Automatic cleaning device of arc sieve

An automatic cleaning and cleaning device technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of affecting work efficiency, cumbersome and complicated process, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

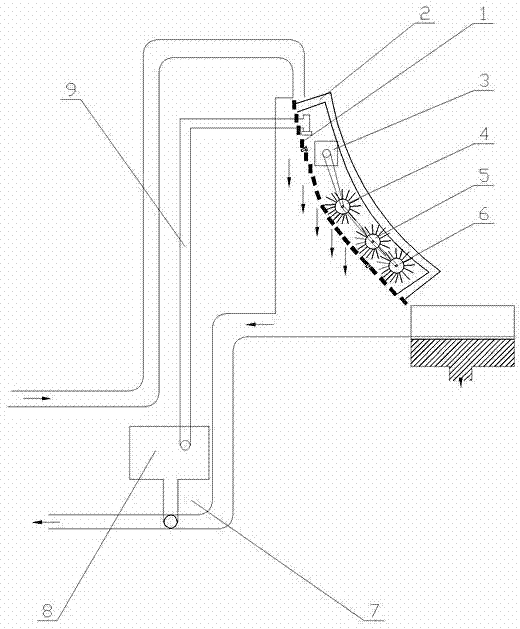

[0008] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like figure 1 Shown: a curved sieve automatic cleaning device, characterized in that: the cleaning device includes a support 2 fixedly arranged above the curved sieve 1, and the general shape of the support 2 is similar to that of the curved sieve 1. 2 is fixedly provided with a motor 3, and at the same time, a soft brush roller 4, a common brush roller 5 and a hard brush roller 6 are rotatably supported above the bracket 2, wherein the soft brush roller 4 is located near the upper part of the curved screen 1. position, the hard brush roller 4 is located close to the lower part of the curved screen 1, while the ordinary brush roller 5 is located between the soft brush roller 4 and the hard brush roller 6, and the motor 3 drives the soft brush roller through the belt drive pair 4. Between the soft brush roller 4 and the ordinary brush roller 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com