Biomass environment-friendly high-calorific-value energy fuel and preparation method thereof

A high calorific value, biomass technology, applied in the direction of biofuels, waste fuels, fuels, etc., can solve the problems of low fuel utilization and fuel efficiency, difficulty in achieving urban environmental protection and low carbon, and flue gas corrosion of combustion equipment, etc., to achieve occupancy The effect of small site, less ash content and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

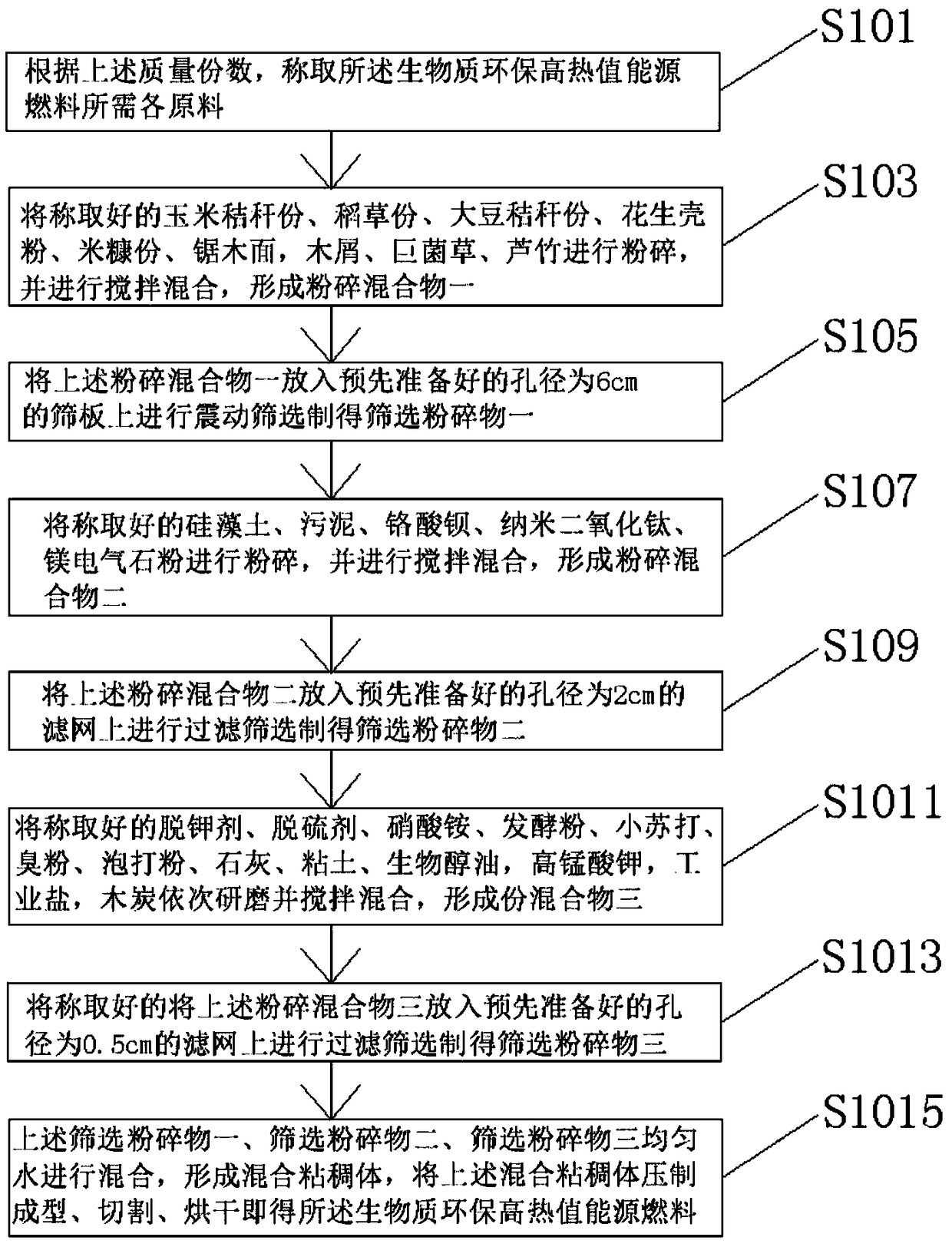

Method used

Image

Examples

Embodiment 1

[0062] A kind of biomass environmental protection high calorific value energy fuel, this biomass environmental protection high calorific value energy fuel is made of the following raw materials in mass parts:

[0063] Corn straw 50g, rice straw 35g, soybean straw 20g, peanut shell powder 30g, rice bran 20g, sawn wood surface 20g, sawdust 35g, giant fungus grass 25g, reed bamboo 25g, diatomaceous earth 2g, sludge 8g, barium chromate 2g, It consists of 1g of nano titanium dioxide, 2g of magnesium tourmaline powder, 10g of water, 5g of depotassiation agent, 5g of desulfurization agent, 2g of swelling agent, 20g of adhesive, and 20g of combustion enhancer.

[0064] Wherein, the expanding agent includes the following raw material components: 0.5 g of ammonium nitrate, 0.5 g of baking powder, 0.5 g of baking soda, 0.3 g of smelly powder, and 0.2 g of baking powder.

[0065] The binder comprises the following raw material components: lime 5g, clay 15g.

[0066] The combustion enhanc...

Embodiment 2

[0077] A kind of biomass environmental protection high calorific value energy fuel, this biomass environmental protection high calorific value energy fuel is made of the following raw materials in mass parts:

[0078] Corn straw 60g, rice straw 37.5g, soybean straw 22.5g, peanut shell powder 50g, rice bran 22.5g, sawn wood surface 25g, sawdust 45g, giant fungus grass 35g, reed bamboo 32.5g, diatomaceous earth 3.5g, sludge 13g, Composed of 3.5g of barium chromate, 2.5g of nano-titanium dioxide, 4g of magnesium tourmaline powder, 20g of water, 7g of depotassiation agent, 7g of desulfurization agent, 3.5g of swelling agent, 25g of binder, and 25g of combustion enhancer.

[0079] Wherein, the expanding agent includes the following raw material components: 0.75 g of ammonium nitrate, 0.75 g of baking powder, 0.75 g of baking soda, 0.65 g of odorous powder, and 0.6 g of baking powder.

[0080] The binder comprises the following raw material components: lime 7.5g, clay 17.5g.

[008...

Embodiment 3

[0092] A kind of biomass environmental protection high calorific value energy fuel, this biomass environmental protection high calorific value energy fuel is made of the following raw materials in mass parts:

[0093] Corn straw 70g, rice straw 40g, soybean straw 25g, peanut shell powder 70g, rice bran 25g, sawn wood surface 30g, sawdust 55g, giant fungus grass 45g, reed bamboo 40g, diatomaceous earth 5g, sludge 20g, barium chromate 5g, 4g of nano titanium dioxide, 6g of magnesium tourmaline powder, 30g of water, 10g of depotassiation agent, 10g of desulfurization agent, 5g of expanding agent, 30g of binder, and 30g of combustion enhancer.

[0094] Wherein, the expanding agent includes the following raw material components: 1 g of ammonium nitrate, 1 g of baking powder, 1 g of baking soda, 1 g of smelly powder, and 1 g of baking powder.

[0095] The binder comprises the following raw material components: lime 10g, clay 20g.

[0096] The combustion enhancer includes the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com