough cleaning tank 3 is provided with an ultrasonic vibrating plate 4, and the ultrasonic vibrating plate 4 is treated with hard chrome plating, which greatly improves the service life of the vibrating plate. Then it enters the ultrasonic fine cleaning tank 6 through the positioning roller 5, and the ultrasonic fine cleaning tank 6 is also provided with an ultrasonic vibrating plate 4 at the bottom. The ...

Embodiment 2

[0031] On the basis of the above examples, if Figure 1-Figure 3 As shown, further, strip 1 is in the front view figure 1 Running from right to left, it enters the rough ultrasonic cleaning tank 3. The rough ultrasonic cleaning tank 3 uses SUS304 stainless steel plate as the tank body. Compared with other steel plates, such as SUS303 steel plate, SUS304 stainless steel plate has better corrosion resistance; Good ultrasonic transmission efficiency and corrosion resistance. An ultrasonic vibrating plate 4 is arranged at the bottom of the rough ultrasonic cleaning tank 3 . Ultrasonic vibrating plate 4 is made of SUS316L stainless steel. SUS316L stainless steel has better corrosion resistance than SUS304. Since SUS316L stainless steel contains 2-3℅ of molybdenum, it improves the resistance to reducing salts and various inorganic and organic acids and alkalis. , Corrosion resistance of salt. The vibration amplitude surface is treated with hard chromium plating. Since the workpie...

Embodiment 3

[0033] On the basis of the above examples, if Figure 1-Figure 3 As shown, further, due to the active force of the receiving mechanism 8, the material strip 1 enters the ultrasonic fine cleaning tank 6 through the positioning roller 5, and the same ultrasonic vibrating plate 4 in the ultrasonic rough cleaning tank 3 is arranged in the ultrasonic fine cleaning tank 6 . Its function and purpose are the same. This secondary cleaning setting can greatly improve the cleaning effect of the material belt 1, and prevent serious cleaning agent pollution caused by long-section cleaning, which affects the cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com