Mineral-oil-based high-temperature chain oil and preparation method thereof

A high-temperature chain and mineral oil technology, applied in the direction of lubricating compositions, etc., can solve the problems of high-temperature chain oil that cannot be recycled, synthetic oil resource shortage, waste of resources and energy, etc., achieve good performance indicators, and have good lubrication and friction reduction effects , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

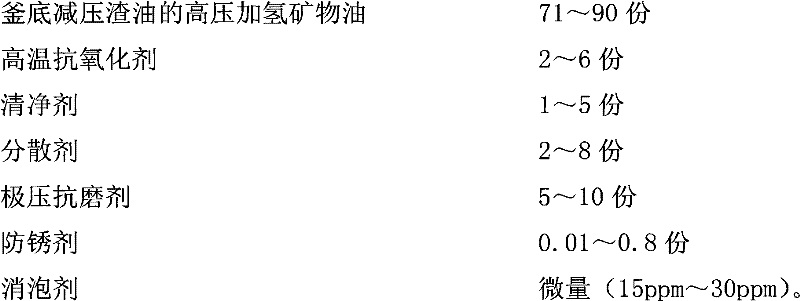

[0026] formula:

[0027]

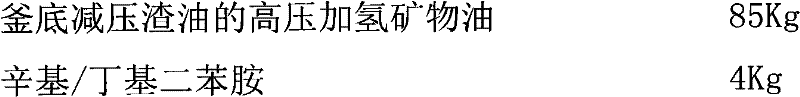

[0028]

[0029] Concrete preparation method comprises the following steps:

[0030] a. Add the high-pressure hydrogenated mineral oil of the vacuum residue at the bottom of the reactor in proportion to the reactor, and gradually heat up to 60°C during the stirring process;

[0031] b. Add octyl / butyl diphenylamine, low-basic calcium petroleum sulfonate, monoalkenyl butyrimide, acidic dibutyl phosphite, barium petroleum sulfonate and simethicone in proportion;

[0032] c. Stir for 45 minutes after all the addition, and filter through a 20um filter bag to obtain the finished chain oil.

Embodiment 2

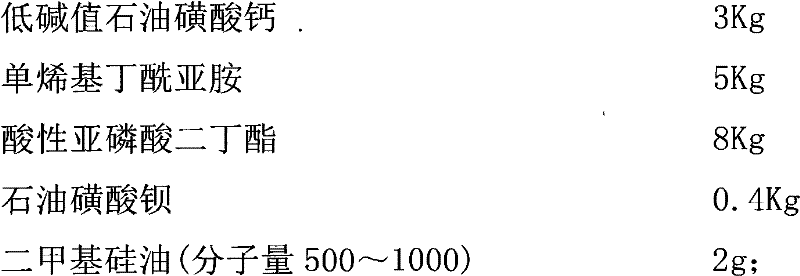

[0034] formula:

[0035]

[0036] Concrete preparation method comprises the following steps:

[0037] a. Add the high-pressure hydrogenated mineral oil of the vacuum residue at the bottom of the reactor in proportion to the reactor, and gradually heat up to 40°C during the stirring process;

[0038] b. Add 4,4'-methylene-bis-2,6-di-tert-butylphenol, medium alkali value synthetic calcium sulfonate, polyisobutylene polysuccinimide, and phosphorothioate in proportion , benzotriazole, dodecenylsuccinic acid and simethicone;

[0039] c. Stir for 55 minutes after all the addition, and filter through a 20um filter bag to obtain the finished chain oil.

Embodiment 3

[0041] formula:

[0042]

[0043] Concrete preparation method comprises the following steps:

[0044] a. Add the high-pressure hydrogenated mineral oil of the vacuum residue at the bottom of the reactor in proportion to the reactor, and gradually heat up to 70°C during the stirring process;

[0045] b. Add thiophosphodioctyl basic zinc, polyisobutylene sulfur barium phosphide, polyene succinimide, dibenzyl disulfide, dodecenyl succinic acid and dimethyl silicone oil in proportion;

[0046] c. Stir for 45 minutes after all the addition, and filter through a 20um filter bag to obtain the finished chain oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com