Automatic laser cleaning system and method for traction motor of rail transit vehicle

A technology for rail transit vehicles and traction motors, which is applied in the field of laser cleaning, can solve the problems that restrict the wider application of laser cleaning technology, the shape of the shell is complex, and the dirt cannot be cleaned, so as to reduce the labor intensity of workers, improve the degree of automation, The effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

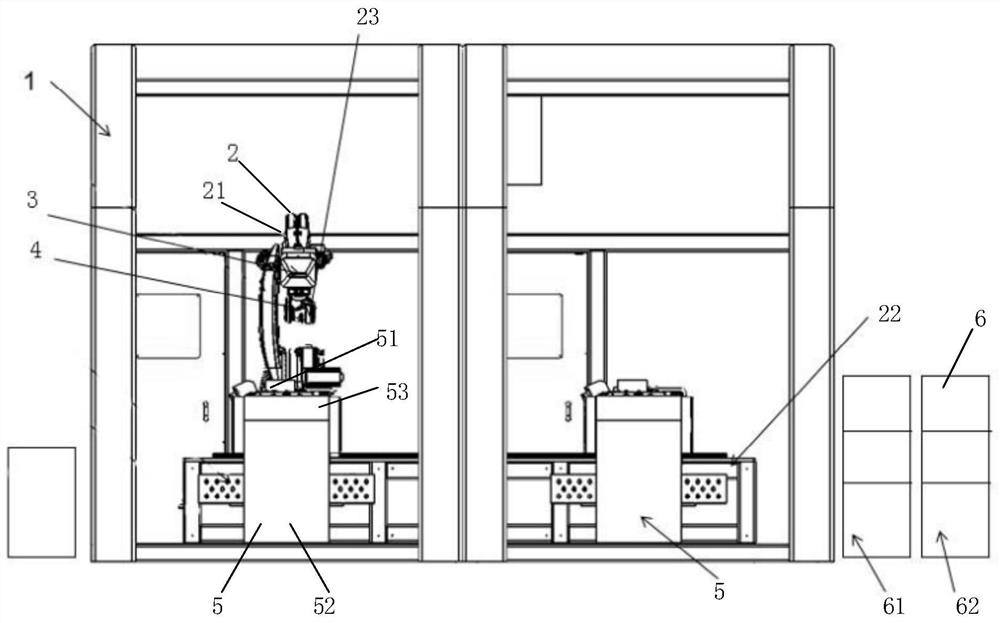

[0034] like figure 1 As shown, the automatic laser cleaning system for rail transit vehicle traction motors of the present embodiment includes a robot unit 2, a workpiece motion unit 5 and a control unit 6; the workpiece motion unit 5 is used to fix a workpiece (such as a motor) to be cleaned and Its motion, motion comprises rotation, overturn or translation etc.; Robot unit 2 comprises manipulator 21, and laser head 23 and three-dimensional scanning unit 4 (as conventional laser scanner) are installed on manipulator 21; Three-dimensional scanning unit 4, is used for motor Scan to obtain the three-dimensional shape of the motor and the area to be cleaned; the control unit 6 is connected to the three-dimensional scanning unit 4 and the laser head 23 respectively, and is used to determine the trajectory and scanning mode of the laser head 23 acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com