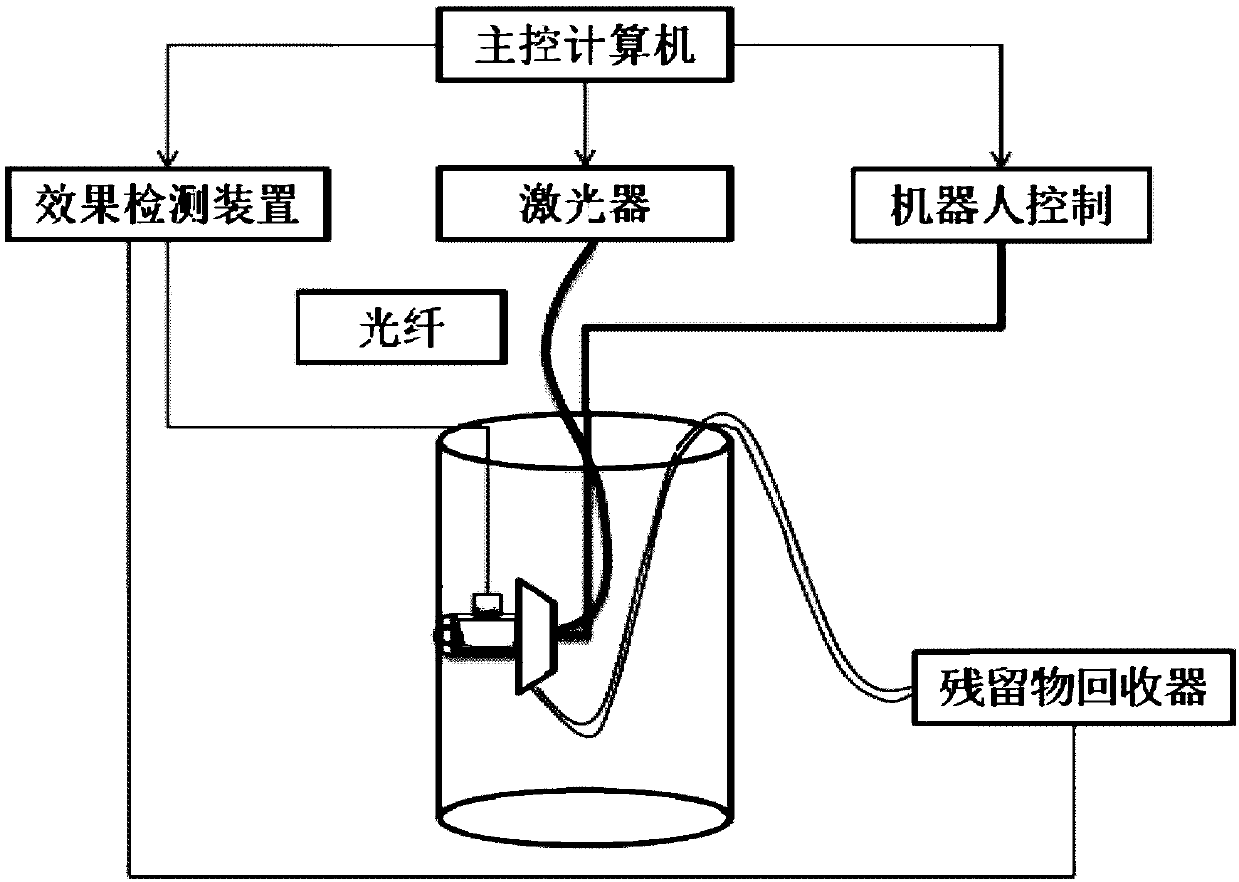

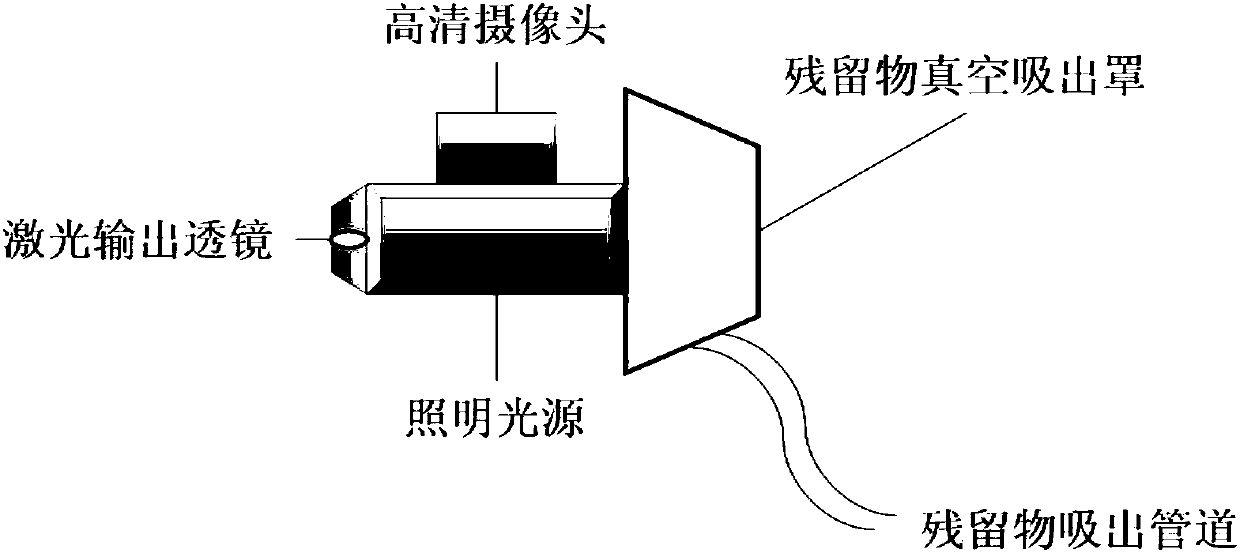

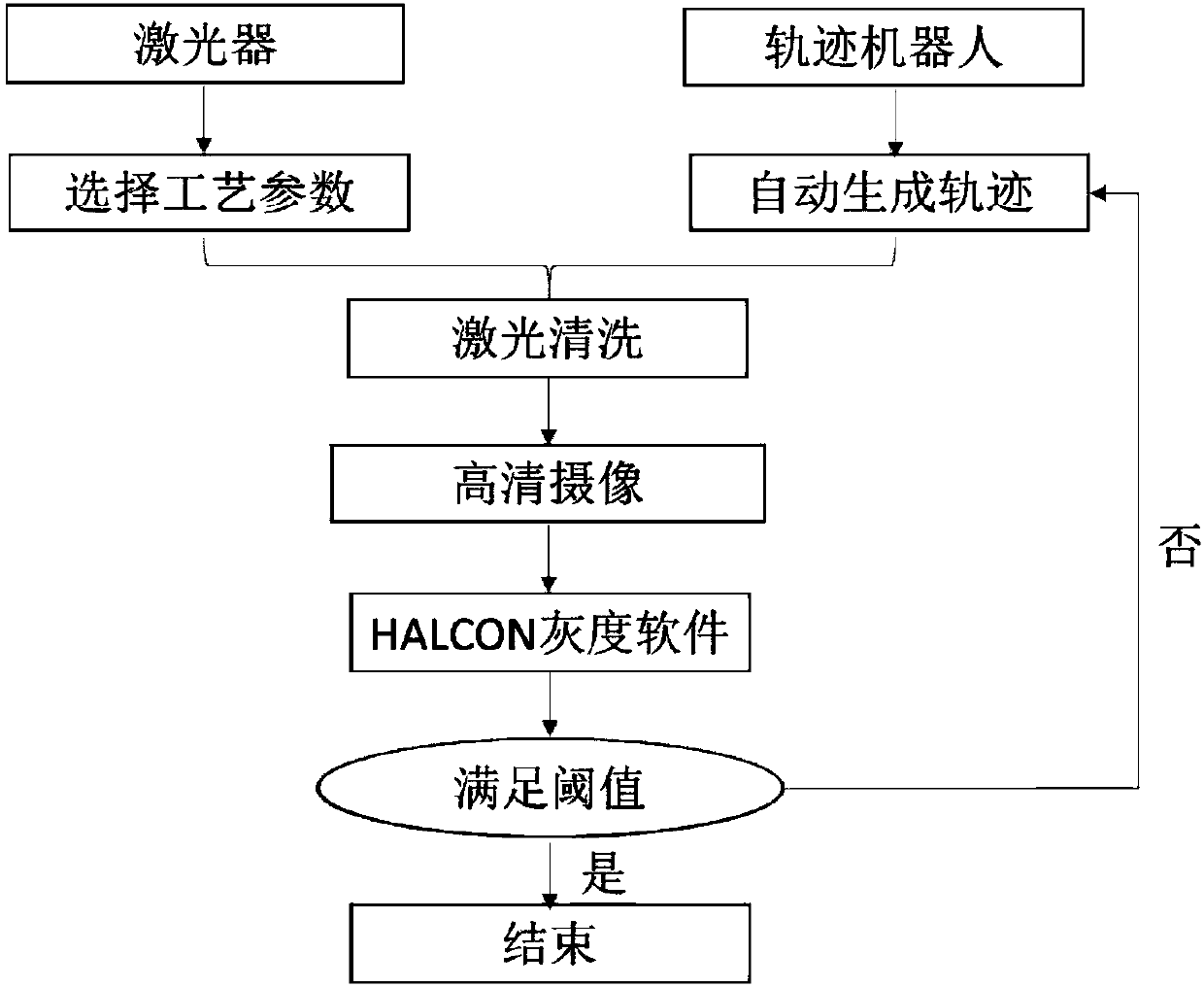

Automatic online laser cleaning device for large cavity inner wall dirt and method thereof

A laser cleaning and cavity technology, applied in cleaning methods and utensils, chemical instruments and methods, laser welding equipment, etc., can solve the problems of pollution, low efficiency, long time consumption, etc., to improve cleaning efficiency, and the cleaning effect is obvious and stable. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present invention performs laser cleaning on the surface stains on the inner wall of the 7075 aluminum alloy circular cavity:

[0042] Considering the performance of 7075 aluminum alloy and the state of surface stains, we adopt the following process parameters: laser wavelength 1064nm; laser output power 500W, fiber coupling efficiency ≥ 85%; laser power instability ≤ 3%; laser frequency 10kHz The laser pulse width is 30ns; the laser diameter of the laser source is 3mm (±0.1mm); the far-field divergence angle is ≤2.0mrad; the spatial distribution of the beam is a super-Gaussian flat-top distribution. Then modify the pulse width, respectively, using 40ns and 20ns and then cleaning. As shown in Table 1.

[0043] Table 1 7075 aluminum alloy surface stain laser process parameters

[0044] Laser wavelength

power

coupling efficiency

frequency

pulse width

divergence angle

Laser diameter

1064nm

500W

≥85%

≤3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Laser pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com